Understanding the intricate details of machinery is essential for maintenance and repair. This section aims to provide an insightful overview of the various elements that contribute to the functionality of specific lawn care equipment. By grasping the layout and relationships between these components, users can enhance their operational efficiency.

Each piece plays a vital role in ensuring seamless performance. Whether it’s the engine, drive system, or other crucial parts, recognizing how they interact can lead to improved troubleshooting and a longer lifespan for the equipment. An organized visual representation can be the ultimate tool for both novice and experienced users.

Moreover, knowing the specific roles of each element allows for informed decisions during repairs or upgrades. The journey into this realm will help enthusiasts and professionals alike to delve deeper into the mechanics, fostering a greater appreciation for the technology at work.

Understanding the LT160 Parts Diagram

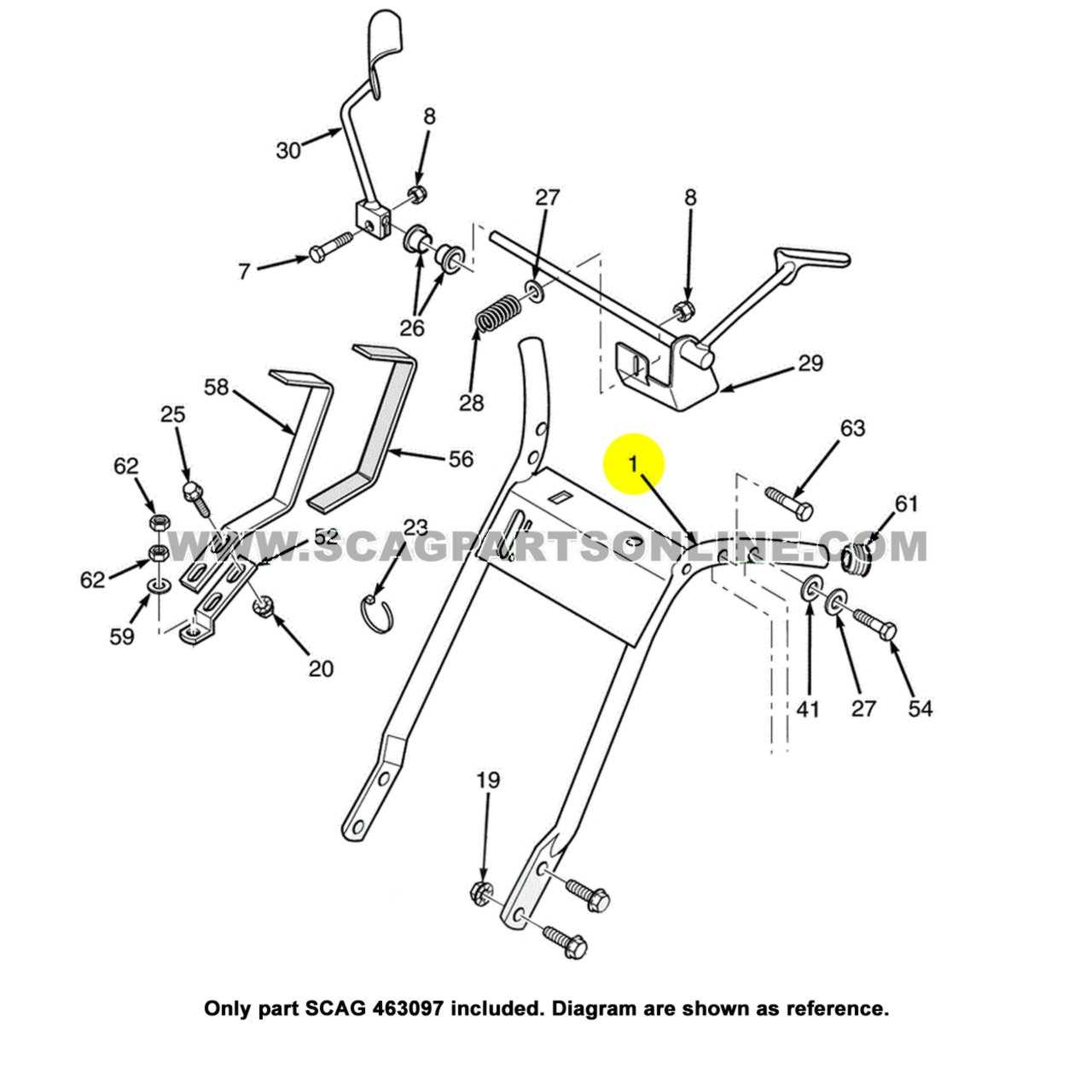

Grasping the intricacies of a specific equipment schematic is essential for effective maintenance and repairs. A visual representation can greatly aid in identifying individual components and their relationships within the machinery. This understanding ensures that users can efficiently troubleshoot issues and perform necessary replacements.

Key Components and Their Functions

Each element within the visual guide plays a critical role in the overall functionality. From the engine assembly to the transmission system, recognizing these parts allows for informed decision-making when servicing the equipment. Familiarity with each section will ultimately enhance performance and longevity.

Benefits of Using a Visual Reference

Utilizing a visual reference provides clarity, reducing the likelihood of mistakes during repairs. Not only does it streamline the process, but it also empowers users with knowledge about their machinery. This informed approach can lead to improved operational efficiency and satisfaction.

Key Components of John Deere LT160

Understanding the essential elements of this machine enhances its functionality and maintenance. Each component plays a critical role in ensuring optimal performance and reliability.

| Component | Description |

|---|---|

| Engine | Provides the necessary power for operation, ensuring efficient performance. |

| Transmission | Facilitates smooth gear shifting, allowing for better control and maneuverability. |

| Deck | The cutting mechanism, designed for precision and durability during mowing. |

| Wheels | Support movement and stability on various terrains, contributing to overall mobility. |

| Battery | Powers electrical systems, ensuring reliable start-up and operation of components. |

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for anyone working on machinery maintenance or repairs. These visuals provide a clear representation of various components and their arrangements, making it easier to identify and source the necessary elements.

To effectively interpret these visuals, consider the following steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout; note the arrangement of parts. |

| 2 | Identify key labels and numbers that correspond to specific items. |

| 3 | Use the reference list or key to find additional details about each component. |

| 4 | Cross-check with manuals for assembly instructions or maintenance tips. |

By following these guidelines, you can navigate through the visuals with ease, ensuring you have the ultimate understanding of your machinery’s requirements.

Common Issues with LT160 Parts

When maintaining a lawn tractor, users often encounter various challenges related to its components. These issues can stem from wear and tear, environmental factors, or improper maintenance practices. Understanding these common problems can help ensure better performance and longevity of the machine.

Worn Components

One frequent concern involves the deterioration of essential elements, which can lead to reduced efficiency. Components like belts, blades, and filters are particularly susceptible to wear, requiring regular inspection and timely replacement. Ignoring these signs can result in decreased performance and potential damage to the engine.

Electrical Failures

Another prevalent issue arises from electrical malfunctions. Battery failures, faulty connections, and worn switches can hinder operation. Ensuring that all electrical components are functioning correctly is vital for smooth performance. Regular checks can prevent unexpected breakdowns and enhance the overall reliability of the tractor.

Where to Find Replacement Parts

Finding suitable components for your machinery can be crucial for maintaining its efficiency and longevity. Numerous avenues exist for sourcing these essential items, each offering unique benefits. Understanding where to look can save time and ensure that you obtain high-quality replacements.

Online Retailers: Numerous e-commerce platforms specialize in machinery components. These websites often provide detailed descriptions and customer reviews, helping you make informed decisions.

Local Dealers: Authorized dealerships can be a reliable source for genuine components. They typically offer expert advice and may have parts in stock, allowing for immediate purchase.

Salvage Yards: Exploring salvage yards can yield surprising finds. Often, you can discover gently used components at significantly reduced prices.

Manufacturer Websites: Visiting the official website of your equipment’s manufacturer can lead to valuable resources. Many sites feature catalogs of available components and instructions for ordering.

In summary, utilizing a combination of these resources can help you efficiently locate the replacements you need to keep your machinery operating smoothly.

Maintenance Tips for LT160 Owners

Proper upkeep of your equipment ensures longevity and optimal performance. By following a few essential practices, you can enhance efficiency and prevent unexpected breakdowns, leading to a smoother experience in your outdoor tasks.

Regular Inspections

Conducting routine checks on various components is vital. Look for signs of wear and tear, and ensure that all parts function correctly. Pay special attention to belts, blades, and fluid levels to maintain a high standard of operation.

Scheduled Servicing

Establish a maintenance schedule tailored to your usage patterns. Frequent oil changes, air filter replacements, and sharpening of cutting blades are key to preserving performance. Following the manufacturer’s recommendations will help you avoid costly repairs and maximize your machine’s lifespan.

Comparing LT160 to Other Models

This section explores the distinctions and similarities between a specific lawn care model and its counterparts in the industry. By analyzing various features, capabilities, and user experiences, we aim to provide insights that can guide potential buyers in their decision-making process.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 20 HP | 22 HP | 19 HP |

| Cutting Width | 42 inches | 48 inches | 36 inches |

| Weight | 450 lbs | 480 lbs | 430 lbs |

| Fuel Capacity | 1.5 gallons | 2 gallons | 1.2 gallons |

| Transmission Type | Automatic | Hydrostatic | Manual |

By examining these various models, potential owners can delve into the ultimate features that best suit their landscaping needs, ensuring a well-informed purchase.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery offers numerous advantages that can significantly enhance performance and longevity. These original elements are specifically designed to meet precise specifications, ensuring optimal functionality and reliability. By choosing genuine items, users can rest assured they are maintaining the integrity of their equipment.

One major benefit is the assurance of quality. Authentic components undergo rigorous testing and adhere to strict manufacturing standards, reducing the risk of premature failure. Additionally, using original replacements can help preserve warranties, protecting your investment over time.

Moreover, genuine items often provide better compatibility with existing systems, minimizing the chances of operational issues. This seamless integration contributes to smoother performance and reduces maintenance costs in the long run. Ultimately, opting for original components leads to improved efficiency and peace of mind.

Resources for LT160 Repair Guides

Finding the right materials for maintenance and repairs can significantly enhance the longevity and performance of your equipment. This section provides valuable resources that can guide you through various repair processes, ensuring that you have the information needed to tackle any issue effectively.

Consider the following resources:

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community-driven platforms where users share tips, tricks, and experiences related to equipment maintenance. | Visit Forum |

| Manufacturer Manuals | Official guides providing detailed instructions for repairs, including diagrams and specifications. | Access Manuals |

| Video Tutorials | Visual guides available on platforms like YouTube, demonstrating step-by-step repair processes. | Watch Tutorials |

| Repair Shops | Local or online services offering professional assistance for more complex repairs. | Find a Shop |

Utilizing these resources will empower you to manage repairs more effectively and keep your machinery in optimal condition.