Understanding the essential elements of your lawn care machinery is crucial for maintaining its efficiency and longevity. Each component plays a significant role in the overall performance, making it vital to recognize their functions and interrelations. By grasping how these elements work together, you can ensure optimal operation and troubleshooting when necessary.

In this section, we will explore the intricate layout of various components associated with lawn care equipment. You will gain insight into their design and how to identify them effectively. A comprehensive understanding will enable you to make informed decisions when servicing or upgrading your machinery.

Whether you’re a seasoned professional or a dedicated enthusiast, having access to detailed information about each part can greatly enhance your maintenance routine. Dive into the specifics and discover how to keep your equipment running smoothly for years to come.

Understanding John Deere Mower Deck Components

The assembly of cutting equipment plays a crucial role in ensuring efficient performance and longevity. Familiarizing oneself with its various elements can enhance maintenance practices and improve functionality. Each component contributes to the overall operation, making it essential for users to grasp their significance.

Key elements include the cutting blades, which are vital for achieving a precise finish. Additionally, the spindles support the blades, allowing for smooth rotation, while the housings protect these mechanisms from debris. Understanding the interaction between these parts can lead to better care and optimal results.

Moreover, belts serve as the link between the engine and the cutting assembly, transferring power efficiently. Regular inspection of these components can prevent unexpected failures, ensuring consistent performance over time.

Overview of Mower Deck Functionality

The functionality of cutting equipment is essential for achieving a well-manicured landscape. Understanding how these systems operate can greatly enhance the effectiveness of lawn maintenance. This segment delves into the core principles behind the mechanisms that facilitate efficient grass trimming and yard care.

Key Components

- Blades: These sharp elements rotate to slice through grass, ensuring an even cut.

- Drive System: This mechanism powers the blades, providing the necessary force for operation.

- Chassis: The structure supports all components, ensuring stability during use.

- Height Adjustment: This feature allows users to modify cutting heights for varying grass types and conditions.

Operational Efficiency

Effective functioning relies on several factors, including:

- Power Source: A robust engine delivers the energy required for smooth operation.

- Cutting Width: A wider span can reduce the time needed to cover large areas.

- Maintenance: Regular upkeep ensures optimal performance and longevity.

By grasping the fundamentals of these systems, users can make informed decisions about their landscape maintenance practices, leading to improved results and satisfaction.

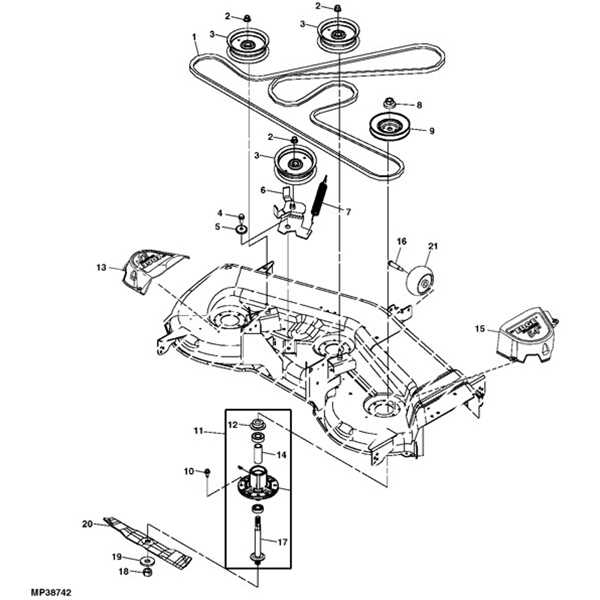

Key Parts in 54 Inch Deck

This section provides an overview of the essential components that contribute to the functionality and efficiency of a 54-inch cutting system. Understanding these elements is crucial for maintenance and optimal performance, ensuring that your equipment operates smoothly and effectively.

Blade Assembly

The blade assembly is a vital component responsible for the cutting action. It typically includes sharp blades that rotate at high speeds, providing a clean and precise cut. Regular inspection and sharpening of these blades are necessary to maintain performance and prevent damage to the lawn.

Spindle Housing

The spindle housing plays a critical role in supporting the blades and allowing them to rotate freely. It houses bearings that facilitate smooth operation. Keeping this area well-lubricated and free from debris is essential to avoid unnecessary wear and tear, ensuring longevity and reliability in performance.

Identifying Common Issues with Decks

Understanding the frequent challenges associated with cutting equipment is essential for optimal performance. Proper maintenance and timely identification of these issues can enhance efficiency and prolong the lifespan of the apparatus.

- Uneven Cutting: This is often caused by dull blades, improper height adjustments, or uneven tire pressure.

- Excessive Vibration: Loose components or misalignment can lead to unwanted movement during operation.

- Clumping of Grass: This issue arises from damp conditions or clogged discharge areas, affecting the overall cut quality.

- Noisy Operation: Unusual sounds may indicate worn bearings or loose parts that require immediate attention.

Regular inspections and maintenance practices can help in early detection and resolution of these problems. Keeping an eye on performance and conducting routine checks ensures that the equipment remains in top condition.

- Check blade sharpness and replace if necessary.

- Inspect all bolts and fasteners for tightness.

- Clean out any debris from the cutting area to prevent blockages.

- Verify tire pressures to ensure even support during operation.

By addressing these common concerns promptly, users can maintain efficiency and achieve the best results from their equipment.

Importance of Regular Maintenance Practices

Consistent upkeep is crucial for ensuring the longevity and efficiency of equipment. Neglecting routine care can lead to diminished performance, costly repairs, and even premature failure. By implementing structured maintenance protocols, users can avoid unexpected downtime and enhance the overall functionality of their machinery.

Benefits of Regular Upkeep

Routine maintenance provides numerous advantages, including:

| Benefit | Description |

|---|---|

| Increased Longevity | Regular checks and servicing can extend the life of the machinery. |

| Improved Efficiency | Well-maintained equipment operates more smoothly and effectively. |

| Cost Savings | Proactive care can prevent expensive repairs in the long run. |

Key Practices to Implement

Essential maintenance tasks include cleaning, lubrication, and periodic inspections. These actions help identify potential issues early, allowing for timely interventions that ensure optimal performance.

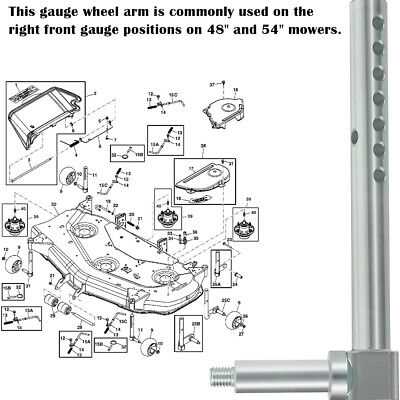

How to Read Parts Diagrams Effectively

Understanding visual schematics can greatly enhance your ability to identify components and their functions within machinery. A well-constructed illustration serves as a roadmap, guiding you through the intricate relationships between various elements. Mastering the art of reading these visuals not only simplifies repairs but also empowers you with knowledge about the equipment.

Familiarize Yourself with Symbols and Notations

Each illustration contains a set of symbols and annotations that convey crucial information. Take time to learn these representations; they often denote specific components or indicate how parts fit together. Recognizing common symbols can save you time and prevent confusion during the assembly or disassembly process.

Follow the Flow of the Assembly

Visual guides are typically arranged to reflect the sequence of assembly. Start from the base and work your way up, observing how each part interacts with the next. This sequential approach helps in understanding the operational flow and can be particularly useful when troubleshooting or performing maintenance tasks.

Tips for Ordering Replacement Parts

When it comes to acquiring new components for your equipment, making informed decisions can significantly enhance performance and longevity. Proper preparation and knowledge can streamline the process, ensuring you receive the correct items without unnecessary delays.

Here are some helpful strategies to consider:

| Tip | Description |

|---|---|

| Know Your Model | Always have your equipment’s model number on hand. This information is crucial for identifying compatible components. |

| Verify Part Numbers | Check part numbers against the manufacturer’s specifications to avoid any mix-ups. This ensures you are ordering exactly what you need. |

| Consult the Manual | Your user manual contains valuable information about required items and maintenance guidelines. Refer to it for clarity. |

| Use Reputable Suppliers | Choose well-reviewed vendors to guarantee quality and reliability. Research customer feedback to make an informed choice. |

| Ask for Assistance | If uncertain, don’t hesitate to seek help from customer service representatives. They can guide you in selecting the right items. |

By following these guidelines, you can ensure a smoother experience when obtaining essential components, ultimately enhancing the performance of your equipment.

Comparative Analysis of Different Deck Models

When evaluating various cutting apparatus models, it is essential to consider their distinct characteristics and functionalities. Each model offers unique advantages, impacting performance, efficiency, and ease of use. This analysis aims to highlight the differences between popular variants, enabling users to make informed decisions based on their specific needs.

Performance: Different models exhibit varying levels of cutting efficiency. Some are designed for quick, precise trimming, while others may excel in handling thicker vegetation. Understanding these capabilities can greatly affect the overall effectiveness of the equipment.

Design and Durability: The construction materials and design features also differ significantly across models. Robust materials may provide enhanced longevity, whereas lighter designs could offer better maneuverability. Assessing these elements is crucial for choosing equipment that will withstand regular use.

User Experience: Ergonomics and ease of operation vary widely among models. Certain variants may offer advanced technology, enhancing user comfort and reducing fatigue during extended use. Evaluating user feedback and operational features can guide potential buyers toward the most suitable option.

Maintenance: Maintenance requirements can differ from one model to another. Some may necessitate frequent servicing, while others boast user-friendly designs that simplify upkeep. Awareness of these aspects is vital for ensuring the longevity and reliability of the equipment.

In conclusion, a comparative analysis of various cutting apparatus models reveals critical insights that can inform purchasing decisions. By understanding performance, design, user experience, and maintenance needs, users can select the most appropriate equipment for their requirements.

Expert Recommendations for Mower Care

Maintaining your lawn equipment is essential for optimal performance and longevity. Regular attention to key areas can enhance efficiency and reduce the risk of breakdowns. Here are some expert tips to ensure your machine remains in top condition.

- Regular Cleaning: Keep the exterior and cutting components free from grass clippings and debris. A clean machine operates better and lasts longer.

- Sharp Blades: Ensure that cutting blades are sharp. Dull blades can tear grass rather than cut it, leading to a poor finish and potential damage to the lawn.

- Oil Changes: Change the engine oil as recommended by the manufacturer. Fresh oil reduces friction and extends the life of the engine.

- Air Filter Maintenance: Check and clean the air filter regularly to ensure proper airflow. A clean filter improves performance and fuel efficiency.

- Fuel Quality: Use high-quality fuel and consider adding a stabilizer to prevent deterioration, especially if the equipment is not used frequently.

Following these guidelines will help you maintain your equipment effectively and enjoy a beautifully manicured lawn year-round.