Understanding the intricate design of agricultural machinery is essential for effective maintenance and repair. Each element plays a crucial role in ensuring optimal performance, making it imperative for operators and technicians to familiarize themselves with the various components involved.

In this section, we will delve into a comprehensive overview of the essential elements that constitute these powerful machines. By examining the layout and interconnections, users can better grasp how each component functions within the larger system, ultimately enhancing their operational efficiency.

Whether you’re a seasoned mechanic or a novice operator, having access to a detailed visualization of these elements can significantly improve your troubleshooting skills. Armed with this knowledge, you can tackle repairs more confidently and keep your equipment running smoothly.

Understanding John Deere 430 Parts

Gaining insight into the components of agricultural machinery is essential for effective maintenance and repair. Each element plays a vital role in the overall functionality and efficiency of the equipment. Recognizing how these various segments interact can significantly enhance performance and longevity.

When exploring the essential components, it is helpful to categorize them into several key groups. This organization allows for easier identification and understanding of their specific functions within the machine.

| Component Category | Description |

|---|---|

| Engine | The heart of the machine, responsible for providing the necessary power for operation. |

| Transmission | Enables the transfer of power from the engine to the wheels or other working parts. |

| Hydraulics | Facilitates the movement of various attachments and implements, enhancing versatility. |

| Chassis | The framework that supports all components, ensuring stability and durability. |

| Electrical System | Powers lighting, ignition, and other essential electronic functions. |

Understanding the specific roles and interrelationships of these components will empower users to make informed decisions regarding maintenance and repairs, ultimately leading to improved efficiency and reduced downtime.

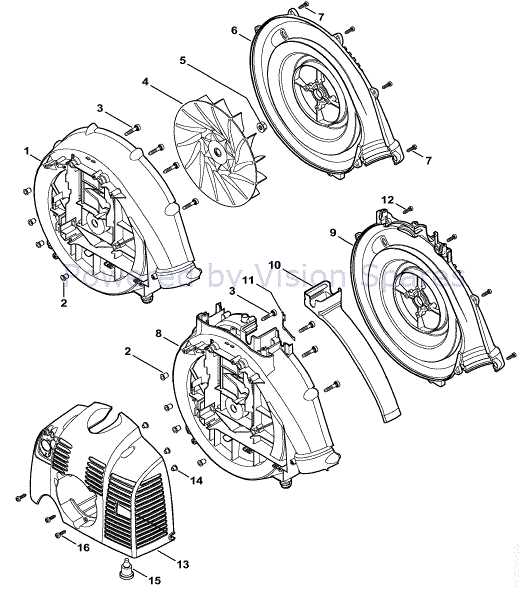

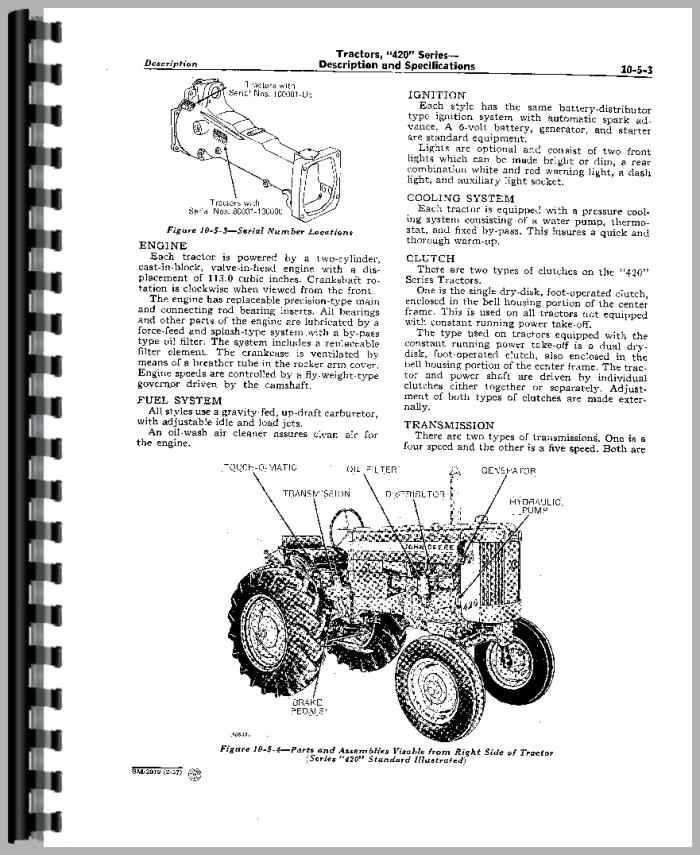

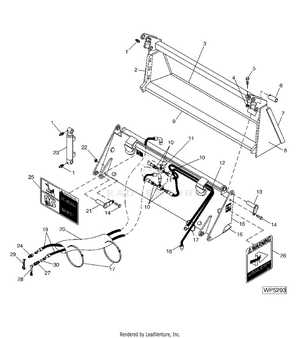

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair. These illustrations serve as a guide for identifying individual elements, ensuring that technicians can efficiently locate and replace any faulty or worn-out pieces. Accurate depictions minimize the risk of errors and enhance overall productivity in servicing machinery.

Enhanced Efficiency

When specialists have access to detailed illustrations, they can quickly understand the assembly and disassembly processes. This clarity reduces the time spent searching for components and helps streamline operations. Moreover, it allows for faster troubleshooting, enabling quicker resolutions to issues that may arise during usage.

Improved Safety

Clear and precise visual aids contribute to a safer working environment. When operators can easily identify components, they can execute repairs with greater confidence and reduce the likelihood of accidents. Additionally, having a reliable reference minimizes the chances of using incorrect elements, which could lead to malfunctions and potential hazards.

In summary, accurate visual representations of machinery components are vital for effective maintenance, enhancing efficiency and safety in operations.

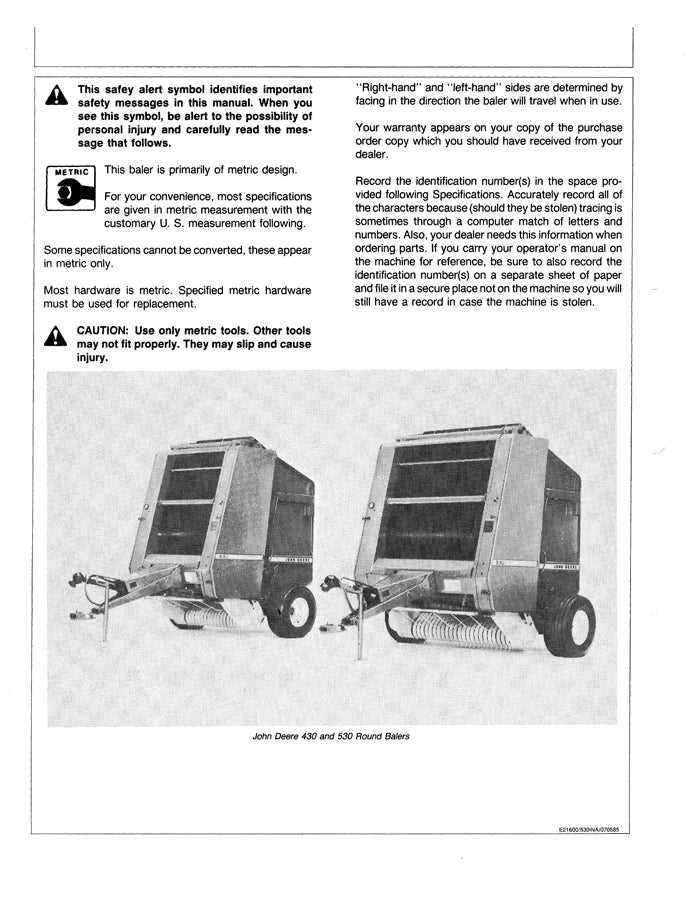

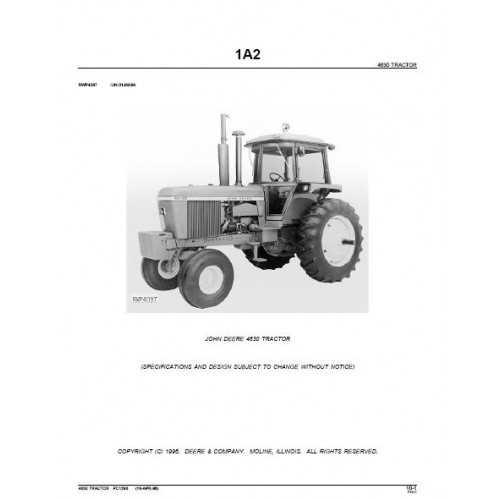

Common Components of the John Deere 430

The machinery in question is characterized by a variety of essential elements that work together to ensure optimal performance and reliability. Understanding these components is crucial for effective maintenance and operation, as they play significant roles in the overall functionality of the equipment.

Engine Assembly

The engine assembly serves as the heart of the machine, providing the necessary power for various tasks. This unit typically includes critical elements such as pistons, crankshafts, and camshafts, all designed to work in harmony. Regular inspection and maintenance of the engine are vital to prevent operational issues and ensure longevity.

Transmission System

The transmission system is responsible for controlling the speed and torque delivered to the wheels. It consists of various gears, clutches, and shafts that enable smooth operation across different terrains. Proper care of this system can enhance efficiency and extend the life of the equipment.

Where to Find Parts Diagrams

Locating visual representations of components can greatly simplify maintenance and repair tasks. These illustrations provide invaluable insights into the various elements of machinery, helping users identify and source the necessary replacements efficiently.

Numerous resources are available for accessing these detailed visuals:

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often offer comprehensive catalogs that include schematic illustrations and lists of components. |

| Online Forums | Communities of enthusiasts and professionals frequently share resources, including diagrams and maintenance tips. |

| Retailer Catalogs | Authorized dealers usually provide detailed brochures that feature diagrams alongside part numbers and pricing. |

| Service Manuals | Detailed manuals often include exploded views and installation instructions for various machinery. |

| Third-Party Websites | Dedicated platforms specializing in equipment may offer extensive libraries of visual resources and component listings. |

Utilizing these sources can significantly enhance your ability to maintain and repair machinery effectively.

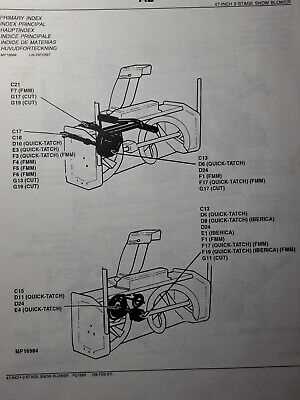

How to Read Parts Diagrams

Understanding visual representations of components is crucial for efficient maintenance and repair of machinery. These illustrations provide a comprehensive view of the elements involved, making it easier to identify and locate specific items needed for various tasks.

To effectively interpret these visuals, follow these guidelines:

- Familiarize Yourself with the Layout: Each illustration typically includes sections that categorize components by function or location. Spend time understanding the overall arrangement.

- Identify Key Symbols: Different shapes and lines represent various parts and connections. Refer to the legend or key provided to decode these symbols.

- Locate Item Numbers: Most visuals feature numerical labels next to each component. These numbers are essential for ordering replacements or understanding assembly sequences.

- Check for Notes and Annotations: Additional information may be included alongside the visuals. Pay attention to these notes as they often highlight important details or specifications.

By mastering these techniques, you can navigate illustrations with confidence, ensuring a smoother experience when working on machinery. Familiarity will enhance both your efficiency and accuracy in locating necessary components.

Benefits of Using OEM Parts

When it comes to maintaining and repairing equipment, opting for original manufacturer components can offer significant advantages. These specialized components are designed specifically for compatibility and performance, ensuring that machinery operates at its best.

Quality Assurance: Original parts are manufactured to meet the highest standards set by the manufacturer. This guarantees durability and reliability, reducing the likelihood of premature failure and the need for frequent replacements.

Perfect Fit: Utilizing components from the original source ensures an exact fit. This minimizes the risk of improper installation, which can lead to additional complications and costly repairs.

Enhanced Performance: Original components are engineered to work seamlessly with your equipment. This enhances overall performance, efficiency, and safety, allowing for optimal operation under various conditions.

Warranty Protection: Many manufacturers offer warranties on their original components. Using these parts can protect your investment and provide peace of mind, knowing that you are covered in case of defects or malfunctions.

Resale Value: Equipment maintained with original components tends to retain its value better over time. Potential buyers often prefer machines that have been cared for with genuine parts, recognizing the benefits they bring.

In conclusion, selecting original components for your machinery not only promotes longevity and efficiency but also supports the overall integrity of your equipment.

Maintenance Tips for John Deere 430

Regular upkeep is essential for optimal performance and longevity of your equipment. By following a structured maintenance routine, you can prevent issues and ensure smooth operation throughout the year.

- Check Fluid Levels: Regularly inspect oil, coolant, and hydraulic fluid levels to avoid overheating and ensure efficient operation.

- Clean Air Filters: Keep air filters free of debris to enhance engine performance and fuel efficiency.

- Tire Maintenance: Monitor tire pressure and tread wear to maintain traction and stability during operation.

- Inspect Belts and Hoses: Look for signs of wear and tear; replace any damaged components promptly.

- Grease Moving Parts: Apply lubricant to joints and pivots to reduce friction and wear.

Following these guidelines will help maintain your machinery in peak condition and extend its lifespan.

Repair vs. Replacement: Making the Choice

When it comes to maintaining machinery, the decision between fixing a component or replacing it entirely can be a challenging one. Both options carry their own set of advantages and disadvantages, and the choice often hinges on various factors such as cost, time, and the long-term effectiveness of the solution.

Repairing a faulty element can be a cost-effective approach, particularly if the damage is minor. This method not only saves money but also extends the lifespan of the equipment. However, one must consider whether the repair will provide a lasting solution or if it’s merely a temporary fix. Frequent repairs can accumulate costs over time, potentially leading to greater expenses than a full replacement.

On the other hand, replacement often guarantees enhanced performance and reliability. Investing in a new component can provide peace of mind, knowing that the equipment is less likely to fail in the near future. However, the initial cost can be a significant barrier, making it crucial to assess whether the benefits of a new part outweigh the financial investment.

Ultimately, the choice between repairing or replacing should be made based on a thorough evaluation of the specific situation. Factors such as the extent of damage, overall equipment condition, and budgetary constraints play vital roles in this decision-making process. By weighing these elements carefully, one can arrive at a solution that best suits both immediate needs and long-term goals.

Resources for Parts and Support

Finding the right components and assistance is essential for maintaining machinery efficiency. Numerous resources are available to help users locate the necessary items and receive expert guidance. This section outlines various avenues to explore when seeking out replacements and support for your equipment.

Online Resources

- Manufacturer’s Website: Check the official site for detailed catalogs and specifications.

- Online Retailers: Explore platforms specializing in agricultural machinery for a wide selection of components.

- Forums and Communities: Join online discussion groups where users share experiences and recommendations.

Local Support Options

- Authorized Dealers: Visit nearby dealerships for genuine replacements and professional advice.

- Service Centers: Contact local repair shops that specialize in machinery maintenance.

- Workshops and Training: Attend local workshops to enhance your knowledge about repairs and upkeep.