Understanding the internal structure and functionality of agricultural machinery is essential for effective maintenance and repairs. This guide aims to provide a detailed look into the critical components of a widely-used farming machine, offering insights into how different elements work together to ensure optimal performance.

In this section, we will explore the main mechanical elements, focusing on their roles and connections within the equipment. By identifying and analyzing these elements, users can make informed decisions regarding replacements and upkeep, enhancing the longevity and efficiency of the machine.

With a clear understanding of these components, users will be able to easily address common issues and maintain their equipment in peak condition. This guide will serve as a valuable resource for anyone looking to optimize the operation and performance of their farming machinery.

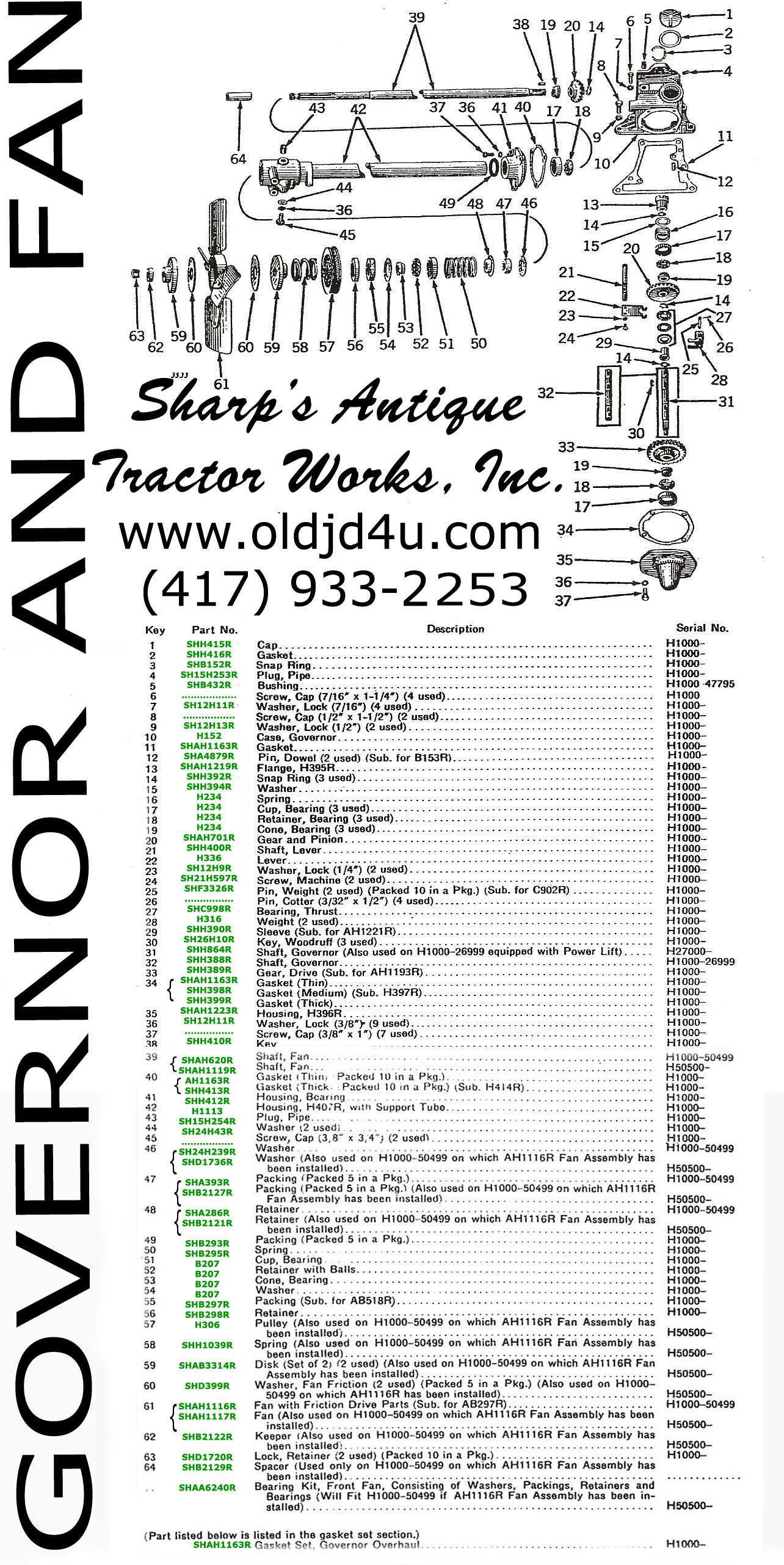

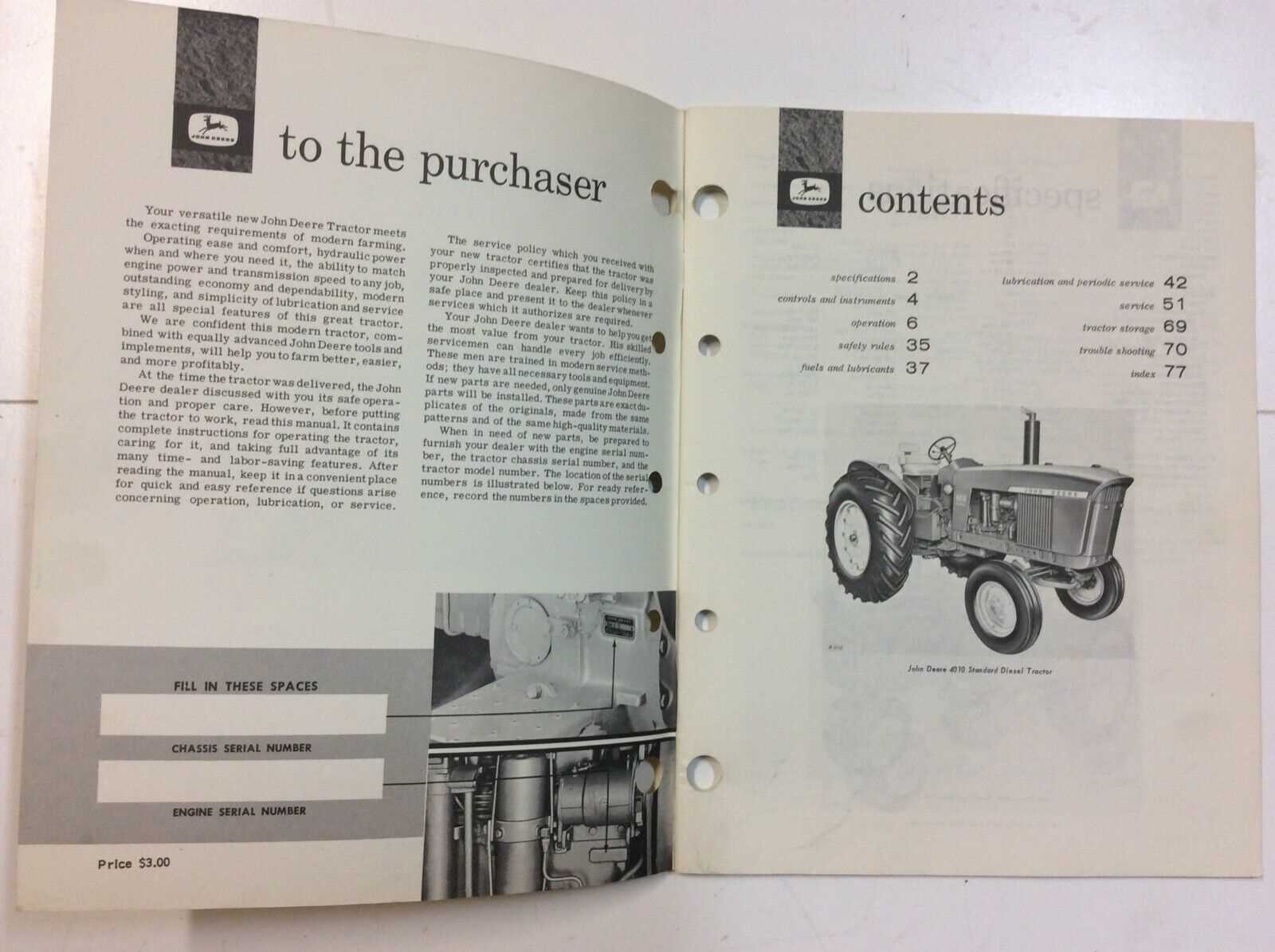

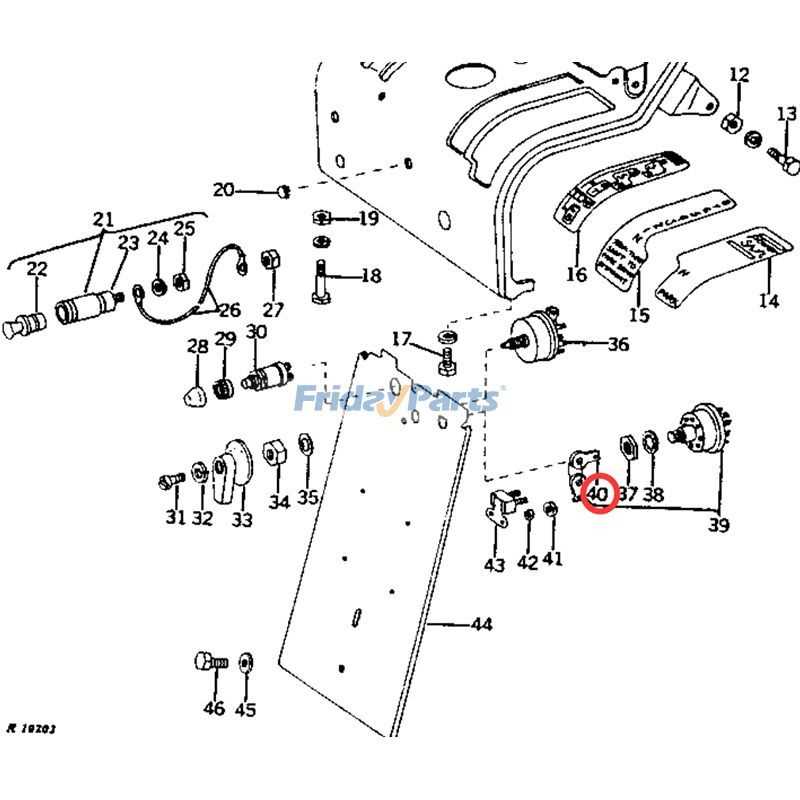

John Deere 4010 Parts Diagram

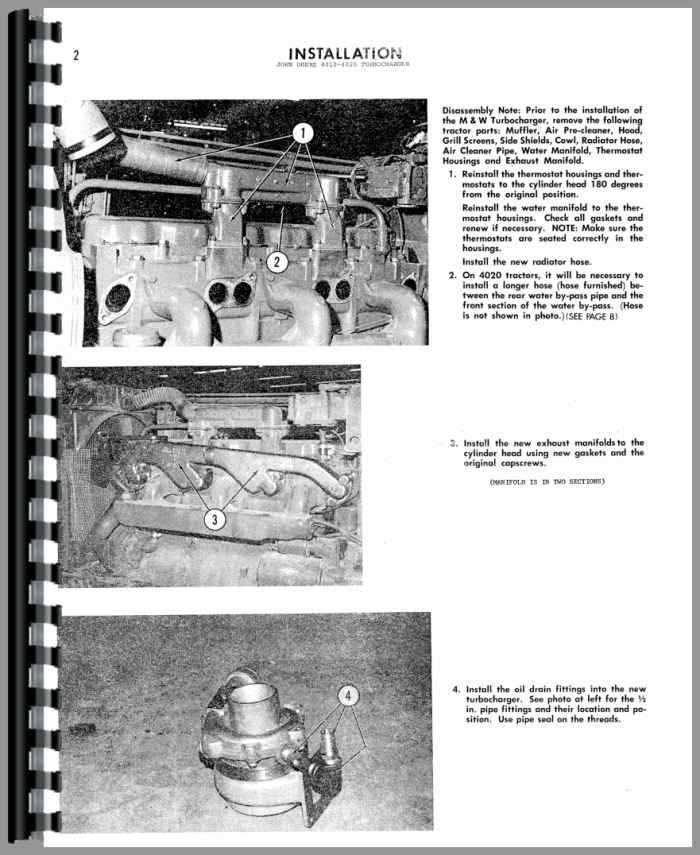

Understanding the detailed breakdown of machinery components is essential for effective maintenance and repair. The visual representation provides a clear guide to the location and connection of various elements, ensuring the correct identification and assembly during repair or replacement procedures. This structured overview allows users to navigate complex systems with ease, contributing to the smooth operation and extended lifespan of the equipment.

| Component | Description | Function |

|---|---|---|

| Engine | Main power unit | Provides energy for operation |

| Transmission | Gear system | Controls speed and torque |

| Hydraulics | Fluid power system | Enables lifting and movement |

| Axles | Structural shafts | Support and move the wheels |

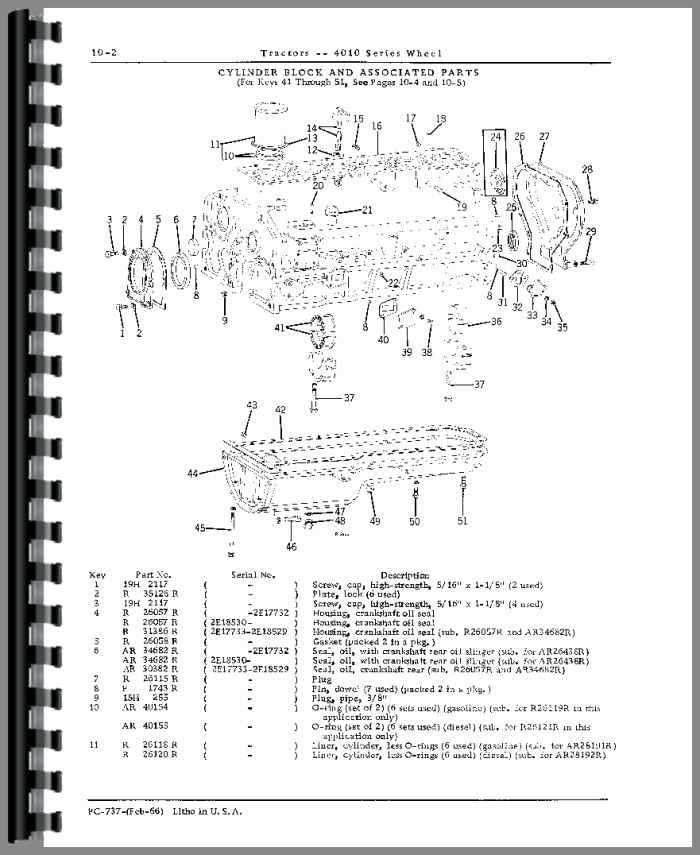

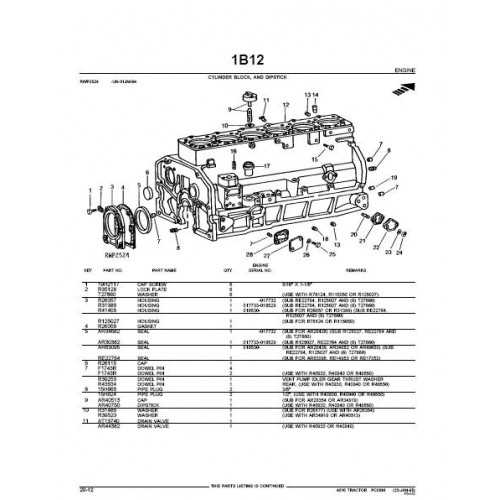

Overview of Key Engine Components

Understanding the primary components of an engine is essential for maintaining optimal performance and ensuring efficient operation. These elements work together to deliver the power needed to run various machinery and vehicles. Below is a summary of the most important components that make up a reliable and high-performing engine.

- Cylinder Block: The main structure that houses cylinders and other essential parts, providing stability and support for engine function.

- Pistons: Responsible for converting energy generated during combustion into mechanical force, driving the engine’s movement.

- Crankshaft: This part transforms the up-and-down motion of the pistons into rotational movement, allowing the machine to operate.

- Camshaft: Coordinates the timing of the engine’s valves, ensuring proper air intake and exhaust for smooth performance.

- Valves: Control the flow of air and fuel into the cylinders, as well as the expulsion of exhaust gases, playing a key role in the combustion process.

- Cooling System: Keeps the engine from overheating by circulating coolant, helping maintain a stable operating temperature.

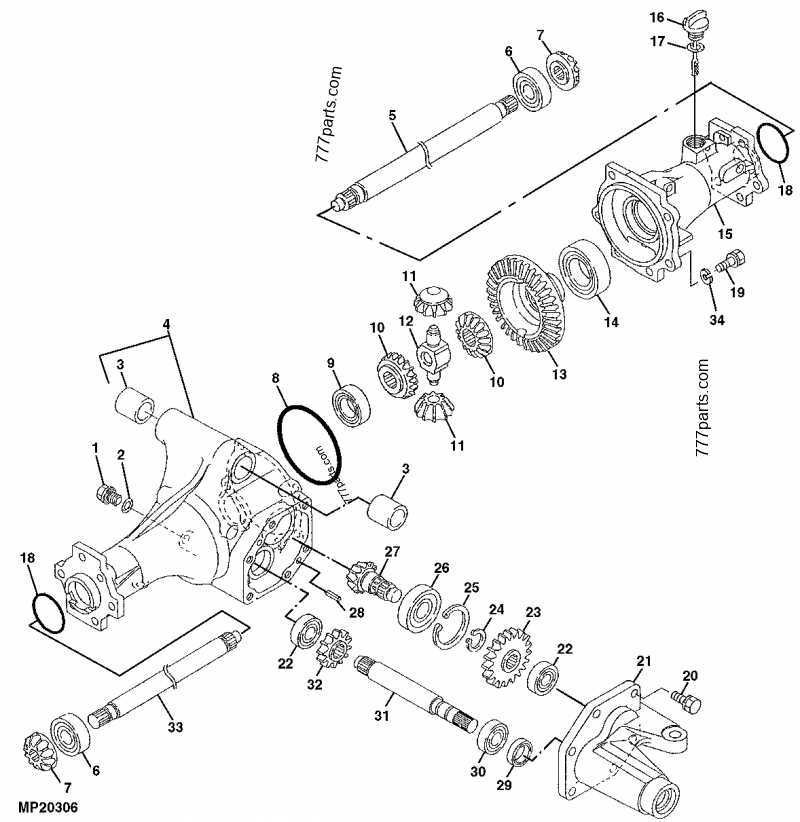

Transmission and Drivetrain Structure

The transmission and drivetrain system plays a crucial role in ensuring the efficient transfer of power from the engine to the wheels. This complex assembly is responsible for managing torque, enabling smooth gear shifts, and maintaining the overall performance of the machinery. Each component within the system must work in harmony to provide optimal traction and control under various conditions, making it essential for both agricultural and industrial use.

At the heart of this system, the transmission allows for the adjustment of speed and power, ensuring that the equipment operates at peak efficiency. Meanwhile, the drivetrain components facilitate the movement of power to the wheels, providing the necessary drive force. Together, these elements contribute to the machine’s ability to handle heavy workloads and maintain stability, regardless of the terrain.

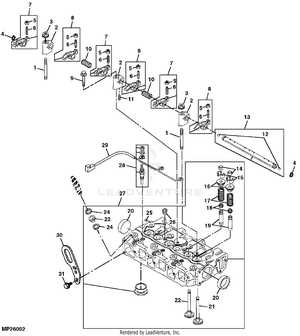

Hydraulic System Parts and Functionality

The hydraulic mechanism plays a crucial role in ensuring efficient operation by managing fluid pressure to perform various tasks. Understanding the key elements of this system helps in maintaining smooth functionality, ensuring that equipment remains operational and efficient. Each component works in harmony to deliver the necessary power to different parts of the machinery.

Main Components of the Hydraulic System

The core elements of the hydraulic setup include pumps, valves, and cylinders. These components control the flow and pressure of fluid within the system, ensuring proper movement and force distribution. Pumps generate the necessary flow, valves regulate this flow, and cylinders convert fluid pressure into mechanical movement.

System Maintenance and Efficiency

Proper upkeep of the hydraulic system is essential for maintaining performance. Regular inspection of fluid levels, seals, and filters prevents leaks and pressure drops, which can lead to reduced efficiency or damage. Ensuring all parts are in good condition enhances the reliability and lifespan of the system.

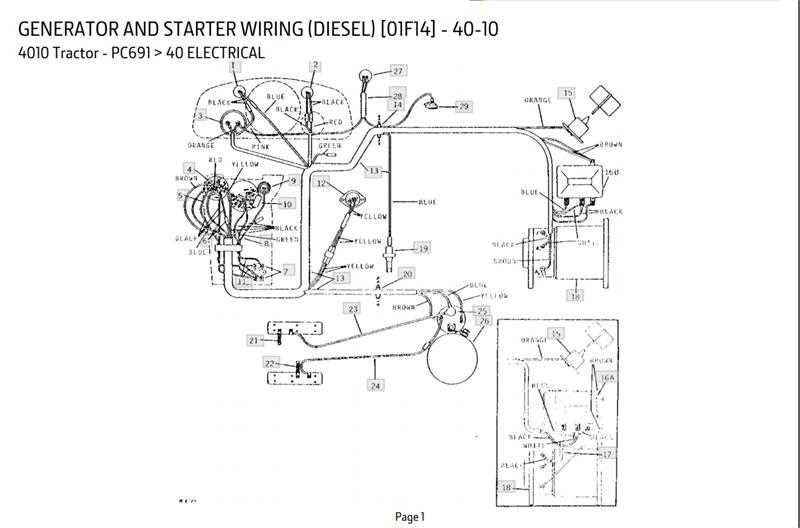

Electrical System Layout and Wiring

The electrical system in any equipment serves as the foundation for powering various components and ensuring smooth operation. A well-structured wiring layout minimizes potential issues and improves maintenance efficiency, providing a clearer path for current flow and protecting sensitive parts from overloading.

Understanding the layout and key connections within the system is essential for both troubleshooting and upkeep. Below is an overview of the primary elements of the wiring setup:

- Battery connection: The power source that supplies electricity to the entire system.

- Starter motor: Initiates the engine by converting electrical energy into mechanical movement.

- Alternator: Recharges the battery and supplies energy to other components during operation.

- Fuses and relays: These elements ensure safety by preventing overloads and short circuits.

- Grounding system: Provides a safe path for electrical discharge, preventing damage to the system.

Each component in the wiring network is interconnected to maintain efficient power distribution. Proper insulation and secure connections are vital to prevent energy loss and ensure reliable operation.

Fuel System Diagram and Components

The fuel system is a crucial aspect of any machinery, ensuring the efficient delivery of fuel to the engine. Understanding the various elements involved in this system can aid in effective maintenance and troubleshooting. This section will provide an overview of the key components that play a role in fuel management, their functions, and how they interact within the system.

Key Components

- Fuel Tank: Stores the fuel until it is needed by the engine.

- Fuel Pump: Moves fuel from the tank to the engine at the required pressure.

- Fuel Filter: Removes impurities and debris from the fuel before it reaches the engine.

- Fuel Injector: Delivers the precise amount of fuel into the combustion chamber.

- Fuel Lines: Transport fuel between the various components of the system.

Functionality Overview

The fuel system operates by drawing fuel from the tank through the pump. The pump pressurizes the fuel and sends it through the filter to eliminate contaminants. Once filtered, the fuel is injected into the engine’s combustion chamber, where it mixes with air and ignites to produce power. Regular maintenance of each component is essential to ensure optimal performance and longevity.

Brake System Assembly Breakdown

The brake system is a crucial component in ensuring the safety and functionality of machinery. It consists of various interconnected elements that work together to facilitate effective stopping and control. Understanding the assembly of this system is essential for proper maintenance and troubleshooting.

Components of the Brake System include the master cylinder, brake lines, and brake calipers. Each part plays a specific role in the overall operation. The master cylinder generates hydraulic pressure, which is transmitted through the brake lines to the calipers, enabling the application of braking force on the wheels.

Additionally, regular inspection and maintenance of the brake assembly are vital for optimal performance. Signs of wear, such as fluid leaks or diminished stopping power, should be addressed promptly to avoid potential hazards. Understanding the breakdown of the brake system can aid in identifying issues and ensuring safety in operation.

Steering and Suspension Diagram Explanation

The steering and suspension system plays a crucial role in ensuring stability and control for vehicles. This section delves into the components and functions of these systems, providing insight into their intricate designs and interactions. Understanding these elements is essential for maintaining optimal performance and safety.

Components of the Steering System

The steering mechanism comprises several key components, including the steering wheel, column, and gearbox. Each part contributes to the overall functionality, enabling precise navigation and control. A well-functioning steering system allows for smooth turning and maneuverability, essential for both safety and efficiency.

Suspension System Overview

The suspension system is designed to absorb shocks and maintain vehicle stability on various terrains. It consists of components such as springs, shock absorbers, and control arms. This system enhances ride quality by reducing vibrations and impacts, ensuring a comfortable driving experience. Proper maintenance of the suspension components is vital for prolonging their lifespan and ensuring the vehicle’s performance.

Maintenance Tips Based on Parts Diagram

Proper upkeep of machinery relies heavily on understanding its various components and their functions. Familiarity with the schematics allows operators to identify crucial areas requiring regular attention. By focusing on specific elements, one can enhance the efficiency and longevity of equipment.

- Regular Inspections: Conduct frequent checks on all critical components to ensure they are in optimal condition. Look for signs of wear or damage.

- Lubrication: Maintain a consistent schedule for lubrication of moving parts. This helps reduce friction and prevent premature wear.

- Cleaning: Keep all surfaces clean from dirt and debris. This can prevent blockages and ensure proper functioning of various systems.

- Parts Replacement: Be proactive in replacing worn or damaged components. Timely substitutions can prevent more significant issues down the line.

- Consultation: Refer to the visual representation of components to identify specific parts needing attention during maintenance routines.

By implementing these strategies, operators can ensure their equipment runs smoothly and efficiently, reducing downtime and enhancing productivity.