Understanding the internal structure of a power tool is essential for efficient maintenance and repair. By familiarizing yourself with the layout and individual elements of the machine, you can troubleshoot issues, replace worn-out pieces, and ensure long-lasting performance. A clear representation of all the essential components helps identify specific parts quickly, making repair tasks much more manageable.

Detailed illustrations that showcase the arrangement of various segments are invaluable for both experienced users and beginners. These visual aids not only provide a roadmap to the inner workings but also highlight the connections between different sections. Whether it’s for routine upkeep or restoring a malfunctioning device, having access to a well-organized schematic can significantly ease the process.

In this guide, we will explore the various tools and methods for finding and interpreting such diagrams, ensuring that you have the right information to make informed decisions. Whether you’re looking to replace a specific component or seeking a more in-depth understanding of your machine’s design, this resource will be indispensable.

Understanding the Stihl 034 Chainsaw

For those involved in forestry, landscaping, or heavy-duty cutting tasks, having a reliable power tool is crucial. One such machine, designed for durability and precision, is widely regarded for its performance in both professional and home settings. This particular model combines strength, longevity, and ease of maintenance, making it a popular choice among woodcutting enthusiasts and professionals alike. Understanding how the tool operates and the key components that make it function smoothly is essential for optimal use and maintenance.

Key Features of the Tool

This chainsaw is designed to handle tough tasks with ease. The powerful engine ensures consistent performance even under heavy load, while the ergonomic design helps reduce operator fatigue during extended use. The components are engineered for high efficiency, contributing to both the tool’s performance and its longevity. Knowing the essential parts that work together allows users to troubleshoot and maintain their machine properly, ensuring it serves them for years.

Maintenance and Care

Regular maintenance is key to ensuring the chainsaw remains in top working condition. Each component, from the engine to the chain system, requires periodic attention to avoid wear and tear. Proper cleaning, oiling, and replacing worn-out parts are critical steps in prolonging the tool’s lifespan. A well-maintained chainsaw delivers better results and reduces the risk of unexpected breakdowns.

Key Components of the Stihl 034

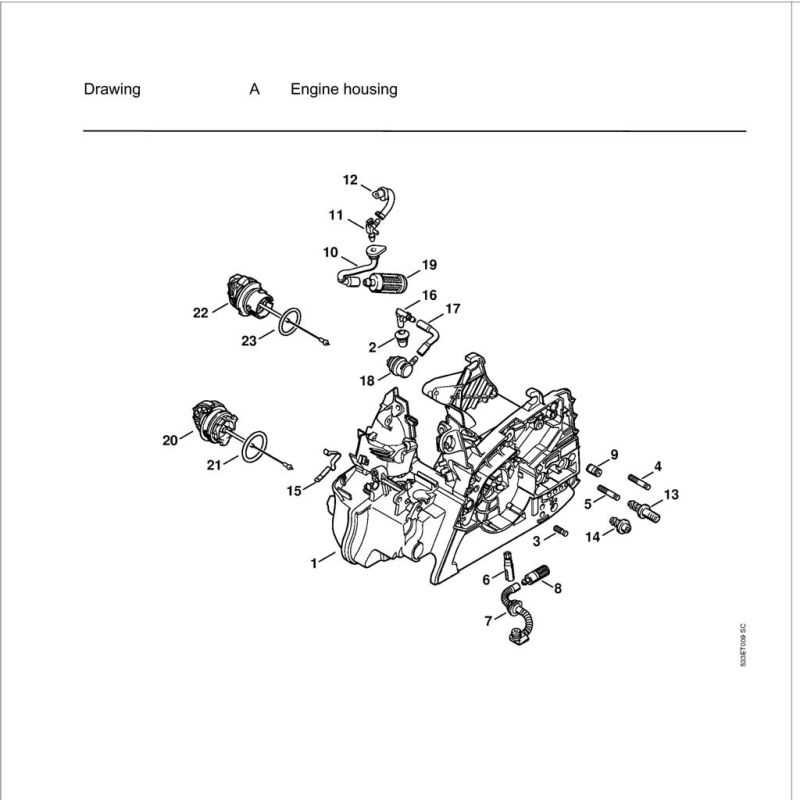

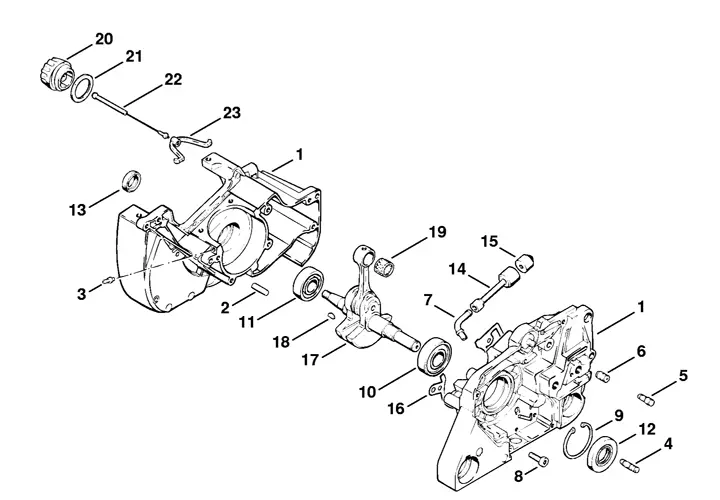

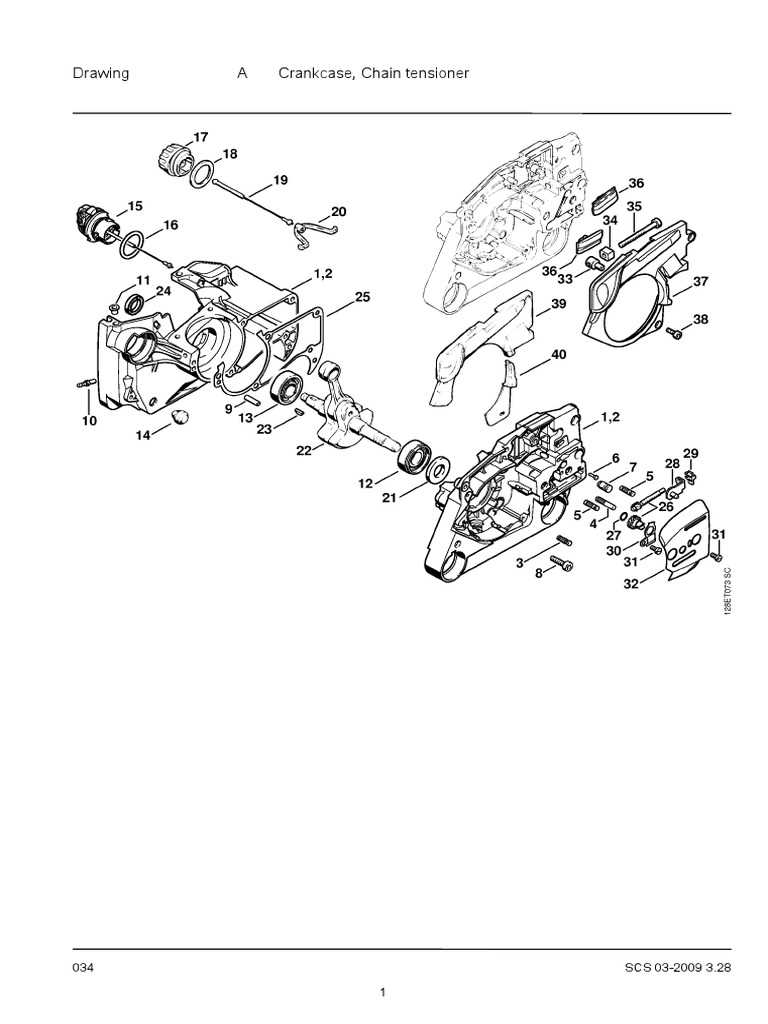

Understanding the essential parts of a power tool is crucial for its optimal performance and maintenance. Each mechanism plays a significant role in ensuring smooth operation and longevity. This section focuses on the primary elements that make up the engine assembly, highlighting their functions and importance for efficient use.

Engine and Powertrain

The core of any outdoor power equipment is the engine, which converts fuel into mechanical energy to drive the tool’s functions. The combustion engine, carburetor, and ignition system work together to provide consistent power output, enabling the machine to perform at its best. Additionally, the powertrain components, such as the clutch and drive mechanism, are essential for transferring engine power to the working parts of the tool.

Fuel and Air Management

Proper fuel delivery and air intake are vital for ensuring optimal combustion and engine efficiency. The fuel system components, including the fuel tank, fuel lines, and filter, work to store and deliver fuel to the engine. Meanwhile, the air filter and carburetor maintain the correct air-to-fuel ratio, optimizing performance while reducing emissions and wear on internal components.

| Component | Function |

|---|---|

| Fuel Tank | Stores fuel for engine operation |

| Air Filter | Prevents debris from entering the engine |

| Carburetor | Mixes air and fuel for combustion |

| Fuel Lines | Carry fuel from the tank to the engine |

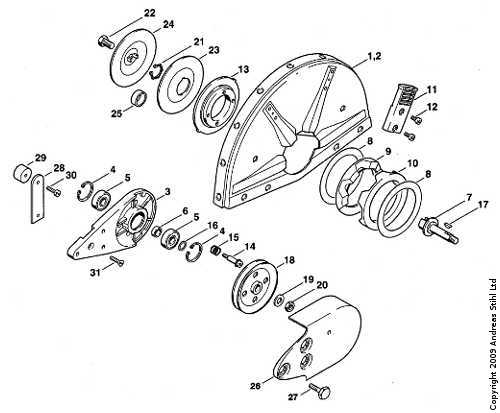

How to Read a Parts Diagram

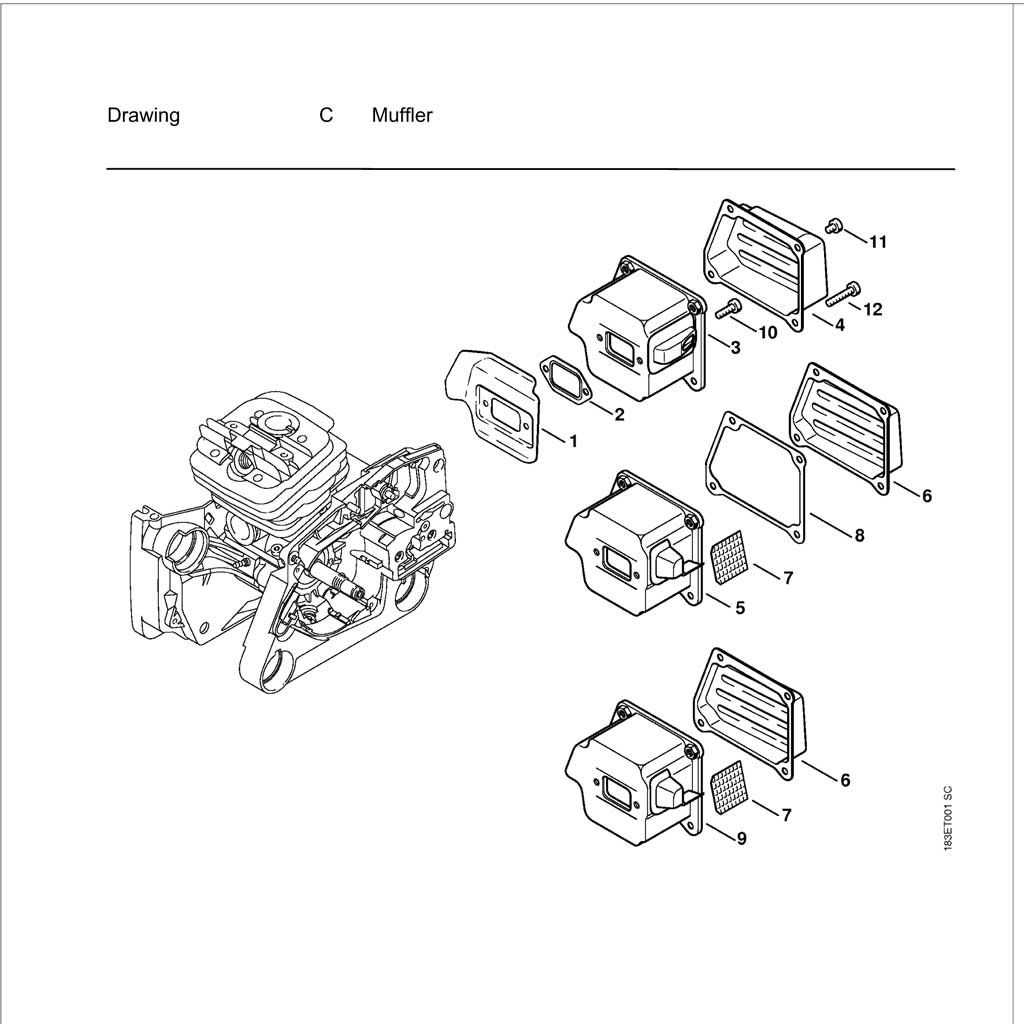

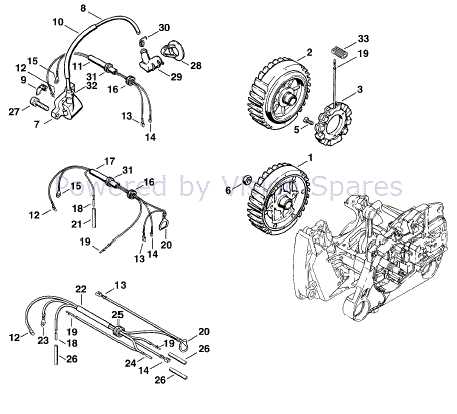

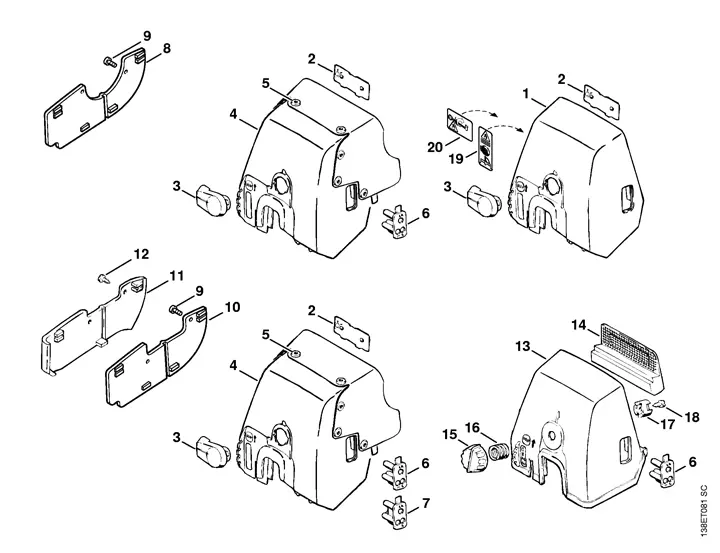

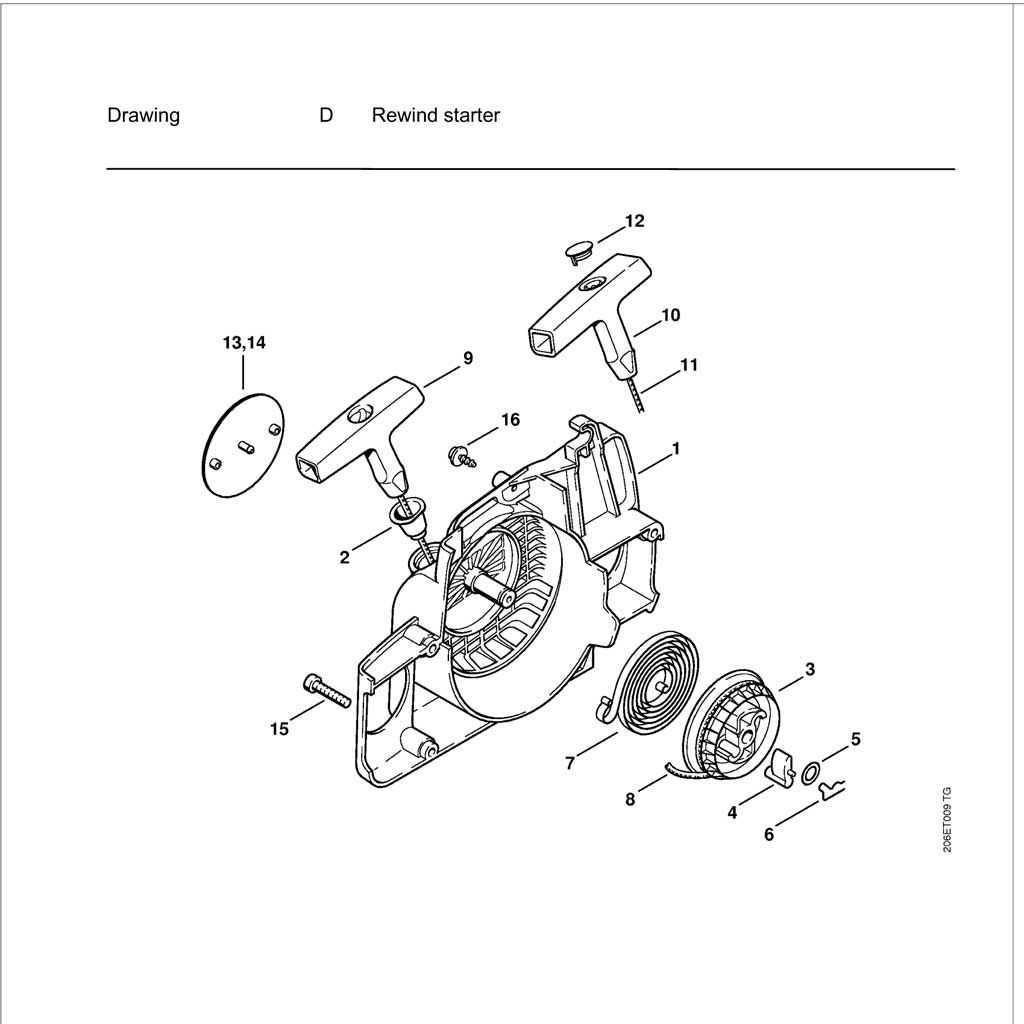

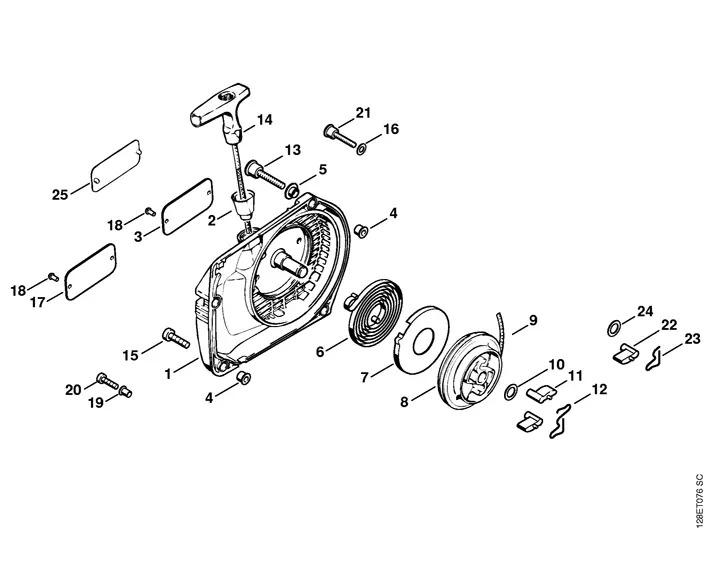

Understanding how to interpret a technical illustration of machine components is essential for effective repair and maintenance. These visual guides provide detailed representations of the individual elements that make up a device. The ability to read these illustrations allows users to identify parts, understand their relationships, and make informed decisions during assembly or disassembly.

Key Components and Labels

Each component in an illustration is usually marked with a number or letter, which corresponds to a reference list. This reference list is often provided separately and includes the part’s description, part number, and sometimes additional information such as quantities or assembly instructions. The components are typically shown in their actual position within the assembly, and arrows or lines may indicate the direction of movement or connection points.

How to Use the Reference List

The reference list is crucial for identifying the exact components needed for repairs or replacements. By cross-referencing the numbers or letters in the visual guide with those in the list, you can determine the specific part required. Often, the reference list will also include important details like the manufacturer’s code, which helps to ensure compatibility with other models or versions of the device.

| Component | Description | Part Number |

|---|---|---|

| Gear Assembly | Main gear for operation | 123-456-789 |

| Fuel Tank | Storage for fuel | 987-654-321 |

| Throttle Handle | Controls speed and power | 111-222-333 |

By mastering the interpretation of these diagrams, users can streamline maintenance tasks and ensure the longevity and efficiency of their equipment. It’s important to follow the provided reference list carefully, as it helps avoid mistakes that could arise from using incompatible or incorrect components.

Common Issues with Stihl 034 Parts

Over time, equipment components can experience wear and tear, leading to various operational problems. These issues can arise from poor maintenance, incorrect usage, or simply age. Understanding the common failures and knowing how to address them can extend the lifespan of your machine and improve its performance.

Here are some frequent issues encountered with these components:

- Fuel Delivery Problems: Clogged fuel lines or a malfunctioning fuel pump can result in insufficient fuel reaching the engine, leading to poor performance or stalling.

- Air Filter Blockage: A dirty or damaged air filter can restrict airflow, reducing engine efficiency and increasing fuel consumption.

- Ignition System Failures: Worn-out spark plugs or damaged ignition coils can cause misfires, preventing the engine from starting or running smoothly.

- Carburetor Issues: A faulty carburetor can cause the engine to run too rich or too lean, affecting power output and causing rough idle or poor acceleration.

- Chain Tension and Bar Wear: Improper chain tension or excessive wear on the guide bar can lead to decreased cutting performance and safety risks during operation.

- Oil Pump Malfunctions: An oil pump that doesn’t function properly can lead to insufficient lubrication, which can cause overheating and damage to the moving parts.

Regular maintenance and periodic inspections are crucial for minimizing these issues. Identifying the problem early can prevent costly repairs and downtime, ensuring your machine runs efficiently for longer periods.

Where to Find Genuine Stihl Parts

Finding high-quality components for your outdoor power equipment is essential for maintaining its performance and longevity. Whether you’re looking to replace a damaged part or upgrade your machinery, sourcing original elements ensures that your equipment operates efficiently. Below are some trusted sources where you can find authentic replacements for your tools.

- Authorized Dealers – The most reliable place to purchase original components is through licensed retailers. These dealers often have an extensive inventory of spare elements and offer expert advice on compatibility and installation.

- Official Website – The manufacturer’s website provides a wide range of replacement pieces and accessories. You can also access user manuals and detailed specifications to help you choose the right items.

- Local Repair Shops – Many professional repair centers carry genuine replacements. These shops can also assist with installation and offer maintenance services to ensure the optimal functioning of your equipment.

- Online Marketplaces – Some reputable online platforms specialize in authentic components. However, be cautious when purchasing online to avoid counterfeit products. Always check the seller’s credibility and reviews.

- Service Centers – For those who prefer a hands-on approach, visiting a certified service center is an excellent way to find quality replacements. Service centers often have a wide variety of authentic options available, and technicians can guide you in choosing the right one.

By choosing these trusted sources, you can ensure that your equipment continues to perform at its best with the right components. Always prioritize authenticity over cheaper alternatives to avoid potential performance issues or safety risks.

Step-by-Step Repair Guide for Stihl 034

When tackling a malfunctioning outdoor power tool, understanding how to approach the repair process can make a significant difference in both time and effort. This guide will help you restore your equipment with a structured, easy-to-follow method. Whether it’s a worn-out component or a system malfunction, the steps outlined below will assist in bringing the tool back to optimal working condition.

Before starting the repair, ensure you have a clean workspace, the necessary tools, and replacement parts. You will also need to refer to the manufacturer’s instructions for specific details that might be unique to your model.

- Preparation and Safety

- Turn off and disconnect the power source to avoid accidents.

- Wear protective gear, such as gloves and safety goggles.

- Clear the work area of any unnecessary items for ease of movement and to avoid misplacing small components.

- Initial Inspection

- Check for visible signs of damage, such as cracks, loose parts, or corrosion.

- Assess the overall functionality of major components, like the engine, chain brake, and fuel system.

- Identify any broken or worn-out parts that need replacing.

- Disassembly

- Start by removing any outer casing or housing that may be obstructing access to the internal components.

- Carefully detach the fuel tank, air filter, and any other external components that can be removed without damaging the system.

- Keep track of screws, bolts, and fasteners, organizing them to ensure easy reassembly later.

- Identifying the Fault

- Test the functionality of individual components, such as the spark plug, ignition system, and carburetor, to locate the root cause of the problem.

- If there are performance issues, clean the spark plug or replace it if necessary.

- If the engine is not starting, inspect the carburetor and fuel lines for clogs or leaks.

- Replacing Components

- Swap out damaged or faulty parts with the correct replacements, ensuring that each part fits properly and is secured in place.

- When replacing a fuel filter, make sure it is clean and free from blockages.

- For worn-out seals or gaskets, ensure the new ones match the exact specifications to prevent air or fuel leaks.

- Reassembly

- Carefully reassemble the tool, following the reverse order of disassembly.

- Ensure all screws and bolts are tightened securely, but avoid overtightening, which may cause damage to components.

- Reconnect the fuel tank and air filter, making sure they are properly aligned and sealed.

- Testing and Final Inspection

- After reassembly, perform a quick test to check for any irregularities in function.

- Check for leaks, unusual noises, or vibrations, and make any necessary adjustments.

- Ensure the tool is running smoothly before returning it to full operation.

With these steps, your outdoor tool should be in excellent working condition. Regular maintenance and timely repairs can help prolong the life of your equipment, keeping it running efficiently season after season.

Tools Required for Stihl 034 Maintenance

Proper upkeep of your equipment requires having the right set of tools. Maintaining the functionality and longevity of a chainsaw or similar machinery involves a combination of basic hand tools and specialized items. Having the right tools on hand ensures that each task, from routine cleaning to more intricate repairs, is completed efficiently and safely.

Among the essential tools, you will need screwdrivers for removing screws, wrenches to adjust bolts, and pliers for securing components. Additionally, a spark plug wrench will be necessary for replacing or cleaning the spark plug, while chain brake tools are important for managing the chain system. Don’t forget to have a cleaning brush and lubricants for proper maintenance of moving parts and to prevent premature wear.

Investing in a high-quality toolset is essential, as using the wrong tools can damage the machine and make future repairs more complicated. A well-maintained toolkit ensures that you can handle common maintenance tasks and address potential issues with ease, keeping your equipment in top shape for extended use.

Upgrading Stihl 034 with New Parts

Improving the performance and longevity of your outdoor power equipment often requires replacing or enhancing certain components. By installing modern, high-quality elements, you can breathe new life into an aging machine. Whether you’re aiming to boost efficiency, reliability, or simply restore its original performance, upgrading with new parts is an essential step.

Enhanced Performance comes as one of the main benefits when replacing outdated or worn-out elements. Upgrading the engine’s critical components, such as the spark plug or carburetor, can help restore smooth operation and prevent frequent breakdowns. A well-maintained engine will run smoother and consume fuel more efficiently, improving overall productivity during work.

Durability and Longevity are key factors that make new parts worth considering. As machinery ages, wear and tear can affect the structural integrity of its parts. Replacing critical elements, such as the air filter or fuel lines, ensures that the machine continues to perform at its peak for a longer period, reducing the need for frequent repairs and maintenance.

Investing in upgraded components not only increases functionality but can also bring your tool into alignment with current technology. Modern materials and manufacturing techniques result in parts that are more resistant to wear and environmental damage, which is particularly beneficial for those who use their equipment in harsh conditions.

In conclusion, upgrading with new components can significantly extend the lifespan of your machine while enhancing its performance. It’s an investment that pays off by increasing reliability and reducing long-term maintenance costs.

Maintaining Longevity of Your Chainsaw

Ensuring the extended lifespan of your power saw requires regular attention and proper care. Routine maintenance can significantly reduce wear and tear, enhance performance, and prevent costly repairs. By following some basic practices, you can keep your machine running smoothly and efficiently for years to come.

Regular Cleaning and Inspection

A well-maintained tool begins with cleanliness and routine checks. Keeping the engine and components free from dirt, debris, and sawdust is crucial. Here are key steps to follow:

- Clean the air filter regularly to ensure proper airflow to the engine.

- Inspect the spark plug for signs of wear or carbon buildup and replace it when needed.

- Check the fuel system for leaks or blockages and clean the fuel filter as required.

- Ensure that the chain is well-lubricated to reduce friction and extend its life.

Proper Lubrication and Chain Maintenance

The chain and bar need consistent lubrication to prevent damage from friction. Neglecting this can result in overheating and increased wear. Follow these tips:

- Use the correct type of chain oil that suits your specific tool.

- Monitor oil levels and refill as necessary to keep the chain running smoothly.

- Sharpen the chain regularly to maintain cutting efficiency and reduce unnecessary strain on the motor.

- Check the tension of the chain frequently, adjusting it to the recommended level for optimal performance.

By integrating these practices into your maintenance routine, you ensure that your saw stays in top condition, leading to improved reliability and performance over time.