Maintain proper tire pressure for balanced handling.

How to Identify Key Parts

Understanding the essential components of a utility vehicle can greatly enhance maintenance and troubleshooting. By familiarizing yourself with the various elements and their positions, you can efficiently detect areas that might require attention, ensuring the vehicle remains in optimal working condition.

Recognizing Major Components

Start by locating prominent sections such as the engine, transmission, and suspension. These areas are often the most critical for functionality and should be checked regularly. Pay attention to any signs of wear, loose connections, or unusual noises, as these can indicate potential issues.

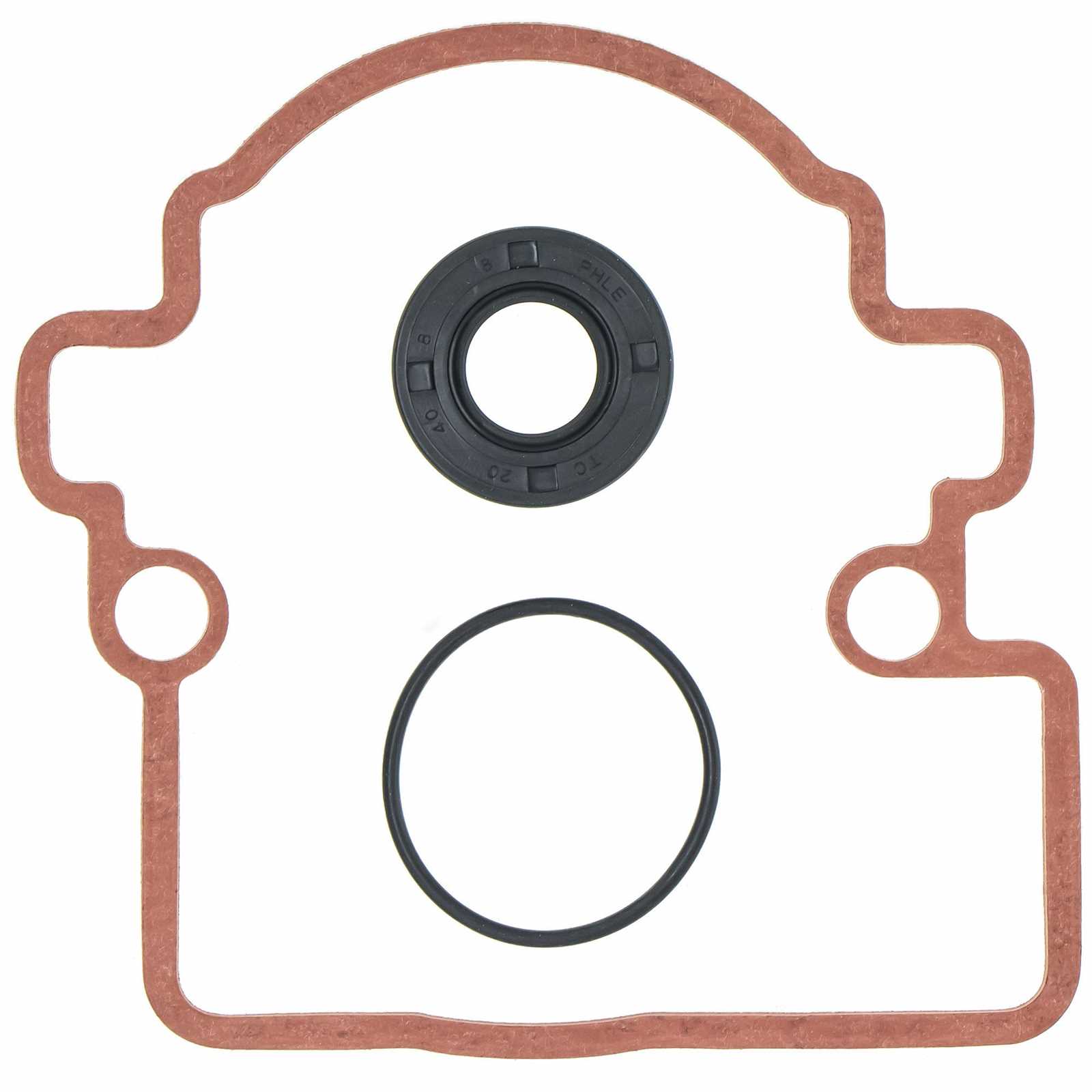

Inspecting Smaller Elements

Smaller components like filters, belts, and hoses also play significant roles in the overall performance. Examine these parts for cracks, leaks, or other signs of deterioration. Regularly replacing or repairing minor elements can prevent larger, more costly repairs in the future.

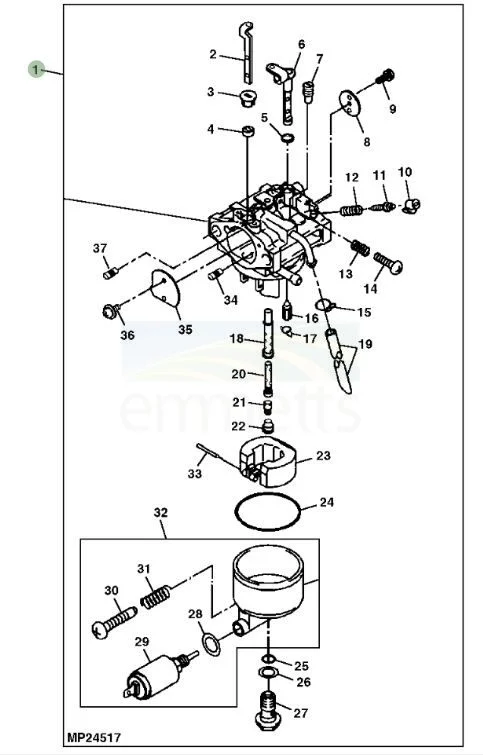

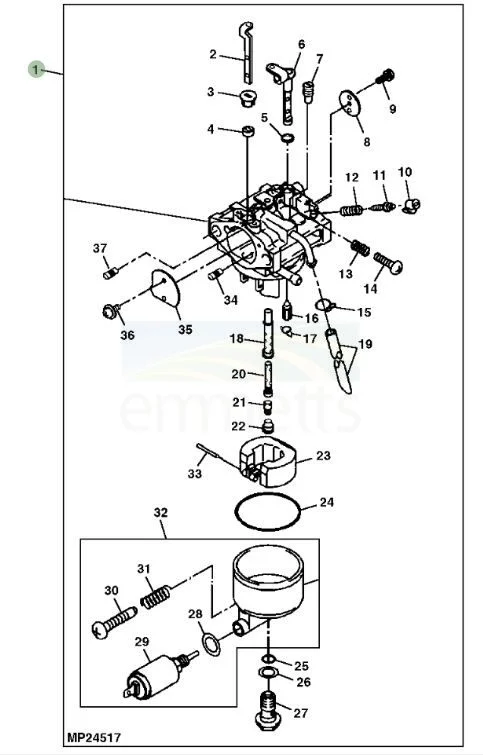

Engine Parts Layout Explained

The layout of a machine’s engine is crucial for understanding how different components work together to ensure efficient operation. Each element within the system has a specific function, contributing to overall performance. Knowing the positions and roles of various components can aid in maintenance and troubleshooting.

Key components include the fuel system, cooling elements, and various internal mechanisms that drive the engine’s motion. The placement of these elements ensures optimal functionality, allowing each part to interact seamlessly. The arrangement is designed to maximize power output while maintaining efficiency.

Understanding the layout helps in identifying potential issues quickly, enabling targeted repairs and routine maintenance. Familiarity with the configuration allows for smoother operation and better performance over time. Regular inspection of critical areas can prevent wear and tear from escalating into larger problems.

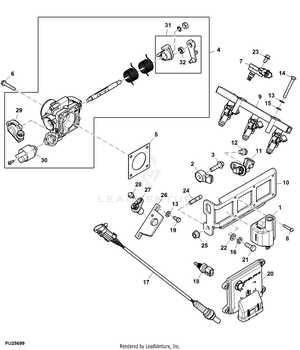

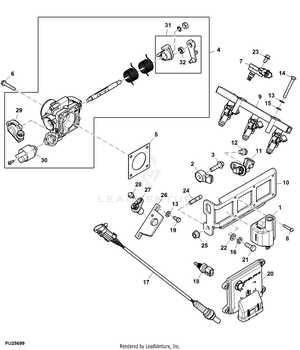

Gator 835M Electrical System Overview

The electrical framework of this utility vehicle is designed to ensure optimal performance and reliability under various conditions. This intricate network facilitates the smooth operation of critical components, enabling enhanced functionality and user experience. By understanding its layout, operators can maintain efficiency and prevent potential issues.

At the core of this electrical system are the battery and alternator, which work in tandem to supply power to essential systems. The wiring harness connects various elements, ensuring seamless communication between components. Additionally, fuses and relays protect the system from overloads, while switches allow users to control different functionalities effortlessly.

Incorporating advanced technology, this electrical architecture supports features such as lighting systems, ignition mechanisms, and auxiliary power outlets. Regular inspections and maintenance of these elements contribute significantly to the longevity and performance of the vehicle. Familiarity with the electrical setup empowers users to address minor issues and optimize their driving experience.

Guide to Gator 835M Transmission

The transmission system of a utility vehicle plays a crucial role in its overall performance and efficiency. Understanding the components and functions of this mechanism is essential for ensuring optimal operation and longevity. This section provides a comprehensive overview of the transmission system, including its key parts and maintenance practices.

Key components of the transmission system include:

- Gearbox: This houses the gears and facilitates the transfer of power from the engine to the wheels.

- Driveshaft: A crucial element that transmits torque from the engine to the wheels.

- Differential: This allows for variations in wheel speed during turns, enhancing maneuverability.

- Clutch: Engages and disengages the engine from the transmission, allowing for smooth shifting.

Regular maintenance of the transmission system is vital. Here are some essential practices:

- Check fluid levels regularly to ensure proper lubrication.

- Inspect for leaks or signs of wear in the components.

- Change the transmission fluid at recommended intervals to maintain performance.

- Consult the owner’s manual for specific guidelines regarding maintenance tasks.

By understanding the structure and function of the transmission system, operators can enhance the reliability and efficiency of their utility vehicles, ensuring a smooth and productive experience.

Suspension Parts and Their Functions

The suspension system of a vehicle plays a crucial role in providing stability and comfort during operation. It is designed to absorb shocks and maintain optimal contact between the wheels and the ground, ensuring a smooth ride even on uneven terrain.

Key components of the suspension system include:

- Shocks and Struts: These elements absorb impact from bumps and dips in the road, reducing the force transmitted to the vehicle’s frame.

- Springs: Springs support the weight of the vehicle, allowing for compression and expansion as the terrain changes, which helps in maintaining a balanced ride.

- Control Arms: These connect the chassis to the wheels and allow for controlled movement, ensuring stability during turns and maneuvers.

- Bushings: Made from rubber or polyurethane, bushings provide cushioning between metal parts, reducing noise and vibration while allowing for some movement.

- Anti-roll Bars: Also known as stabilizer bars, these help reduce body roll during cornering, enhancing handling and control.

Understanding these components and their functions can aid in the maintenance and performance of the suspension system, contributing to the overall efficiency and safety of the vehicle.

Exploring the Gator 835M Safety Features

Safety is paramount when operating utility vehicles designed for various terrains and tasks. The model in focus incorporates an array of advanced safety mechanisms that enhance operator protection and promote secure operation. Understanding these features is essential for users aiming to maximize their experience while minimizing risks during use.

Key Safety Mechanisms

- Seat Belts: Equipped with robust seat belts, ensuring that operators and passengers are securely fastened during travel.

- Roll-Over Protection Structure: Features a protective framework designed to safeguard occupants in case of accidental rollovers.

- Stability Control: Advanced stability control systems help prevent tipping by adjusting to varying terrains and load distributions.

- Braking System: Efficient hydraulic brakes provide reliable stopping power, allowing for controlled descents and sudden stops.

- Lighting: High-visibility headlights and tail lights enhance visibility in low-light conditions, ensuring safer navigation.

Operator Awareness and Training

In addition to built-in safety features, user awareness plays a crucial role in ensuring safe operation. Regular training on the vehicle’s capabilities and limitations can significantly reduce accidents. Operators should be encouraged to familiarize themselves with safety protocols, including:

- Conducting pre-operation inspections to identify any potential issues.

- Understanding load capacity and distribution to prevent overloading.

- Practicing defensive driving techniques in varied environments.

By emphasizing both vehicle safety features and operator awareness, users can enjoy a safer and more efficient experience with their utility vehicles.