In the world of gardening and landscaping, the efficiency and reliability of your tools can greatly impact the outcome of your work. One essential piece of equipment, designed for precise trimming and shaping, consists of numerous intricate elements that ensure optimal performance. A comprehensive overview of these components is vital for anyone seeking to maintain or repair their device effectively.

By familiarizing yourself with the various sections of your trimmer, you can gain insights into its functionality and discover the importance of each individual piece. This knowledge not only enhances your ability to troubleshoot potential issues but also aids in the overall upkeep, extending the lifespan of your equipment.

Whether you are a seasoned professional or an enthusiastic hobbyist, understanding the internal workings can empower you to tackle repairs confidently. With a clear depiction of the assembly, you will be better equipped to make informed decisions regarding maintenance and upgrades.

Overview of Stihl HS 56 C

The HS 56 C is a robust tool designed for precise trimming and shaping of hedges and shrubs. This model combines efficiency with user-friendly features, making it suitable for both professionals and enthusiasts. Its lightweight construction and ergonomic design contribute to a comfortable handling experience, reducing fatigue during extended use.

Key Features

One of the standout attributes of this model is its powerful engine, which ensures optimal performance even in dense vegetation. The dual blade system enhances cutting efficiency, allowing for swift and clean results. Additionally, the innovative anti-vibration technology minimizes user strain, promoting a smoother operation.

Maintenance and Care

Regular upkeep is essential to maintain the longevity and effectiveness of this trimming tool. Keeping the blades sharp and clean is crucial for achieving the best performance. Furthermore, periodic inspections of the engine and other components can help identify any wear and tear, ensuring reliable operation for years to come.

Essential Components of the Model

This section explores the fundamental elements that contribute to the functionality and efficiency of the equipment. Understanding these components is crucial for maintenance and optimal performance.

Key Elements

The main parts include the motor, cutting blades, and control mechanisms. Each element plays a vital role in ensuring the machine operates smoothly and effectively.

Component Overview

| Component | Description |

|---|---|

| Motor | Powers the entire system, providing the necessary force for operation. |

| Blades | Designed for precise cutting, available in various configurations. |

| Control Mechanism | Allows users to adjust settings for different tasks and environments. |

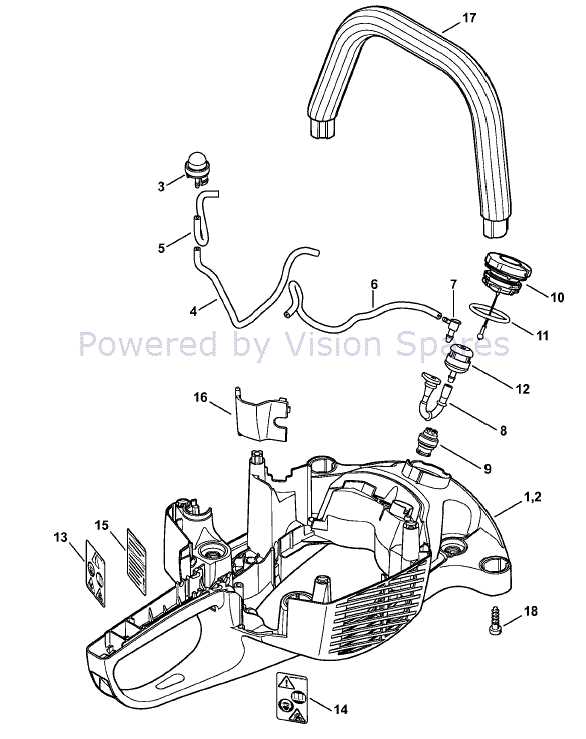

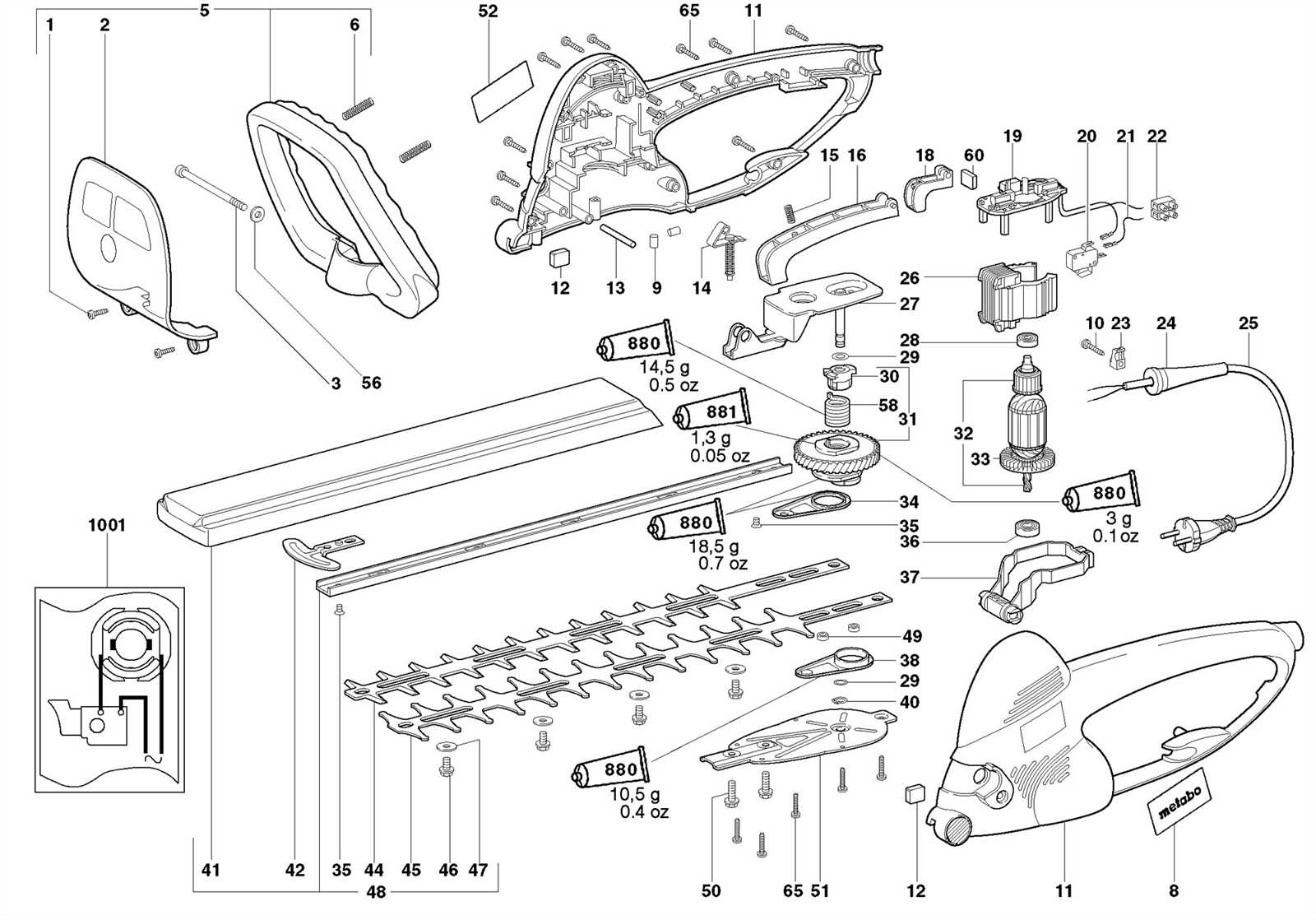

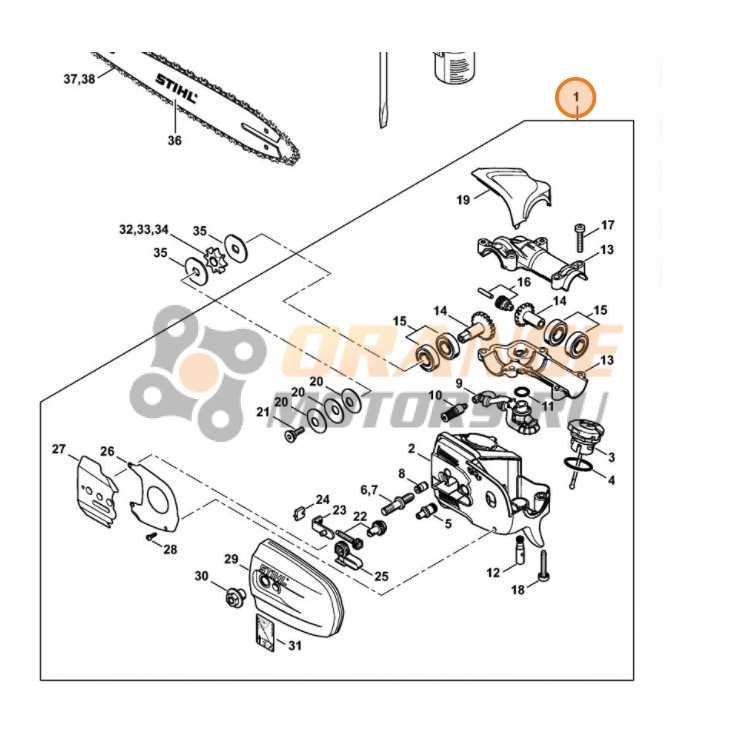

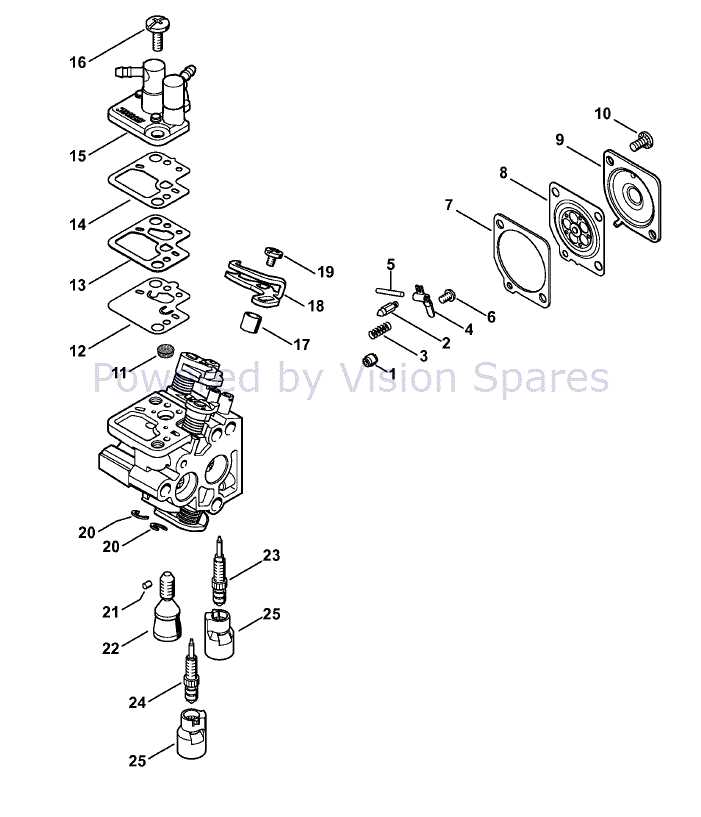

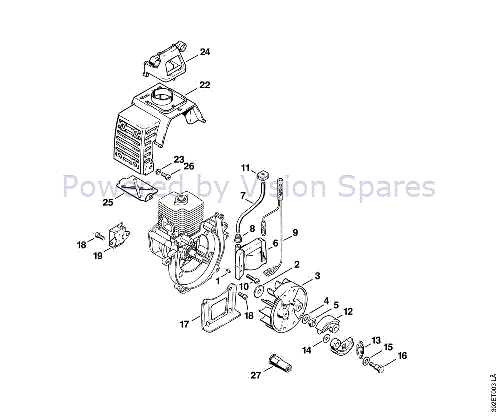

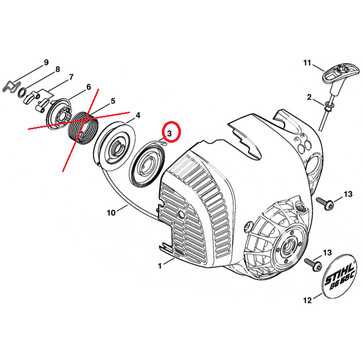

Understanding the Parts Diagram

Gaining insight into the assembly blueprint is crucial for maintaining and troubleshooting your equipment. This visual representation not only showcases the individual components but also illustrates how they interact within the entire system.

Familiarity with this schematic enables users to:

- Identify each element and its function.

- Recognize potential issues by observing wear or damage.

- Facilitate accurate reassembly after maintenance.

- Streamline the replacement process for faulty items.

To effectively utilize this guide, it’s important to focus on:

- Understanding the layout, which typically follows a logical order.

- Learning the names and purposes of various elements.

- Reviewing connections and interactions among components.

- Referencing this resource during repairs or upgrades.

By comprehending this illustration, users can enhance their operational efficiency and prolong the lifespan of their machinery.

Common Repairs for Stihl HS 56 C

Maintenance and repair tasks are essential for ensuring the longevity and optimal performance of outdoor equipment. Familiarizing oneself with common issues can help users address problems promptly and efficiently. Below are some frequent repairs encountered with this model.

Frequent Issues

- Worn-out blades

- Fuel system clogs

- Electrical failures

- Loose or damaged wiring

- Air filter obstructions

Repair Process

- Blade Replacement: Regularly check blades for signs of wear. If they are dull or chipped, replace them to maintain cutting efficiency.

- Fuel System Cleaning: Inspect the fuel lines and filters for clogs. Clean or replace them to ensure proper fuel flow.

- Electrical Inspection: Test electrical connections and components. Repair any loose or damaged wiring to prevent operational failures.

- Air Filter Maintenance: Clean or replace the air filter periodically to ensure optimal airflow and engine performance.

By staying proactive with these common repairs, users can extend the life of their equipment and ensure it operates smoothly.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your equipment requires regular care and attention. Simple maintenance tasks can significantly extend its lifespan and enhance efficiency. By following a few essential practices, you can keep your tools in optimal condition and ready for any task.

| Task | Frequency | Benefits |

|---|---|---|

| Clean air filter | Every 10 hours | Improves airflow and engine efficiency |

| Sharpen blades | After every use | Ensures clean cuts and reduces strain |

| Check fuel level | Before each use | Avoids interruptions during operation |

| Inspect cables and connections | Monthly | Prevents electrical issues |

| Store in a dry place | After use | Prevents rust and damage |

Identifying Replacement Parts Easily

Understanding the components of your equipment can significantly enhance the process of finding suitable substitutes. By familiarizing yourself with each element’s function and appearance, you can streamline the replacement process, ensuring that you select the right items swiftly and efficiently.

| Component | Description | Common Issues |

|---|---|---|

| Blade | Primary cutting tool, varying in length and sharpness. | Dullness, damage, or bending. |

| Fuel Filter | Prevents debris from entering the engine. | Clogging or wear over time. |

| Air Filter | Ensures clean air intake for optimal performance. | Blockage or degradation. |

| Spark Plug | Ignites the fuel-air mixture for combustion. | Fouling or failure to ignite. |

Where to Buy Stihl Parts

When it comes to acquiring components for your outdoor equipment, knowing where to find quality replacements is essential. A wide range of options exists, from authorized dealers to online marketplaces, ensuring that you can easily access what you need for maintenance and repairs.

Authorized Retailers

Visiting certified retailers guarantees authenticity and reliability. These locations often carry a comprehensive selection of components tailored for various models. Additionally, staff members are usually well-informed and can assist you in selecting the correct items for your machinery.

Online Marketplaces

For convenience and often better pricing, online shopping has become increasingly popular. Websites dedicated to outdoor equipment often stock a vast array of items. Ensure you choose reputable sellers with good reviews to avoid counterfeit products. Comparing prices and checking return policies can help secure a satisfactory purchase.

FAQs About Stihl HS 56 C Parts

This section addresses common inquiries related to components of the model in question, offering clarity and insight for users. Understanding the various elements can enhance the experience and maintenance of your equipment.

What should I do if a component breaks? It’s advisable to consult a professional or refer to your user manual for replacement options and guidance.

How can I identify the correct replacement for a specific piece? Check the model number and consult your local dealer or the manufacturer’s website for accurate specifications.

Are there any aftermarket alternatives available? Yes, many users opt for compatible substitutes, but ensure they meet quality standards to avoid potential issues.

How often should I inspect the components? Regular inspections are recommended to ensure optimal performance, typically at the beginning of each season.

Can I perform maintenance myself? Basic maintenance tasks can often be handled by the user, but for more complex repairs, professional assistance is recommended.