For those who are responsible for maintaining large green spaces, effective waste management solutions play a crucial role in keeping the landscape clean and presentable. Whether dealing with fallen leaves or trimmed grass, specialized equipment can make the task much simpler, allowing for seamless collection and disposal. It’s essential to be familiar with the various elements that contribute to the smooth operation of such systems, ensuring longevity and optimal performance.

To ensure proper functionality, it’s important to grasp how different mechanical elements work together. Knowing the structure of these components helps not only in regular maintenance but also in identifying potential issues early. By gaining an understanding of the setup, operators can perform more efficient repairs and upgrades when necessary, keeping the equipment in top shape.

This guide will explore the essential elements of collection systems, providing insights into their role in achieving clean and efficient operations. By breaking down the

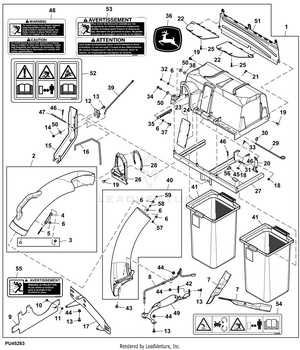

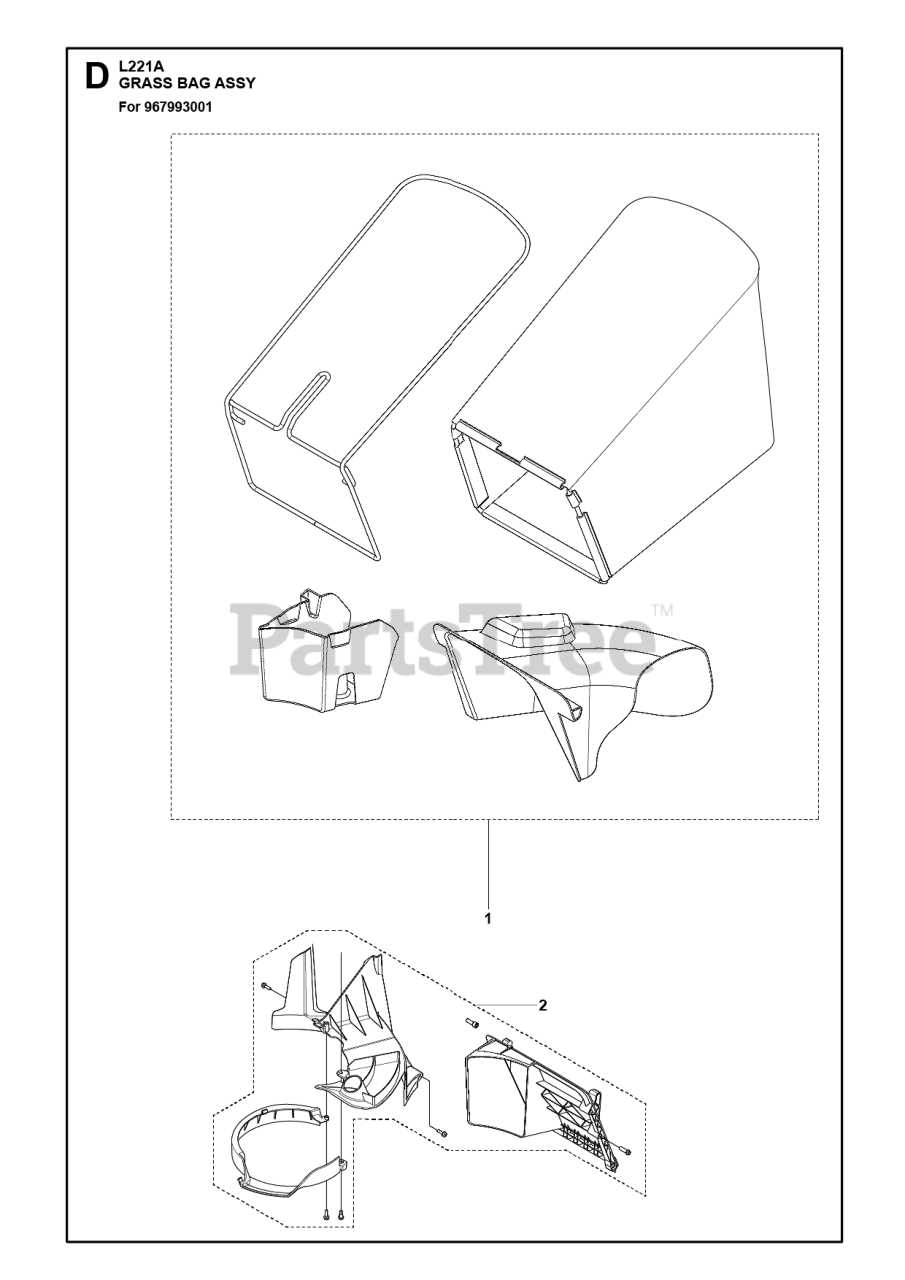

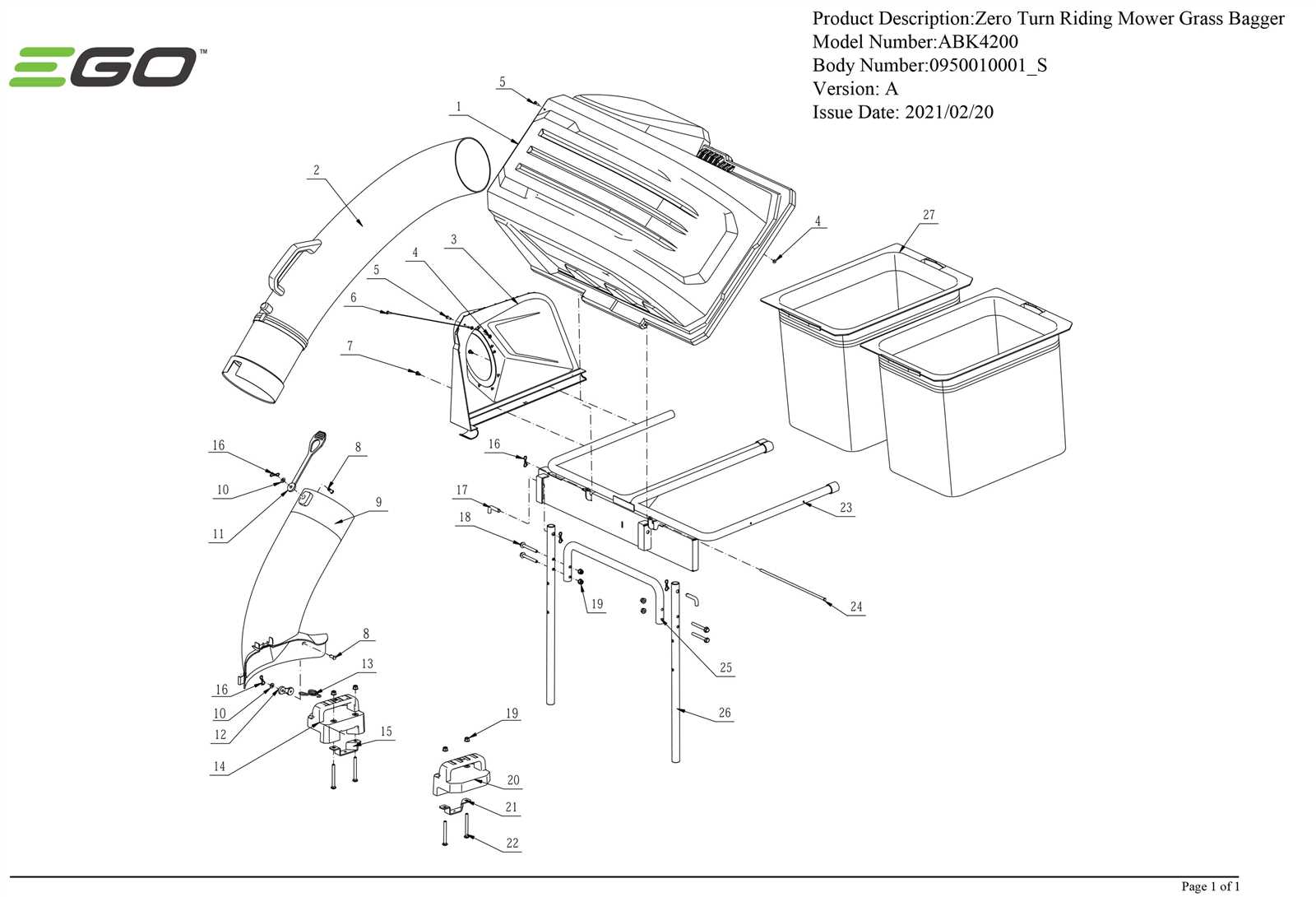

Understanding the Components of a Bagger System

The collection system in outdoor machinery consists of several key elements that work together to ensure efficient operation. Each part plays a specific role in directing and storing materials, making the overall system effective for extended use. By recognizing the function of each element, it becomes easier to maintain and troubleshoot when necessary.

Main Structural Elements

One of the most important components is the chute, which serves as a pathway for materials to be funneled from the cutting area to the collection unit. Additionally, the frame provides necessary support, ensuring that the entire mechanism remains stable during operation.

Storage and Disposal Units

The container or compartment is designed to hold collected materials until it’s time for disposal. A properly sealed unit prevents spillage and ensures safe handling, allowing for more efficient management of materials during work.

Key Functions of Bagger Attachments

Grass collection systems play an essential role in maintaining a neat and well-organized lawn. They ensure that cut grass, leaves, and other debris are efficiently gathered during mowing, leaving the landscape clean. These systems are designed to improve the efficiency of lawn care tasks while minimizing manual labor. The following outlines the primary functions of these attachments, emphasizing their role in optimizing garden maintenance.

Efficient Debris Collection

One of the primary roles of these add-ons is to collect debris swiftly and effectively. Whether it’s fallen leaves in autumn or grass clippings in the summer, these systems help reduce the time spent raking and disposing of waste. By directly capturing material during the mowing process, they streamline outdoor maintenance and reduce the need for post-mowing cleanup.

Capac

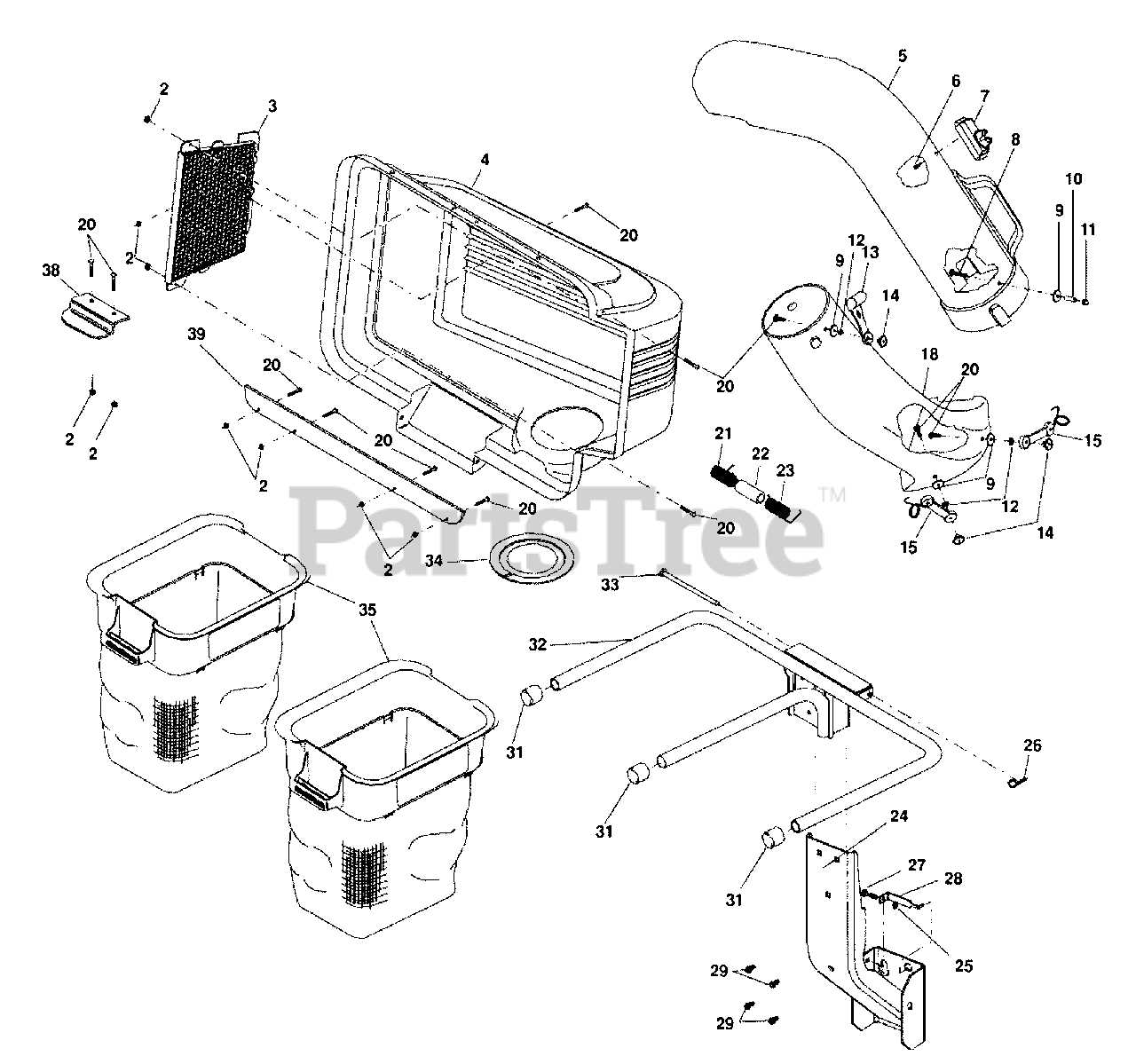

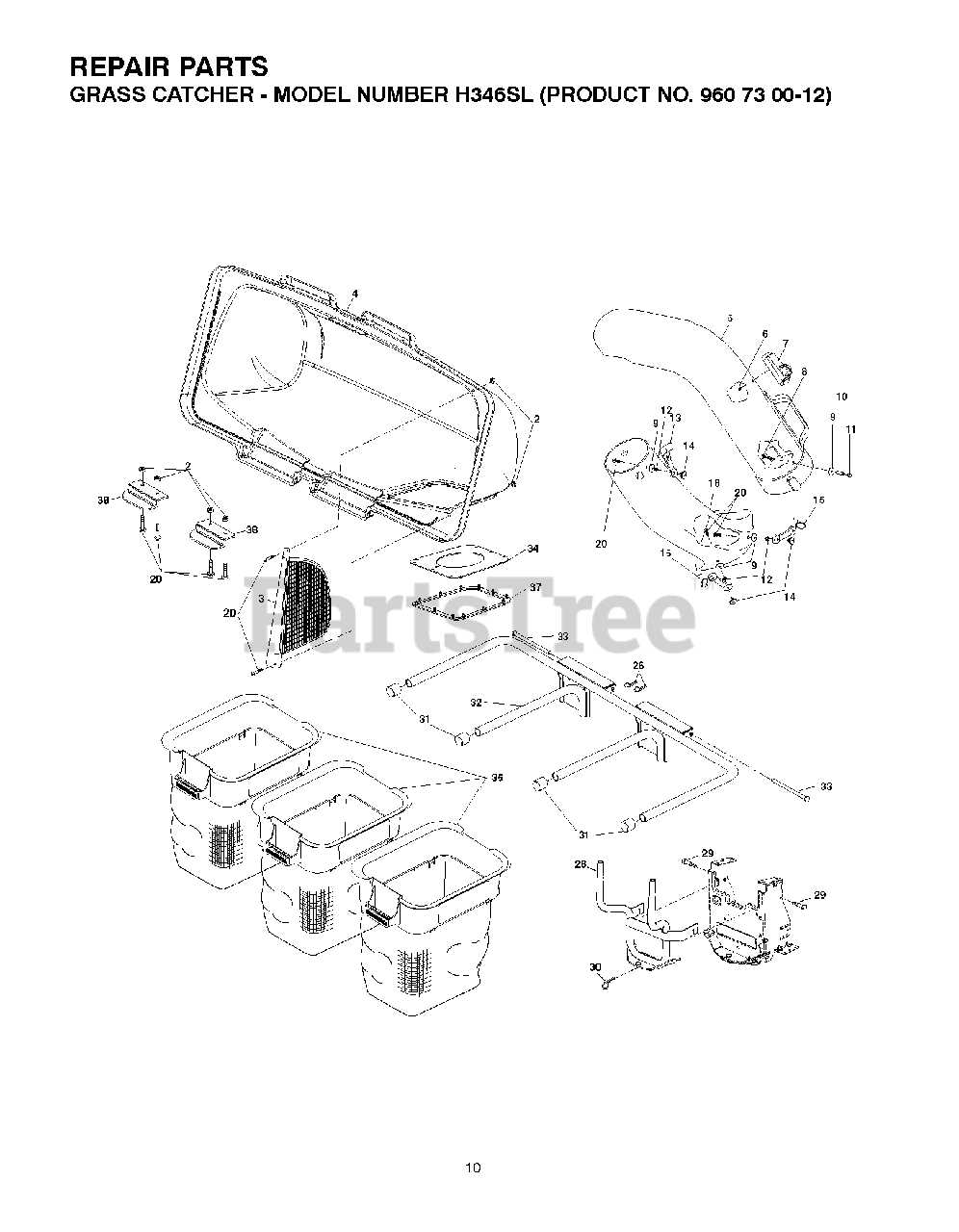

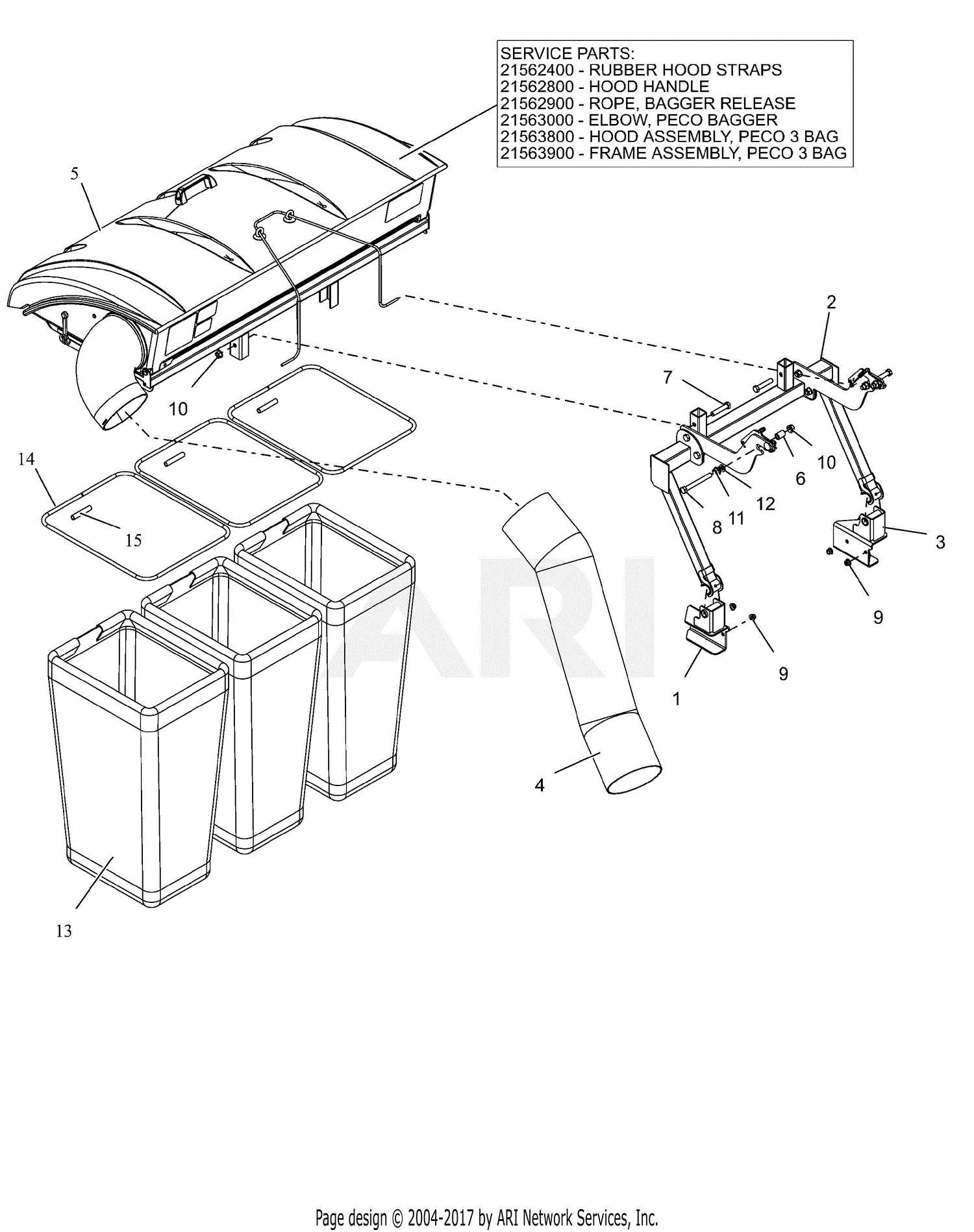

Identifying the Main Bagger Housing Parts

The structure of a collection system is composed of several interconnected elements that work together to efficiently gather and store material. Understanding the primary components involved in this system helps to ensure proper maintenance and operation.

The outer shell serves as the protective casing, designed to shield internal mechanisms from external factors. It provides durability and helps maintain the overall integrity of the system during use.

Inside, various elements channel material through the system. Key components include the inlet section, where material is directed into the storage, and the chute, which guides the flow efficiently. These sections are crucial for smooth operation and prevent blockages.

Another critical section is the latch mechanism, ensuring secure closure of the collection area during use. Proper function of this part guarantees safety and prevents spillage.

By familiarizing yourself with these primary structural components, you can improve your ability t

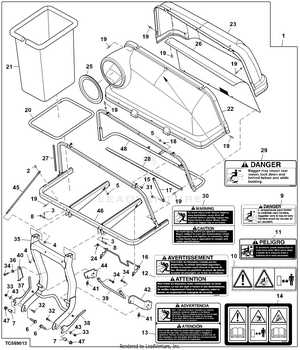

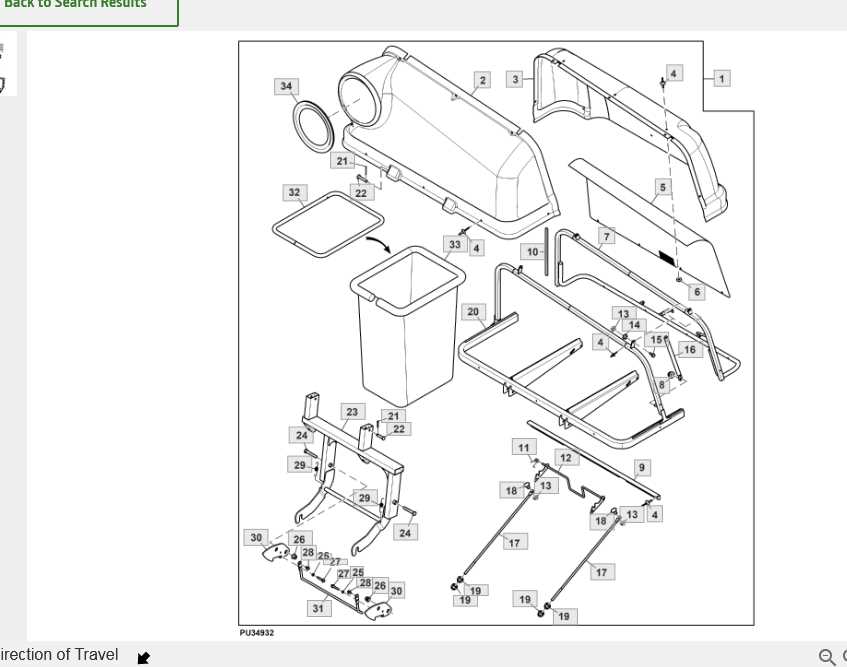

Overview of Collection Blower and Tube Design

The design of the collection blower and tube is crucial for ensuring efficient material gathering and smooth airflow. These components work in harmony to transport debris from the ground to the collection unit, making sure that the process is both streamlined and effective.

Blower function revolves around creating the necessary force to direct the gathered material through the system. It operates by generating a steady airflow that keeps the material moving without clogging or slowing down the process.

Tube design plays an equally important role, as it must be engineered to minimize friction and reduce blockages. A well-constructed tube ensures that the flow of debris is uninterrupted and can handle various materials with ease, adapting to different operating conditions.

In summary, the combined performance of the blower and tube is vital for

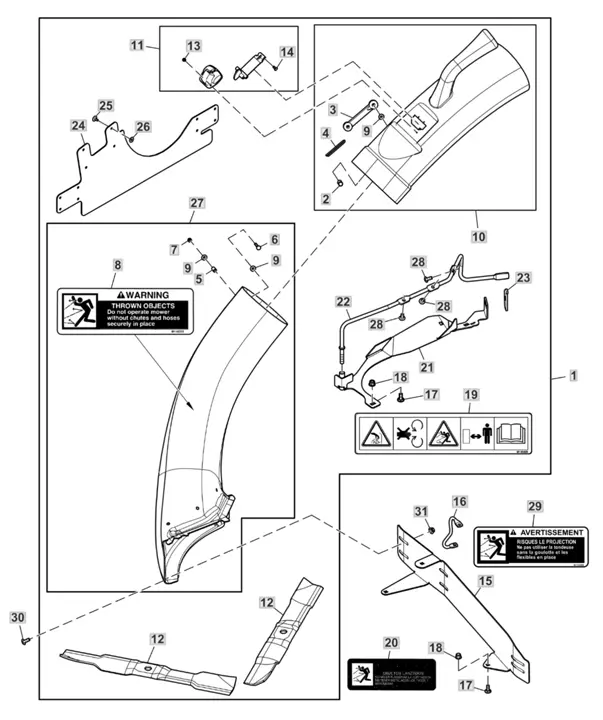

Critical Differences in Bagger Blade Types

Understanding the differences between various blade designs is essential for achieving optimal performance and results. Each type of cutting edge is engineered to serve specific functions, enhancing efficiency and adapting to particular environments. Choosing the right blade for the job significantly impacts the overall efficiency and precision of the cutting process.

High-lift blades are ideal for maximizing airflow, making them well-suited for situations where thorough material collection is necessary. These blades generate a strong upward force, helping to propel clippings efficiently.

Low-lift blades, on the other hand, are better suited for handling shorter grass or dry conditions. Their lower suction reduces strain on the machine, making them

Examining the Role of Deflector Shields

Deflector shields play a crucial role in ensuring efficient material management and directing debris during operation. Their main purpose is to control the flow and trajectory of various materials, reducing the risk of clogging or damage to surrounding components. Properly positioned shields contribute to smoother functioning and enhanced safety.

Key Functions of Deflector Shields

- Redirection of loose debris away from sensitive areas.

- Prevention of blockages by guiding materials into the proper channels.

- Minimization of wear and tear on other mechanical elements by acting as a protective barrier.

Maintenance Tips for Bagger Belts and Pulleys

Ensuring the proper upkeep of drive mechanisms and rotating components is essential for the smooth operation of equipment. Regular inspections and timely replacements can prevent potential breakdowns and extend the life of critical elements. Focus on addressing wear and alignment to maintain efficiency and avoid costly repairs.

Start by checking for any signs of cracks, fraying, or stretching on the drive bands. Over time, these issues can lead to reduced performance or failure. Replace worn components immediately to avoid unexpected downtime. Ensure proper tension to avoid excessive strain on the system, which can accelerate wear.

In addition to the bands, inspect the rotating wheels for signs of wear. If the surface becomes smooth or the edges appear damaged, it’s important to replace them. Misalignment or improper tension can result in noisy operation and uneven performance, leading to further wear on other components.

Regular cleaning of the area around the drive system is also crucial. Accumulated debris can affect the movement of the belts and pulleys, reducing their efficiency and causing unnecessary wear. Periodically removing

How to Properly Install Bagger Mounts

Installing mounting brackets for efficient collection systems requires precision and attention to detail. A correct installation ensures optimal performance and safety, helping to secure the system firmly and allowing for smooth operation. Below are the essential steps to properly set up these supports on your equipment.

- Start by identifying the correct placement locations on your machine. Ensure that the frame is free from obstructions and can handle the additional weight.

- Align the brackets with the designated points, and use a level to verify they are positioned evenly. This prevents any imbalance during use.

- Secure the brackets tightly with bolts, ensuring they are fastened securely to avoid any shifts or movements.

- Once installed, test the stability by applying gentle pressure. If there’s any give or movement, tighten the fasteners as needed.

- Finally, inspect the entire setup to make sure nothing obstructs the movement of other components and that the frame can support the added system during operation.

Following these steps will help ensure a reliable

Common Issues with Bagger Latch Mechanisms

Latch mechanisms are crucial for securing attachments during operation, but over time, they can encounter problems that affect functionality. Identifying these common issues early helps to maintain smooth performance and avoid complications in the long run.

Latch Alignment Problems

One frequent issue is the misalignment of the latch, which may prevent proper closure or make it difficult to fasten securely. This misalignment can result from wear, improper usage, or damage to the attachment points. Regular inspection and adjustment can help resolve these issues before they lead to further complications.

Wear and Tear of Latching Components

Over time, components like springs, catches, and hooks can become worn, leading to a weakened hold. This not only compromises the locking mechanism but may also cause unintended disengagement. To avoid operational int