Understanding the intricate details of machinery is essential for effective maintenance and repair. This section delves into the vital elements that constitute heavy-duty equipment, enabling operators and technicians to grasp the essentials of each component’s role in overall functionality.

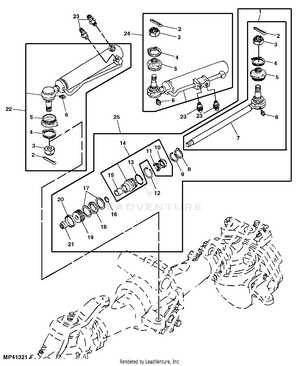

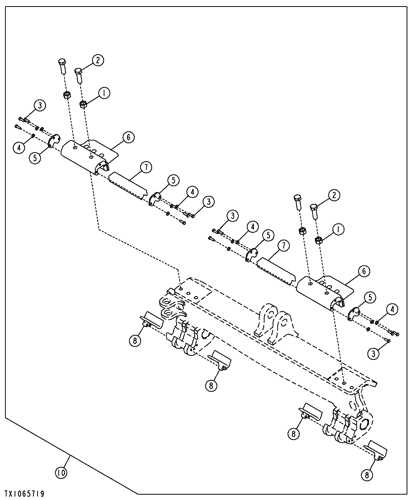

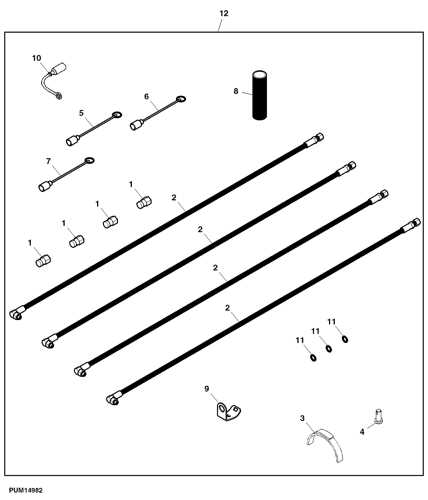

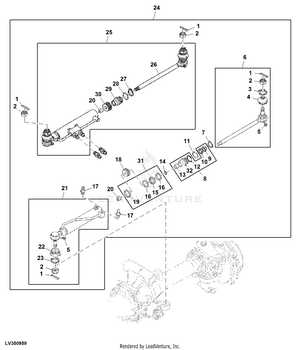

Visual representations play a crucial role in this learning process. By examining detailed illustrations, users can easily identify specific features and connections among various elements. Such insights not only enhance troubleshooting skills but also contribute to a more profound appreciation of the machinery’s design and engineering.

Furthermore, the importance of proper upkeep cannot be overstated. Familiarity with the structure of these machines ensures that operators can perform necessary repairs efficiently and accurately, minimizing downtime and maximizing productivity in the field. Embracing a thorough understanding of the mechanical layout paves the way for successful operations.

Understanding the John Deere 970

This section delves into the essential features and functionalities of a renowned agricultural machine. A comprehensive exploration reveals its significance in enhancing efficiency on the field. Users often appreciate its robust design and reliability, making it a preferred choice for many tasks.

Equipped with advanced technology, this equipment stands out for its operational ease and effectiveness. The intuitive controls facilitate seamless handling, allowing operators to focus on productivity rather than mechanics. Additionally, the durability ensures longevity, providing value over time.

Maintenance is a crucial aspect, ensuring that the machinery performs optimally. Familiarity with components and systems can lead to better upkeep and quicker troubleshooting. Understanding the layout and functionality of each element enables users to maximize performance and minimize downtime.

In summary, a thorough grasp of this machinery’s characteristics empowers operators to leverage its capabilities fully. Whether for farming or landscaping, it remains a significant asset in modern agricultural practices.

Key Components of the 970 Model

This section explores the essential elements that contribute to the functionality and performance of this agricultural machinery. Understanding these components is crucial for operators and technicians, as they play a significant role in the overall efficiency and reliability of the equipment.

At the heart of the machine is the powerful engine, which provides the necessary horsepower to tackle various tasks. Coupled with a robust transmission system, it ensures smooth operation across different terrains. The hydraulic system is another vital aspect, facilitating the movement of attachments and enhancing productivity.

The frame and chassis offer structural integrity, designed to withstand heavy loads and rough conditions. Additionally, the steering mechanism allows for precise navigation, making it easier to maneuver in tight spaces. Wheels and tires are engineered for optimal traction, ensuring stability and control during operation.

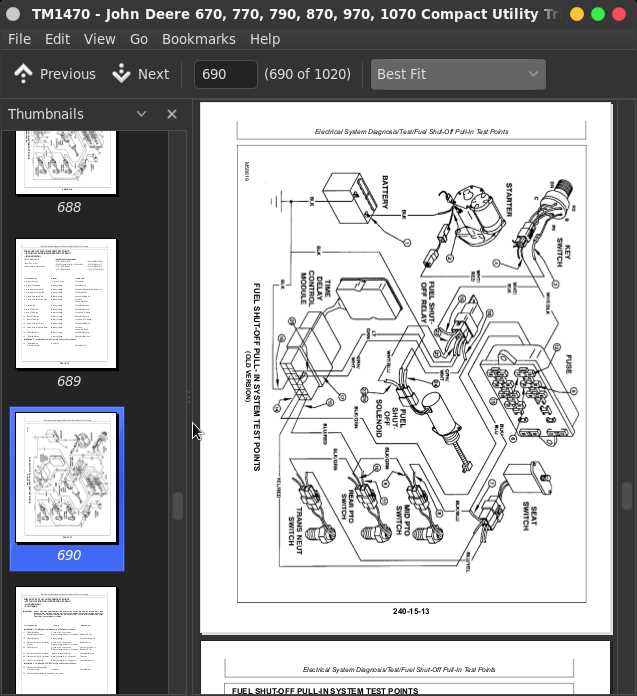

Finally, the electrical system plays a key role in the overall functionality, powering essential components and providing control interfaces for the operator. Each of these parts is integral to the seamless performance of the machinery, highlighting the importance of regular maintenance and inspections.

Benefits of Using Original Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. These genuine elements are crafted to meet specific standards, providing peace of mind and reliability for operators.

Quality Assurance

- Manufactured to exact specifications.

- Undergo rigorous testing for durability.

- Designed to integrate seamlessly with existing systems.

Cost-Effectiveness

- Reduces the likelihood of future repairs.

- Enhances overall efficiency, saving time and resources.

- Preserves the resale value of the equipment.

Common Issues and Troubleshooting Tips

When operating heavy machinery, encountering challenges is inevitable. Understanding typical problems and having effective solutions can significantly enhance performance and longevity. This section outlines common malfunctions and practical advice for addressing them.

- Engine Starting Issues

- Check the battery condition and connections.

- Inspect the fuel supply and filters.

- Examine the ignition system for faults.

- Hydraulic Problems

- Verify fluid levels and quality.

- Inspect hoses and fittings for leaks or damage.

- Test hydraulic pumps for proper operation.

- Transmission Difficulties

- Ensure fluid is at the correct level and is clean.

- Check for any obstructions in the system.

- Listen for unusual noises that may indicate internal issues.

- Electrical Failures

- Examine wiring for wear or corrosion.

- Test fuses and relays for functionality.

- Use a multimeter to check for voltage irregularities.

Regular maintenance and timely troubleshooting can prevent small issues from becoming significant problems. Keeping a close eye on these common areas will help ensure smooth operation and reduce downtime.

Where to Find Replacement Parts

Locating suitable components for agricultural machinery can be a straightforward process with the right resources. Various options are available to ensure you find high-quality replacements that meet your equipment’s needs.

Online Retailers are among the most convenient sources. Numerous websites specialize in agricultural tools and accessories, providing extensive catalogs that include user reviews and competitive pricing. Be sure to check for warranty options and return policies to ensure satisfaction with your purchase.

Local Dealerships often stock essential components and can offer personalized service. Engaging with knowledgeable staff can help you identify the exact items needed for your machine. Additionally, they may provide insight into maintenance tips and part compatibility.

Salvage Yards present another viable option. These locations often have used machinery from which you can obtain functioning components at a fraction of the new part cost. It’s advisable to inspect items thoroughly to ensure they are in good condition before making a purchase.

Forums and Community Groups can also be invaluable. Online communities of enthusiasts and professionals often share advice on where to find specific components, as well as personal experiences that can guide your purchasing decisions.

By exploring these avenues, you can effectively source reliable replacements that enhance the performance and longevity of your agricultural equipment.

Step-by-Step Repair Guide

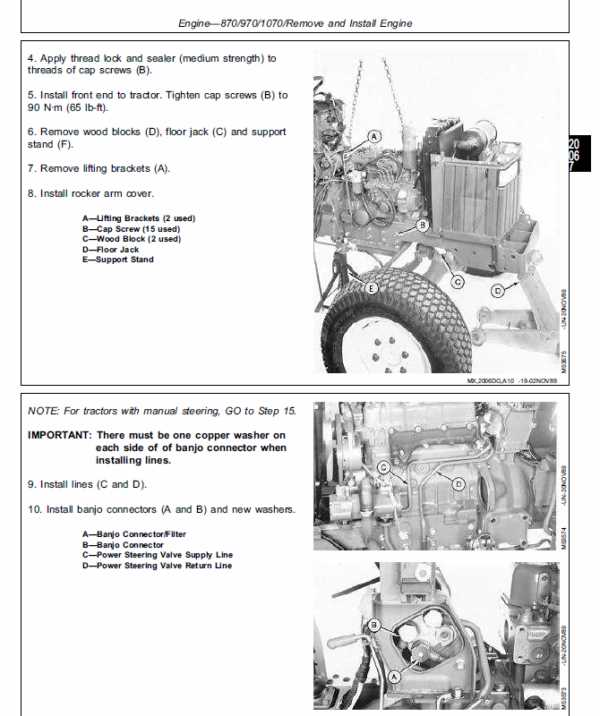

This section provides a comprehensive approach to effectively troubleshoot and restore your machinery. By following a structured method, you can ensure that each aspect of the repair is addressed, minimizing potential issues and maximizing performance.

Preparation and Tools

Before starting any maintenance task, gather all necessary tools and materials. This includes wrenches, screwdrivers, and replacement components. Having everything on hand will streamline the process and help prevent unnecessary delays. Make sure to consult the manufacturer’s manual for any specific tools that might be required.

Repair Process

Begin by identifying the problem area. Carefully inspect all components for signs of wear or damage. Once the issue is located, disassemble the relevant parts according to the guidelines provided in the manual. Document each step to ensure proper reassembly. After replacing or repairing the damaged parts, reassemble the machine meticulously, following the reverse order of disassembly. Finally, conduct a thorough test to verify that everything is functioning as expected.

Importance of Regular Maintenance

Consistent upkeep of machinery is essential for ensuring optimal performance and longevity. It not only enhances efficiency but also minimizes the risk of unexpected breakdowns that can disrupt operations. By investing time and resources in regular checks, owners can identify potential issues early, saving both time and money in the long run.

Routine inspections allow for the timely replacement of worn-out components, which is crucial in maintaining the overall functionality of the equipment. This proactive approach helps in avoiding severe damages that could lead to costly repairs.

Moreover, regular maintenance practices promote safety. When machinery is well-maintained, the chances of accidents or malfunctions decrease significantly. Ultimately, a commitment to routine care leads to improved reliability and a smoother operational experience.

Upgrades and Accessories for the 970

Enhancing the functionality and performance of your equipment can significantly improve efficiency and user experience. There are numerous modifications and additional features that can be integrated, catering to various needs and preferences. This section explores some popular options that can elevate the capabilities of your machine.

- Performance Enhancements

- Upgraded engines for increased power output.

- Advanced transmission systems for smoother operation.

- Enhanced cooling systems to maintain optimal performance under heavy loads.

- Comfort and Convenience

- Ergonomic seat options for improved operator comfort.

- Soundproofing kits to reduce noise levels during operation.

- Climate control systems for better working conditions in extreme weather.

- Technology Integration

- GPS navigation systems for precise field mapping.

- Telematics solutions for real-time performance monitoring.

- Automated control systems to enhance operational efficiency.

- Attachments and Implements

- Plows and tillers for versatile soil management.

- Seeders and spreaders for efficient planting and fertilization.

- Front-end loaders for increased material handling capabilities.

By investing in these enhancements and accessories, users can tailor their machinery to meet specific operational demands, thereby maximizing productivity and effectiveness in the field.

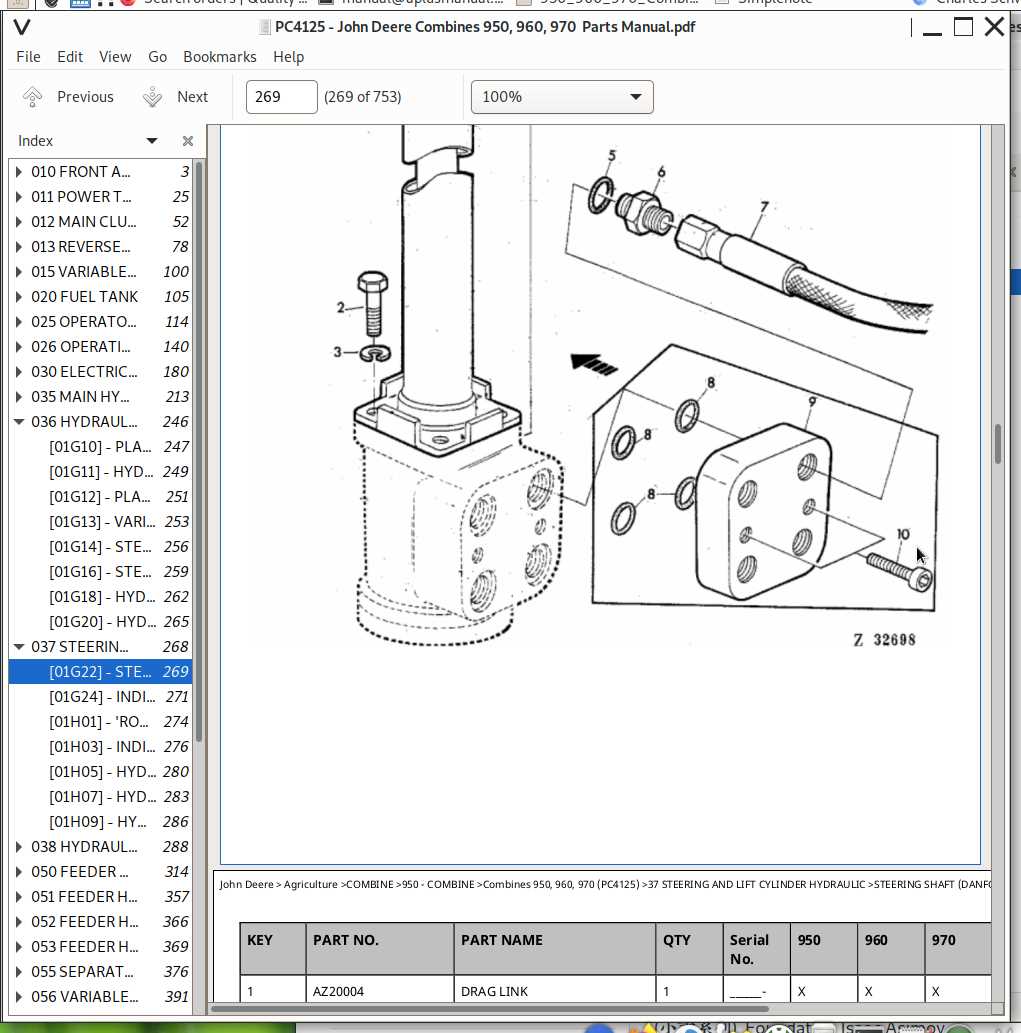

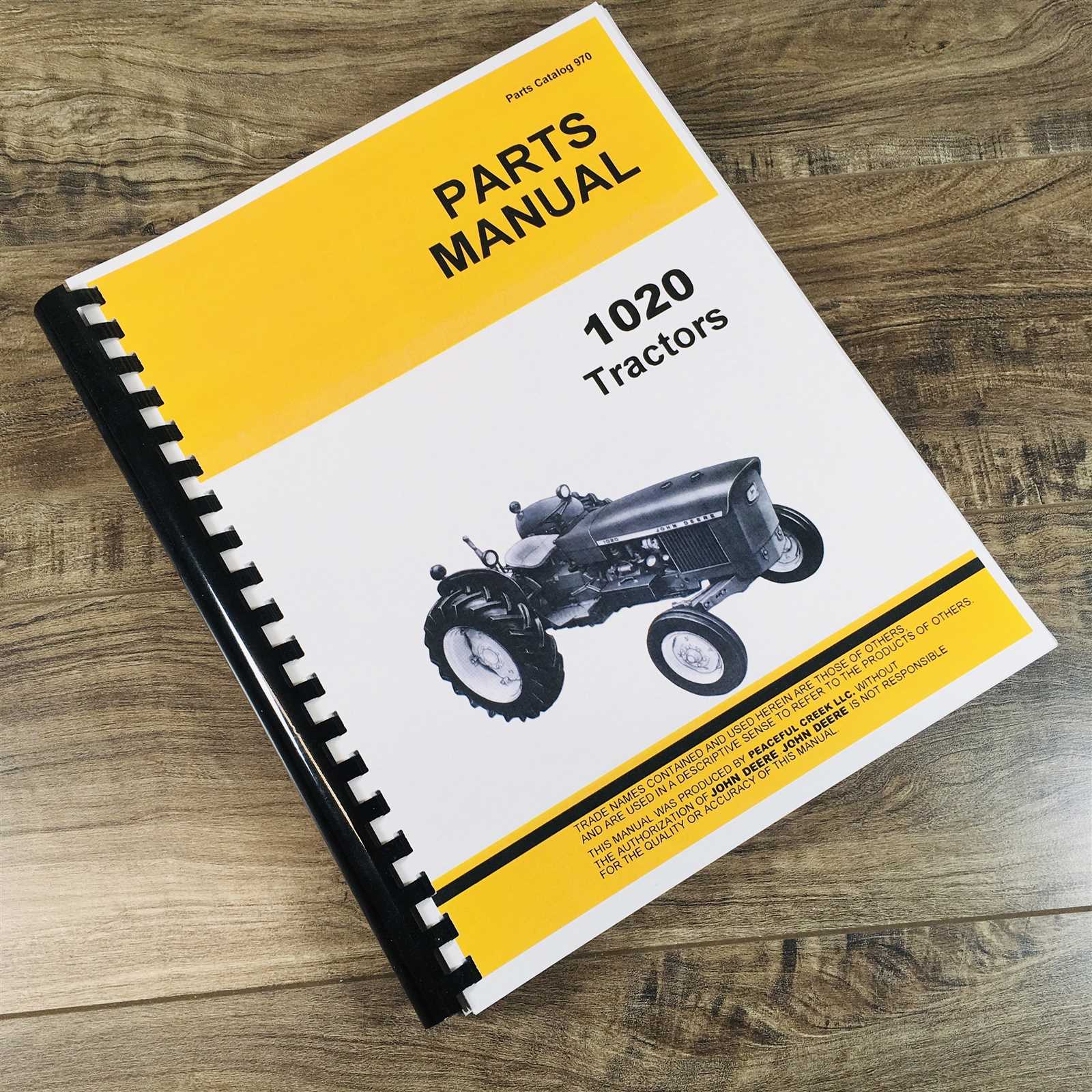

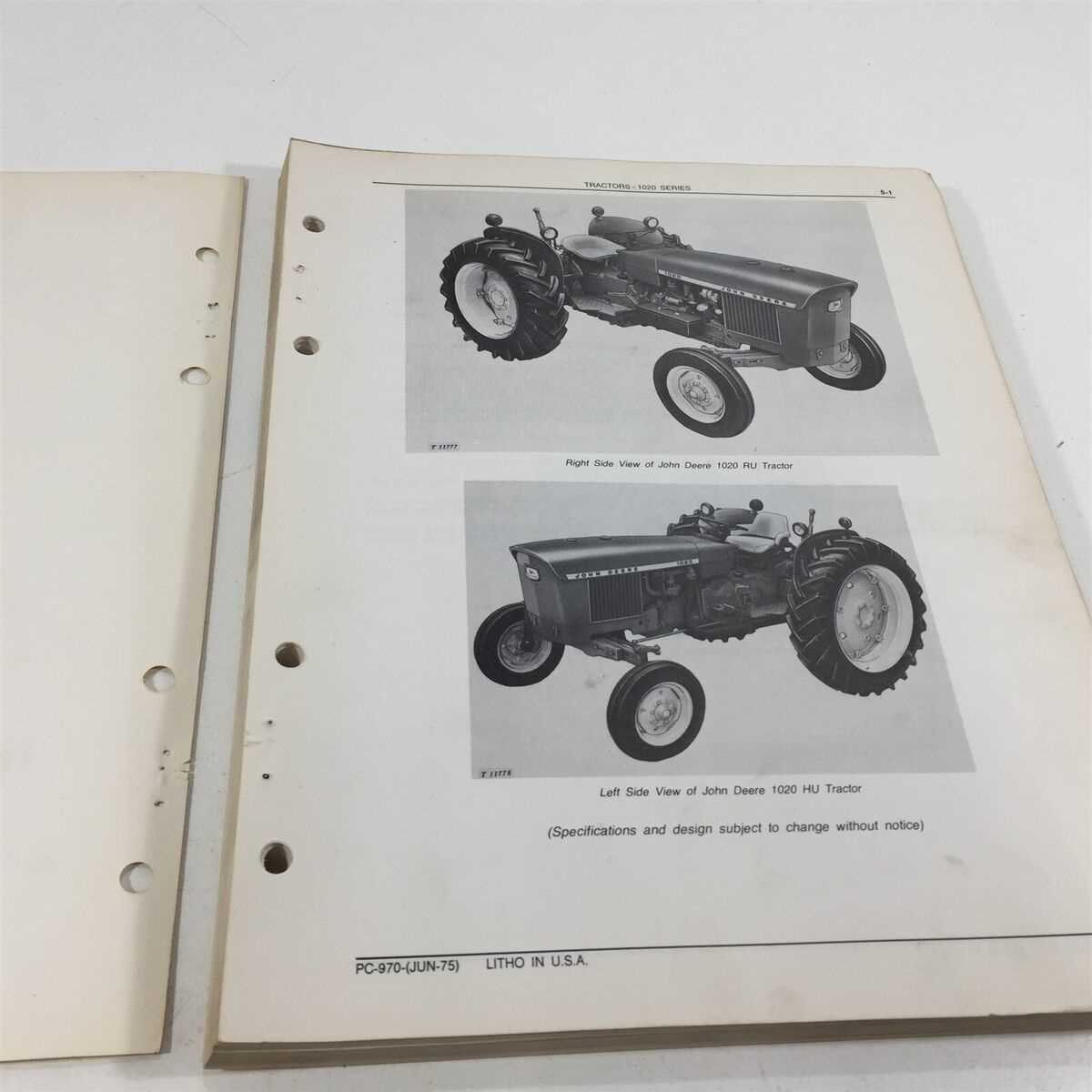

Resources for Parts Diagrams

Accessing visual references is essential for anyone looking to maintain or repair machinery. These resources provide detailed illustrations that highlight components and their relationships, ensuring a smoother workflow for enthusiasts and professionals alike.

Online Databases

Numerous websites offer extensive collections of visual references. These databases typically allow users to search by model or type, making it easier to locate specific visuals. Utilizing these platforms can greatly enhance the understanding of machinery assembly and disassembly.

Manuals and Guides

Printed or digital manuals often contain valuable illustrations and schematics. These documents not only outline parts but also provide troubleshooting tips and maintenance advice. Investing in a comprehensive manual can be an ultimate resource for anyone serious about equipment care.