In the world of outdoor machinery, comprehending the intricate arrangement of elements is essential for effective maintenance and repair. This knowledge not only enhances the longevity of your equipment but also ensures optimal performance in various conditions. Familiarity with the structure of your machine empowers you to tackle challenges with confidence.

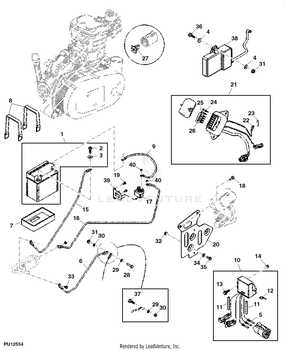

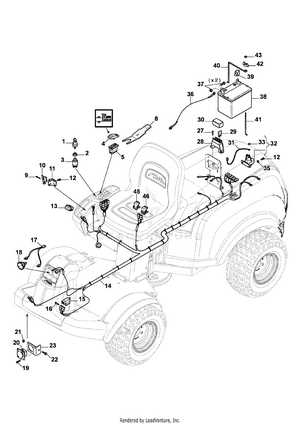

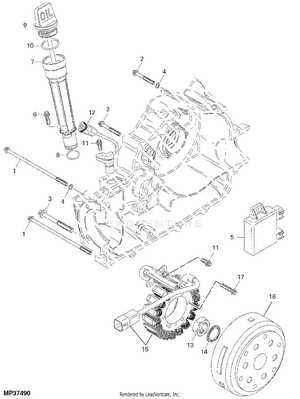

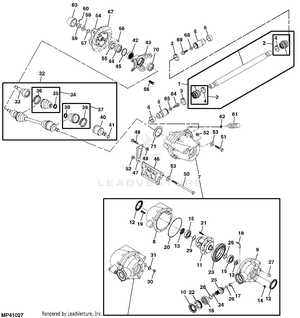

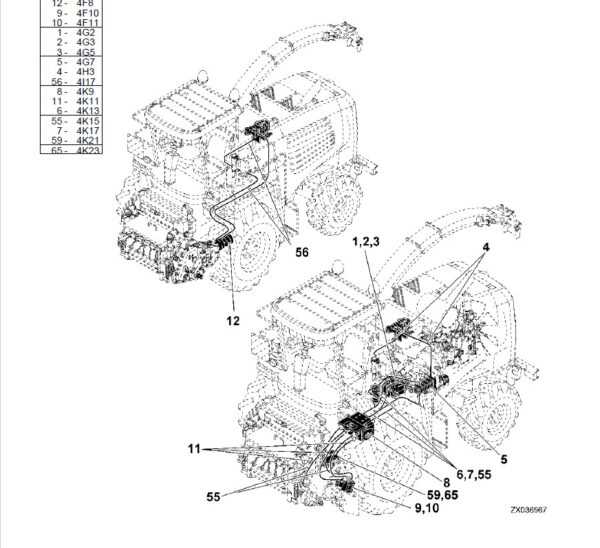

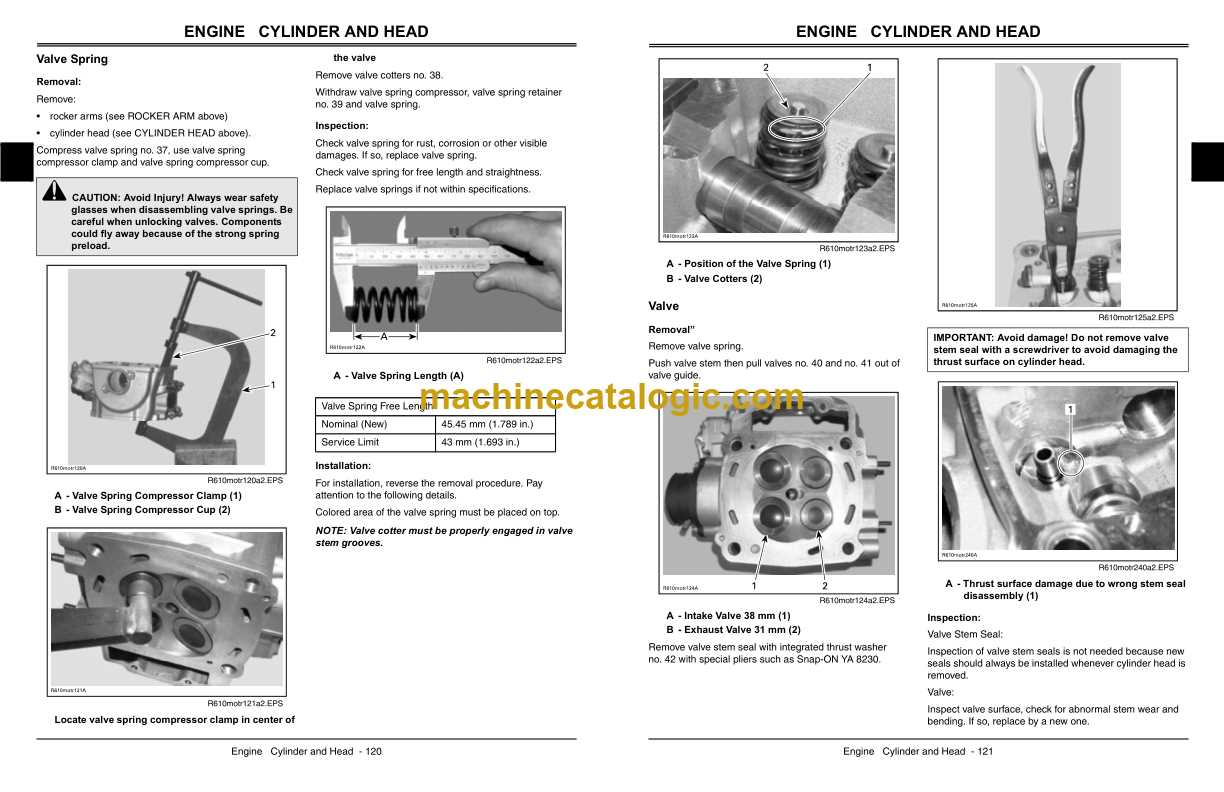

Exploring the schematic representation of components provides invaluable insights into how each part interacts within the system. Such visual guides serve as a roadmap, allowing enthusiasts and professionals alike to navigate the complexities of their equipment. By studying these illustrations, one can quickly identify components, facilitating smoother repairs and replacements.

Furthermore, recognizing the significance of each element within the assembly highlights the importance of regular inspections and timely upkeep. This proactive approach mitigates potential issues, ensuring that your machinery operates at its best. In this discussion, we will delve deeper into the various aspects of the component layout and its implications for effective machinery management.

Understanding John Deere Trail Buck 650

This section aims to explore the intricacies of a specific utility vehicle designed for versatility and performance. By examining its features and functions, one can appreciate its engineering and the role it plays in various applications.

Key Characteristics: The vehicle is known for its robust construction and adaptability, making it suitable for both recreational and work-related tasks. Efficiency and durability are paramount, ensuring it meets the demands of diverse environments.

Maintenance Insights: Regular upkeep is essential to prolong its lifespan and maintain optimal functionality. Understanding the components can aid users in troubleshooting and performing necessary repairs effectively.

Key Features of the Trail Buck 650

The exceptional qualities of this utility vehicle cater to both recreational enthusiasts and practical users. With a robust design and thoughtful engineering, it ensures a reliable experience in various terrains.

Powerful Engine: The vehicle is equipped with a high-performance motor that delivers impressive torque and acceleration, making it suitable for demanding tasks.

All-Terrain Capability: Its advanced suspension system allows for smooth navigation over rough landscapes, ensuring stability and comfort.

Spacious Cargo Area: The generous storage compartment provides ample space for equipment and personal belongings, enhancing utility.

User-Friendly Controls: Intuitive design features make operation straightforward, allowing users to focus on their activities without distractions.

Durability: Constructed with high-quality materials, this vehicle is built to withstand harsh conditions, ensuring longevity and reliability.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended lifespan of any machinery. By adhering to a systematic maintenance schedule, owners can prevent premature wear and tear, enhancing both performance and reliability. Neglecting routine checks can lead to significant issues that compromise functionality and safety.

Enhancing Performance

Consistent maintenance not only helps in identifying potential problems early but also ensures that the equipment operates at its optimal level. Clean components, properly lubricated parts, and well-adjusted systems contribute to improved efficiency and effectiveness, ultimately leading to better productivity.

Cost-Effectiveness

Investing time and resources in maintenance can yield significant savings in the long run. By avoiding major repairs and replacements through regular inspections, owners can protect their investment and minimize operational costs. A well-maintained machine is less likely to encounter unexpected breakdowns, allowing for uninterrupted usage and enhanced value.

Common Parts and Their Functions

Understanding the various components of a utility vehicle is essential for maintaining its efficiency and longevity. Each element plays a critical role in ensuring optimal performance, from the engine to the suspension system. Familiarity with these parts can aid in troubleshooting and enhance overall functionality.

Engine Components

The heart of any machine, the engine, is responsible for converting fuel into mechanical energy. Key components include the pistons, which create the power needed for movement, and the crankshaft, which converts linear motion into rotational force. Additionally, the fuel injector ensures precise delivery of fuel, improving combustion efficiency.

Chassis and Suspension

The chassis serves as the structural framework, providing stability and support for all other components. Within this framework, the suspension system plays a vital role in absorbing shocks and maintaining traction on various terrains. Essential parts like shock absorbers and leaf springs work together to enhance ride quality and handling.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Numerous resources are available to ensure you find high-quality replacements that meet your needs. Understanding these options will help you maintain your equipment efficiently and effectively.

Online Retailers are one of the most convenient sources for sourcing components. Many websites specialize in aftermarket and OEM offerings, allowing you to compare prices and availability easily. Searching for reputable vendors ensures you receive reliable items that fit your model.

Local Dealerships often stock specific components and can provide expert guidance tailored to your machinery. Visiting these establishments allows you to consult knowledgeable staff who can assist you in identifying the right parts.

Salvage Yards can be treasure troves for hard-to-find components. These facilities often carry a wide range of used items at significantly lower prices. While quality may vary, thorough inspection can yield valuable finds for those willing to explore.

Online Marketplaces such as auction sites and classified ads can also offer opportunities to find components from other owners. Here, prices may be negotiable, and you might find unique items that are no longer in production.

By utilizing these various sources, you can efficiently find the components needed to keep your machinery running smoothly.

Interpreting the Parts Diagram Effectively

Understanding the visual representation of components is essential for effective maintenance and repairs. A well-constructed visual guide not only aids in identifying individual elements but also provides clarity on their arrangement and functionality within the entire system. Mastering the interpretation of these illustrations can enhance both efficiency and accuracy in your tasks.

Key Elements to Consider

When examining the illustration, focus on several critical aspects to ensure proper comprehension:

| Element | Description |

|---|---|

| Labels | Identify each component clearly, often with corresponding numbers for reference. |

| Connections | Observe how parts link together, which is crucial for understanding the overall structure. |

| Annotations | Look for notes that may provide insights into specific assembly or disassembly instructions. |

Tips for Effective Usage

To maximize the utility of the illustration, consider these strategies:

- Cross-reference the visual with a service manual for comprehensive guidance.

- Utilize magnification tools for detailed views of smaller components.

- Keep a list of frequently referenced elements to streamline future repairs.

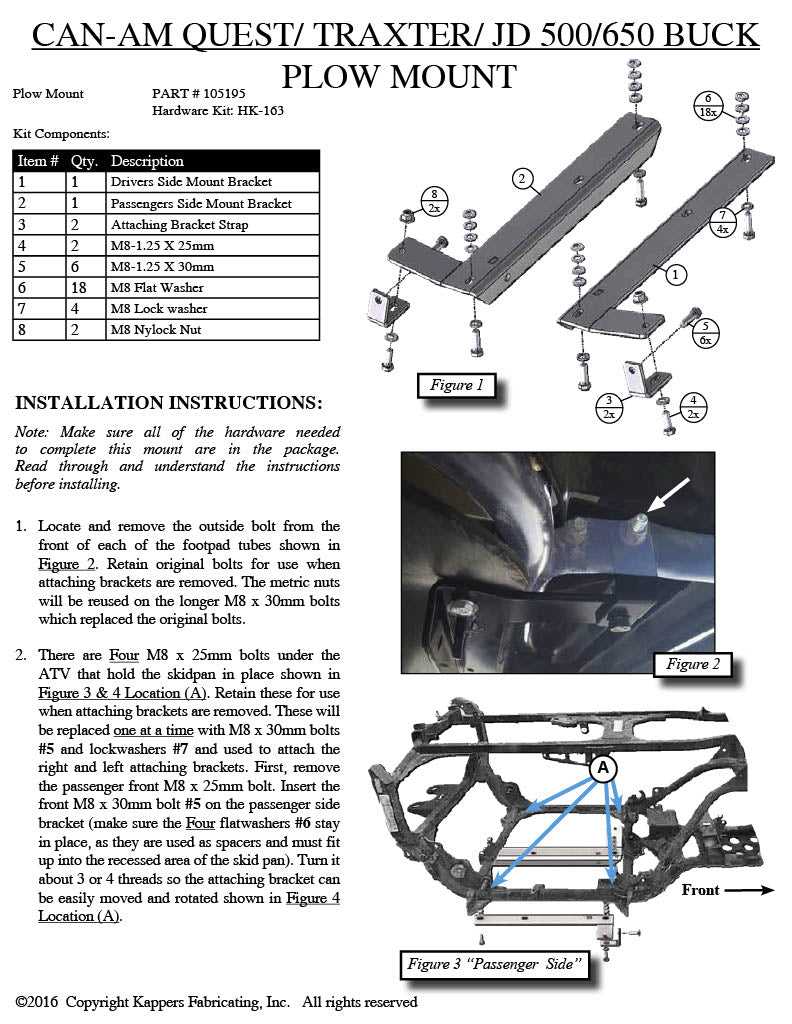

Tips for DIY Repairs and Upgrades

Engaging in do-it-yourself maintenance and enhancements can be both rewarding and economical. Understanding the fundamentals of your equipment allows you to address issues promptly and effectively, while also enabling you to customize features according to your needs. This section offers practical advice to ensure successful projects, whether you’re fixing an existing system or making improvements.

Essential Tools and Supplies

Having the right tools is crucial for any repair or upgrade task. Consider investing in quality equipment that will last over time. Here’s a list of must-have items:

| Tool | Purpose |

|---|---|

| Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Handling various types of screws |

| Multimeter | Checking electrical components |

| Safety Gear | Protecting yourself during repairs |

Step-by-Step Approach

When tackling repairs or upgrades, follow a systematic process. Begin by diagnosing the issue clearly before proceeding. Document your steps to avoid confusion. Break down the task into smaller parts, allowing you to focus on one aspect at a time. This methodical approach reduces the risk of errors and improves overall efficiency.

Resources for Parts and Manuals

When maintaining and repairing machinery, having access to reliable resources is essential. Whether you’re seeking replacement components or detailed operational guides, the right tools can significantly enhance your efficiency and understanding. This section highlights various avenues to obtain valuable information and supplies to keep your equipment running smoothly.

Online Resources

The internet is a treasure trove of information for those looking to source components and manuals. Numerous websites specialize in equipment maintenance, offering downloadable manuals and parts catalogs. These platforms often feature user forums where enthusiasts and professionals share insights and advice, making them an excellent resource for troubleshooting and tips.

Local Dealers and Distributors

In addition to online options, visiting local dealers can provide personalized assistance. Authorized distributors often have access to official documentation and genuine components. Establishing a relationship with your local dealer can lead to valuable insights into equipment care and updates on new products.

Utilizing these resources effectively will empower you to make informed decisions regarding your machinery, ensuring optimal performance and longevity.

Expert Opinions on Performance and Reliability

In the realm of outdoor utility vehicles, insights from industry specialists shed light on critical factors influencing overall effectiveness and durability. These assessments often focus on how well machines handle various terrains and tasks, along with their capacity for long-term performance under demanding conditions.

According to numerous experts, a vehicle’s reliability is paramount for operators who depend on consistent functionality. Regular maintenance and quality of components play significant roles in ensuring longevity. Feedback from users highlights that robust engineering and innovative design significantly enhance operational efficiency, minimizing downtime and repair costs.

Moreover, many professionals emphasize the importance of user experience in evaluating performance. Vehicles that offer intuitive controls and superior comfort contribute to increased productivity. Ultimately, the consensus is clear: selecting a well-reviewed model from a reputable brand can significantly impact performance and reliability in the field.