When it comes to maintaining a lush and well-manicured outdoor space, having a reliable cutting machine is essential. Knowing the intricate details of its assembly can enhance performance and prolong the lifespan of the equipment. This section delves into the vital elements that make up this machinery, focusing on their roles and interconnections.

By familiarizing yourself with the various sections and their specific functions, you can ensure optimal operation and tackle any issues that may arise. The visual representation of these components serves as a helpful reference for both maintenance and troubleshooting, making it easier to identify the right elements needed for repair or replacement.

Whether you’re an experienced user or a newcomer to outdoor maintenance, understanding the layout and functionality of these key components can significantly improve your efficiency. This knowledge empowers you to keep your equipment in peak condition, ready to tackle the challenges of your lawn care tasks.

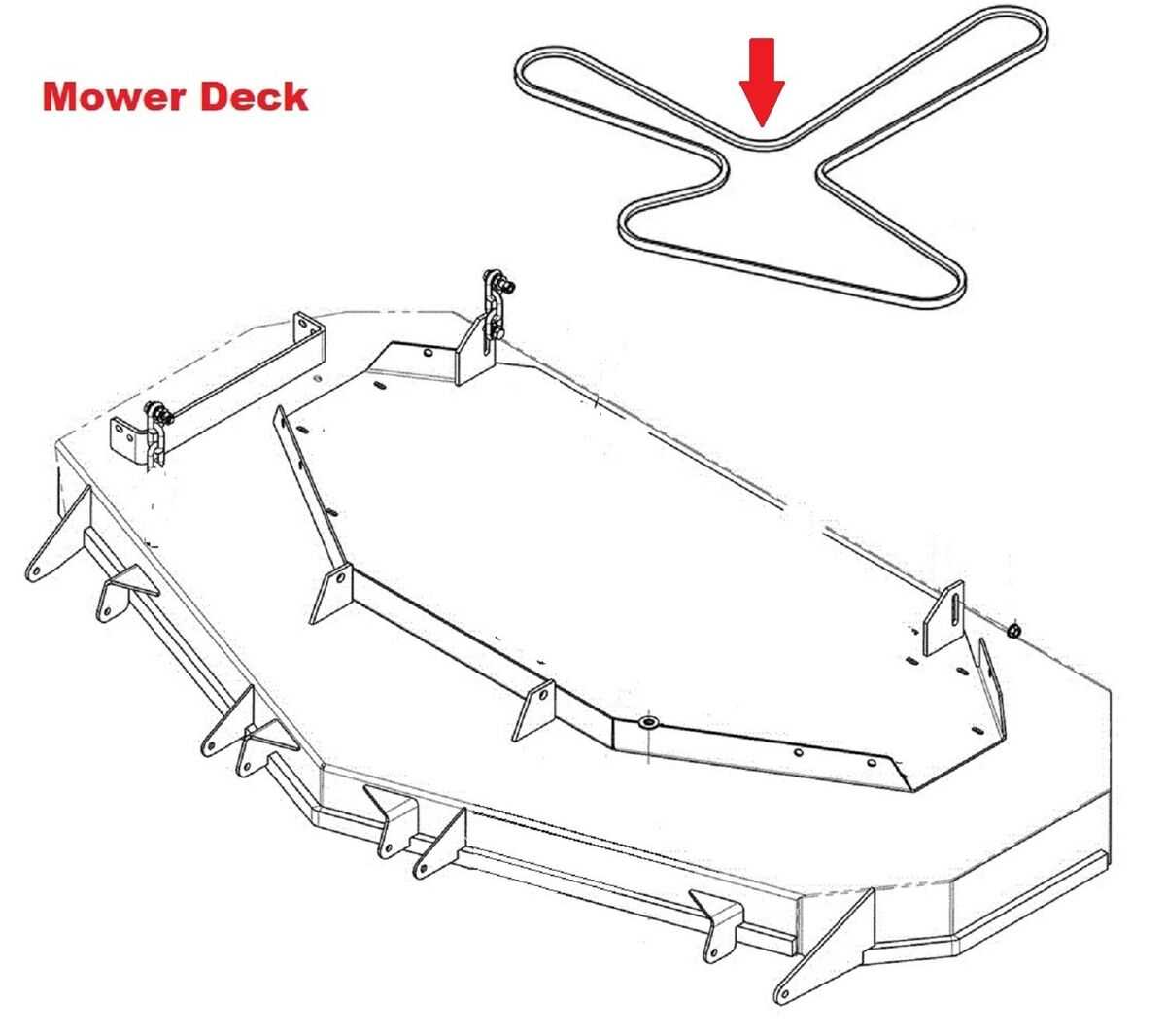

Understanding the D130 Mower Deck

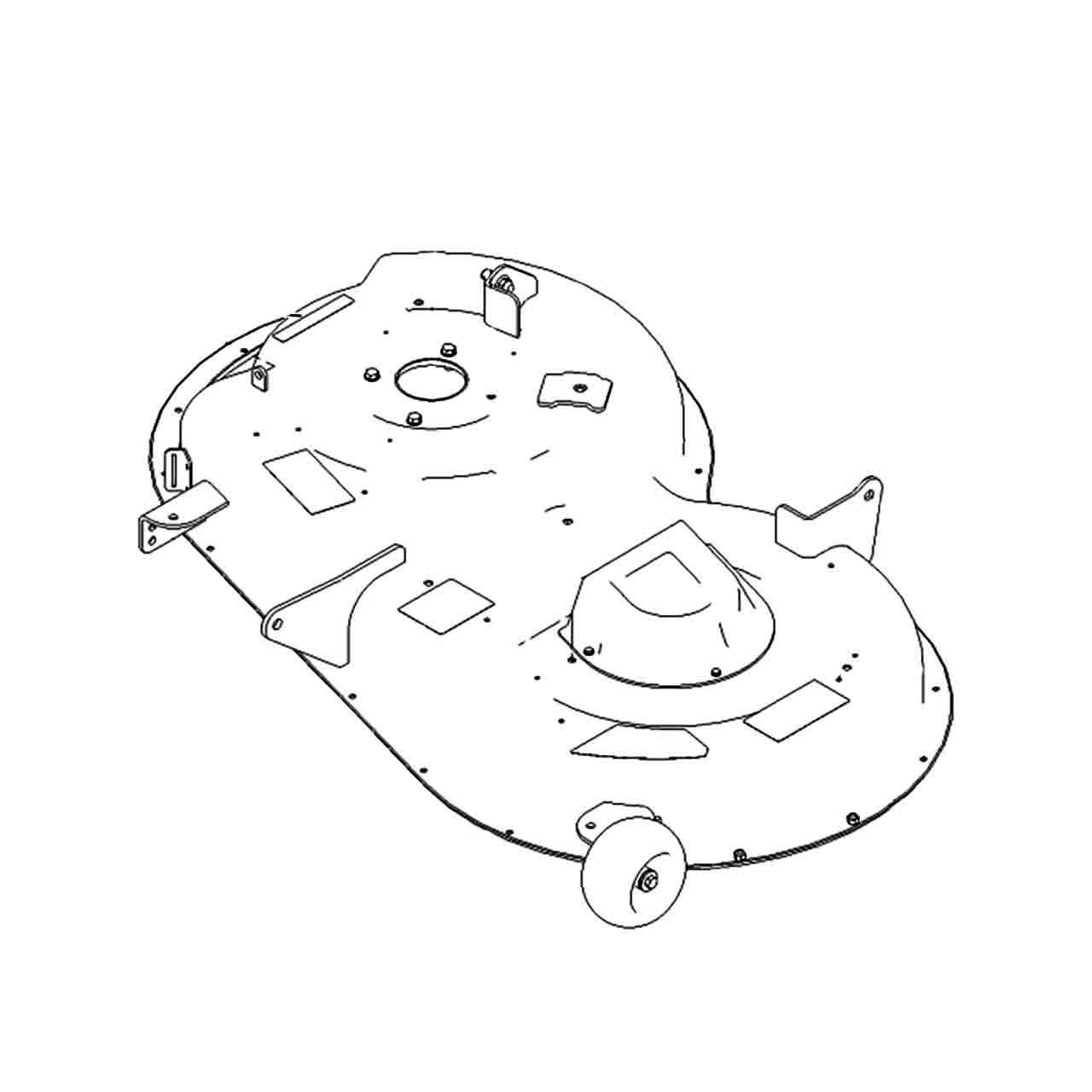

The functionality of a lawn cutting machine heavily relies on its cutting mechanism, where precision, durability, and design play crucial roles. One of the main components that influence the overall performance of the equipment is the part that holds the blades and facilitates efficient grass trimming. Understanding how this crucial component works, its structure, and the different elements that make it effective is essential for proper maintenance and smooth operation.

Key Components

The structure that supports the cutting action consists of various interconnected parts, each serving a specific function. These include the housing that shelters the rotating blades, components that manage the height adjustments, and elements that ensure proper distribution of power from the engine to the blades. Regular inspection and maintenance of these parts ensure longevity and optimal performance. Additionally, certain features such as blade engagement and release mechanisms play a critical role in improving safety and ease of use.

Maintaining Performance

Routine care and upkeep of the cutting assembly can prevent many operational issues. Keeping the parts free of debris, ensuring the blades remain sharp, and checking for any signs of wear are essential practices. Correctly adjusted components help maintain consistent cutting height, reduce strain on the engine, and ensure a clean, even cut across the lawn.

Key Components of the Mower Deck

The functionality and performance of a lawn cutting machine are largely dependent on its main functional parts. These components work together to ensure a smooth and efficient operation, providing a clean and even cut across various terrains. Understanding the essential elements that make up this system is crucial for maintaining optimal performance and prolonging the lifespan of the equipment.

Among the most important elements are the spinning blades, which are responsible for cutting grass at an even height. These blades are powered by the engine and are typically designed to be durable and sharp. Additionally, the pulley system plays a key role in transferring power from the engine to the blades, allowing them to rotate at the required speed.

The housing or casing encases all of the rotating parts, providing protection while also helping to direct the grass clippings in the desired direction. A well-designed casing also aids in reducing vibrations and maintaining stability during operation. Another crucial part is the adjustment mechanism, which enables the user to control the cutting height, adapting the machine to different grass lengths and terrain conditions.

Finally, supporting arms and linkages hold the entire structure in place, allowing it to move in harmony with the rest of the machine. These parts need to be strong and well-maintained to avoid unnecessary wear and ensure smooth operation throughout the season.

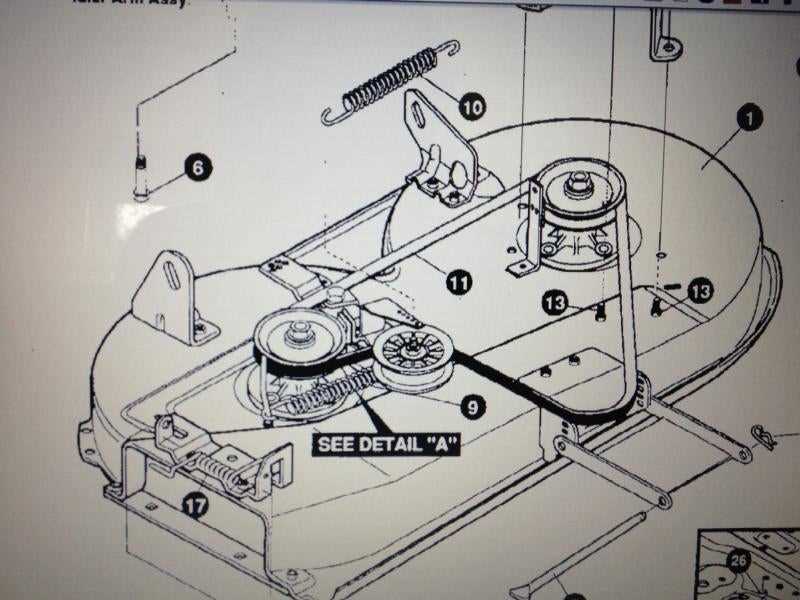

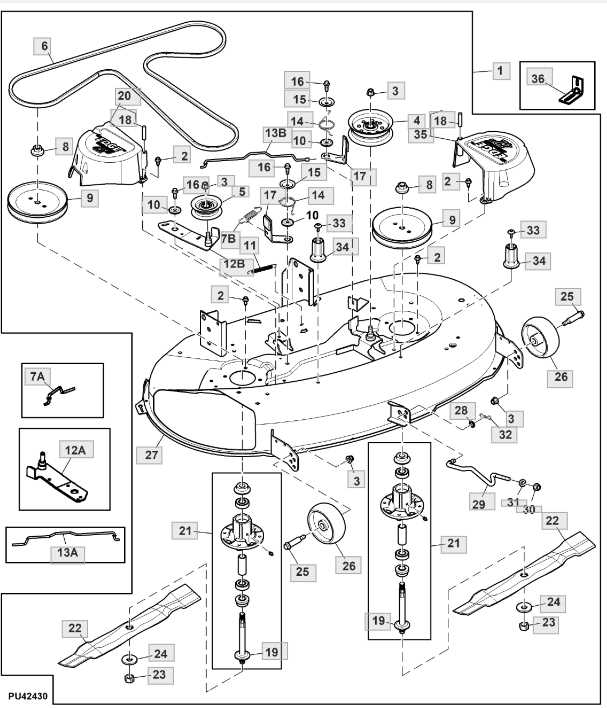

Identifying Parts in the Diagram

Understanding the components of your lawn equipment is essential for maintenance and repairs. The visual representation of these elements helps users easily locate and identify each part, ensuring the right tools and procedures are used during service. By breaking down the different sections, it’s possible to streamline the process of troubleshooting, replacing, or upgrading individual pieces.

First, examine the overall layout. The illustration typically divides the assembly into manageable areas, each representing a functional zone. These sections will often be marked with specific numbers or labels that correspond to individual components, which can be cross-referenced with a list for further clarification. Familiarity with how each part interacts within the system will improve your ability to assess its condition.

Next, pay attention to the scale and orientation. It’s important to understand how parts are sized relative to one another and their positions within the entire structure. This will help you determine which components might be easier to reach or more difficult to replace based on their placement and access points. Knowing the proper alignment is crucial when reassembling after maintenance tasks.

Lastly, double-check any accompanying instructions or guides, as these may provide additional context or updates to the parts list. Always ensure that you’re working with the most current and accurate representation to avoid confusion during the maintenance process.

Common Issues with Mower Deck Parts

When operating a lawn care machine, several components that contribute to the cutting and grass management process can face various problems over time. These issues can hinder performance, cause uneven cuts, and may even lead to equipment failure if not addressed promptly. Understanding the most common problems associated with these crucial elements can help owners perform routine maintenance and resolve issues efficiently.

Worn Blades and Ineffective Cutting

One of the most frequent problems encountered is the dullness or damage to the cutting blades. As the blades wear down, they become less effective in cutting grass evenly, leading to a rough and uneven lawn appearance. Over time, these blades can also become bent or chipped due to impacts with hard objects, such as rocks or tree stumps. Regular inspection and replacement are essential to maintain a clean, smooth cut.

Clogging and Build-up

Grass and debris tend to accumulate under the unit, leading to clogging and restricted airflow. This build-up can hinder the performance of the entire system, resulting in poor cutting performance and potential engine strain. Cleaning and clearing the area underneath regularly is critical to ensure the machine operates at its best. In some cases, frequent buildup may indicate an issue with the grass discharge system, which may need adjustment or repair.

Proactive Maintenance is key to preventing these issues. Routine checks and part replacements can significantly extend the lifespan of the equipment, ensuring smooth operation throughout the mowing season.

Maintenance Tips for D130 Deck

Proper care and regular upkeep of your lawn equipment are essential for ensuring optimal performance and longevity. Focusing on key areas of maintenance will not only improve efficiency but also prevent costly repairs down the road. Keeping vital components in top condition helps achieve a smooth operation, which results in a better mowing experience overall.

Cleanliness is one of the most important aspects of maintenance. After each use, thoroughly remove any grass clippings, dirt, and debris that may accumulate. These materials can clog the system, affecting performance and causing wear over time. Using a scraper or specialized cleaning tool will help reach hard-to-access spots.

Sharpness of the cutting blades is crucial for clean and precise grass cutting. Dull blades can tear grass rather than cutting it, leading to a ragged appearance and potential damage to the turf. Regularly inspect the blades for wear and sharpen or replace them as needed. It’s important to follow the manufacturer’s guidelines for blade maintenance.

Lubrication of moving parts ensures smooth operation and reduces friction, preventing premature wear. Apply lubricant to bearings, pulleys, and any other parts with moving components. Be sure to check fluid levels, including engine oil and transmission fluid, and replace them as recommended.

Belts and tension are critical in maintaining optimal function. Inspect the belts regularly for signs of wear, cracking, or loosening. Tighten or replace any damaged belts to avoid interruptions during operation and ensure maximum power transmission.

Storage also plays a significant role in the longevity of your machine. When the equipment is not in use, especially during the off-season, store it in a dry, sheltered location to prevent rust and corrosion. Covering it with a protective tarp will keep dust and debris from accumulating.

By adhering to these simple yet effective maintenance practices, you’ll help extend the life of your equipment and ensure it operates smoothly when you need it most.

Replacement Parts: What You Need

Maintaining the efficiency of your outdoor equipment requires knowing which components may need to be replaced over time. Regular wear and tear, as well as occasional damage, can affect the performance of your machine. Understanding the essential components that might require replacement is key to ensuring a long lifespan and optimal operation.

When it comes to upkeep, there are a few vital elements to monitor, such as the cutting mechanism, drive system, and engine components. These parts are subject to frequent use and often need to be replaced to maintain peak performance. Having access to the correct replacements will minimize downtime and enhance productivity. Ensure that replacements are compatible with your specific model for a seamless repair experience.

Timing belts, blades, and pulleys are among the most common items to replace. It is also wise to check the spindles and bearings, as they play a crucial role in the smooth operation of the system. Regular inspection and timely replacement of these components will keep your machine in top condition.

Step-by-Step Assembly Guide

This guide provides detailed instructions for assembling the essential components of your lawn care equipment. Follow each step carefully to ensure proper installation and optimal performance of your machine.

Before beginning, ensure you have all the necessary tools and parts. Having everything organized and easily accessible will make the process smoother and faster.

- Prepare the Workspace: Clear a flat, clean area with enough space to lay out the parts. Make sure the environment is free from distractions and debris.

- Assemble the Frame: Start by connecting the main structural components. Align the parts according to the manual’s instructions, securing each with the appropriate bolts and screws. Double-check each connection for tightness.

- Install the Blades: Carefully attach the cutting blades to the frame. Make sure each blade is oriented correctly for proper rotation. Tighten the bolts securely but avoid over-tightening to prevent damage.

- Attach the Pulley System: Position the pulley system as per the assembly diagram. Connect the drive belts, ensuring they are aligned and tensioned correctly to avoid slipping during operation.

- Secure the Wheels: Attach the wheels to the designated axles. Tighten the nuts to hold them in place. Check for smooth rotation before proceeding.

- Check for Proper Alignment: After assembling the main parts, perform a thorough check for alignment. Ensure all components are in the correct position and that the moving parts operate freely without obstruction.

- Final Inspection: Review the entire assembly, verifying that all bolts, screws, and components are properly secured. Look for any loose connections or parts that might affect the performance or safety of the equipment.

- Test Run: Conduct a brief test run to confirm everything is functioning correctly. Monitor for any unusual sounds, vibrations, or malfunctions. If needed, adjust parts and recheck the connections.

By following these steps, you ensure that your machine will perform at its best, providing efficient and reliable service for your lawn care tasks.

Where to Find Replacement Diagrams

Finding the right illustrations for components can significantly ease the repair and maintenance process. Various resources are available to help you locate accurate and detailed schematics. These visuals provide essential information for identifying specific elements, ensuring a smoother replacement experience.

Online Resources

- Manufacturer Websites: Most manufacturers offer official diagrams on their sites, often in the support or parts section.

- Repair Manuals: Digital versions of repair manuals frequently include comprehensive schematics, available for purchase or free download.

- Online Forums: Communities dedicated to equipment maintenance can be valuable. Users often share diagrams and tips on where to find them.

Local Resources

- Authorized Dealers: Visiting or contacting a local dealer can yield printed diagrams or even expert assistance.

- Repair Shops: Local repair shops may have access to reference materials and can provide guidance on sourcing diagrams.

- Library Resources: Public libraries often carry repair guides and manuals that include the necessary illustrations.

Enhancing Performance with Upgrades

Improving the efficiency and functionality of your equipment can lead to significant gains in performance. By carefully selecting enhancements, users can experience smoother operation, increased reliability, and a longer lifespan of their machinery. Upgrading specific components not only boosts productivity but also enhances the overall experience of using the equipment.

Key Areas for Improvement

Focusing on several critical areas can yield substantial benefits. For instance, replacing the blades with high-performance options can improve cutting efficiency and reduce wear. Upgrading the engine components can enhance power output, allowing for faster and more effective operations. Additionally, enhancing the transmission system can provide smoother gear shifts and improved torque delivery.

Choosing Quality Components

When selecting upgrades, it is essential to prioritize quality. High-grade materials and precision-engineered parts ensure that the enhancements perform optimally. Investing in reliable components not only boosts performance but also minimizes the risk of breakdowns and costly repairs. Furthermore, consulting with experts or reading reviews can help identify the best options tailored to specific needs.