The intricate machinery used in modern agriculture plays a crucial role in enhancing productivity and efficiency. Understanding the various elements that comprise these machines is vital for optimal performance and maintenance. A well-organized representation of these components provides insights into their functions and interconnections.

In this exploration, we will delve into a specific model’s components, offering a comprehensive look at their arrangement and significance. This understanding aids operators in troubleshooting and ensuring that the equipment operates smoothly, ultimately leading to improved yields and reduced downtime.

Whether you’re a seasoned operator or new to the field, grasping the layout and functionality of these essential elements is indispensable. Knowledge of these components not only fosters effective maintenance practices but also empowers users to make informed decisions when repairs or replacements are necessary.

Understanding John Deere 468 Baler

This section aims to explore the intricate machinery designed for efficient hay and straw collection. Familiarity with its components can significantly enhance performance and maintenance.

- Functionality: This equipment is engineered to compress and bundle agricultural materials effectively.

- Key Components:

- Feeding system

- Compression chamber

- Binding mechanism

- Tie system

- Maintenance: Regular checks and timely replacements are crucial for optimal operation.

Understanding these elements allows operators to maximize efficiency and minimize downtime.

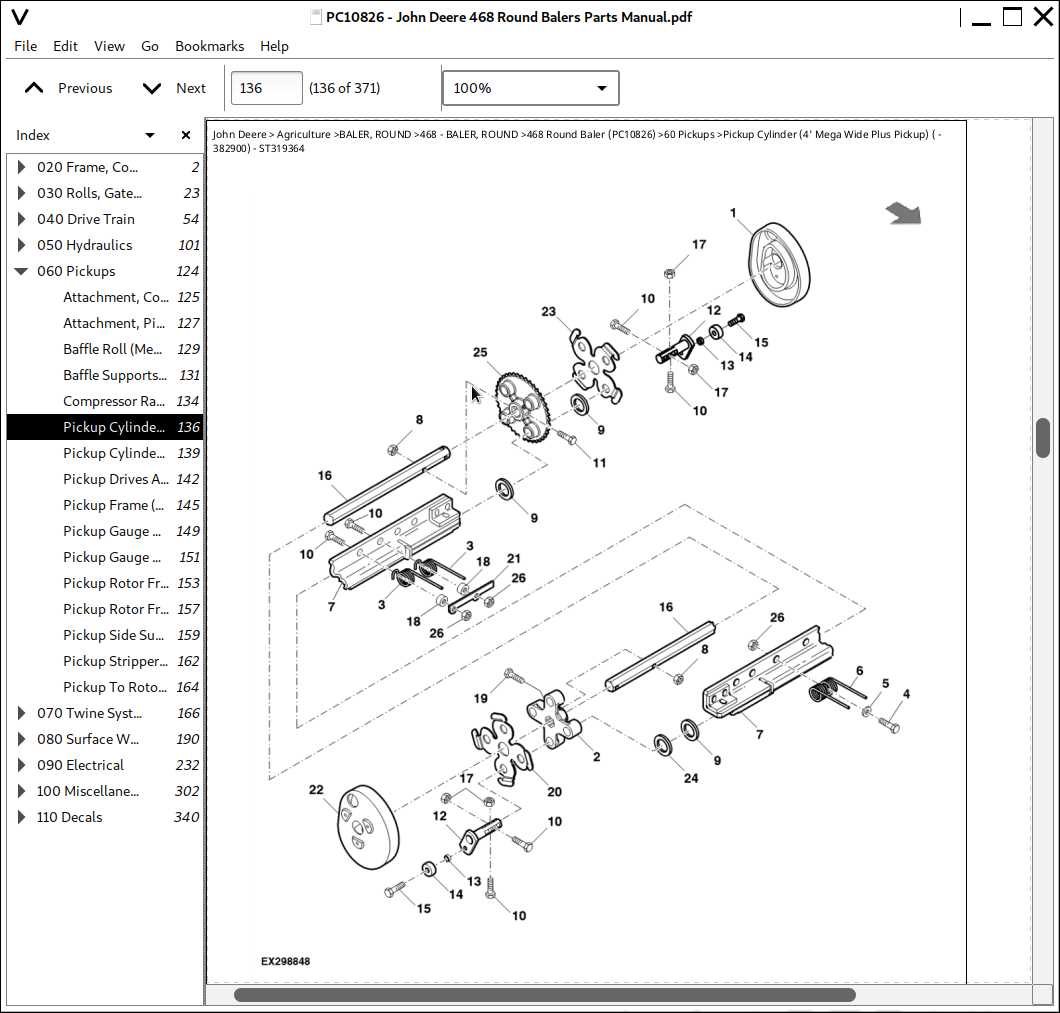

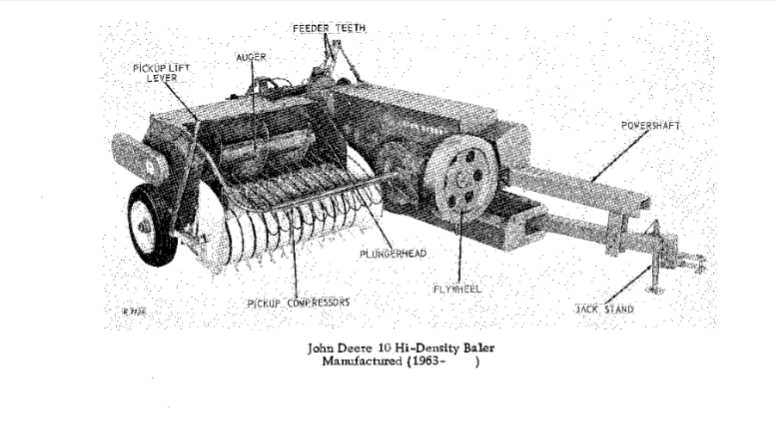

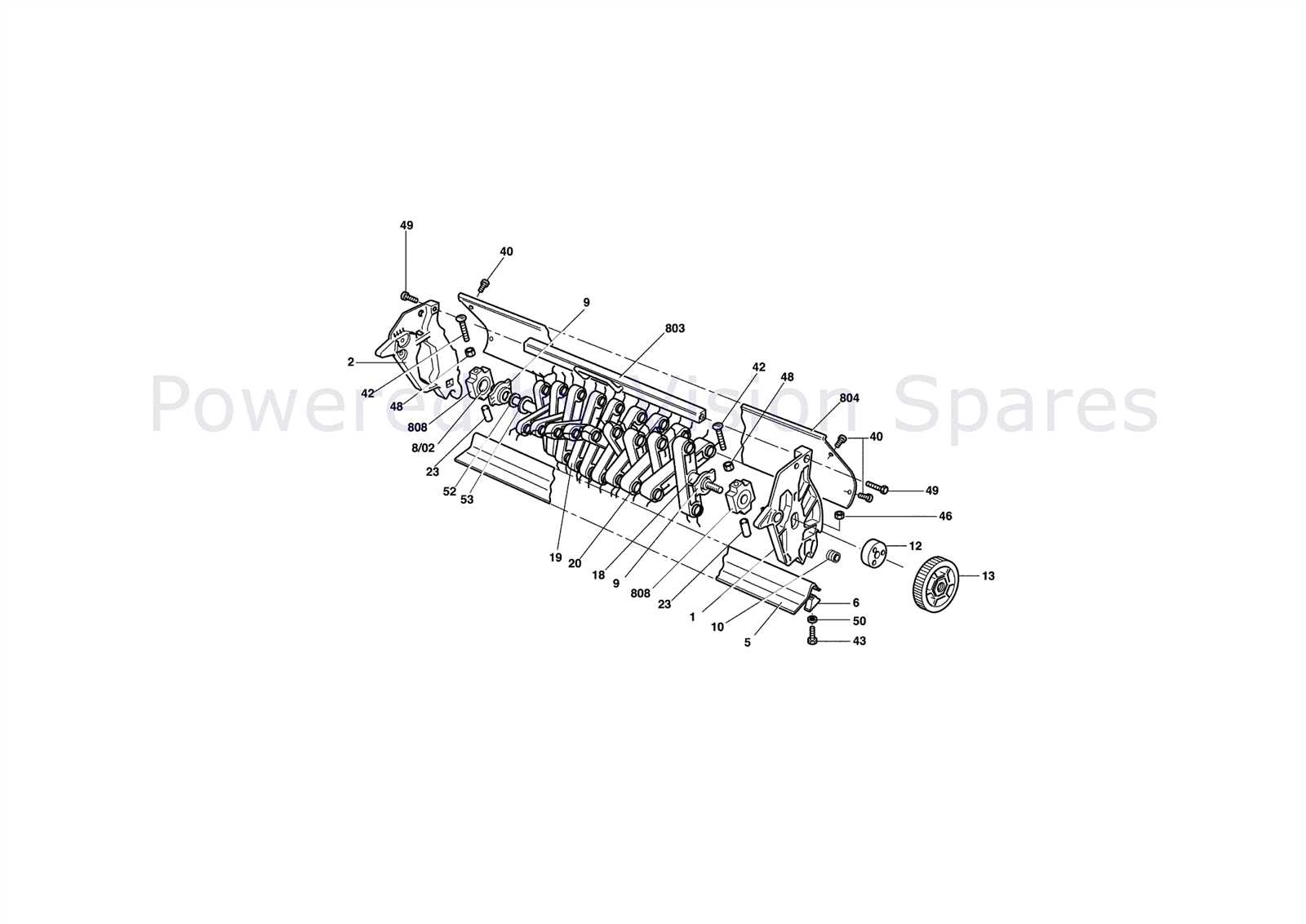

Key Components of the Baler

The effective operation of an agricultural compactor relies on several essential elements that work in harmony to achieve optimal performance. Understanding these critical components can enhance maintenance and improve efficiency in the field.

| Component | Description |

|---|---|

| Feeder Mechanism | This part directs material into the compaction chamber, ensuring a steady flow for efficient processing. |

| Compression Chamber | The area where the material is compacted into bales, utilizing pressure to form tightly bound units. |

| Binding System | Responsible for securing the bales, typically using twine or netting to maintain structural integrity. |

| Pickup Header | This component collects and lifts the material from the ground for processing, playing a crucial role in efficiency. |

Importance of Maintenance and Repairs

Regular upkeep and timely fixes are crucial for the longevity and efficiency of machinery. Neglecting these aspects can lead to reduced performance, increased downtime, and costly replacements. Understanding the significance of routine care can help ensure optimal functionality and minimize unforeseen issues.

Here are some key reasons why maintenance and repairs should be prioritized:

- Enhanced Performance: Well-maintained equipment operates more effectively, resulting in higher productivity and better output quality.

- Cost Efficiency: Regular checks can identify minor issues before they escalate into major problems, saving money on extensive repairs.

- Safety: Keeping machinery in good condition reduces the risk of accidents, ensuring a safer working environment.

- Extended Lifespan: Consistent maintenance practices can prolong the operational life of the equipment, maximizing the return on investment.

- Compliance: Adhering to maintenance schedules may be necessary for compliance with industry regulations and standards.

In conclusion, investing time and resources into the upkeep of machinery is essential. The benefits of maintenance far outweigh the costs, leading to improved efficiency, safety, and overall performance.

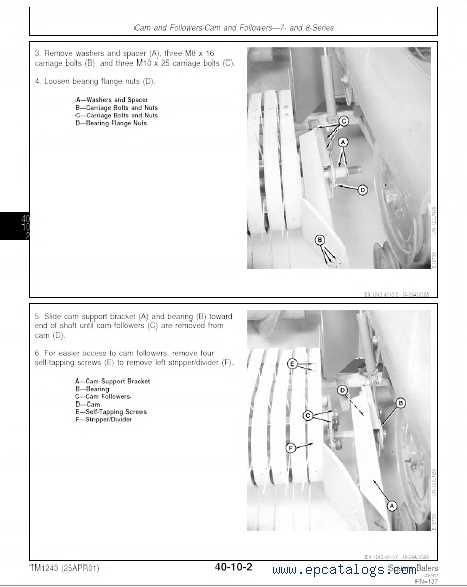

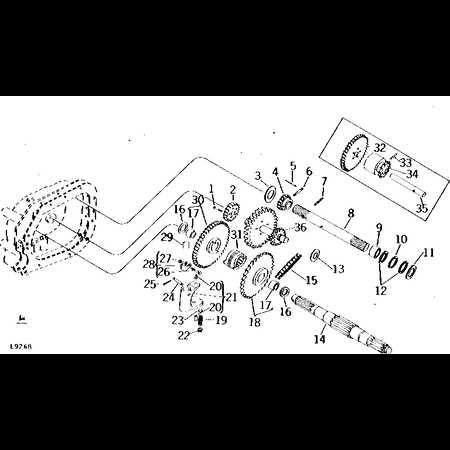

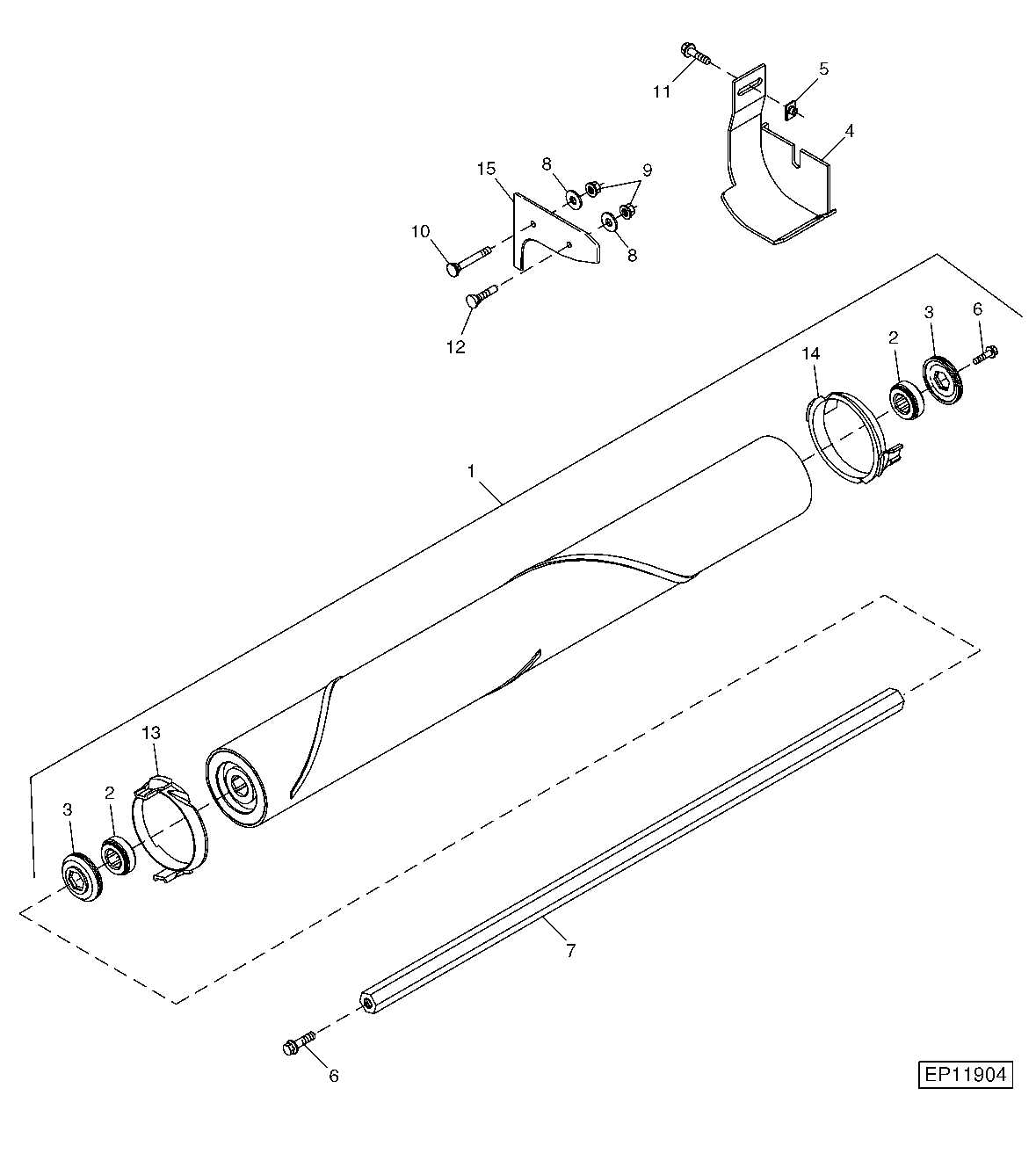

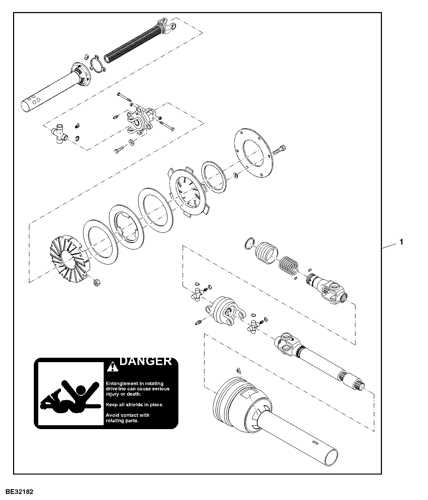

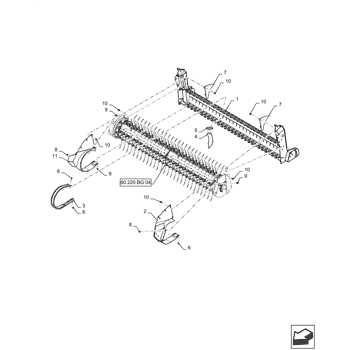

How to Read Parts Diagrams

Understanding assembly illustrations is essential for anyone looking to maintain or repair machinery effectively. These visuals provide a comprehensive overview of components, helping users identify and locate necessary items.

To interpret these illustrations successfully, follow these steps:

- Familiarize yourself with the layout, noting how components are arranged.

- Identify the labels associated with each element, which often include part numbers or descriptions.

- Use a magnifying tool if necessary to enhance visibility of small details.

Additionally, consider these tips:

- Refer to the accompanying manual for clarification on specific parts.

- Take notes on any components you may need to order or replace.

- Review multiple angles or sections to gain a complete understanding of assembly.

By mastering the interpretation of these visuals, you’ll ultimately streamline your repair and maintenance efforts.

Common Issues with the 468 Baler

When operating large-scale agricultural machinery, certain challenges may arise that can hinder efficiency and productivity. Understanding these common problems is crucial for maintaining optimal performance and extending the lifespan of the equipment.

1. Twine Jamming: One frequent issue involves the binding material getting stuck in the mechanism. This can lead to delays and increased maintenance time. Regular inspection and proper tensioning can help mitigate this problem.

2. Uneven Density: Inconsistent compression can result in unevenly formed packages. Factors such as moisture levels and feed consistency play significant roles. Ensuring uniform feeding and adjusting settings can improve density.

3. Hydraulic Failures: Hydraulic systems are essential for operation, and any failure can halt work entirely. Leaks or pump malfunctions are common. Regular checks and timely replacements are necessary to prevent breakdowns.

4. Wear and Tear: Components naturally degrade over time, affecting overall performance. Regular maintenance and timely replacements of worn parts are essential to keep the machinery functioning efficiently.

5. Electrical Issues: Electrical problems, including faulty wiring and blown fuses, can disrupt operations. Routine inspections and maintenance of the electrical system can help identify and resolve these issues before they escalate.

By recognizing these potential challenges, operators can take proactive measures to ensure smooth and efficient operation of their agricultural machinery.

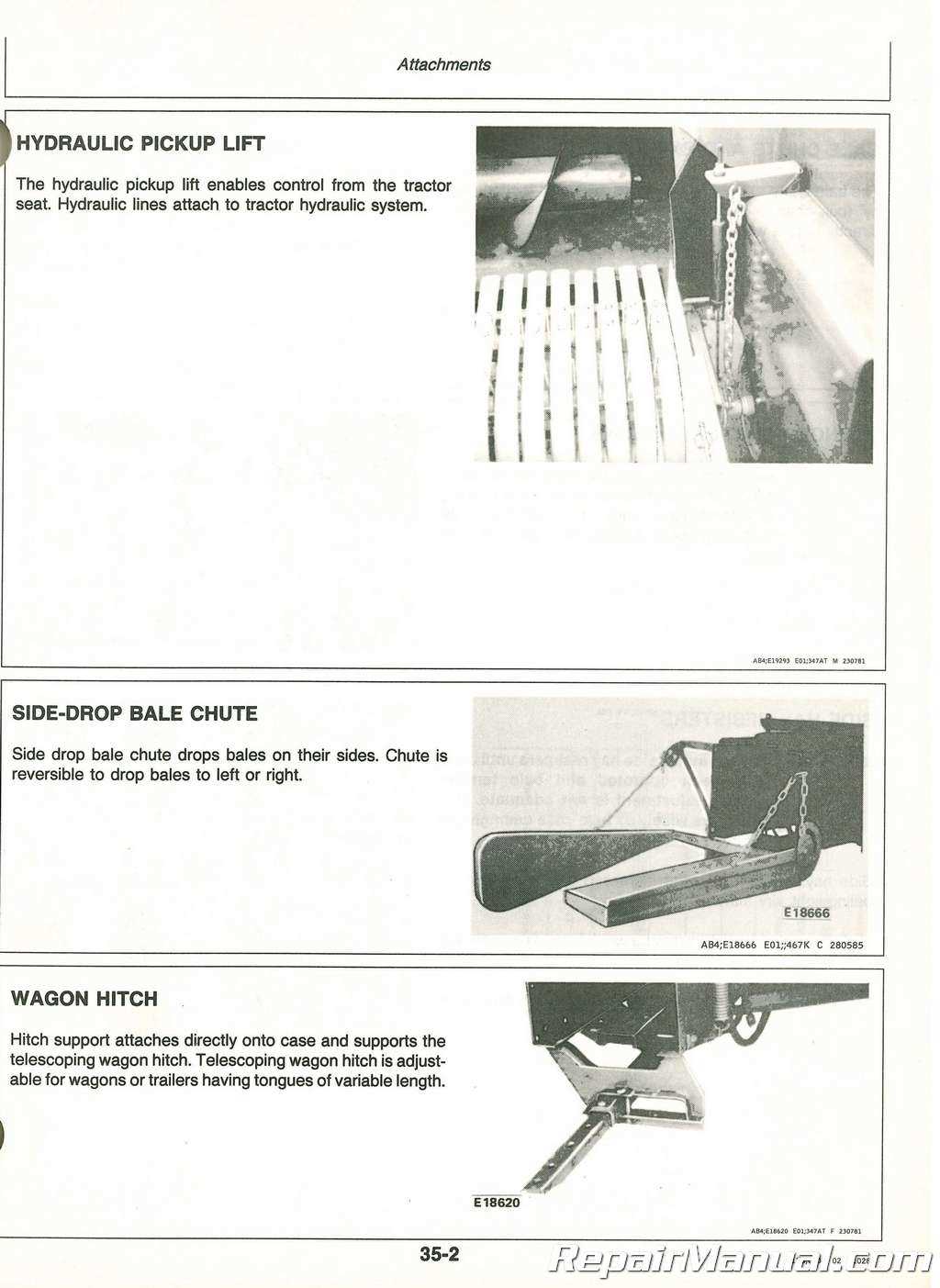

Replacement Parts Availability

Access to suitable components is essential for maintaining optimal performance of agricultural machinery. Ensuring that operators can easily find and procure the necessary replacements helps minimize downtime and enhance productivity.

Sources for Components

- Authorized Dealers

- Online Retailers

- Local Machinery Shops

- Manufacturer Websites

Factors to Consider

- Quality of Components

- Warranty and Support

- Availability of OEM vs. Aftermarket Options

- Delivery Timeframes

By exploring various channels and keeping these considerations in mind, operators can ensure they have the right components when needed, facilitating smoother operations in the field.

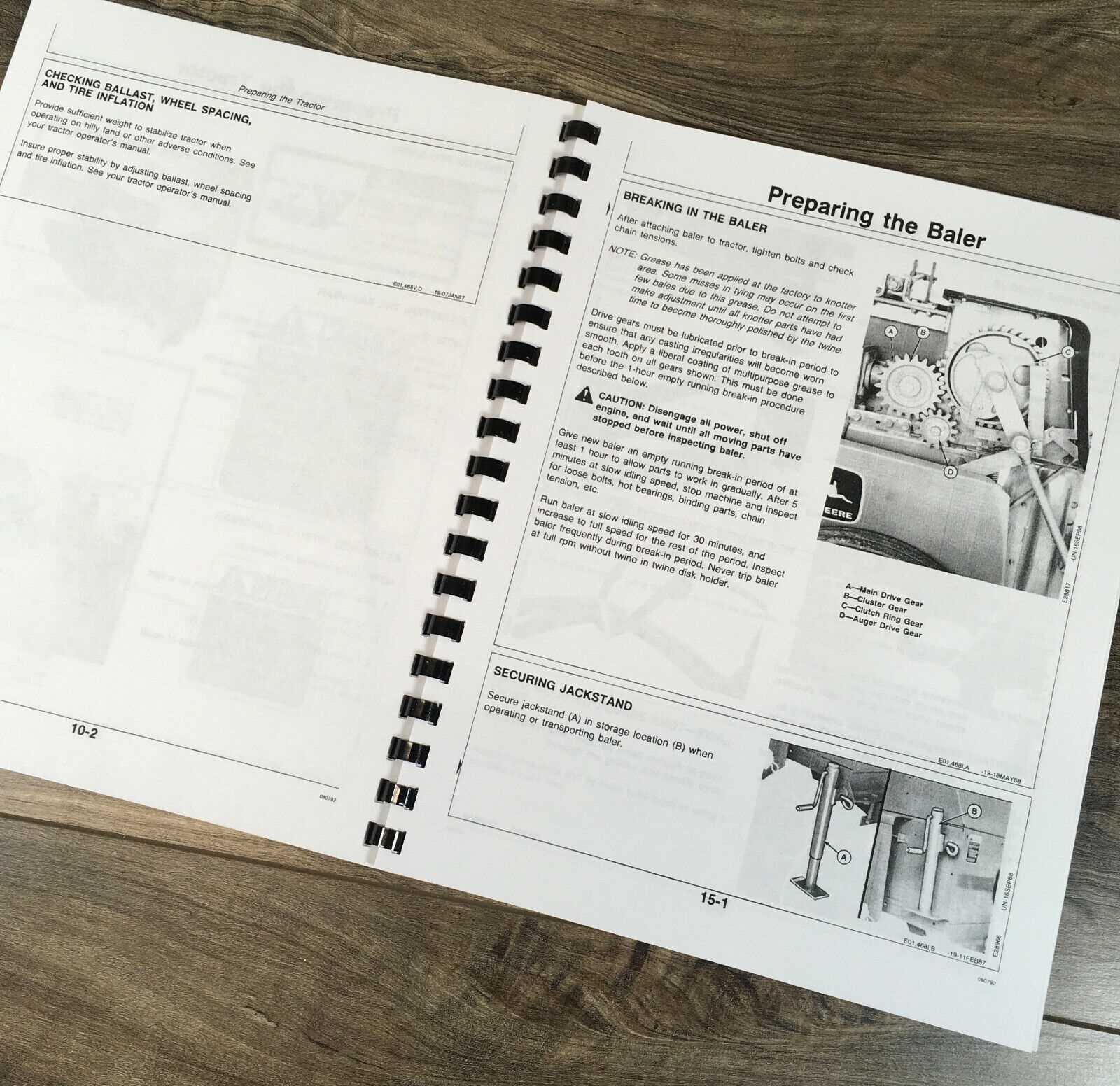

Tips for Efficient Operation

To maximize performance and ensure smooth functionality of your agricultural machinery, it’s essential to adopt best practices in its use and maintenance. Proper techniques not only enhance output but also prolong the lifespan of the equipment.

Regularly inspect all components for wear and tear. This proactive approach helps identify potential issues before they escalate, ensuring that your machine operates at optimal efficiency. Additionally, adhering to the manufacturer’s maintenance schedule is crucial for keeping your equipment in top shape.

Adjusting settings based on field conditions can significantly impact productivity. Tailoring parameters to match crop type, moisture content, and terrain will yield better results. Moreover, familiarize yourself with operational limits to avoid overloading the machine, which can lead to costly repairs.

Training operators on the proper use of machinery can enhance performance and safety. Understanding the equipment’s features and capabilities allows for more effective handling, reducing the risk of accidents and downtime. Encouraging team communication about any issues encountered can also lead to quicker resolutions.

Lastly, maintaining a clean working environment is vital. Regularly clearing debris from the machine prevents unnecessary strain and ensures that it functions efficiently. Taking these steps will not only improve daily operations but also contribute to long-term success in your agricultural endeavors.

Comparing Models: 468 vs. Others

When evaluating various models in the realm of agricultural machinery, it becomes essential to understand their distinct features and functionalities. Each model offers unique benefits tailored to different operational needs. This comparison will highlight key aspects that set one model apart from its counterparts, allowing users to make informed decisions based on their requirements.

Key Features and Performance

Performance is a crucial factor when selecting machinery for agricultural tasks. The model in focus boasts advanced technology that enhances efficiency and productivity. Its robust design allows for optimal handling of materials, while competitors may vary in their ability to manage similar tasks. Understanding these nuances can greatly impact operational success.

Maintenance and Durability

Another important aspect is the maintenance needs of each model. The highlighted machine is designed for easy upkeep, ensuring that downtime is minimized. In contrast, some alternatives may require more frequent attention, leading to potential interruptions in workflow. Evaluating durability and service intervals is vital for long-term investment considerations.

In summary, a thorough analysis of various models can aid users in selecting the most suitable option for their agricultural operations. Focusing on performance and maintenance will ensure that the chosen equipment aligns with both immediate and future needs.

Resources for Baler Enthusiasts

This section offers a wealth of information and tools for those passionate about forage harvesting equipment. Whether you are a seasoned operator or a newcomer, understanding the various components and their functionalities is essential for optimal performance and maintenance.

Online Communities

Joining forums and social media groups dedicated to harvesting machinery can provide invaluable insights. These platforms allow users to exchange tips, share experiences, and seek advice from fellow enthusiasts, fostering a sense of community and support.

Technical Manuals and Guides

Accessing detailed technical documentation is crucial for mastering equipment operation. Manuals often contain comprehensive specifications, troubleshooting steps, and maintenance schedules, ensuring that users can delve into the intricacies of their machines and enhance their overall efficiency.