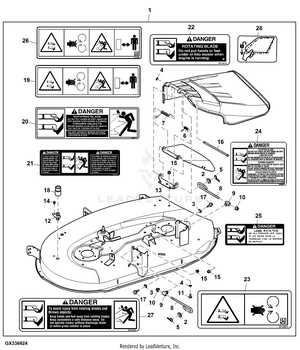

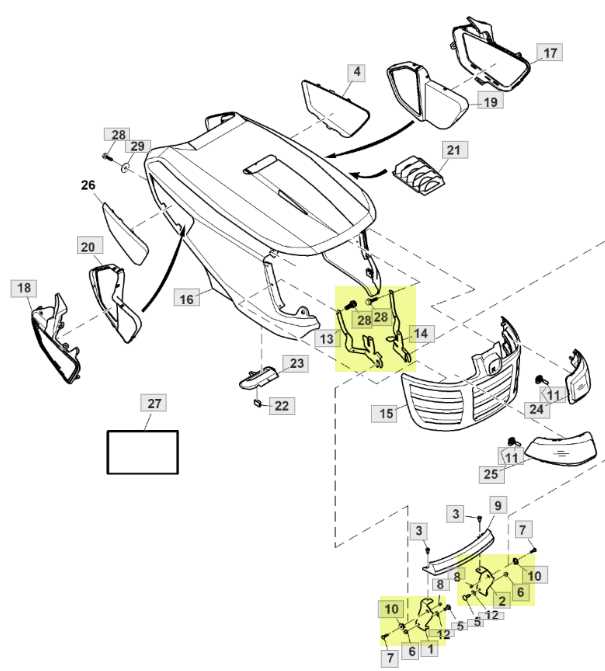

When it comes to maintaining a reliable lawn mower, having a comprehensive understanding of its components is essential. Every element, from the engine to the cutting deck, plays a crucial role in ensuring optimal performance. This section will explore the intricate layout of a popular model, highlighting the significance of each piece in the overall operation of the machine.

By examining the various elements involved, users can gain valuable insights into how their equipment functions. Knowledge of these components not only aids in troubleshooting but also enhances the ability to perform necessary maintenance tasks effectively. Whether it’s replacing a worn-out element or upgrading specific features, being familiar with the layout can lead to more informed decisions and improved longevity of the mower.

In this discussion, we will delve into the relationships between different components, illustrating how they work together to deliver a seamless mowing experience. From understanding the importance of each individual part to recognizing the benefits of proper upkeep, readers will find useful information that contributes to the efficient use of their lawn care equipment.

Overview of John Deere E100

This section provides a comprehensive look at a popular model of riding mower known for its reliability and efficiency. Designed to cater to homeowners and landscapers alike, it combines user-friendly features with robust performance, making it a suitable choice for various lawn care tasks.

Key features of this model include:

- Powerful engine designed for enhanced cutting performance.

- Easy-to-use controls that facilitate a smooth operation.

- Durable construction, ensuring longevity and resilience against wear and tear.

- Comfortable seating designed to reduce fatigue during extended use.

Moreover, the mower is equipped with various attachments and accessories, allowing for versatility in handling different tasks, from mowing to mulching. Maintenance is straightforward, making it an attractive option for those seeking a low-maintenance yet effective solution for lawn care.

In summary, this riding mower stands out for its combination of power, comfort, and ease of use, catering to the diverse needs of its users.

Understanding Parts Functionality

When it comes to machinery, each component plays a vital role in ensuring smooth operation and efficiency. Grasping the significance of these elements helps users maintain and troubleshoot equipment effectively. This knowledge can lead to enhanced performance and longevity of the machinery.

Components are designed to work in harmony, contributing to the overall functionality of the machine. For instance, the engine generates power while the transmission delivers it to the wheels, allowing for movement. Each element, whether a minor accessory or a major assembly, is crucial for the system to operate optimally.

Understanding how individual components interact with one another is essential for effective maintenance. Users can identify potential issues before they escalate, ensuring the equipment remains in top condition. Knowledge of functionality also aids in making informed decisions regarding repairs and replacements.

Moreover, familiarizing oneself with the different components can enhance troubleshooting skills. When issues arise, recognizing the role of each part allows for quicker diagnosis and resolution. This proactive approach can significantly reduce downtime and increase productivity.

Common Issues and Solutions

When operating a lawn care machine, various challenges may arise, affecting performance and efficiency. Understanding these common problems and their solutions can help users maintain their equipment in optimal condition. Below are some frequent issues faced by operators and effective strategies for resolution.

- Engine Not Starting:

- Check the fuel level and ensure it is fresh and uncontaminated.

- Inspect the battery connections for corrosion or looseness.

- Examine the ignition switch and wiring for faults.

- Uneven Cutting:

- Verify that the blades are sharp and properly aligned.

- Adjust the cutting height settings to match the terrain.

- Check for uneven tire pressure, which can affect balance.

- Overheating:

- Ensure the cooling system is free from debris and blockages.

- Check the oil level and condition, replacing it if necessary.

- Inspect the air filter for cleanliness and replace if dirty.

- Transmission Issues:

- Examine the drive belt for wear and proper tension.

- Check the fluid levels in the transmission system.

- Inspect for leaks that could affect performance.

By addressing these common issues promptly, users can ensure their machinery operates smoothly and efficiently, minimizing downtime and prolonging its lifespan.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. By adhering to a systematic maintenance routine, you can enjoy reliable operation and efficiency for many seasons.

Routine Checks

Conducting frequent inspections is vital for identifying potential issues before they escalate. Look for signs of wear and tear, and ensure that all components are functioning correctly. Establishing a checklist for routine assessments can help streamline this process.

Cleaning and Lubrication

Keeping your machinery clean is paramount. Dirt and debris can cause unnecessary strain on various parts. Regularly clean the exterior and interior components to maintain optimal performance. Additionally, ensure that all moving parts are well-lubricated to reduce friction and prolong their lifespan.

| Maintenance Task | Frequency |

|---|---|

| Inspect belts and hoses | Monthly |

| Change oil and filters | Every 50 hours of use |

| Clean air filter | Every 25 hours of use |

| Check tire pressure | Monthly |

| Sharpen blades | As needed |

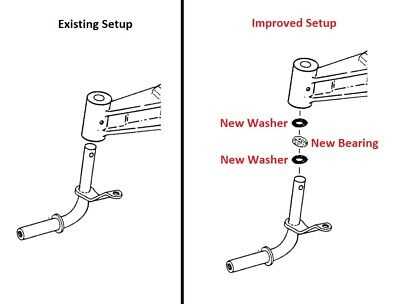

How to Replace Worn Parts

Maintaining the efficiency of your equipment is crucial for its longevity and performance. Over time, certain components may show signs of wear, leading to decreased functionality. Understanding how to properly replace these elements can help restore your machinery to optimal condition, ensuring it runs smoothly for years to come.

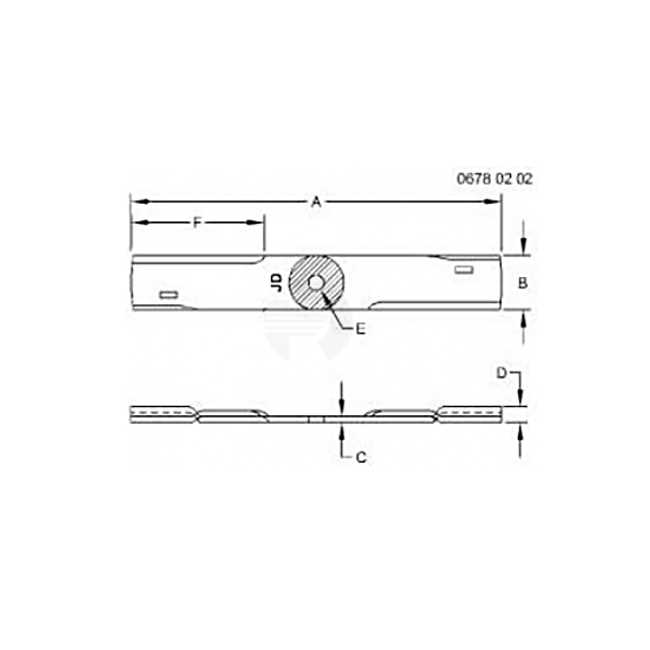

Assessing Wear: Before proceeding with any replacements, it’s essential to evaluate the condition of various components. Look for signs of damage such as cracks, excessive play, or unusual wear patterns. This assessment will help you determine which items require immediate attention.

Gathering Tools and Materials: Once you’ve identified the worn components, gather the necessary tools and replacement materials. Ensure you have the right specifications for each part to avoid compatibility issues. It’s advisable to consult the manufacturer’s recommendations for accurate measurements.

Step-by-Step Replacement: Begin by disconnecting any power sources and removing any necessary covers or shields to access the components. Carefully detach the worn items, taking note of their arrangement for easier reinstallation. Follow the manufacturer’s guidelines for installing the new parts, ensuring they are securely fitted. Double-check all connections before reassembling any protective coverings.

Testing and Maintenance: After replacing the worn elements, conduct a thorough test to ensure everything functions correctly. Regular maintenance checks will help you identify potential issues early, prolonging the life of your equipment. Stay proactive in your approach to care and replacement to keep your machinery operating at peak performance.

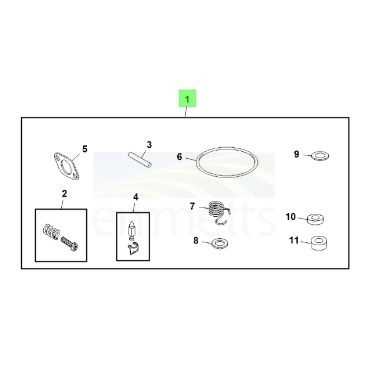

Finding Authentic Replacement Components

Ensuring that your machinery operates smoothly often hinges on the quality of its replacement components. Using genuine items can enhance performance, longevity, and overall reliability. This section explores how to identify and obtain authentic components that meet high standards of quality and compatibility.

To successfully locate genuine items, consider the following strategies:

- Research Authorized Dealers: Look for certified vendors or dealerships that specialize in your equipment brand. They typically carry original components that are specifically designed for your machinery.

- Verify Manufacturer Websites: Check the official website of the brand for lists of authorized sellers. This resource often includes guidance on locating genuine replacements.

- Use Online Marketplaces Wisely: While online platforms may offer a range of options, ensure you read reviews and check seller ratings to avoid counterfeit items.

- Consult Your Equipment Manual: The user manual often contains information about the recommended components, including part numbers and specifications, aiding in accurate identification.

By following these steps, you can secure authentic components that enhance the performance and reliability of your equipment, ensuring it remains in optimal working condition.

Tools Required for Repairs

Having the right tools on hand is essential for effective maintenance and repair tasks. A well-equipped toolkit not only enhances efficiency but also ensures that repairs are performed safely and accurately. Understanding the various instruments necessary for specific jobs can significantly streamline the repair process and lead to better results.

Basic Hand Tools: Essential hand tools include wrenches, screwdrivers, and pliers. These are fundamental for most repair tasks, allowing for adjustments and replacements of various components. A comprehensive set of these tools can cater to a wide range of situations.

Power Tools: For more demanding tasks, power tools such as drills and impact wrenches can save considerable time and effort. They are particularly useful for removing stubborn fasteners or performing heavy-duty assembly work.

Specialized Equipment: Depending on the complexity of the repair, specialized equipment may be required. This can include diagnostic tools, torque wrenches, or alignment jigs, which help ensure that repairs meet specific standards and specifications.

Safety Gear: Never overlook the importance of personal protective equipment. Safety glasses, gloves, and masks protect against potential hazards associated with repairs, such as flying debris or harmful substances.

By assembling a well-rounded toolkit and ensuring safety precautions are in place, individuals can effectively tackle maintenance challenges and prolong the life of their machinery.

Safety Precautions During Maintenance

Ensuring a safe working environment during equipment upkeep is essential to prevent accidents and injuries. Proper preparation and adherence to safety protocols can significantly reduce risks associated with maintenance tasks. This section outlines key safety measures that should be observed to protect both the operator and the machinery.

Personal Protective Equipment (PPE)

Utilizing appropriate personal protective gear is crucial when performing maintenance tasks. This equipment helps safeguard individuals from potential hazards, including sharp objects, chemicals, and heavy components. The following table summarizes essential PPE for maintenance activities:

| Type of PPE | Description |

|---|---|

| Safety Glasses | Protects eyes from debris and harmful substances. |

| Gloves | Prevents cuts and chemical exposure while handling parts. |

| Steel-Toed Boots | Offers foot protection from heavy items and equipment. |

| Ear Protection | Reduces noise exposure when working near loud machinery. |

| Respirators | Filters harmful airborne particles and gases. |

Proper Tools and Equipment

Using the correct tools is vital for safe and efficient maintenance. Improvised tools can lead to accidents and damage. Always ensure that tools are in good condition and suitable for the task. Regularly inspecting tools can prevent malfunctions and enhance safety.

Where to Purchase Parts Online

In today’s digital age, finding components for machinery has become easier than ever. Numerous online platforms offer a wide selection of items for various models, ensuring that customers can locate the necessary replacements swiftly and conveniently. Whether for maintenance or upgrades, knowing where to search is essential for a smooth experience.

Major retailers often feature dedicated websites for their inventory, providing users with an intuitive browsing experience. These sites typically allow for quick searches using model numbers, ensuring that the right components are identified. Additionally, many suppliers offer detailed descriptions and specifications, helping customers make informed decisions.

Online marketplaces can also serve as valuable resources, connecting buyers with numerous sellers. These platforms often include user reviews and ratings, offering insights into product quality and vendor reliability. Engaging with these communities can provide additional tips and recommendations, enhancing the purchasing process.

For those seeking specialized components, manufacturer websites are an excellent option. They often feature the latest products and updates directly from the source, ensuring authenticity. Furthermore, reaching out to customer support can facilitate locating specific items that may not be prominently displayed on the site.

To maximize convenience, consider signing up for newsletters from various suppliers. This can provide updates on promotions and new arrivals, enabling users to stay informed about the best deals. With a little research and engagement, obtaining the required components online can be a straightforward and efficient endeavor.