Exploring the intricate design of agricultural equipment is essential for effective maintenance and repair. A comprehensive overview of the various elements involved can significantly enhance operational efficiency and longevity of machinery.

Visual aids serve as invaluable resources for technicians and enthusiasts alike, providing clarity on the arrangement and functionality of different components. By examining these representations, one can easily identify each segment’s role within the entire system.

Moreover, accessing detailed illustrations helps streamline the repair process, allowing for quick and informed decision-making when it comes to replacements or adjustments. Understanding these details is key to achieving optimal performance and reliability in the field.

Understanding the John Deere 4200

This section aims to provide insights into a well-regarded compact utility vehicle known for its efficiency and reliability. It is essential for various agricultural tasks and offers a versatile approach to land management. Understanding its components and functionality can enhance its utility and longevity.

Key Features

- Compact design suitable for small to medium-sized operations

- Powerful engine delivering impressive performance

- Versatile attachment options for different tasks

- Efficient fuel consumption, making it economical

Common Applications

- Ground maintenance in residential and commercial properties

- Agricultural tasks such as plowing and tilling

- Landscaping and garden preparation

- Snow removal in winter conditions

By exploring these aspects, users can maximize the efficiency of this utility machine, ensuring it meets their operational needs effectively.

Key Components of the 4200 Model

This section explores the essential elements of a particular agricultural machine known for its efficiency and reliability. Understanding these components is crucial for maintaining optimal performance and longevity.

- Engine: The heart of the machinery, providing the necessary power for various tasks.

- Transmission: This system ensures smooth power transfer from the engine to the wheels, allowing for different speed options.

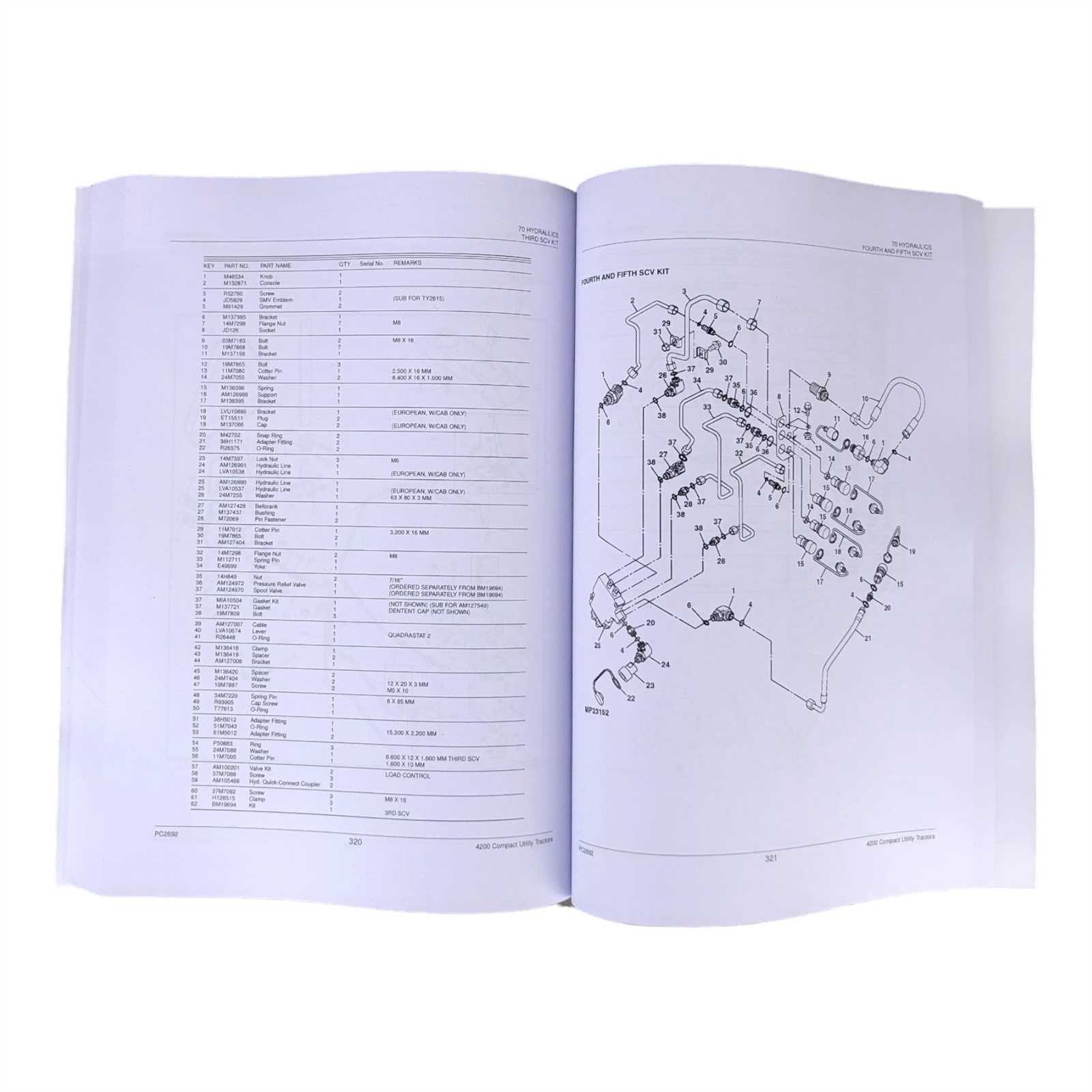

- Hydraulic System: Vital for operating attachments and implements, this system enables flexibility in various farming operations.

- Chassis: The framework that supports the entire structure, ensuring stability and strength under various conditions.

- Electrical System: This component powers essential features, including lights and ignition, playing a crucial role in overall functionality.

Understanding each of these elements helps users troubleshoot issues and perform maintenance effectively, ensuring the machine operates at its best.

Importance of Accurate Parts Diagrams

Precision in visual representations of components is crucial for efficient maintenance and repair of machinery. Accurate illustrations serve as a roadmap, guiding technicians through complex assembly processes and ensuring that each element is correctly identified and utilized. This clarity reduces the risk of errors and enhances the overall effectiveness of repair efforts.

Benefits of Detailed Illustrations

- Streamlined Repairs: Clear visuals facilitate quicker identification of required elements, leading to faster resolution of issues.

- Reduced Downtime: When technicians can easily access accurate references, machinery can be returned to operation more swiftly.

- Enhanced Safety: Correct identification of components minimizes the chance of mishandling or incorrect assembly, promoting a safer working environment.

Challenges with Inaccurate Representations

- Increased Errors: Misleading or unclear visuals can result in mistakes during repairs, potentially causing further damage.

- Wasted Resources: Incorrect parts ordering due to poor representation leads to unnecessary expenditures and delays.

- Frustration for Technicians: Ambiguities in illustrations can lead to confusion and inefficiencies in repair workflows.

Common Issues with 4200 Parts

When it comes to machinery maintenance, several frequent challenges can arise with specific components. Understanding these common problems can aid in effective troubleshooting and ensure optimal performance. Addressing these issues promptly can prevent further complications and enhance the longevity of the equipment.

Wear and Tear: Over time, various elements can experience significant deterioration due to regular use. This wear may lead to decreased efficiency and performance issues. Regular inspections can help identify early signs of damage.

Compatibility Problems: Utilizing incorrect components can result in malfunctioning systems. Ensuring that all parts are compatible with the overall machinery is crucial for seamless operation. Verification of specifications is essential before replacement.

Corrosion: Exposure to harsh environments can lead to rust and corrosion on metallic components. This can compromise structural integrity and performance. Implementing protective measures can mitigate these effects.

Misalignment: Proper alignment of moving parts is essential for smooth operation. Misalignment can cause excessive wear and increase the risk of mechanical failure. Regular adjustments and checks are recommended to maintain correct positioning.

Fluid Leaks: Leaks in hydraulic or lubrication systems can severely affect functionality. Identifying the source of leaks and addressing them swiftly can prevent further damage and maintain operational efficiency.

By being aware of these common issues, operators can take proactive measures to ensure their machinery remains in peak condition and minimizes unexpected downtime.

Where to Find Replacement Parts

Locating suitable components for machinery can be a crucial task for maintenance and repair. Several reliable sources exist that cater to enthusiasts and professionals alike, ensuring efficient functionality and longevity of equipment.

Here are some excellent options to consider:

| Source | Description |

|---|---|

| Manufacturer Websites | Official platforms often provide a comprehensive catalog of components specific to various models. |

| Online Retailers | Popular e-commerce sites stock a wide range of replacements, often with customer reviews for guidance. |

| Local Dealers | Authorized distributors can offer personalized service and may have inventory readily available. |

| Salvage Yards | Second-hand options can provide cost-effective alternatives, particularly for older machinery. |

| Forums and Communities | Online groups can be a treasure trove of information and suggestions for sourcing hard-to-find items. |

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to identify and acquire the necessary elements for machinery maintenance. These illustrations provide a clear layout, making it easier to navigate through complex assemblies.

To effectively interpret these visuals, follow these steps:

- Familiarize Yourself with Symbols: Learn the common icons and notations used in the illustrations, as they often represent specific functionalities.

- Identify Key Sections: Most representations are divided into segments; recognizing these will help you locate the desired components swiftly.

- Reference the Legend: Use the accompanying legend to understand the details regarding each item, including part numbers and descriptions.

- Follow the Flow: Observe how components interact with each other, as this will give insight into assembly and disassembly processes.

By mastering these techniques, you can delve deeper into machinery care and ensure the longevity of your equipment.

Maintenance Tips for the 4200

Regular upkeep is essential to ensure the longevity and optimal performance of your machinery. By adhering to a structured maintenance routine, you can prevent potential issues, enhance efficiency, and ultimately save on repair costs. This section outlines key practices to keep your equipment in top shape.

Routine Inspections

Conducting frequent inspections is crucial. Check for any signs of wear and tear, fluid leaks, or unusual noises. Pay special attention to critical components such as the engine, transmission, and hydraulic systems. Early detection of problems can lead to quicker resolutions and avoid extensive damage.

Fluid Management

Maintaining proper fluid levels is vital for the smooth operation of your machinery. Regularly check and change engine oil, coolant, and hydraulic fluid according to the manufacturer’s recommendations. Clean filters and ensure all seals are intact to prevent contamination and maintain optimal performance.

Emphasizing these maintenance practices will significantly contribute to the reliability and efficiency of your equipment, ensuring that it serves you well for years to come.

Upgrading Parts for Enhanced Performance

Improving machinery functionality often hinges on selecting superior components. By focusing on quality and compatibility, operators can significantly enhance overall efficiency and longevity. This approach not only boosts productivity but also contributes to more reliable operation, minimizing downtime and maintenance costs.

Choosing Quality Components

Investing in high-grade materials and advanced technology can transform performance levels. Whether it’s through precision-engineered elements or innovative features, prioritizing quality ensures that each upgrade brings measurable benefits. Researching reputable suppliers and examining user reviews can guide decision-making, helping to identify the most effective enhancements.

Compatibility and Installation

Ensuring that new components fit seamlessly with existing systems is crucial. Compatibility affects both functionality and safety, making it vital to verify specifications before making a purchase. Professional installation might be necessary for complex upgrades, guaranteeing that all modifications are implemented correctly and efficiently for optimal results.

Customer Reviews and Experiences

Feedback from users provides invaluable insights into the reliability and performance of machinery components. Customers often share their satisfaction with durability, ease of maintenance, and overall functionality. This section highlights personal stories that reflect the experiences of various individuals in their use of these essential tools.

Many users have noted that high-quality components significantly enhance the efficiency of their equipment. One user mentioned, “The upgrades made a noticeable difference in performance, allowing for smoother operations.” Such testimonials underscore the importance of selecting superior components.

Others have expressed appreciation for the availability of replacement options. As one reviewer stated, “Finding the right replacements was straightforward, and they fit perfectly.” This accessibility is crucial for maintaining optimal performance and reducing downtime.

In conclusion, user reviews not only highlight positive experiences but also serve as a guide for potential buyers, emphasizing the benefits of investing in reliable components for improved productivity.