In the world of farming equipment, knowing the intricate details of machinery can significantly enhance maintenance and repair efficiency. This section delves into the essential components that make up a popular utility vehicle, offering insights into its structure and function. A clear understanding of these elements can empower operators and technicians alike, ensuring optimal performance and longevity.

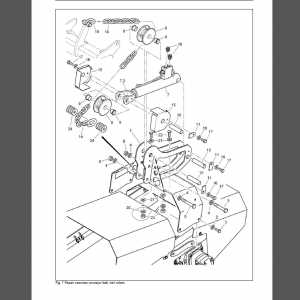

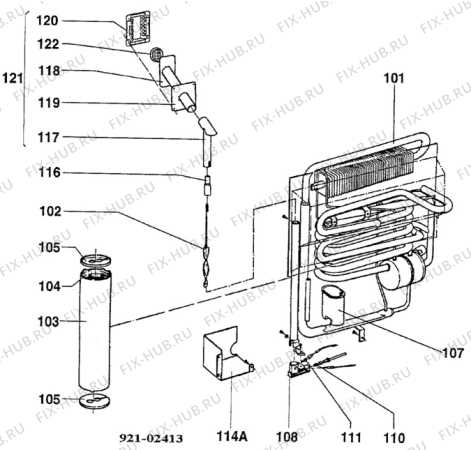

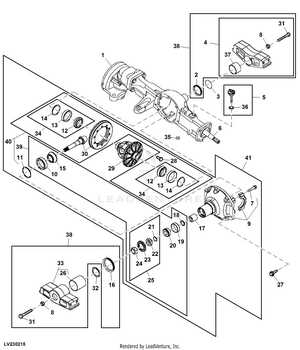

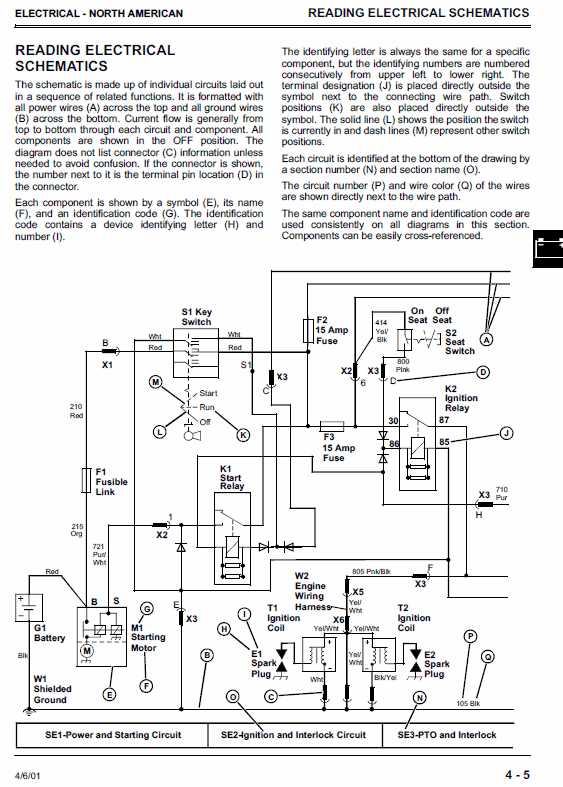

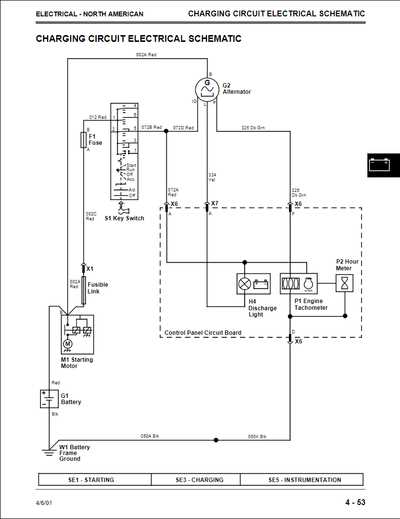

By exploring the various illustrations that outline the configuration of this machinery, users can easily identify each segment and its role. This knowledge is crucial for anyone involved in the upkeep of such vehicles, as it facilitates informed decision-making when it comes to repairs and replacements. Clear visual references serve as valuable tools, enhancing comprehension and aiding in troubleshooting.

Furthermore, these detailed representations provide a roadmap for anyone looking to enhance their technical skills or improve their operational efficiency. Understanding the layout and relationships between components can lead to better diagnostics and a more streamlined maintenance process. Ultimately, grasping these foundational aspects paves the way for a more effective interaction with agricultural machinery.

Understanding John Deere 4300 Components

Familiarizing oneself with the essential elements of machinery is crucial for efficient operation and maintenance. Each component plays a vital role, contributing to the overall performance and reliability of the equipment. A comprehensive understanding of these elements not only aids in troubleshooting but also enhances the ability to perform timely repairs and upgrades.

The various sections of the machinery encompass numerous parts, each designed for specific functions. Recognizing how these components interact can lead to improved handling and longevity of the equipment.

| Component | Description |

|---|---|

| Engine | The powerhouse of the machinery, providing the necessary energy for operation. |

| Transmission | Facilitates power transfer from the engine to the wheels, affecting speed and torque. |

| Hydraulics | Utilizes fluid pressure to operate various implements and attachments efficiently. |

| Chassis | The structural framework supporting the entire system and its components. |

| Electrical System | Powers all electrical components, ensuring proper functionality and safety. |

Understanding these key elements enables operators to maintain and optimize their machinery, leading to better performance in various tasks.

Importance of Parts Diagrams

Understanding the intricate details of machinery components is crucial for effective maintenance and repair. Visual representations serve as essential tools that aid in identifying various elements, ensuring proper assembly and disassembly, and facilitating troubleshooting processes.

Here are several reasons why these illustrations are vital:

- Clarity: Visual guides provide a clear overview of how components fit together, reducing confusion during repairs.

- Efficiency: Quick reference to diagrams can significantly speed up the maintenance process, minimizing downtime.

- Accuracy: These visuals help ensure that the correct pieces are replaced or repaired, preventing costly errors.

- Learning: For those new to machinery, these representations serve as excellent educational resources, enhancing understanding of mechanical systems.

Overall, utilizing visual aids is essential for anyone involved in the upkeep of equipment, contributing to improved functionality and longevity of machinery.

Common Issues with 4300 Models

Many users of this machinery encounter specific challenges that can impact performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

Engine Performance Concerns

One frequent issue involves the engine not starting or running smoothly. This can be attributed to factors such as fuel system blockages, air leaks, or battery failures. Regular maintenance and timely inspections can help identify these issues before they escalate.

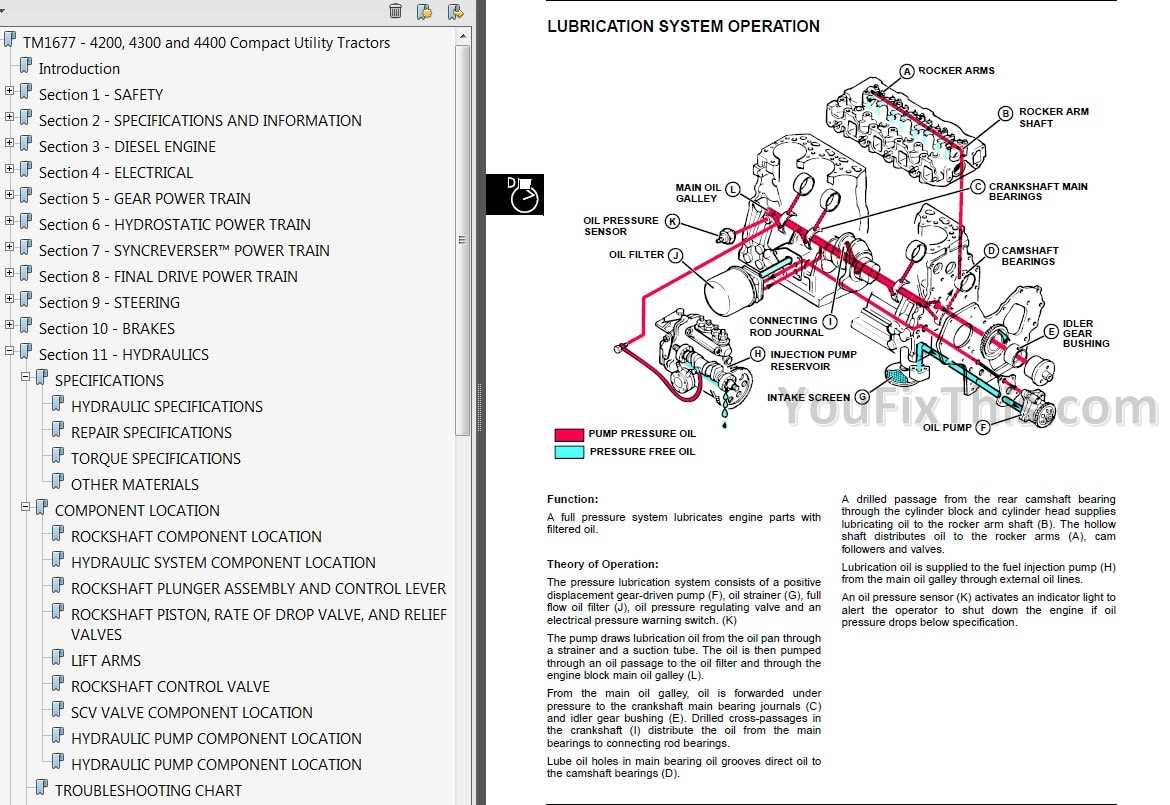

Hydraulic System Failures

Another area where operators often face difficulties is within the hydraulic system. Leaks in hoses or connections can lead to inadequate power for attachments. Additionally, contaminated fluid can affect overall system efficiency. Ensuring proper fluid levels and conducting routine checks is vital to avoid these complications.

By being aware of these common issues and implementing preventive measures, users can enhance the reliability and effectiveness of their machinery.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for maintaining its efficiency and longevity. Ensuring you source the right items can significantly enhance performance and reduce the risk of malfunctions. Several reliable channels are available for acquiring these essential elements, each with its unique advantages.

Authorized Dealers

One of the most dependable sources for original components is through authorized distributors. These vendors are certified and offer a wide selection of high-quality items, ensuring compatibility with your equipment. Additionally, they often provide warranties and support services.

Online Marketplaces

Reputable online platforms also serve as valuable resources. Many websites specialize in genuine components, allowing users to compare prices and find specific items conveniently. Always check reviews and ratings to confirm the reliability of the sellers.

DIY Repair Tips for 4300

Engaging in self-repair can be a rewarding endeavor for machinery enthusiasts. Understanding your equipment’s components and maintenance can save both time and money. Here are some practical suggestions for tackling common issues.

- Consult Manuals: Always refer to the user manual for guidance on assembly and disassembly.

- Gather Tools: Ensure you have the right tools at your disposal, such as wrenches, pliers, and screwdrivers.

- Start Small: Begin with minor repairs to build confidence before moving on to more complex tasks.

- Take Notes: Document each step you take during repairs to simplify reassembly.

- Use Quality Parts: Source high-quality replacement components to enhance performance and durability.

Remember to prioritize safety. Always wear appropriate protective gear and ensure the machine is turned off before beginning any repairs. With patience and attention to detail, you can effectively address many mechanical challenges.

- Check for leaks regularly.

- Inspect belts and hoses for wear and tear.

- Clean air filters to ensure efficient operation.

- Keep all lubricants up to date.

- Test functionality after any repair to ensure everything is in working order.

By applying these tips, you can extend the lifespan of your machinery while gaining valuable skills along the way.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components ensures compatibility and reliability in machinery maintenance. These elements are designed specifically for certain models, promoting optimal performance and longevity.

Quality Assurance: OEM components undergo rigorous testing to meet high standards, providing peace of mind regarding durability and efficiency.

Enhanced Performance: Utilizing these specialized parts can significantly improve the overall functionality of your equipment, leading to fewer breakdowns and increased productivity.

Warranty Protection: Many manufacturers offer warranties on their original components, safeguarding your investment against potential defects and ensuring quality service.

Availability of Support: When using OEM components, you often gain access to dedicated customer support and resources, making maintenance and repairs more straightforward.

Ultimately, investing in original components is a smart choice for anyone looking to maintain the efficiency and lifespan of their machinery.

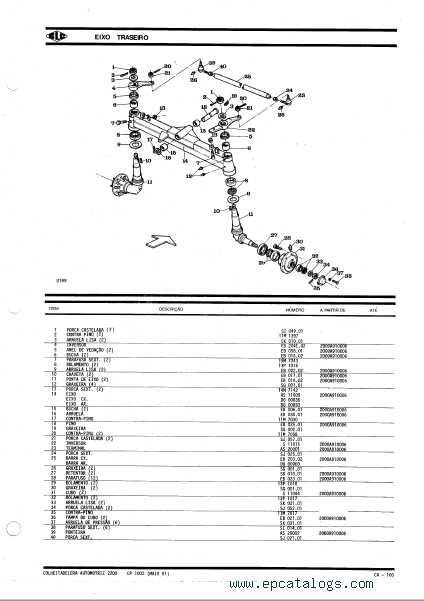

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual representations offer insight into component arrangement and functionality, allowing users to identify necessary items and their specific locations. By familiarizing yourself with these visuals, you can streamline the repair process and ensure that all essential elements are accounted for.

When approaching an illustration, consider the following elements:

| Element | Description |

|---|---|

| Legend | A key explaining symbols used within the image. |

| Numbers | Identifiers next to each item, corresponding to lists of components. |

| Lines | Connections showing how different parts interact or assemble. |

| Views | Different angles or sections that provide a comprehensive understanding of assembly. |

By taking the time to delve into these aspects, you’ll enhance your ability to interpret illustrations, ultimately improving your maintenance efficiency.

Maintenance Practices for Longevity

Ensuring the extended lifespan of machinery requires a dedicated approach to upkeep and care. Implementing consistent maintenance routines not only enhances performance but also prevents unexpected breakdowns and costly repairs. By focusing on key practices, owners can safeguard their investment and ensure smooth operation for years to come.

Regular Inspections

Conducting routine examinations is essential for identifying potential issues before they escalate. Check critical components such as the engine, transmission, and hydraulic systems. Keeping a detailed log of inspections helps in tracking the condition and performance of the equipment over time.

Scheduled Servicing

Adhering to a set servicing schedule is crucial for maintaining optimal function. This includes oil changes, filter replacements, and checking fluid levels. Following manufacturer guidelines for maintenance intervals will greatly contribute to longevity.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 100 hours | Use recommended oil type |

| Filter Replacement | Every 200 hours | Check for clogging |

| Fluid Levels Check | Weekly | Hydraulic and coolant levels |

| Greasing Moving Parts | Every 50 hours | Prevent wear and tear |

By incorporating these practices into a regular routine, operators can ensure their machinery remains in top condition, ultimately leading to improved efficiency and reduced downtime.