When it comes to maintaining a pristine lawn, having a reliable machine is essential. This specific model is renowned for its efficiency and robust design, making it a favored choice among homeowners and landscaping professionals alike. To fully appreciate its functionality, it’s crucial to delve into the various components that contribute to its performance.

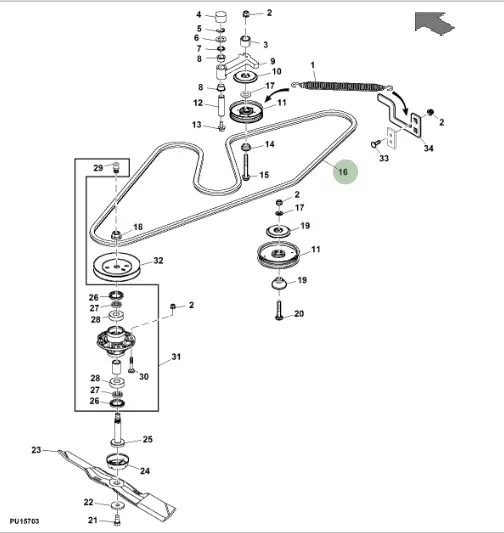

Each segment of this lawn care apparatus plays a vital role in its overall operation. From the engine to the cutting mechanism, understanding how these elements fit together can enhance maintenance and repair efforts. By examining a detailed schematic, users can identify parts, troubleshoot issues, and ensure their machine runs smoothly.

In this article, we will explore the intricate layout of the assembly, shedding light on each section and its significance. Whether you’re looking to replace a worn-out piece or simply want to gain a better understanding of your machine, this guide will provide valuable insights.

Understanding the John Deere Z425

The robust machine in question has become a staple for those seeking efficiency in their lawn care routines. With a design that emphasizes performance and ease of use, it caters to both homeowners and professionals alike. This equipment is celebrated for its durability and versatility, making it an ideal choice for maintaining expansive green spaces.

One of the key features of this mower is its innovative cutting system, which ensures a clean and precise finish. The integration of advanced technology enhances the overall experience, allowing users to tackle various terrains with confidence. Moreover, the ergonomic controls are designed to provide maximum comfort during operation, reducing fatigue even during extended periods of use.

Understanding the intricate components of this machinery is essential for effective maintenance and repair. Familiarity with the essential elements allows owners to ensure optimal performance and longevity. Regular inspections and timely replacements of worn parts contribute to maintaining the mower’s exceptional functionality.

In conclusion, mastering the nuances of this remarkable machine not only enhances the mowing experience but also ensures that your investment remains in peak condition for years to come. By staying informed about the key features and maintenance practices, users can fully leverage its capabilities for a beautifully manicured landscape.

Key Features of the Z425 Mower

This mower model stands out due to its advanced design and functionality, providing users with a robust and efficient mowing experience. With a blend of innovative technology and practical features, it caters to both residential and commercial needs, ensuring high performance in various conditions.

Performance and Efficiency

Engine power and cutting capabilities make this machine ideal for tackling various lawn types. Its efficient fuel consumption allows for extended operation without frequent refueling, making it a favorite among users.

User-Friendly Design

Ergonomically designed controls and comfortable seating enhance the operator’s experience, ensuring ease of use during extended periods. Maintenance accessibility is also prioritized, simplifying upkeep and ensuring longevity.

| Feature | Description |

|---|---|

| Engine Power | Strong engine performance for efficient cutting. |

| Cutting Width | Wide cutting deck for quick lawn maintenance. |

| Fuel Efficiency | Optimized for longer run times and less downtime. |

| Comfort | Ergonomic seating and intuitive controls. |

| Maintenance | Easy access for routine checks and repairs. |

Importance of Parts Diagrams

Understanding the intricate workings of machinery is essential for effective maintenance and repair. Visual representations of components allow users to identify specific elements quickly and accurately, enhancing the efficiency of service tasks. These illustrations serve as invaluable references, ensuring that every piece is accounted for during repairs or upgrades.

Enhanced Maintenance Efficiency

Accessing detailed visuals simplifies the maintenance process, enabling technicians to pinpoint issues without unnecessary delays. When every component is clearly labeled and illustrated, it reduces the likelihood of errors, leading to more successful repairs and prolonged equipment lifespan.

Facilitating Ordering and Replacement

Accurate illustrations assist in identifying necessary items for replacement, streamlining the ordering process. With a clear view of what is needed, users can avoid confusion and ensure they acquire the correct components, minimizing downtime and enhancing overall productivity.

Common Issues with Z425 Components

Every machine has its unique set of challenges, and the model in question is no exception. Understanding frequent complications associated with its elements can greatly enhance maintenance efficiency and prolong the equipment’s lifespan. From wear and tear to operational inefficiencies, various components may exhibit specific problems that need addressing.

One common issue involves the cutting blades, which may become dull over time, resulting in uneven grass cutting and increased strain on the engine. Regular inspection and sharpening are essential to maintain optimal performance.

The drive belt is another component prone to failure. Over time, it may wear out or break, leading to loss of power transmission. Keeping an eye on its condition and replacing it as needed can prevent sudden breakdowns.

Fuel delivery systems can also present challenges, particularly with clogs or leaks that affect engine performance. Regular maintenance, including fuel filter replacement, is critical to ensure smooth operation.

Finally, electrical connections may corrode or become loose, causing intermittent issues with starting or functionality. Periodic checks and cleaning of connectors can mitigate these problems, ensuring reliable performance.

Identifying Genuine John Deere Parts

Ensuring the quality and longevity of equipment relies heavily on the components used. Recognizing authentic replacements is essential for maintaining performance and safety. This section aims to guide users in differentiating between original and counterfeit items, promoting informed purchasing decisions.

Characteristics of Authentic Components

When seeking replacements, several features can help distinguish genuine items. Authentic components often exhibit superior craftsmanship, distinct branding, and proper packaging. Attention to these details can prevent costly mistakes.

Verification Methods

To confirm the authenticity of replacements, consider the following verification methods:

| Method | Description |

|---|---|

| Check Serial Numbers | Examine the serial numbers against manufacturer databases for authenticity. |

| Authorized Dealers | Purchase from certified retailers to ensure the quality and legitimacy of items. |

| Inspect Packaging | Look for professional packaging, which is often indicative of a genuine product. |

Maintenance Tips for Z425 Owners

Regular upkeep is essential for ensuring the longevity and optimal performance of your lawn care equipment. Implementing a few straightforward practices can significantly enhance efficiency and reduce the risk of costly repairs.

Routine Checks

- Inspect the blades for wear and tear. Sharp blades promote clean cuts and reduce strain on the engine.

- Check the air filter regularly. A clean filter ensures optimal airflow, improving engine performance.

- Examine the tires for proper inflation and tread wear. This enhances traction and overall handling.

- Monitor fluid levels, including oil and fuel. Regular changes can prevent engine damage and maintain efficiency.

Seasonal Maintenance

- Before the mowing season, give your equipment a thorough cleaning to remove debris and grass buildup.

- Sharpen or replace the cutting blades as needed to ensure a precise cut.

- In the fall, prepare for storage by draining fuel or using a stabilizer to prevent fuel degradation.

- Store the equipment in a dry, sheltered area to protect it from harsh weather conditions.

Where to Find Parts Diagrams

Locating detailed illustrations and schematics for equipment maintenance is essential for ensuring optimal performance and longevity. Whether you’re a professional technician or a DIY enthusiast, having access to these resources can significantly simplify the repair process and enhance your understanding of the machinery.

Official Manufacturer Resources

One of the most reliable sources for accurate schematics is the official website of the manufacturer. They often provide comprehensive manuals and visual guides specific to each model. These resources can be invaluable for identifying components and understanding assembly processes.

Online Forums and Communities

Engaging with online communities and forums dedicated to equipment maintenance can also yield fruitful results. Many users share their experiences, including links to visual resources and troubleshooting tips. These platforms foster collaboration and can lead to discovering hard-to-find illustrations that are helpful for repairs.

Step-by-Step Repair Guide for Z425

This section provides a comprehensive approach to fixing common issues with your machine. By following these structured steps, you can ensure that your equipment operates efficiently and reliably. Each phase includes essential tasks, tools needed, and tips for success.

-

Assess the Issue: Begin by identifying the problem. Look for signs of wear, unusual noises, or performance issues.

- Check fluid levels.

- Inspect belts and blades for damage.

- Listen for irregular sounds during operation.

-

Gather Necessary Tools: Ensure you have all required tools at hand before starting the repair process.

- Wrench set

- Screwdriver set

- Replacement parts (if needed)

-

Disassemble Components: Carefully take apart the affected areas to access internal parts.

- Remove any covers or shields.

- Label each component as you disassemble for easier reassembly.

-

Inspect and Replace Parts: Examine all parts for damage and replace any that are worn or broken.

- Look for cracks, tears, or excessive wear.

- Ensure replacements are compatible with your model.

-

Reassemble the Equipment: Once repairs are completed, carefully reassemble the machine.

- Follow your labels to put components back in the correct order.

- Tighten all fasteners securely.

-

Test the Equipment: Before putting the machine back to regular use, run a test to ensure everything functions correctly.

- Monitor for any unusual behavior.

- Check fluid leaks or other signs of trouble.

By adhering to these steps, you can effectively address and resolve issues with your machinery, ensuring it remains in peak operating condition.