Effective lawn maintenance relies on specialized equipment designed to enhance efficiency and ease of use. Among these tools, certain systems are crafted to collect and manage grass clippings and debris, ensuring a clean and tidy outdoor space. A clear understanding of the components involved in these systems can significantly improve their operation and longevity.

In this guide, we will explore the intricacies of the collection apparatus, breaking down its various elements and how they function together. Knowledge of each component not only aids in maintenance but also enhances the overall performance of the equipment, allowing for a smoother lawn care experience.

Whether you’re a seasoned landscaper or a homeowner looking to optimize your gardening tools, familiarizing yourself with the specifics of this collection system is invaluable. With the right insights, you can ensure that your equipment remains in top condition and continues to serve you effectively for years to come.

Overview of John Deere Power Flow Bagger

This section explores an efficient collection system designed for lawn maintenance, enhancing the effectiveness of grass and leaf management. This innovative accessory simplifies the process of gathering clippings, ensuring a tidy appearance for landscapes.

Key Features

- Efficient collection mechanism

- Compatibility with various mower models

- Easy installation and removal

- Durable materials for longevity

Benefits

- Reduces the time spent on yard work

- Promotes a cleaner outdoor environment

- Enhances the appearance of lawns

- Facilitates easy disposal of organic waste

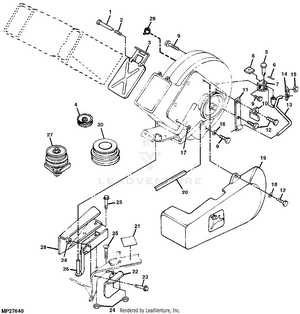

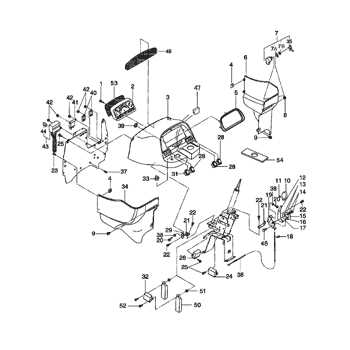

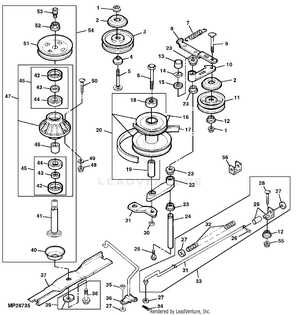

Essential Components of Power Flow Bagger

This section explores the crucial elements that contribute to the effective operation of a grass collection system. Understanding these components can enhance performance and efficiency, ensuring optimal results during lawn maintenance tasks.

- Collector Housing: This structure serves as the main body, housing the collection mechanism and providing durability.

- Collection Bags: These flexible containers are designed to capture and store grass clippings, leaves, and debris.

- Conveyor System: This mechanism transports collected material from the cutting deck to the storage bags, ensuring smooth flow and minimal blockage.

- Mounting Brackets: Essential for securing the system to the mower, these components provide stability and alignment during operation.

- Airflow Vents: Designed to enhance ventilation, these vents help prevent clumping and promote efficient material transfer.

Each of these elements plays a vital role in ensuring the system operates seamlessly, facilitating an effortless lawn care experience.

Understanding the Parts Diagram

Comprehending the schematic representation of components is crucial for effective maintenance and repair of equipment. These visual guides offer a clear illustration of how various elements interconnect and function together. By familiarizing yourself with the layout, you can easily identify each piece, ensuring that any replacements or adjustments are executed smoothly.

Each section of the illustration typically includes labeled components, making it easier to locate specific items. This can significantly reduce downtime, as knowing the exact location of a part allows for quicker troubleshooting. Moreover, understanding the relationships between the different components aids in grasping the overall mechanism of the machinery, enhancing both performance and longevity.

When examining these visual aids, take note of the various categories of elements, such as the drive system, collection units, and any associated hardware. Recognizing the roles of each part will empower you to maintain your equipment more effectively and make informed decisions about repairs or upgrades.

Maintenance Tips for Bagger Parts

Proper upkeep of collection systems is essential for optimal performance and longevity. Regular attention to these components not only enhances functionality but also prevents costly repairs. By following a few key maintenance practices, users can ensure their equipment operates smoothly throughout the season.

Regular Inspections

Conduct frequent checks to identify any signs of wear or damage. Look for cracks, loose fittings, or blockages that could impede operation. Early detection can prevent minor issues from escalating into major problems.

Cleaning and Storage

After each use, thoroughly clean all components to remove debris and grass clippings. Store the equipment in a dry, sheltered area to protect it from environmental factors. Proper storage extends the lifespan of the collection system significantly.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect for damage | Weekly | Check for cracks and loose connections. |

| Clean components | After each use | Remove debris to prevent clogs. |

| Lubricate moving parts | Monthly | Ensure smooth operation. |

| Store properly | Off-season | Keep in a dry, sheltered location. |

Common Issues with Power Flow Systems

Many users encounter a variety of challenges when utilizing collection systems for lawn maintenance. These issues can range from mechanical failures to inefficiencies in the overall operation. Understanding these common problems is essential for maintaining optimal performance and ensuring a smooth experience.

One frequent issue is clogging, which can occur when debris accumulates in the system, obstructing airflow and reducing effectiveness. This often leads to increased workload and frustration, requiring frequent checks and cleanouts. Regular maintenance and proper operation techniques can help mitigate this problem.

Another common concern involves wear and tear on components. Over time, parts may degrade, leading to reduced efficiency and potential breakdowns. It’s crucial to regularly inspect these elements and replace them as needed to prevent more significant issues down the line.

Moreover, improper installation can lead to alignment problems, causing the system to function ineffectively. Ensuring that all components are correctly positioned and secured can enhance performance and extend the lifespan of the equipment.

Finally, variations in power supply can affect the operation of the system. Inconsistent performance may arise from fluctuations in engine power or electrical issues. Keeping the power source in check and ensuring it’s within recommended specifications is vital for seamless operation.

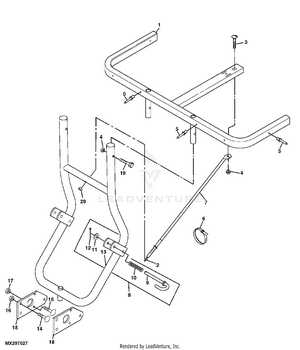

Step-by-Step Assembly Guide

This section provides a clear and detailed process for assembling your collection system, ensuring you have a smooth experience from start to finish. Following these steps will help you achieve optimal functionality and efficiency.

Preparation and Tools Needed

Before you begin, gather the necessary tools and components. You will typically need a wrench set, screwdriver, and the assembly pieces included in your kit. Ensure that you have a clean workspace to facilitate the process.

Assembly Steps

Step 1: Start by laying out all components to familiarize yourself with each piece. Refer to your assembly guide to verify that you have everything required.

Step 2: Begin connecting the main framework. Align the sections according to the provided instructions, ensuring that all connectors fit snugly.

Step 3: Secure the assembly using the appropriate screws and bolts. Make sure to tighten them adequately, but avoid overtightening to prevent damage.

Step 4: Attach any additional components such as the collection bags or support frames. Follow the same principle of alignment and security as in the previous steps.

Step 5: Finally, perform a thorough inspection of the entire setup to ensure stability and readiness for use. Make adjustments if necessary before putting the system into operation.

By adhering to these outlined steps, you will successfully assemble your equipment and be ready to utilize it effectively.

Replacement Parts and Compatibility

Ensuring the optimal performance of your equipment often involves identifying suitable components that can replace worn or damaged ones. Understanding the interchangeability of these elements is crucial for maintaining efficiency and functionality. This section focuses on the essential aspects of component replacement and compatibility, helping you make informed decisions.

Compatibility is a key factor when selecting replacements. It is important to verify that new components align with the specifications of your machinery. Many manufacturers provide lists of compatible alternatives, which can assist you in sourcing the right items. Additionally, consulting user manuals and technical documentation can offer valuable insights into which options are suitable.

When searching for replacement components, consider the quality and warranty offered by various suppliers. Investing in high-quality items can enhance durability and overall performance, while reputable vendors often provide guarantees that safeguard your purchase. Always cross-reference the model numbers and specifications to ensure a perfect match.

Ultimately, being proactive about maintenance and understanding the options available for replacements will significantly contribute to the longevity and reliability of your equipment. By staying informed, you can ensure that your machinery operates at peak performance for years to come.

Upgrading Your Bagger for Efficiency

Enhancing your collection system can significantly improve lawn care effectiveness and reduce maintenance time. By implementing a few strategic modifications, you can boost the overall performance, making yard work more efficient and enjoyable.

One of the first steps in this upgrade process is to assess the current setup and identify areas that can benefit from improvement. Upgrading certain components can lead to a more streamlined operation, ultimately enhancing the collection process.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Collector Bag | High-capacity or breathable materials | Increased volume and better airflow |

| Chassis | Lightweight alloys or reinforced frames | Improved durability and reduced weight |

| Attachment System | Quick-release mechanisms | Faster setup and takedown |

| Blower | High-efficiency motor | Enhanced suction power and energy savings |

By considering these upgrades, users can not only enhance the collection system’s performance but also extend its lifespan. Investing in quality components and innovations will lead to a more effective and enjoyable lawn maintenance experience.