When it comes to maintaining and operating outdoor machinery, having a clear understanding of its various components is essential. Familiarity with each part and its function can greatly enhance the user experience, leading to improved performance and longevity of the equipment. Whether you are a seasoned operator or a newcomer, knowing how to navigate the intricate network of elements within your machine can save time and reduce the risk of issues during operation.

This section aims to provide an overview of the essential elements found in your equipment, highlighting their roles and interconnections. By delving into the specifics of each component, users can gain insights into troubleshooting potential problems and optimizing their machine’s functionality. A comprehensive understanding will empower operators to make informed decisions when it comes to maintenance and repairs.

By exploring the intricate details of these elements, one can develop a deeper appreciation for the engineering behind the machinery. Understanding the significance of each part not only aids in effective usage but also ensures safety during operations. Proper knowledge equips users with the tools necessary to keep their equipment running smoothly, ultimately contributing to greater efficiency in the field.

This model stands out in its category due to its exceptional design and advanced capabilities, making it a reliable choice for various tasks. Users appreciate its efficient performance and user-friendly interface, which contribute to a seamless experience during operation.

Performance and Efficiency

- Powerful engine that delivers optimal output.

- Fuel-efficient technology that reduces consumption.

- Advanced transmission system for smooth gear shifts.

User-Friendly Design

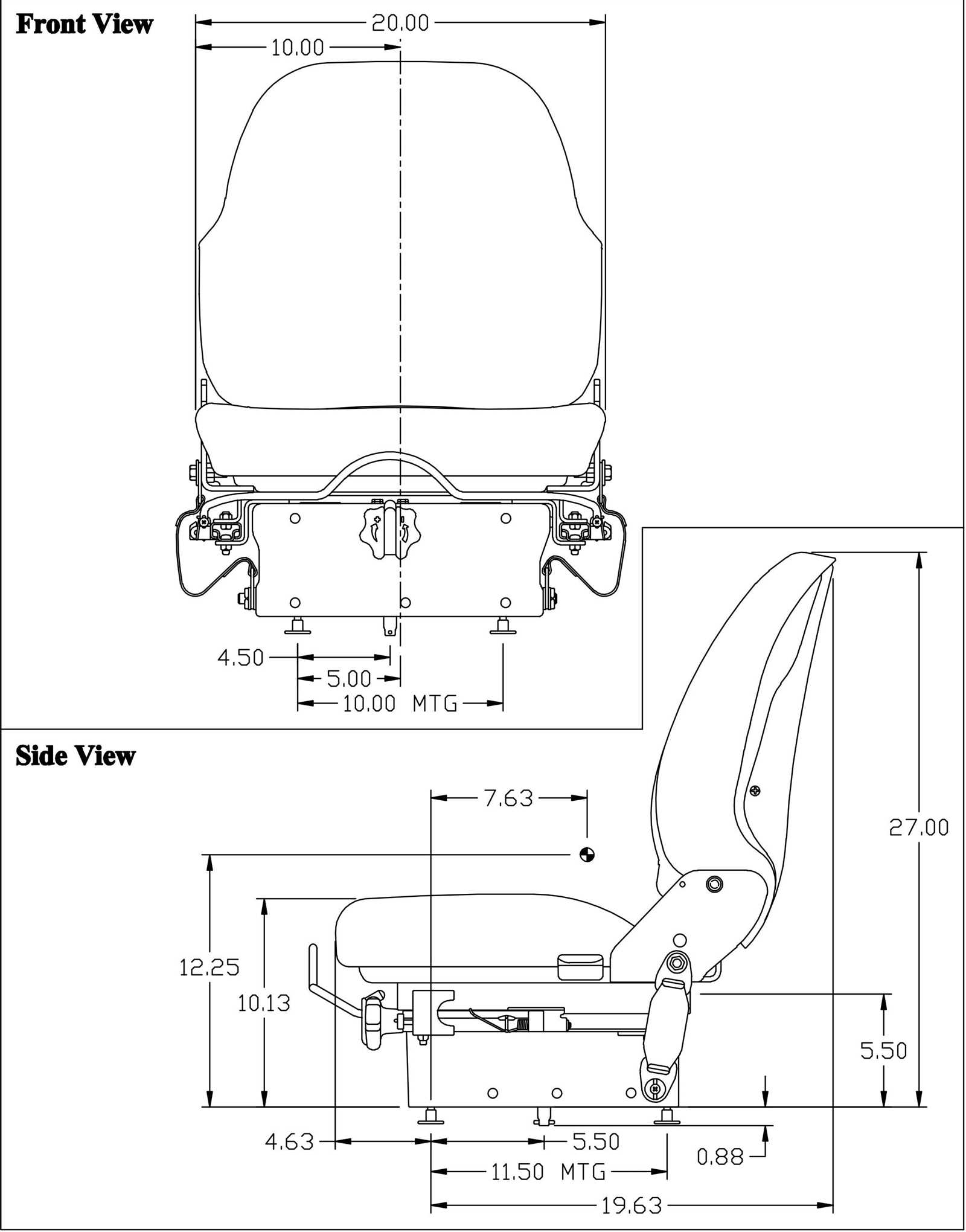

- Ergonomic seat for enhanced comfort during prolonged use.

- Intuitive control panel for easy operation.

- Compact size for improved maneuverability in tight spaces.

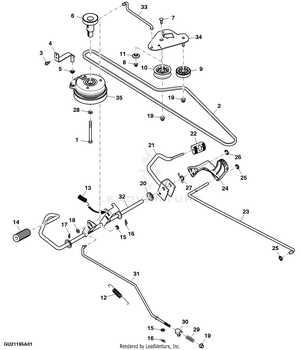

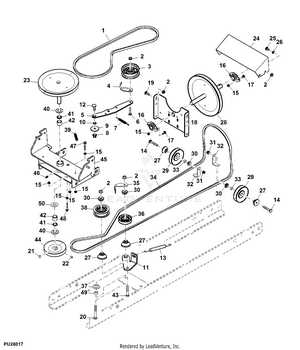

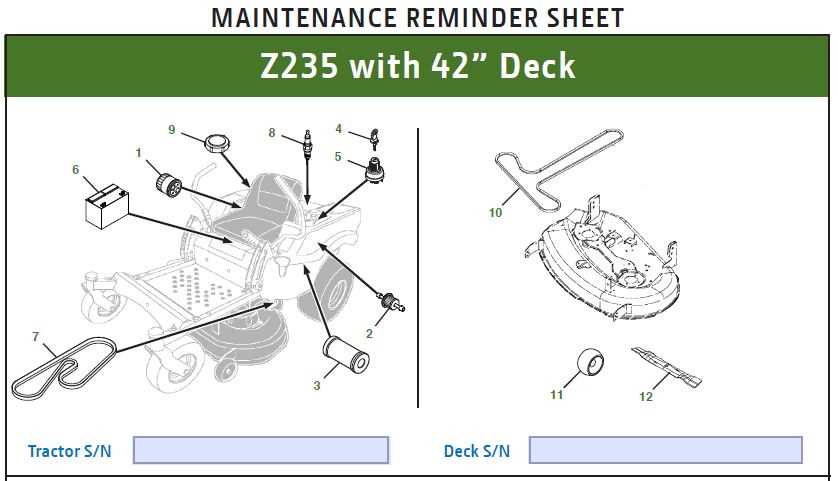

Importance of Parts Diagrams

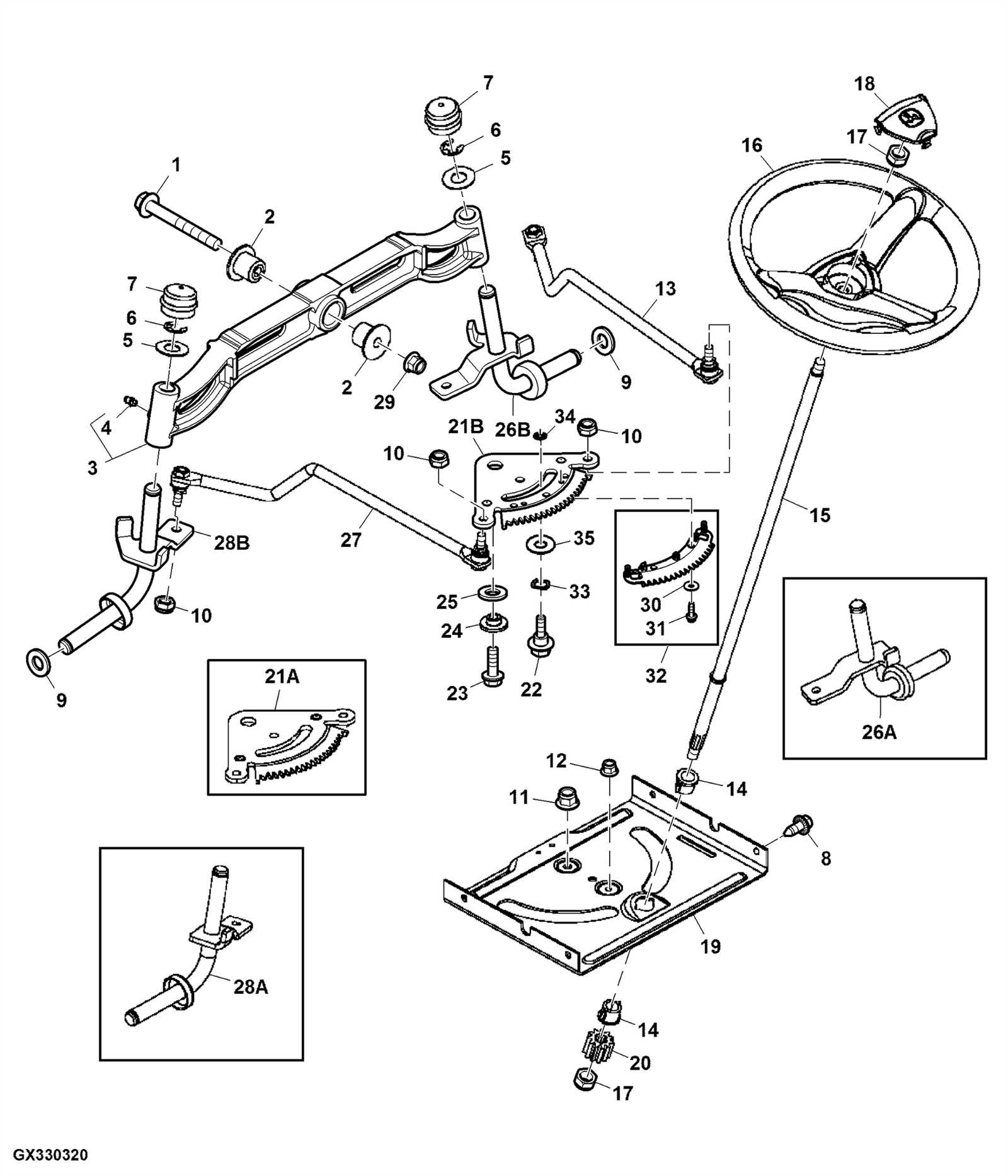

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations help users identify individual elements, understand their functions, and ensure proper reassembly after disassembly. By providing clarity and organization, they contribute significantly to efficient servicing.

Enhanced Understanding

Detailed visuals allow users to grasp the relationships between various elements. This understanding is essential for:

- Recognizing how components interact

- Identifying specific parts that may need replacement

- Facilitating accurate repairs and adjustments

Streamlined Maintenance Processes

Well-structured visuals assist in organizing maintenance tasks. This streamlining leads to:

- Reducing the time spent on repairs

- Minimizing the likelihood of errors during reassembly

- Enhancing overall operational efficiency

Identifying Essential Components

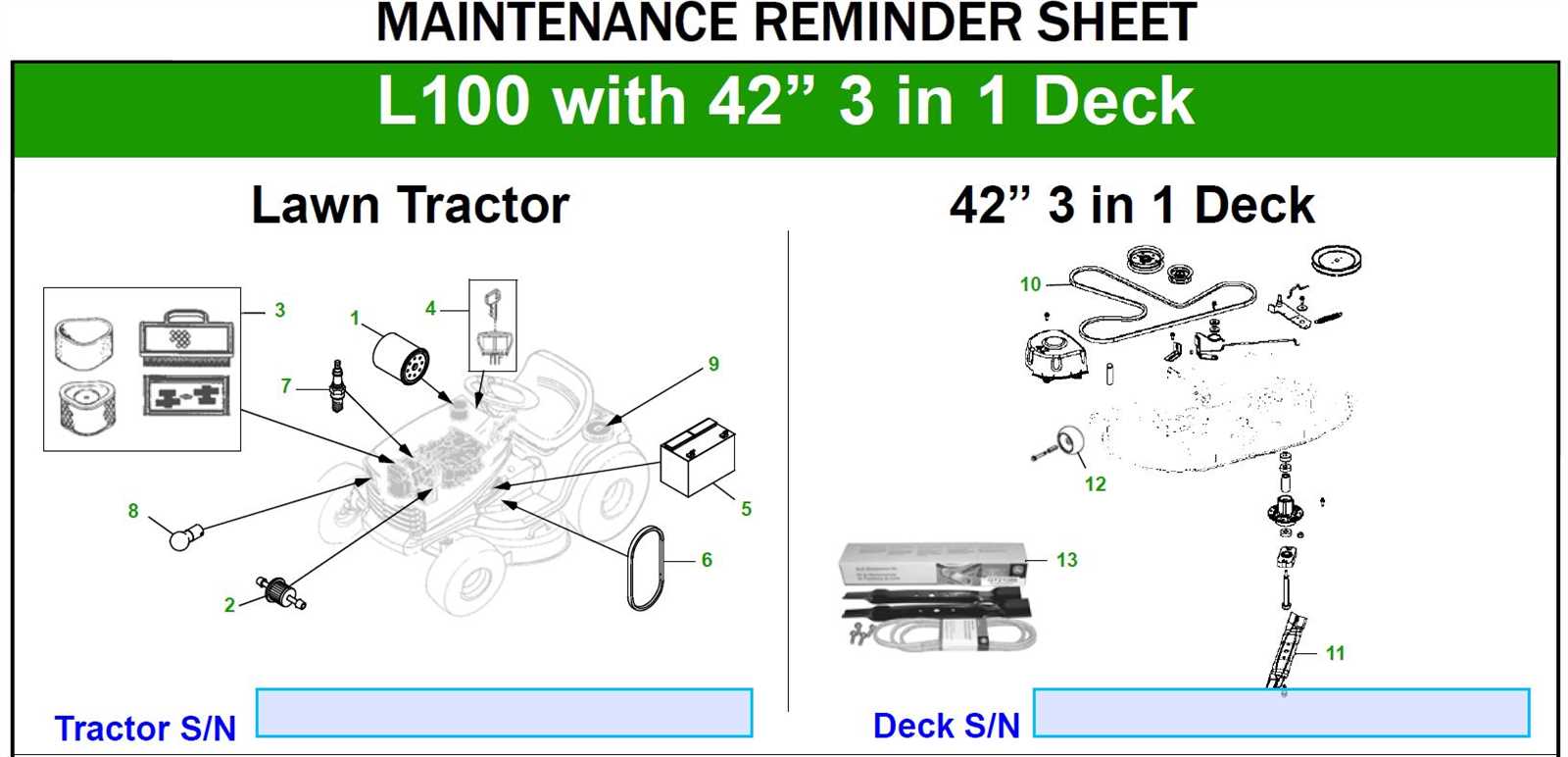

Understanding the vital elements of a lawn tractor is crucial for optimal performance and maintenance. Recognizing each component’s function can significantly enhance the user’s experience and ensure the longevity of the equipment. This section aims to provide insights into the fundamental parts that make up a typical lawn mower, facilitating better care and troubleshooting.

Key Elements and Their Functions

Among the core elements, the engine plays a pivotal role, providing the necessary power to drive the machine. Additionally, the cutting deck is essential for achieving an even trim, while the transmission system enables smooth movement across various terrains. Each of these components must work harmoniously to ensure efficient operation.

Maintenance and Care Considerations

Regular inspection of these essential elements is important for maintaining functionality. Cleaning and lubricating parts can prevent wear and tear, while timely replacements of worn components can avert larger issues. By prioritizing these practices, users can maximize their equipment’s reliability and efficiency.

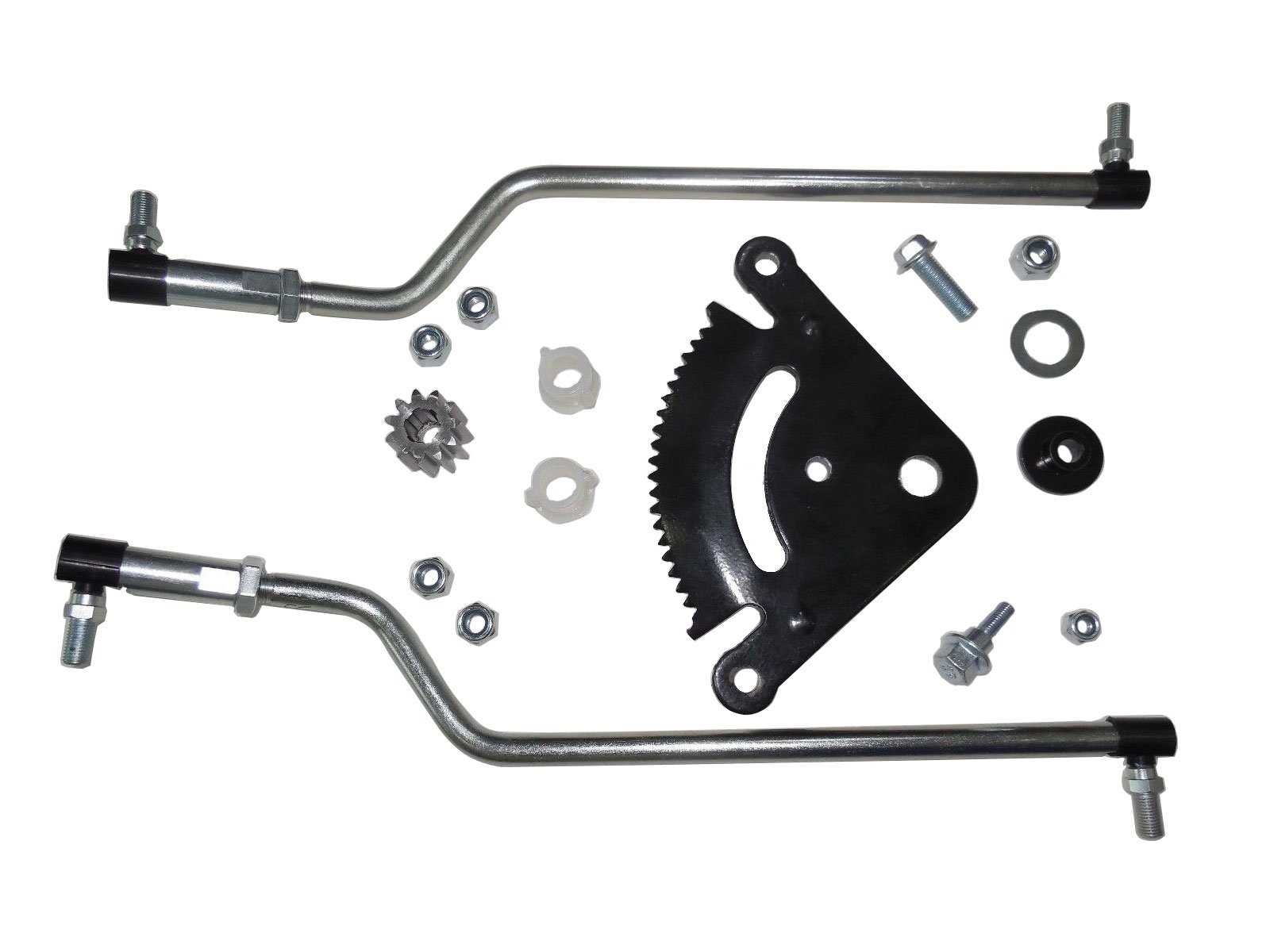

Common Maintenance Parts to Consider

When maintaining your equipment, it is essential to focus on various components that ensure optimal performance and longevity. Regular attention to these elements can help prevent potential issues and enhance overall efficiency.

Filters play a crucial role in protecting your machine’s engine and systems from contaminants. Regularly replacing oil, air, and fuel filters helps maintain clean fluids, which is vital for proper functioning.

Batteries are another key aspect of maintenance. Keeping the battery charged and in good condition is essential for reliable starting and operation. Periodically inspecting terminals and connections can prevent unexpected failures.

Belts and Hoses require attention as well. These components can wear over time, leading to potential breakdowns. Regular checks for signs of wear, cracks, or fraying can help identify issues before they escalate.

Lubricants are necessary to reduce friction and wear in moving parts. Ensuring that all lubrication points are adequately serviced can significantly extend the life of your machinery.

By focusing on these essential components, you can enhance the reliability and efficiency of your equipment, ultimately leading to better performance and reduced downtime.

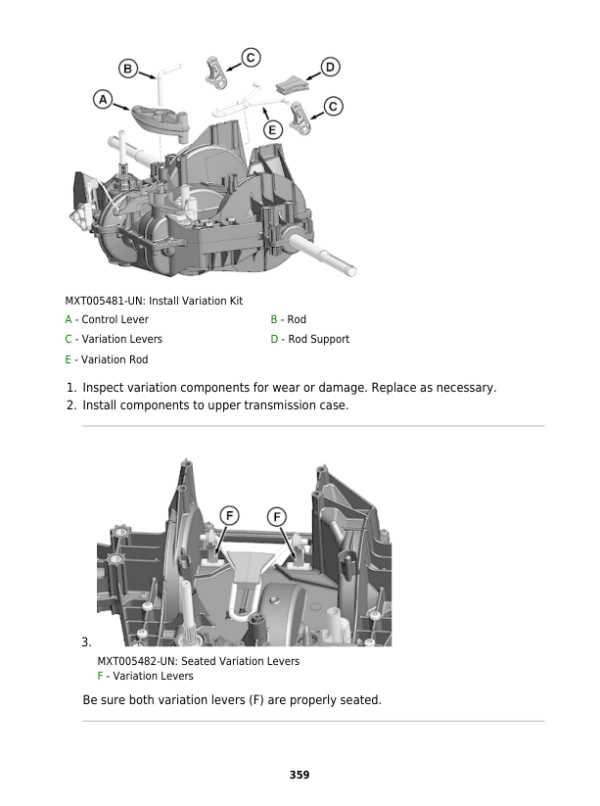

How to Use the Parts Diagram

Understanding the assembly visual is crucial for maintaining and repairing machinery effectively. This guide will provide insights on how to interpret these visuals to enhance your mechanical skills and ensure proper maintenance.

Firstly, familiarize yourself with the layout and numbering system used in the visual representation. Each section typically contains labeled components, making it easier to identify the necessary items for any task.

Secondly, pay attention to the connections between parts. Recognizing how each element fits together will aid in troubleshooting issues and facilitating efficient repairs.

Additionally, refer to the accompanying documentation that often includes detailed descriptions of each component’s function. This knowledge will empower you to make informed decisions during repairs or replacements.

Finally, keep the visual representation handy while working on your equipment. Having it accessible allows for quick reference, ensuring that you can efficiently locate and manage the various elements as needed.

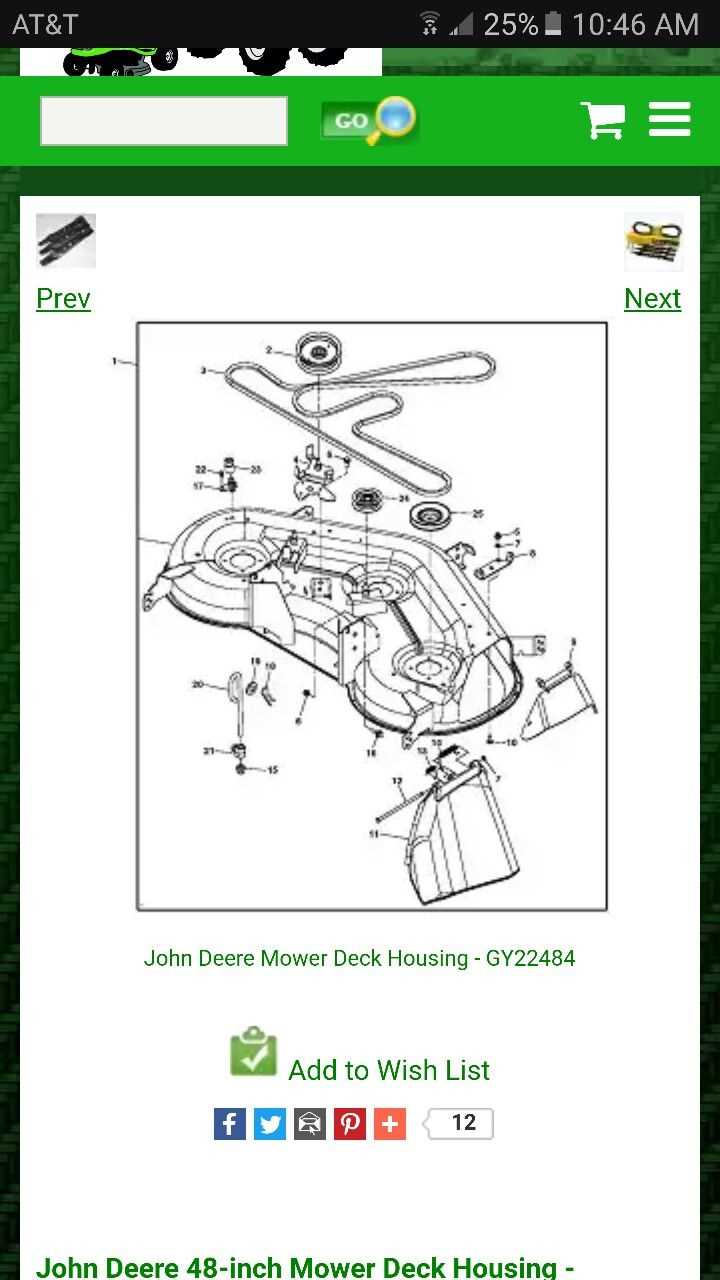

Where to Find Replacement Parts

Finding suitable components for your machinery is essential for maintaining optimal performance and longevity. There are several avenues available for sourcing these necessary items, ensuring that your equipment remains in top condition. Exploring various options can help you locate the exact replacements you need, whether for routine maintenance or unexpected repairs.

One of the most reliable sources is the official manufacturer’s website, which typically offers a comprehensive catalog of items specific to your model. This ensures that you are purchasing genuine components designed for compatibility and reliability. Additionally, authorized dealerships provide expert assistance and may offer installation services, giving you peace of mind in your purchase.

Another effective approach is to check local retail stores that specialize in machinery and equipment. These outlets often stock a variety of commonly used components and can provide valuable advice on installation and compatibility. Alternatively, online marketplaces and auction sites can offer a wide selection of both new and used items, sometimes at more competitive prices.

Joining forums and online communities focused on your equipment can also be beneficial. Members often share insights on where to find quality replacements and may even have suggestions for alternative suppliers. Engaging with fellow enthusiasts can lead to discovering lesser-known resources that provide the parts you need at reasonable prices.

In conclusion, exploring multiple channels–official websites, authorized dealers, local stores, online platforms, and community forums–can significantly enhance your chances of finding the right components for your machinery. This proactive approach not only saves time but also ensures that your equipment continues to operate efficiently.

Troubleshooting Common Issues

When operating machinery, various challenges may arise that can hinder performance. Identifying and addressing these issues promptly is essential to ensure optimal functionality and longevity. This section will guide you through some frequent problems and their potential solutions, helping you maintain your equipment efficiently.

Common Problems and Solutions

- Engine Won’t Start:

- Check the fuel level and ensure it is filled.

- Inspect the battery connections for corrosion or looseness.

- Look for any blown fuses in the electrical system.

- Uneven Cutting:

- Ensure that the cutting blades are sharp and not damaged.

- Check the tire pressure and adjust it to the manufacturer’s specifications.

- Examine the deck for any debris or obstructions that may affect performance.

- Overheating:

- Verify that the cooling system is functioning properly.

- Check for any blockages in the air intake or cooling fins.

- Inspect the oil level and quality, replacing it if necessary.

Preventive Measures

To minimize the occurrence of these issues, regular maintenance is crucial. Implementing a routine inspection schedule can help identify potential problems early. Additionally, always follow the manufacturer’s recommendations for servicing and upkeep.

Benefits of Genuine John Deere Parts

Choosing authentic components for your equipment ensures optimal performance and longevity. These high-quality replacements are designed to meet the specific standards required for seamless operation, resulting in fewer repairs and extended lifespan.

Quality Assurance: Authentic components undergo rigorous testing to guarantee their reliability and effectiveness. This commitment to quality means that users can trust these products to perform consistently under various conditions.

Perfect Fit: Using original replacements ensures that each component fits perfectly, which is essential for maintaining the integrity of the machinery. A precise fit prevents unnecessary wear and tear, minimizing the risk of future issues.

Enhanced Performance: Genuine components are engineered to enhance the overall functionality of your equipment. They contribute to better fuel efficiency and improved operational capabilities, ultimately leading to enhanced productivity.

Long-Term Cost Savings: While original components may have a higher upfront cost, they often result in lower long-term expenses. Their durability reduces the frequency of replacements and repairs, making them a wise investment for equipment owners.

Support and Warranty: Purchasing authentic components often comes with the benefit of customer support and warranty coverage. This means users can have peace of mind knowing they are backed by the manufacturer’s assurance.