In the realm of agricultural equipment, a comprehensive grasp of the various elements that contribute to optimal functionality is essential. Knowledge about individual components can significantly enhance maintenance practices, leading to increased efficiency and longevity of the machinery. This article delves into the intricacies of a specific implement, focusing on its structure and essential features.

Identifying the elements within any machine is crucial for troubleshooting and repair. Each part plays a vital role, and understanding their arrangement can provide valuable insights into how the overall system operates. By familiarizing oneself with these components, operators can make informed decisions when it comes to servicing their equipment.

Moreover, having a visual representation of the machinery layout not only aids in recognition but also fosters a deeper appreciation for the engineering behind it. This understanding can empower users to tackle issues proactively, ensuring that their operations run smoothly and effectively.

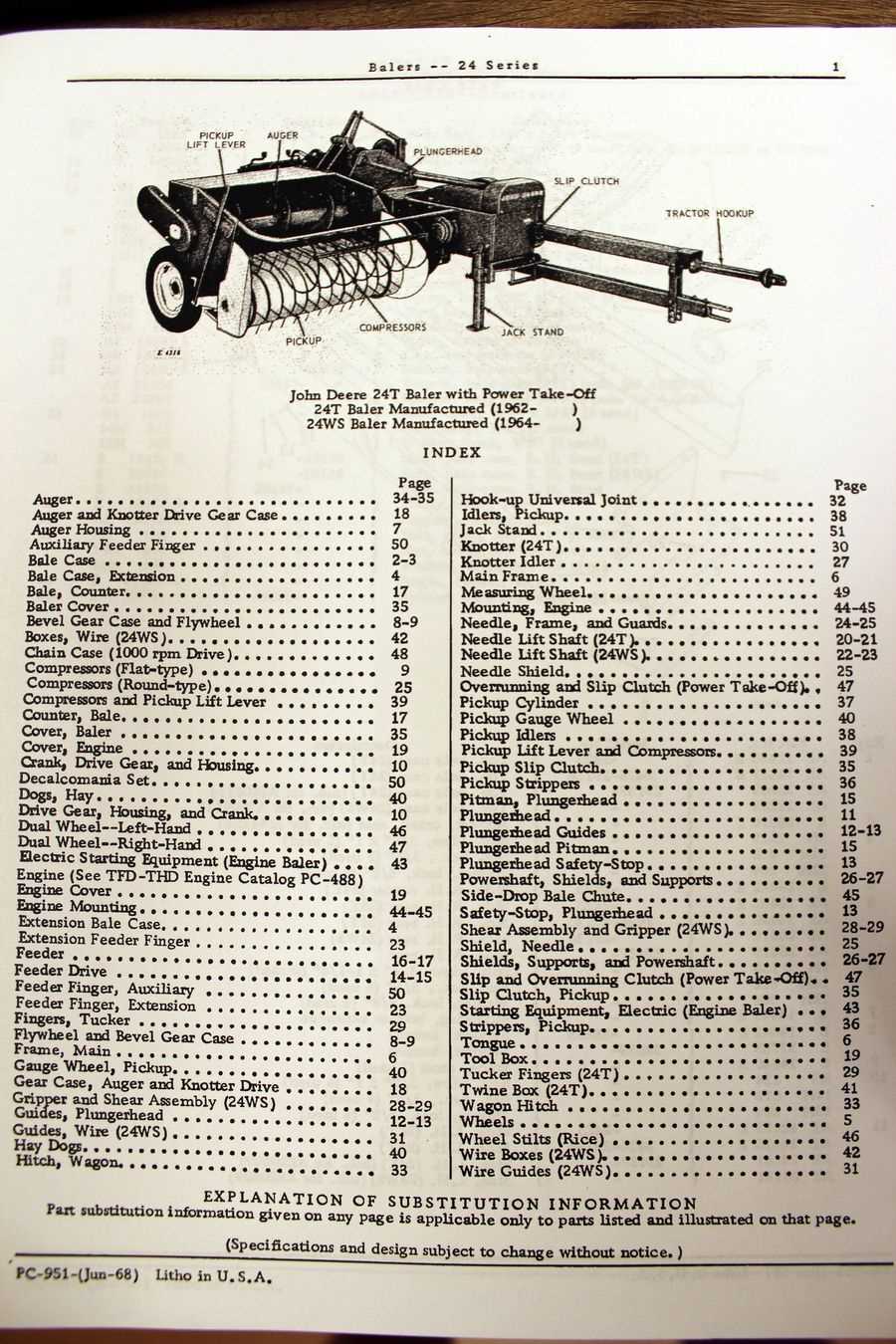

Understanding John Deere 24T Baler

This section explores the mechanics and functionality of a specific agricultural implement designed for harvesting and bundling crops. By examining its components and operation, users can gain insights into optimal performance and maintenance practices.

| Component | Description |

|---|---|

| Feed Chamber | Initial area where material is gathered for processing. |

| Twine System | Mechanism that secures bales using twine. |

| Pickup Header | Part that collects the cut crop from the ground. |

| Compression Chamber | Area where the gathered material is compacted into bales. |

| Discharge Chute | Pathway through which completed bales are released. |

Components of the 24T Baler

The machinery designed for hay and straw processing is comprised of several critical elements that work in unison to achieve optimal performance. Understanding these components is essential for effective operation and maintenance.

Feed System: This part is responsible for guiding the material into the compression chamber. Its design ensures a steady flow, allowing for uniform processing.

Compression Chamber: In this section, the collected material is compacted into dense bundles. The efficiency of this area greatly affects the overall output and quality of the final product.

Twine and Knotting Mechanism: Essential for securing the bundles, this system ties the compressed material with twine. Proper functioning of this mechanism is crucial for preventing loose bales.

Pickup Header: This component gathers the material from the ground and feeds it into the machine. Its height and width can be adjusted to accommodate various crop types.

Drive System: The power source that drives all operational parts. Regular checks on this system are necessary to ensure reliable performance and to avoid downtime.

Chassis and Frame: Providing structural support, the frame must be robust to withstand the stresses of continuous use in various field conditions.

By familiarizing oneself with these essential components, operators can enhance their understanding of the machine’s functionality and ensure its longevity through proper care and maintenance.

Importance of Maintenance for Baler

Regular upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to unexpected breakdowns and costly repairs. Therefore, establishing a consistent maintenance routine is essential for any farmer or operator aiming to enhance efficiency and productivity.

One of the primary benefits of diligent maintenance is the prevention of wear and tear. Components can become worn over time, impacting the overall functionality. By addressing these issues proactively, operators can avoid more serious complications that may arise from delayed repairs.

Additionally, regular inspections allow for the identification of potential problems before they escalate. This not only saves time but also minimizes downtime during peak operational periods. Keeping machinery in top condition ensures that tasks are completed efficiently, which is vital during harvesting seasons.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Lubrication | Every 50 hours | Reduces friction and wear |

| Inspection of Belts | Every 100 hours | Prevents slippage and failures |

| Cleaning | After each use | Prevents buildup and rust |

| Check Hydraulic Systems | Monthly | Ensures optimal pressure and function |

In conclusion, regular maintenance not only enhances the lifespan of machinery but also promotes safety and reliability in agricultural operations. A proactive approach to care can yield significant benefits, making it an indispensable practice for any farming enterprise.

Common Issues with Baler Parts

When it comes to agricultural machinery, various components can encounter difficulties that affect overall performance. Understanding these common challenges is crucial for efficient operation and maintenance. Frequent issues often stem from wear and tear, improper alignment, or inadequate lubrication.

Wear and Tear: Over time, certain elements may become worn, leading to decreased efficiency and increased risk of breakdowns. Regular inspections can help identify these problems before they escalate.

Alignment Problems: Misalignment of moving parts can cause excessive friction and heat, potentially damaging components. Ensuring proper alignment is vital for smooth operation.

Lack of Lubrication: Insufficient lubrication can result in grinding, sticking, or complete failure of mechanical parts. Regular maintenance checks should include lubrication to prolong the life of these components.

Addressing these common issues promptly can prevent more serious complications, ensuring that machinery operates effectively and efficiently throughout the season.

Replacement Parts Overview

In this section, we provide an informative overview of the components required for the maintenance and repair of your agricultural equipment. Our focus is on ensuring the seamless functionality and longevity of your machinery through the use of quality replacement components. Each part plays a crucial role in optimizing performance and efficiency, contributing to the smooth operation of your equipment.

We emphasize the importance of selecting appropriate substitutes to uphold the reliability and operational standards of your machinery. Understanding the function and compatibility of each element ensures the effective integration of replacement parts into your equipment, enhancing overall productivity and reducing downtime. Our comprehensive overview guides you through the essential aspects of replacement components, facilitating informed decisions and meticulous maintenance practices.

By exploring the intricacies of replacement parts, you gain insight into their pivotal role in sustaining peak performance and extending the lifespan of your agricultural machinery. Our commitment to quality ensures that each replacement part meets rigorous standards, aligning with the original specifications to maintain optimal functionality. We empower you with the knowledge needed to navigate the realm of replacement parts effectively, fostering confidence in the upkeep of your equipment.

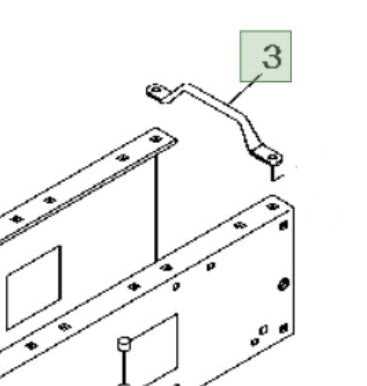

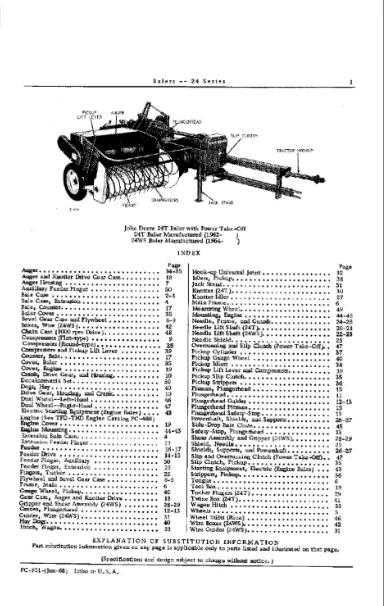

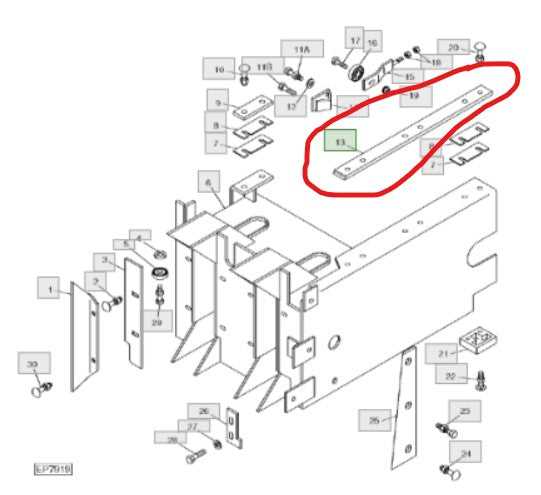

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair tasks. These visual guides provide a comprehensive overview of various elements and their relationships, facilitating easier identification and troubleshooting. Grasping how to interpret these illustrations can significantly enhance your efficiency when working on machinery.

To effectively read such a schematic, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the legend or key, which explains the symbols and notations used in the illustration. |

| 2 | Identify the main assembly or group of components that the guide focuses on, usually highlighted prominently. |

| 3 | Trace the connections and pathways between components to understand how they interact within the system. |

| 4 | Note any numbers or codes associated with each part, which are critical for ordering replacements or conducting repairs. |

| 5 | Cross-reference with the service manual or online resources to get detailed specifications or installation instructions. |

By following these steps, you can effectively decode the information presented, ensuring a smooth and informed approach to any repair or maintenance project.

Benefits of Genuine John Deere Parts

Utilizing authentic components ensures optimal performance and longevity for machinery. Genuine items are designed specifically for equipment, offering numerous advantages that enhance operational efficiency.

- Reliability: Authentic components are tested rigorously, ensuring consistent performance.

- Compatibility: Designed to fit seamlessly, reducing the risk of malfunction.

- Longevity: High-quality materials used in genuine products lead to extended lifespan.

- Warranty Protection: Using original parts often safeguards warranties, providing peace of mind.

- Resale Value: Equipment maintained with genuine components typically holds higher market value.

Investing in authentic parts ultimately fosters a more efficient and dependable operation, proving beneficial for any owner.

Finding Parts for Your Baler

When maintaining agricultural machinery, securing the right components is crucial for optimal performance. Whether you are seeking replacements or upgrades, understanding where to look and what to consider can greatly enhance your efficiency in the field.

Where to Look

Several sources are available for locating the necessary components. Online retailers specialize in agricultural machinery, providing a wide selection. Local dealerships often offer expert advice and may have parts in stock. Additionally, salvage yards can be a treasure trove for hard-to-find items at a fraction of the cost.

Considerations for Selection

When choosing components, ensure compatibility with your machinery model. Review specifications and consult with experts if uncertain. Quality should never be compromised; opting for original equipment or high-quality aftermarket options can save time and money in the long run. Always check for warranties to safeguard your investment.

Tips for Efficient Baler Operation

Achieving optimal performance during the wrapping and binding of materials requires attention to various operational aspects. By understanding key practices, operators can enhance productivity, reduce downtime, and ensure high-quality output. Here are some essential strategies to consider for effective machine management.

Regular Maintenance Checks

Consistent upkeep of the equipment is crucial for preventing malfunctions and ensuring smooth operation. Regular inspections help identify wear and tear before it becomes a significant issue. Key components to monitor include:

| Component | Check Frequency | Action |

|---|---|---|

| Belts | Weekly | Inspect for cracks or fraying |

| Rollers | Every Use | Clean and lubricate |

| Hydraulic System | Monthly | Check fluid levels and leaks |

Optimal Settings and Adjustments

Fine-tuning machine settings according to the material being processed can significantly improve efficiency. Proper adjustments to tension and feed rates can enhance compression and reduce wasted time. Consider these factors:

- Material type and moisture content

- Desired density of the final product

- Feed speed to match the machine’s capacity