Understanding the layout and connection of various essential elements within a mechanical system is crucial for efficient operation and maintenance. By studying the configuration and organization of these key elements, you can gain insight into how different sections interact with each other, ensuring smooth functionality and simplifying any required adjustments or repairs.

This comprehensive overview delves into the specifics of each unit and their respective positions within the system. Identifying these connections allows for a clearer perspective on how they contribute to the overall performance and durability of the machinery. Equipped with this knowledge, you can enhance both troubleshooting skills and preventative care.

Understanding the LX188 Component Layout

When exploring the arrangement of mechanical elements in this type of equipment, it’s essential to grasp how various sections are structured and interact. Each individual part plays a crucial role in maintaining the overall performance, and knowing their positions can help identify and solve potential issues efficiently.

Key sections include the drive system, control mechanisms, and electrical circuits, all positioned to enhance usability and ensure smooth operation. Recognizing these components not only aids in troubleshooting but also supports the effective upkeep of the machine.

Understanding the overall layout is vital for anyone who seeks to maintain or repair the machine with ease. From its framework to the core operational units, each segment is purposefully arranged to ensure longevity and reliability in usage.

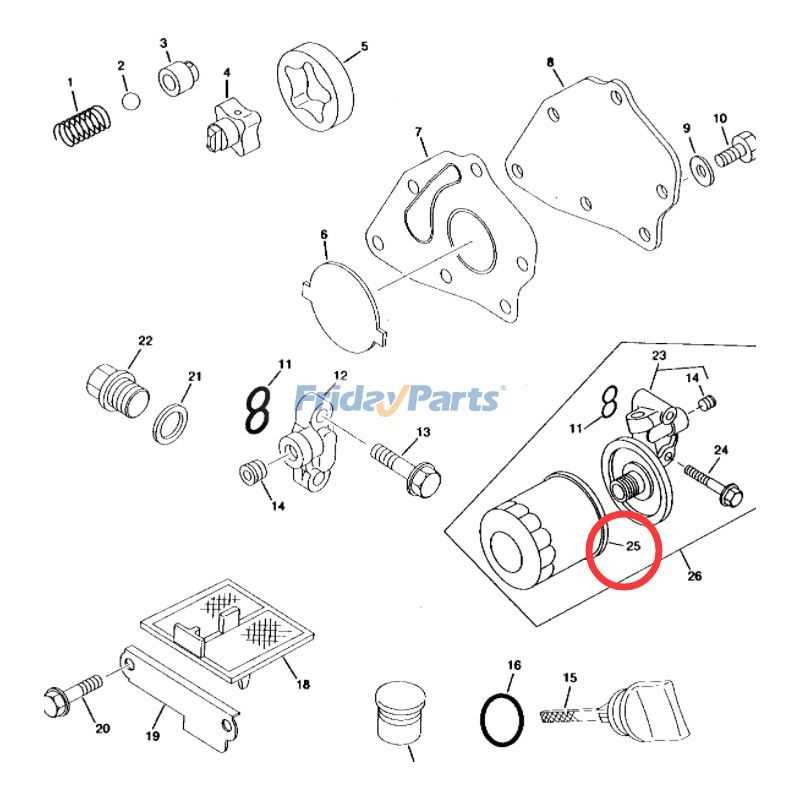

Engine System Overview and Key Parts

The engine system plays a critical role in powering equipment, ensuring smooth and efficient operation. This section provides an overview of how the system works, highlighting the essential components that contribute to its functionality. Understanding these elements is crucial for maintaining optimal performance and avoiding breakdowns.

Main Components of the Engine

The engine consists of several core components, each working in tandem to generate power. Key elements include the combustion chamber, crankshaft, and cooling system. These parts are responsible for converting fuel into energy, maintaining engine temperature, and driving motion through mechanical processes.

Supporting Systems

In addition to the main components, there are auxiliary systems such as the lubrication and exhaust systems. The lubrication system ensures that all moving parts operate smoothly, while the exhaust system helps remove byproducts of combustion, keeping the engine running efficiently and reducing wear.

Chassis Structure and Frame Assembly

The foundation and overall durability of any machinery heavily rely on the robust design and precise arrangement of the chassis and frame. These elements ensure the proper distribution of weight, providing stability and a balanced framework for all other components. Proper attention to these structural aspects is essential for optimal performance, safety, and longevity.

Main Components of the Frame

The frame consists of various interconnected parts that create the backbone of the machinery. These include reinforced beams, mounting points, and brackets that secure key functional units.

- Reinforced side rails to withstand pressure and strain

- Heavy-duty cross members for added support

- Mounting brackets strategically positioned for additional components

Assembly Guidelines

The assembly process must be performed with precision to ensure that each part aligns correctly, ensuring long-term reliability. Pay attention to the following steps when assembling the chassis:

- Secure the side rails in place, ensuring alignment

Steering Mechanism Breakdown

The steering system is a crucial component that allows smooth and accurate control of the machine’s direction. Understanding its construction and operation is essential for ensuring proper function and long-term reliability.

Below is an overview of the key elements involved in the steering setup:

- Steering Wheel: The main interface that the operator uses to control direction, connected directly to the steering shaft.

- Steering Shaft: A rigid connector that links the wheel to the mechanical components, ensuring precise movement transmission.

- Steering Linkage: The assembly that transfers rotational force from the shaft to the steering arms, coordinating the motion.

- Steering Arms: These components control the direction of

Electrical Wiring and Connections

Understanding the layout and structure of electrical systems is essential for ensuring proper functionality. The connections and wiring within machinery must be organized efficiently to maintain a smooth and uninterrupted operation. Each component relies on a network of wires that delivers power and signals throughout the system.

Key elements of electrical circuits involve precise routing of cables and correct

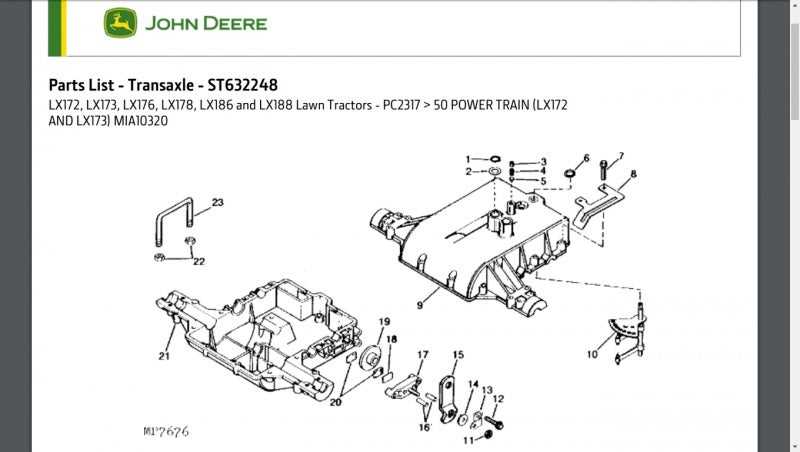

Transmission Components and Functionality

The transmission system plays a crucial role in the operation of various machinery, enabling the efficient transfer of power from the engine to the wheels. This system comprises several essential elements that work together seamlessly to ensure smooth movement and control.

Key components of the transmission system include:

- Gearbox: The gearbox is responsible for adjusting the torque and speed, allowing for different driving conditions.

- Clutch: This component facilitates the engagement and disengagement of the engine from the transmission, enabling smooth starts and stops.

- Drive Shaft: The drive shaft transmits power from the transmission to the wheels, ensuring effective propulsion.

- Differential: The differential allows for variations in wheel speed, particularly during turns, enhancing stability and handling.

- Fluid System: The transmission fluid lubricates the moving parts, preventing wear and maintaining optimal performance.

Each of these components plays a vital role in the overall functionality of the transmission system, contributing to the machine’s efficiency and reliability. Understanding how these elements interact can help in maintaining and troubleshooting the system effectively.

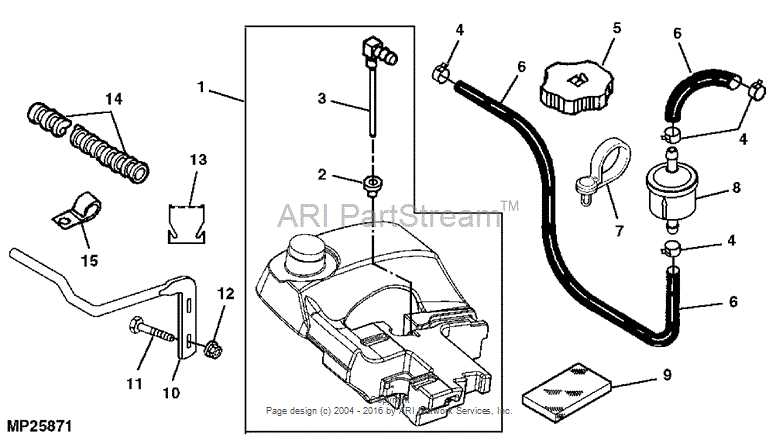

Fuel System and Related Parts

The fuel system is a crucial component of any engine, ensuring efficient delivery and management of fuel to maintain optimal performance. It consists of various elements that work together to store, filter, and supply fuel to the engine, contributing to overall operational efficiency.

Key components of the fuel system include the fuel tank, fuel pump, fuel filter, and fuel lines. Each of these parts plays a significant role in the overall functionality and reliability of the engine.

Component Description Fuel Tank Stores the fuel required for the engine operation. Fuel Pump Moves fuel from the tank to the engine, maintaining the necessary pressure. Fuel Filter Removes impurities and contaminants from the fuel before it reaches the engine. Fuel Lines Transport fuel between the tank, pump, filter, and engine. Deck and Mower Blade Assembly

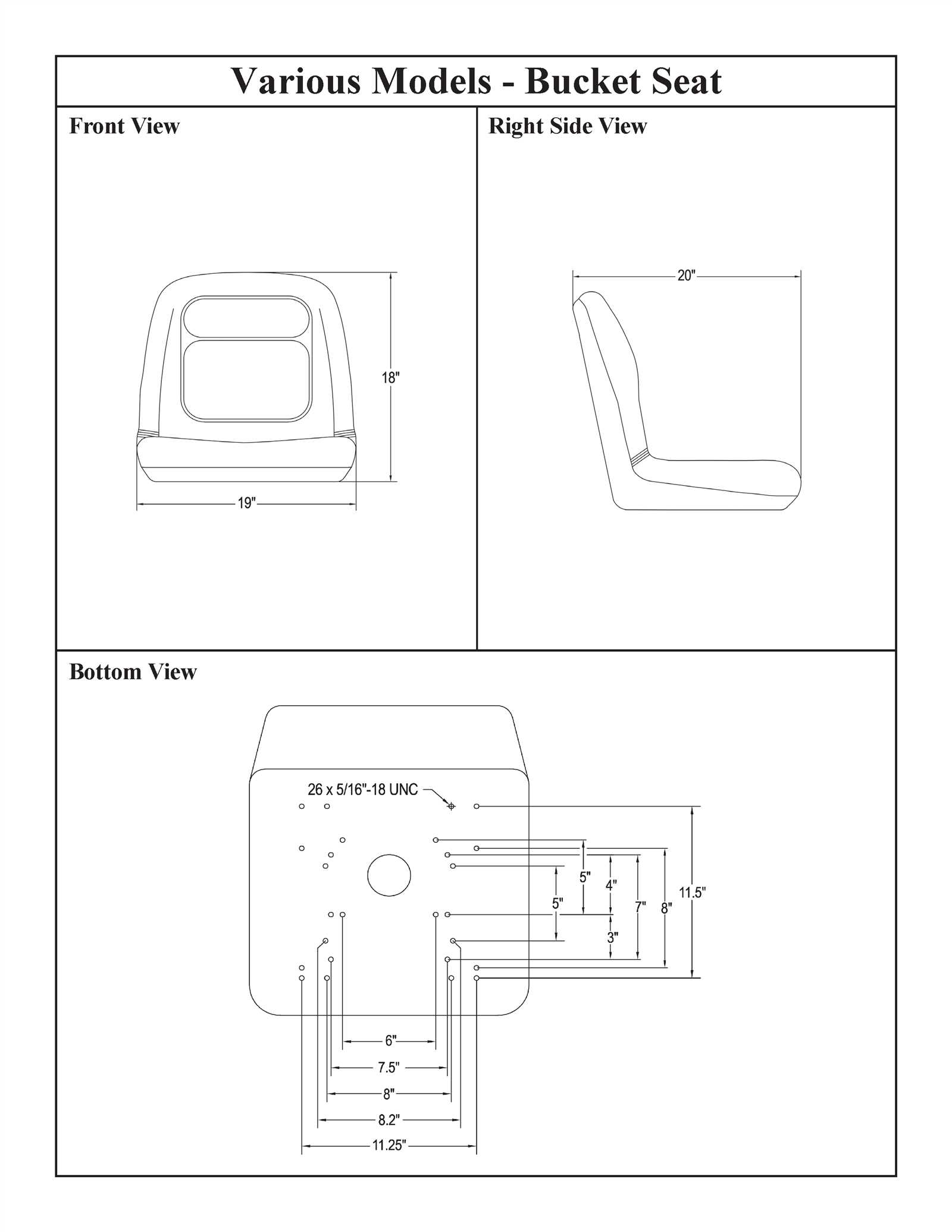

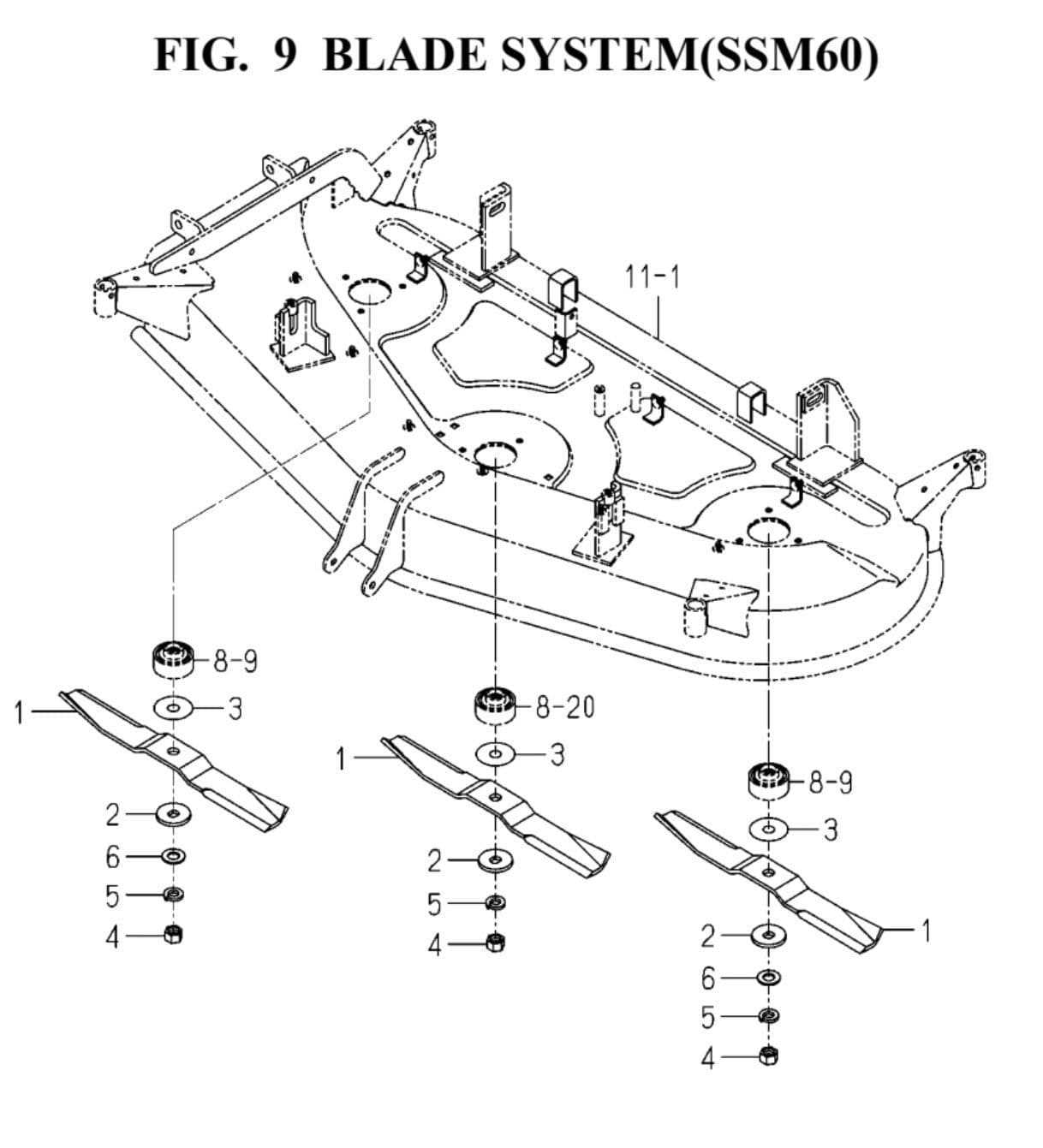

The assembly of the cutting platform and blade is crucial for ensuring effective lawn maintenance. This section outlines the essential components and their roles in achieving optimal performance. Proper configuration and maintenance can enhance the overall functionality and longevity of the mowing equipment.

Understanding the Assembly: The cutting deck serves as the housing for the mower blades, which are responsible for the precise cutting of grass. Each blade must be securely attached to guarantee even cutting and to prevent any operational issues.

Maintenance Tips: Regular inspection of the assembly is important. Look for any signs of wear or damage on the blades and deck. Sharpening the blades periodically will improve cutting efficiency, while cleaning the deck can prevent clippings from accumulating, which can affect performance.

Following the manufacturer’s guidelines for assembly and maintenance will ensure the equipment operates smoothly and effectively throughout the mowing season.

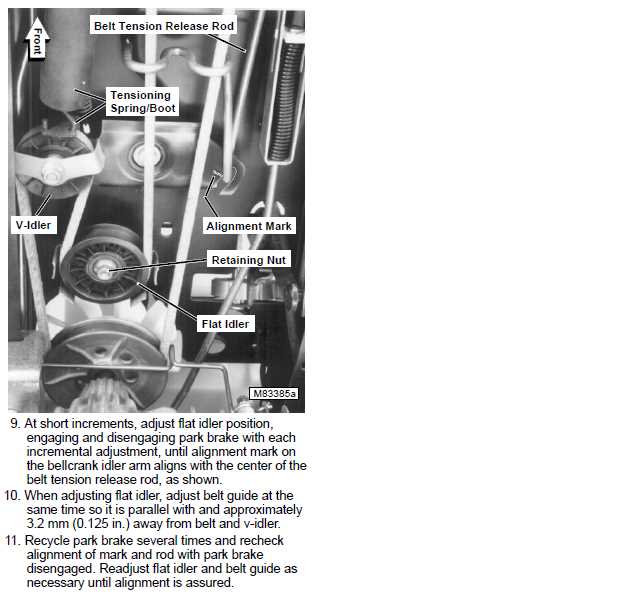

Maintenance Tips for Common Parts

Ensuring the longevity and optimal performance of essential components is crucial for any machinery. Regular upkeep not only enhances efficiency but also prevents unexpected failures. Here are some valuable recommendations to keep various elements in top shape.

Regular Inspection

Conducting frequent evaluations of key components is vital. Look for signs of wear, corrosion, or damage. Timely identification of issues can save both time and resources in the long run. Be thorough in your checks to ensure no detail is overlooked.

Lubrication and Cleaning

Proper lubrication is necessary for reducing friction and wear. Utilize the appropriate lubricants for each component, and maintain a regular schedule for applying them. Additionally, keeping surfaces clean from dirt and debris helps in preventing operational problems. Regular cleaning promotes better performance and extends the life of vital parts.