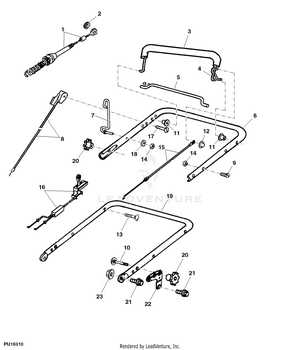

Proper maintenance and repair of agricultural machines require a clear understanding of their internal layout. A visual representation of the machine’s structure can significantly aid in identifying various elements and how they interact. By grasping the organization of different components, users can ensure efficient upkeep and timely repairs.

Exploring these illustrations can simplify the process of locating essential elements, making it easier to perform maintenance tasks or replacements. With a focus on clarity and accuracy, these visual aids enable users to navigate through the intricate system of any agricultural equipment smoothly.

Detailed breakdowns allow for a closer look into the intricate assembly of various elements, ensuring that every aspect of the machine functions as intended. Whether for routine inspections or troubleshooting, having access to such information can prove invaluable for users aiming for optimal performance.

Overview of Key Components

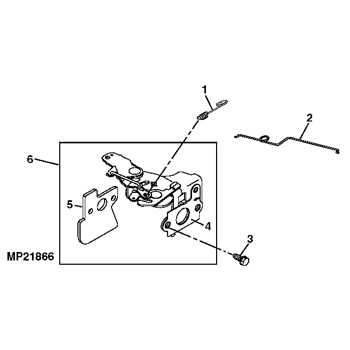

Maintaining and servicing equipment requires a solid understanding of its various components. Each element plays a crucial role in ensuring smooth and efficient performance, contributing to the overall functionality. Familiarity with the different sections and their interactions helps in effective upkeep.

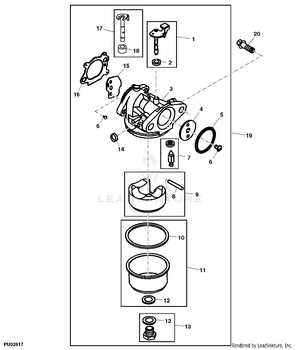

- Engine Assembly: The heart of the system, providing power and ensuring continuous operation. Proper care of this part is essential for reliable use.

- Cutting Mechanism: Responsible for trimming and achieving a precise finish, this part requires regular checks and maintenance for optimal results.

- Drive System: Allows for controlled movement, ensuring easy maneuvering. Keeping this mechanism in good condition aids in smooth operation.

- Fuel Management: Efficient fuel handling ensures consistent power output. Regular inspection and adjustments can enhance longevity.

- Understanding Key Components and Functions

The inner workings of mechanical equipment rely on a variety of essential elements, each playing a crucial role in ensuring smooth operation. Recognizing these elements and how they interact is vital for maintaining optimal performance. This overview focuses on identifying the main features that contribute to functionality, offering a deeper insight into their importance.

Engine Mechanism: The core driving force, this unit powers the entire structure, converting fuel into energy. It requires regular upkeep to ensure continuous and efficient output.

Transmission System: This component controls the movement and speed, allowing for adaptability in different conditions. It ensures the smooth transfer of power from the engine to the wheels, adjusting the speed based on the terrain.

Cutting System: Designed to handle different surfaces, this part is responsible for achieving precision in operation. It adjusts to varying heights and angles, ensuring that tasks are completed with accuracy.

Control Assembly: A central hub for

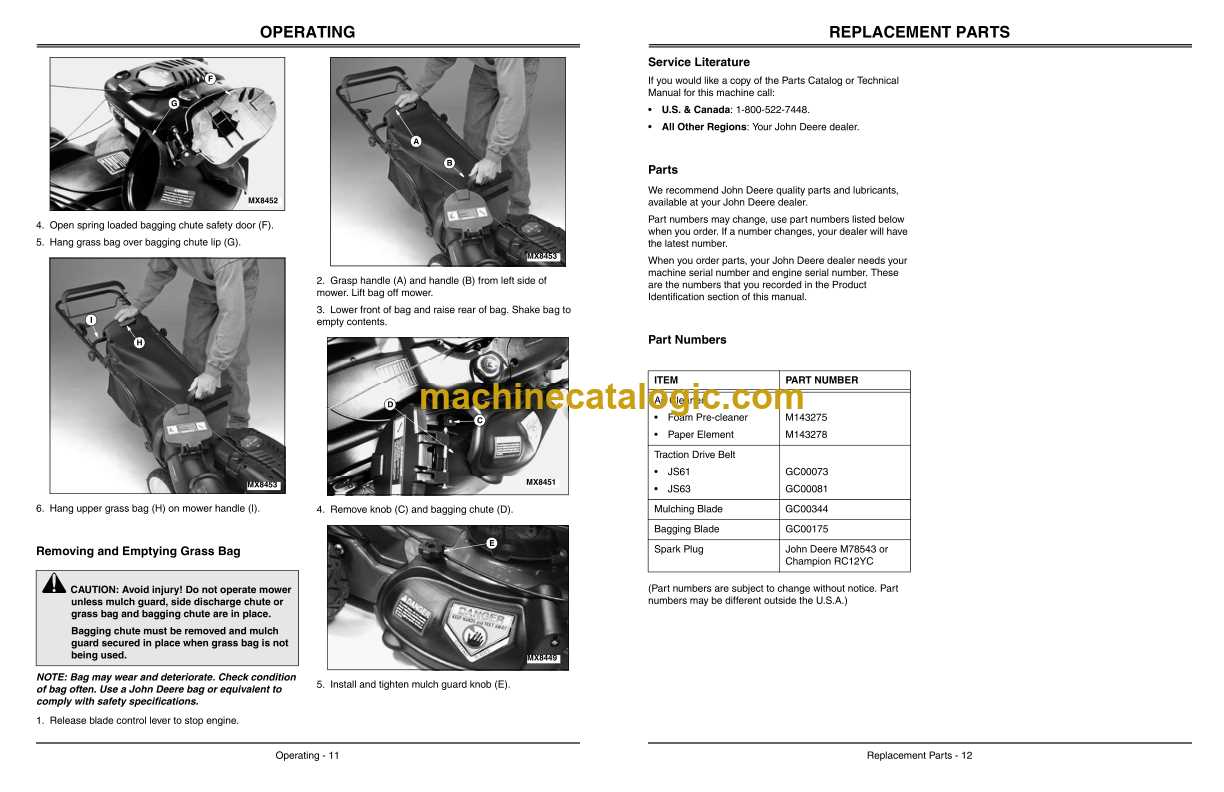

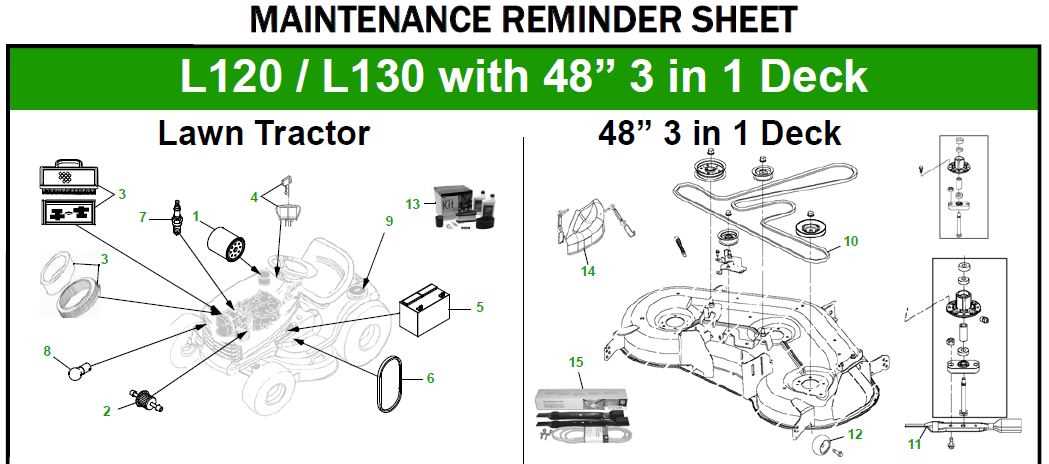

Maintenance Tips for JS63 Mower Parts

Proper upkeep is essential for ensuring the smooth operation and longevity of your lawn equipment. By taking a few simple steps, you can keep the machine running efficiently and extend the life of its components. Regular attention to key areas can prevent wear and ensure optimal performance during each mowing session.

Regular Cleaning and Inspection

Maintaining cleanliness is crucial for the optimal function of your mower. After each use, remove debris from the undercarriage and blades. This prevents build-up, which can hinder movement and cause unnecessary strain on the engine. Regularly inspect the various mechanisms for any signs of damage or wear, ensuring that all parts are in good working order.

- Clear out grass clippings and dirt from critical areas.

- Check for loose screws or fasteners and tighten them if necessary.

- Make sure the blade is free of nicks and properly aligned.

Lubrication and Blade Sharpening

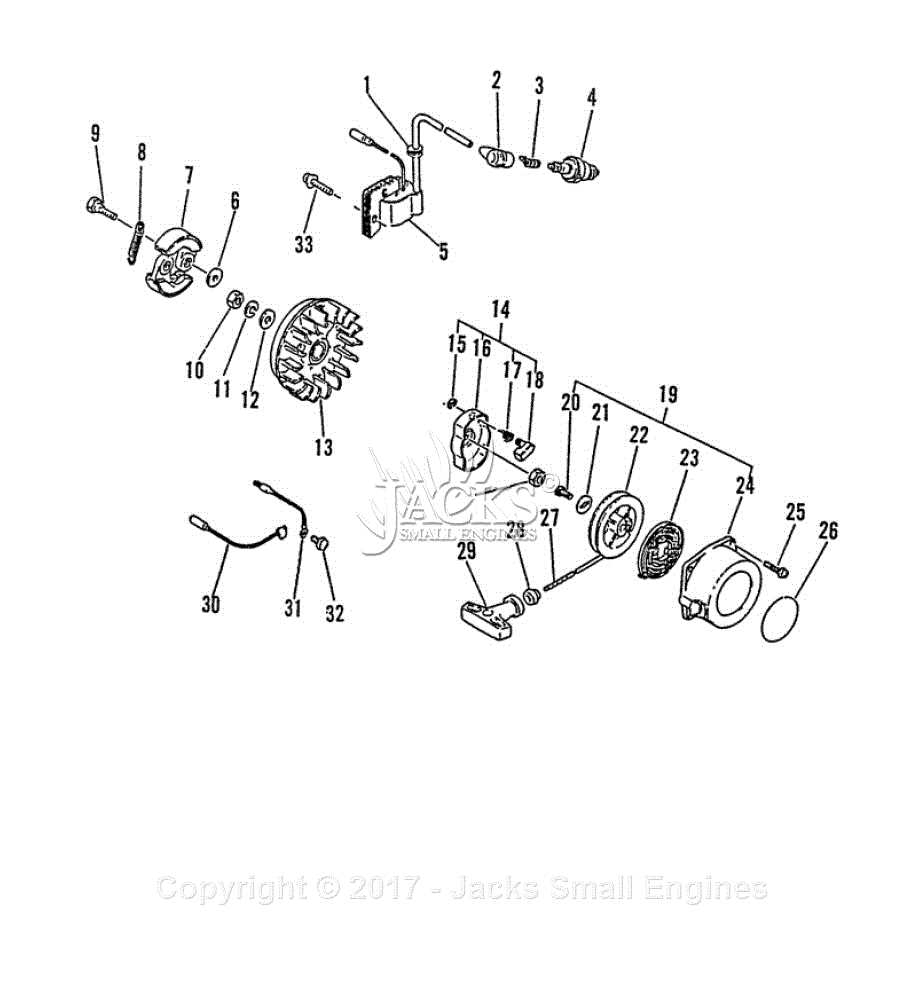

Diagram for Efficient Part Identification

An organized visual guide can be an essential tool for pinpointing each component within a complex mechanism. This approach ensures that users can quickly locate and understand the structure and placement of various elements, streamlining maintenance and repairs. A well-structured visual overview simplifies the recognition process, making it easier to identify key elements without confusion.

- Clear labeling helps users navigate through each component swiftly.

- Detailed layouts ensure that even intricate sections are comprehensible.

- A logical arrangement reduces time spent on identifying specific elements.

By using a structured representation, users gain a clear perspective on how different parts connect and interact. This clarity aids in reducing potential errors during assembly or disassembly. It also serves as a quick reference for understanding the overall structure, ensuring a more efficient approach to technical tasks.

- Start by studying the visual overview to understand

Replacement Parts for Smooth Operation

Maintaining the efficiency and longevity of your equipment requires timely replacement of key components. Regular upkeep ensures that every mechanism functions seamlessly, reducing wear and tear while promoting reliable performance over time. Identifying when to replace specific elements is crucial for optimal operation.

Essential Components to Consider

- Blades: Sharp, well-maintained blades enhance cutting precision, making sure your device operates smoothly.

- Drive Belts: Replacing worn-out belts helps sustain consistent movement, preventing disruptions during use.

- Filters: Clean filters ensure that the engine breathes properly, boosting efficiency and reducing fuel consumption.

Regular Maintenance Benefits

Consistent inspection and replacement of worn elements can prevent unexpected breakdowns. A proactive approach to maintenance can extend the lifespan of your machinery, keeping it in prime condition for years to come.

- Check for visible wear on essential components regularly.

Essential Parts for Optimal Performance

To ensure the best functionality of any machinery, certain components play a crucial role. Understanding these key elements not only enhances operational efficiency but also extends the lifespan of the equipment. Each element contributes to the overall effectiveness, making it vital to recognize their importance and maintain them properly.

Key Components

Identifying and understanding the main components involved can significantly impact performance. Regular inspection and timely replacement of these elements are essential for maintaining peak operation. Below is a table highlighting critical components and their functions:

Component Function Blade Responsible for cutting grass efficiently. Engine Powers the machinery and enables mobility. Deck Holds the blade and provides structural integrity. Wheels Facilitate movement across various terrains. Filter Cleans the air and fuel to enhance performance. Maintenance Tips

To maximize the performance of essential components, regular maintenance is crucial. Here are some tips to consider:

- Inspect components regularly for wear and tear.

- Replace any damaged or worn parts immediately.

- Keep all elements clean to prevent buildup and malfunction.

Troubleshooting Common Part Issues

Addressing frequent component challenges is essential for maintaining optimal performance in any machinery. Understanding how to identify and rectify these issues can significantly extend the lifespan of equipment and enhance overall efficiency.

When facing difficulties with specific elements, it is important to follow a systematic approach to diagnose the problem accurately. Below are common issues and their potential solutions:

Issue Symptoms Recommended Actions Unusual Noise Grinding or rattling sounds during operation Inspect for loose components; tighten screws and bolts; lubricate moving parts. Decreased Efficiency Longer operational times or reduced output Check for clogs; clean filters; replace worn-out elements. Vibration Issues Excessive shaking during use Ensure all components are properly aligned; balance moving parts; replace damaged elements. Regular maintenance and timely interventions are key to preventing minor concerns from escalating into major malfunctions. Implementing a proactive maintenance schedule can help in promptly identifying and resolving issues.

Choosing Genuine Parts for Durability

When maintaining equipment, selecting authentic components is essential for ensuring longevity and optimal performance. Utilizing original products not only enhances reliability but also promotes a seamless fit, which is crucial for overall functionality.

Benefits of Authentic Components

Investing in genuine items offers numerous advantages:

- Quality Assurance: Original items are manufactured to meet specific standards, ensuring consistency in performance.

- Longevity: Authentic components are designed for durability, reducing the frequency of replacements.

- Compatibility: Genuine products guarantee perfect compatibility with your equipment, minimizing the risk of malfunction.

Recognizing Quality Products

To make informed decisions, consider the following tips:

- Check for manufacturer certification to confirm authenticity.

- Review product specifications to ensure they align with your equipment’s requirements.

- Consult authorized dealers for reliable sourcing of genuine items.

Upgrading Parts for Better Efficiency

Improving the components of your equipment can significantly enhance its performance and longevity. By selecting high-quality alternatives and upgrades, users can optimize functionality and reduce maintenance costs. This process often involves evaluating the current setup and identifying areas where enhancements can yield the greatest benefits.

Investing in superior materials and advanced technologies may lead to increased output and smoother operation. Consideration should be given to elements such as blades, belts, and engines, as they play a crucial role in the overall efficiency of the machinery. Upgrading these components not only ensures reliable performance but also contributes to a more sustainable operation.

Additionally, regular assessment of the machinery’s needs can guide timely upgrades, preventing potential breakdowns and ensuring peak efficiency throughout its lifespan. Adopting a proactive approach in maintaining and enhancing your equipment will ultimately result in a more productive and cost-effective solution.