When it comes to outdoor upkeep, knowing the internal makeup of your gardening tools can make a significant difference in maintaining them properly. Familiarity with the individual components allows users to diagnose issues and ensure that each piece is functioning optimally. This understanding helps keep everything running smoothly and extends the life of the machinery.

In this guide, we’ll explore how various elements within these devices interact and what role they play in the overall operation. With this knowledge, you will be better equipped to handle repairs or adjustments, ensuring your equipment remains in top condition season after season.

Whether you’re performing regular maintenance or fixing a specific issue, having a clear view of the internal structure is essential. Understanding the arrangement of each component enables quick troubleshooting and improves overall efficiency during repairs.

Understanding the Craftsman Walk Behind Trimmer

The machine you’re working with is designed to tackle large areas of grass and weeds efficiently. Its powerful engine and cutting system make it ideal for maintaining expansive outdoor spaces where regular tools might not be sufficient. The structure is built for easy maneuverability, offering an effective way to trim overgrown areas with minimal effort.

Main Features

This equipment includes several key components that contribute to its functionality. Its ergonomic design ensures comfortable use over extended periods, while the sturdy build guarantees longevity. The cutting mechanism is engineered to handle dense vegetation, delivering precise results on uneven terrain.

Key Components Overview

| Component | Description | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cutting Mechanism | High-performance system designed to slice through thick grass and weeds effortlessly. | |||||||||||||||||||

| Engine | A robust engine that provides the necessary power to keep the machine running smoothly even in tough conditions. | |||||||||||||||||||

| Frame | Durable construction that ensu

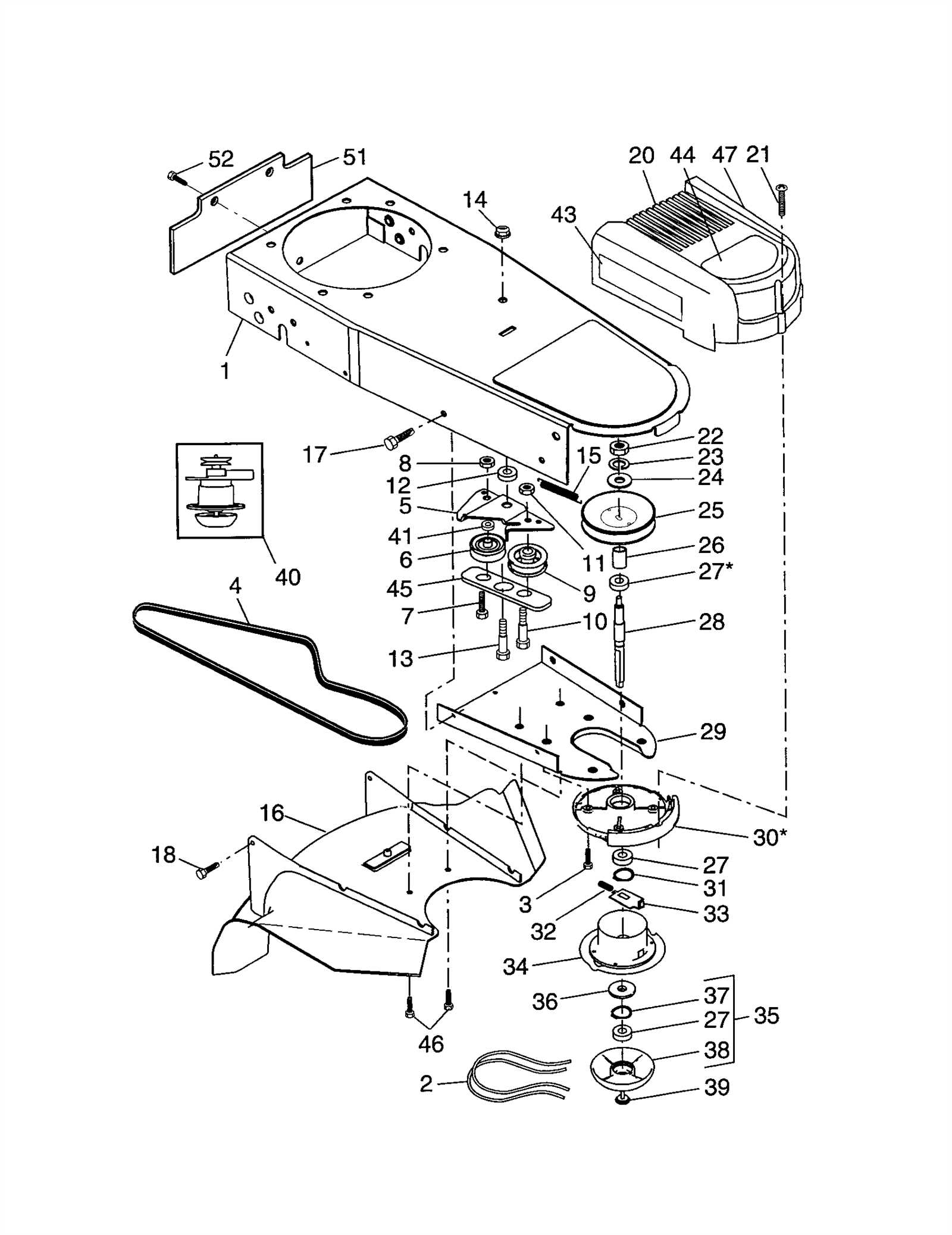

Key Components of the Trimmer System

Understanding the essential elements of a grass-cutting device is crucial for proper operation and maintenance. Each part plays a vital role in ensuring efficient and safe performance. This section provides an overview of the main components that make up the core structure, enabling effective cutting and control during use.

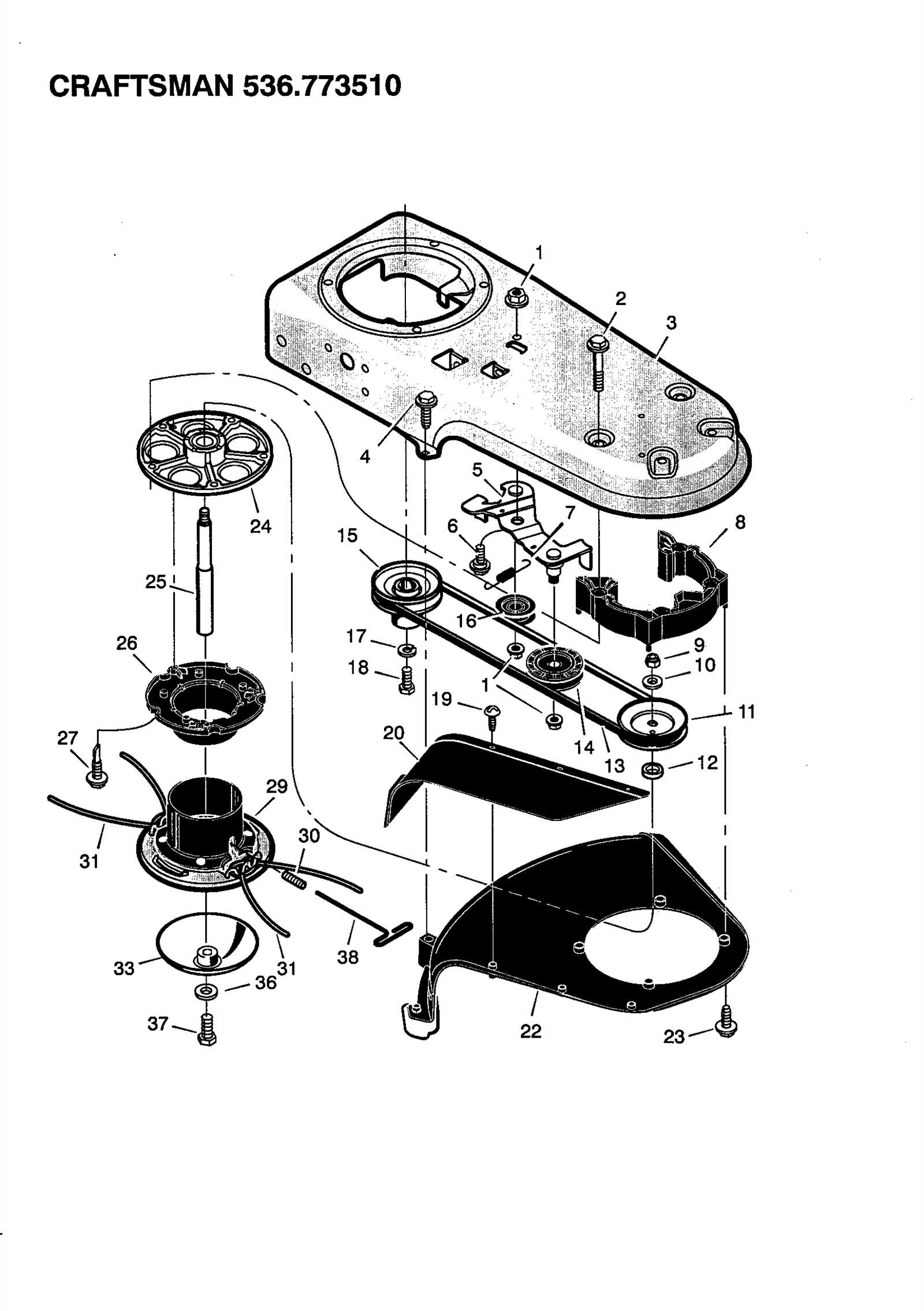

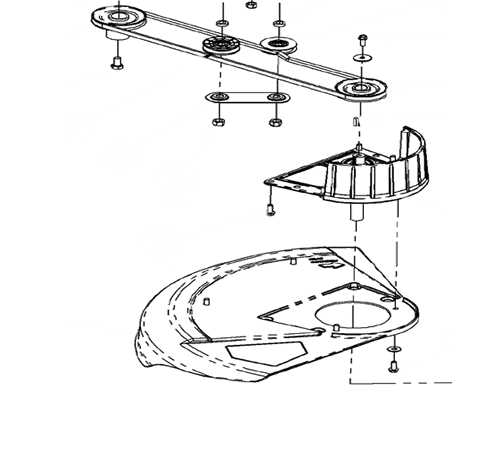

Detailed View of the Cutting Mechanism

The cutting mechanism is designed for efficient and precise trimming. It consists of various interlocking components that work in harmony to ensure clean, even cuts. Understanding how each part operates can help improve both performance and longevity of the equipment. Below is an overview of the primary elements involved in the cutting process.

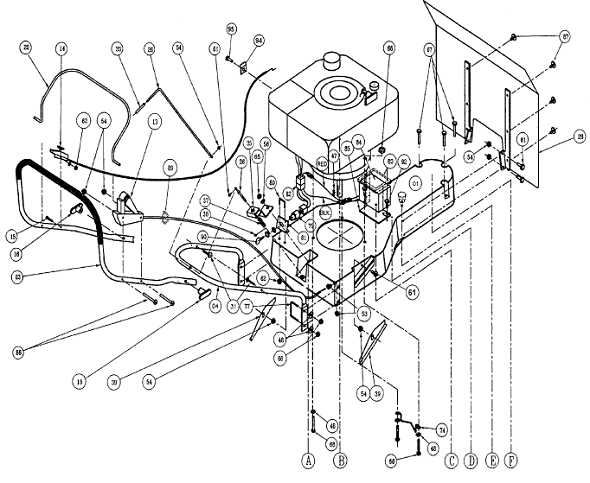

Each of these elements plays a crucial Exploring the Engine and Drive Assembly

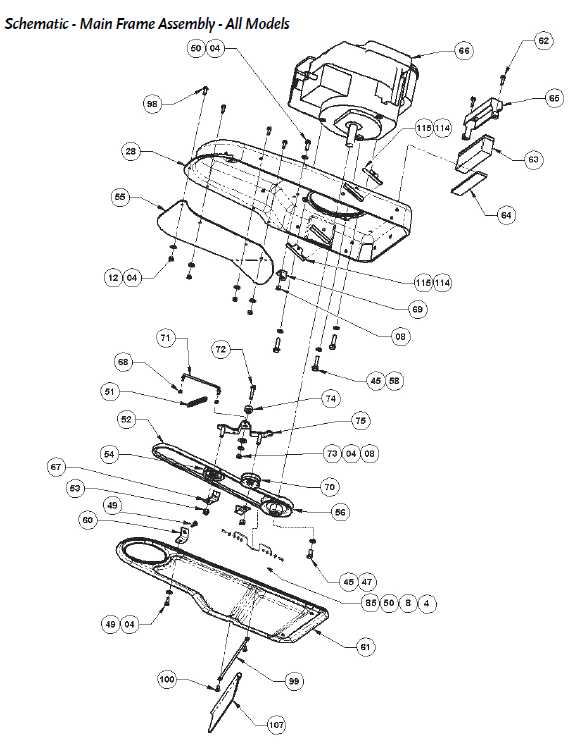

The engine and drive system play a crucial role in ensuring smooth and reliable performance. These components work in unison to provide the necessary power and motion, driving the machine through various terrains and tasks. Understanding how these systems function can help you maintain and troubleshoot your equipment effectively, ensuring it operates efficiently for extended periods. Key Components of the Engine

The motor is the heart of the device, responsible for generating the necessary force to propel the machine. It includes key elements like the cylinder, spark plug, and the fuel system, all of which contribute to the energy output. Regular checks of the fuel and ignition systems ensure optimal functioning and prevent issues. The Drive Mechanism

The drive assembly transfers power from the engine to the wheels, allowing the equipment to move seamlessly. This system includes gears, belts, and pulleys that work together to distribute force efficiently. Proper tension in the belts and alignment of the gears is essential for smooth operation, reducing wear and tear on the How the Handle and Controls Function

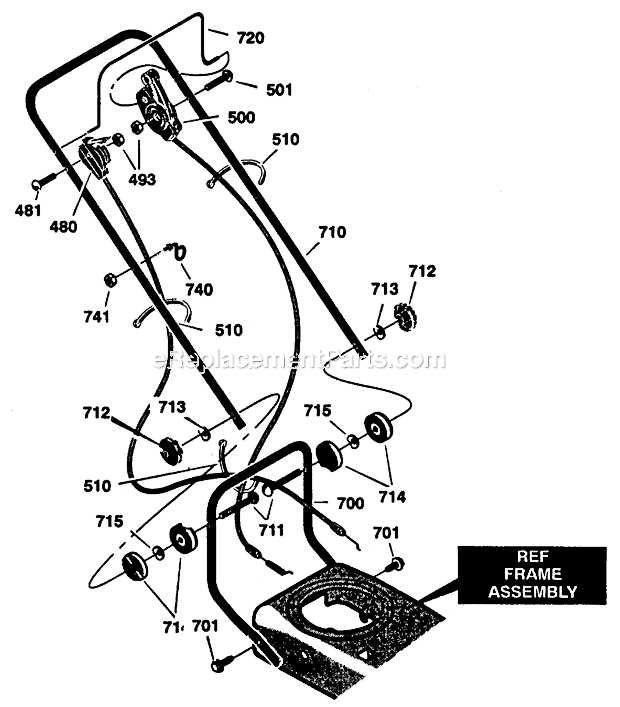

The handle and control mechanisms play a crucial role in providing ease of use and ensuring safety during operation. These elements are designed to offer the operator full command over the equipment, allowing for smooth maneuverability and efficient performance. Understanding the layout and purpose of each control feature is essential for proper handling.

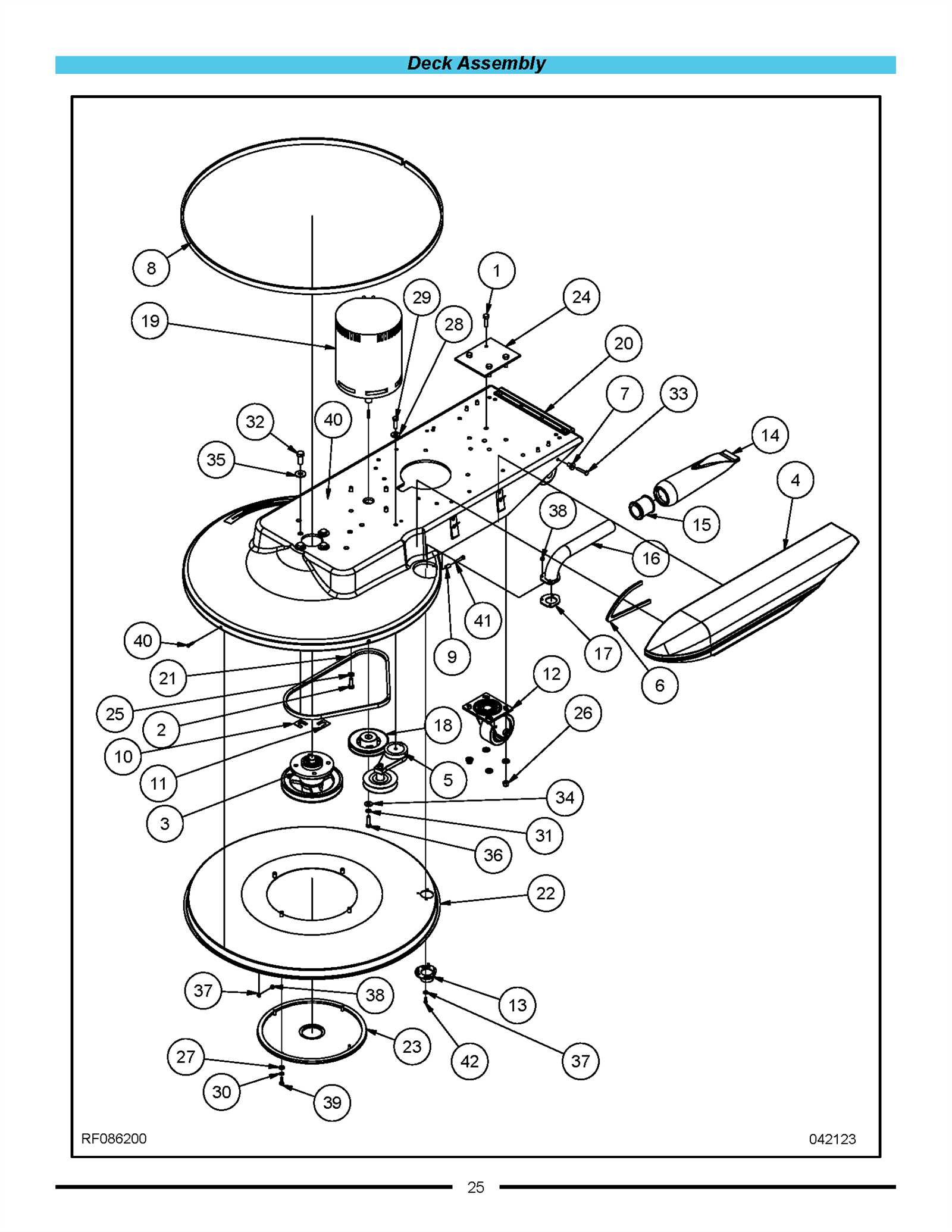

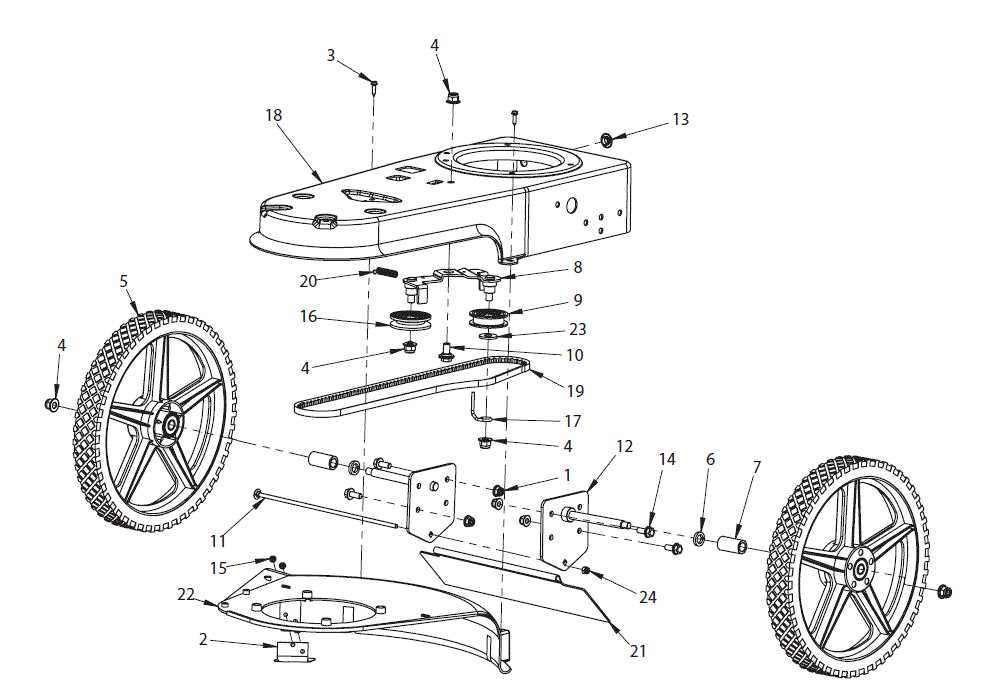

By mastering these elements, operators can work more efficiently while minimizing fatigue and improving overall control over the equipment. Guide to the Wheel and Frame Structure

The wheel and frame assembly plays a crucial role in ensuring the overall stability and maneuverability of the machine. This section outlines the essential components involved in providing support, balance, and ease of movement during operation. Understanding these elements is important for maintaining optimal performance and safety. Main Wheel Components

The wheels are responsible for facilitating smooth movement across various terrains. They are typically attached to axles, allowing for rotation. The material and size of the wheels influence the level of traction and ease of use, especially on uneven surfaces.

|