In the world of mobile living, having a thorough comprehension of the mechanisms that facilitate the extension and retraction of living spaces is essential. These systems enhance the functionality and comfort of recreational vehicles, allowing for a seamless transition between compact travel and spacious living. Grasping how these elements operate is key to ensuring their longevity and reliability.

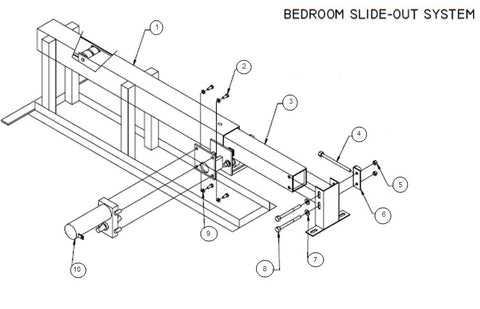

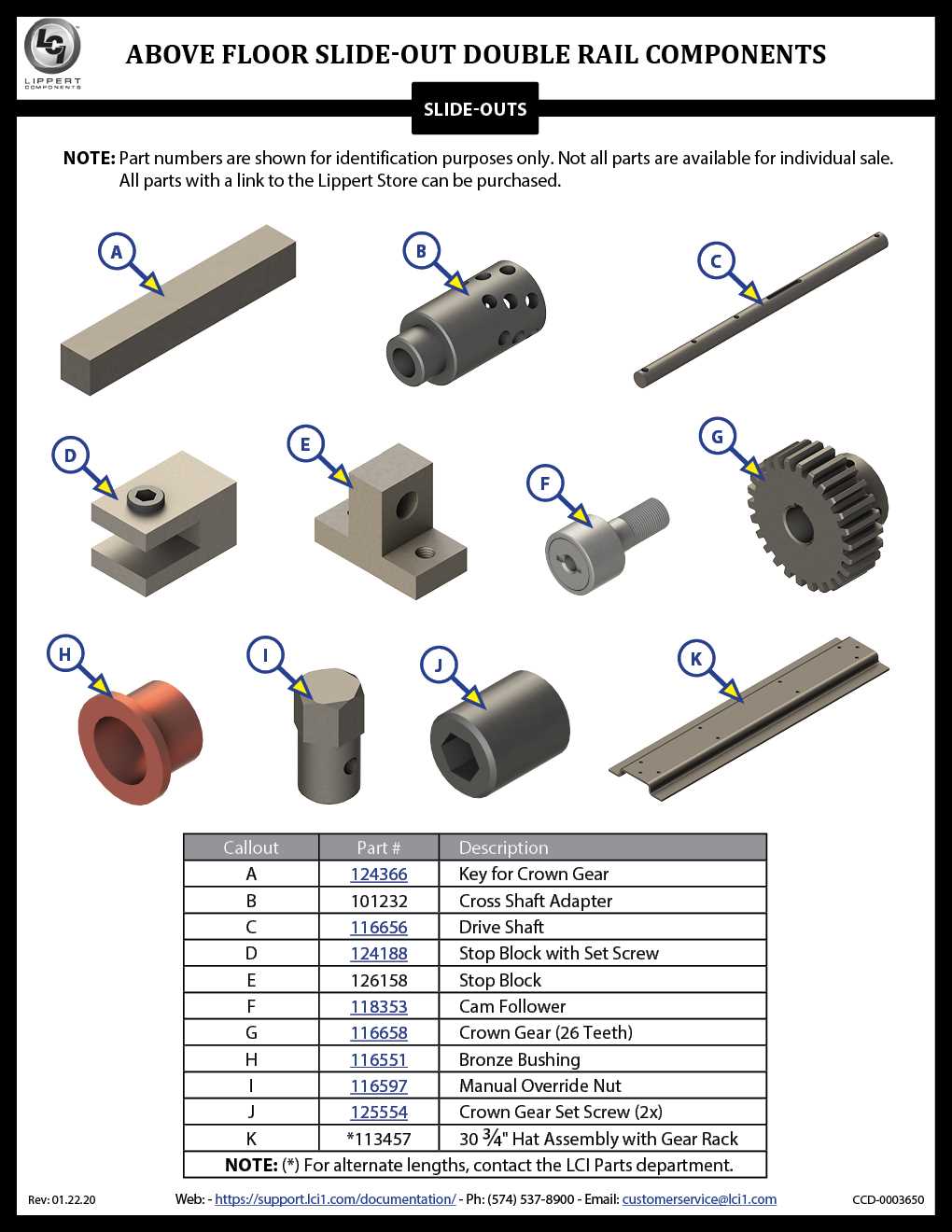

Essential to any functioning system are the individual components that work in harmony to achieve the desired movement. Familiarity with the layout and role of each element is crucial for maintenance and troubleshooting. This knowledge empowers users to effectively manage any issues that may arise, leading to a more enjoyable experience.

Moreover, understanding these mechanisms contributes to informed decision-making when it comes to repairs or upgrades. By recognizing the interplay between different elements, enthusiasts can make choices that enhance performance and reliability, ultimately improving their overall experience on the road.

This section will explore the fundamental concepts and components involved in the operation of extendable systems used in various applications. By delving into the intricacies of these mechanisms, we aim to provide a comprehensive overview that will enhance understanding of their functionality and design.

1. Introduction to Extendable Mechanisms

Extendable mechanisms are widely utilized in different industries, facilitating movement and adaptability. They are crucial in enhancing space and improving efficiency.

2. Basic Components of Extendable Systems

- Structural Framework

- Actuators

- Control Systems

- Support Structures

3. Functionality of Each Component

Understanding how each component interacts is vital for grasping the overall system’s operation. Each part plays a specific role in ensuring seamless movement and stability.

4. Common Issues and Troubleshooting

- Identifying Mechanical Failures

- Recognizing Electrical Problems

- Maintenance Tips for Longevity

5. Innovations in Extendable Technology

Advancements in technology have led to enhanced performance and efficiency in these systems. New materials and designs contribute to greater reliability.

6. Safety Considerations

- Understanding Load Limits

- Proper Installation Guidelines

- Regular Inspection Routines

7. Future Trends in Mechanisms

As technology evolves, so do the systems used for extension and retraction. The future promises even more sophisticated solutions to enhance user experience and functionality.

8. Conclusion

Grasping the core concepts and components involved in extendable mechanisms is essential for effective utilization and maintenance. This knowledge empowers users to make informed decisions and enhance system performance.

Components of Slide-Out Systems

Understanding the essential elements of extension mechanisms is crucial for ensuring smooth operation and reliability. These systems consist of various components that work in unison to facilitate seamless movement and stability. Each element plays a significant role in the overall functionality, making it imperative to comprehend their specific purposes and interrelations.

| Component | Description |

|---|---|

| Frame | The structural framework that supports the entire assembly and provides stability. |

| Track | A guide that allows smooth lateral movement of the extension, ensuring proper alignment. |

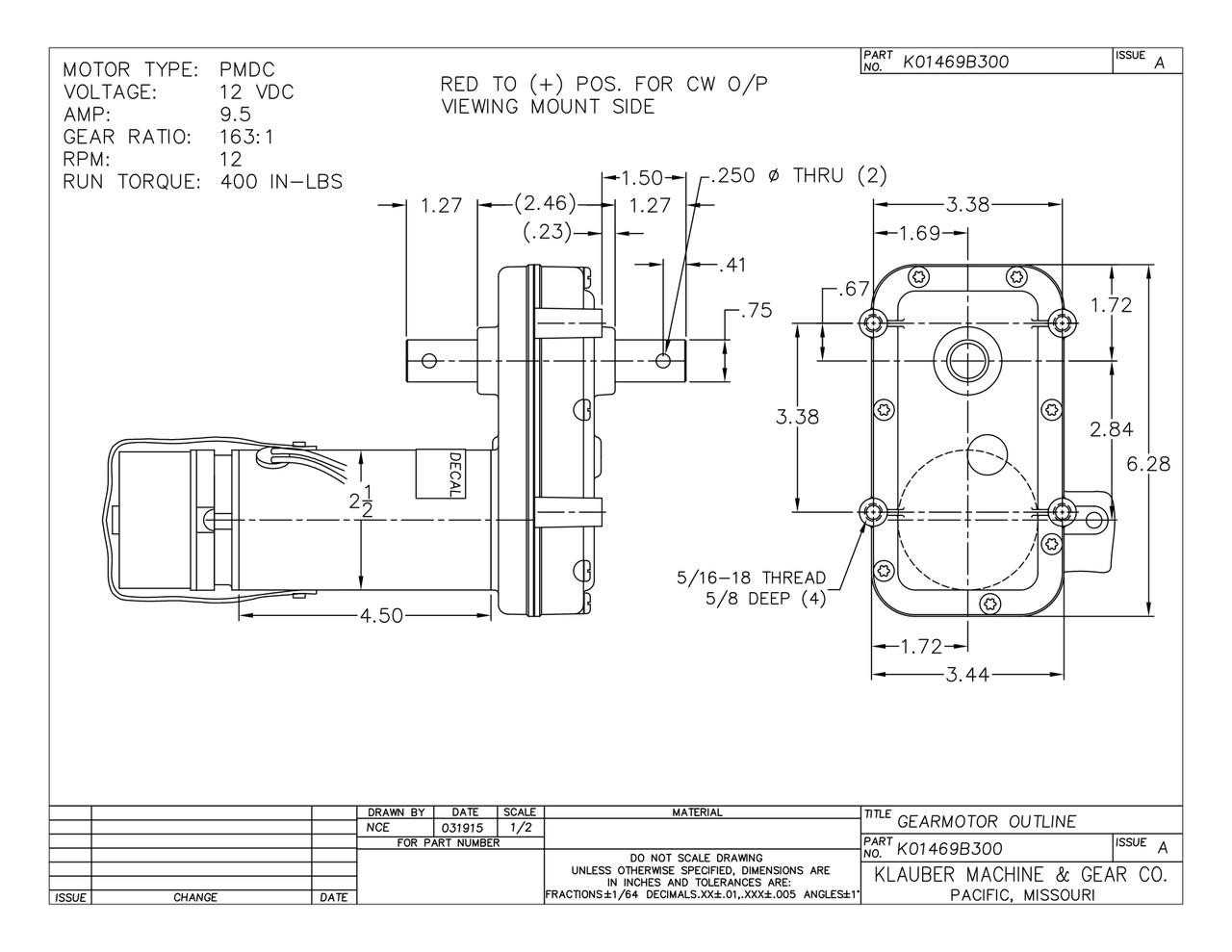

| Motor | The driving force that powers the mechanism, enabling the movement of the assembly. |

| Control System | The interface that allows users to operate the extension, often equipped with safety features. |

| Supports | Stabilizers that maintain the position of the extension while in use, preventing unwanted movement. |

Maintenance Tips for Slide-Out Parts

Regular upkeep is essential for ensuring the longevity and functionality of extending mechanisms in recreational vehicles. By adhering to simple maintenance practices, users can avoid common issues and enhance performance.

Routine Inspection

Conducting frequent checks is vital. Look for signs of wear or damage, which may indicate the need for repairs. Pay attention to the following:

- Examine seals and weather stripping for cracks or degradation.

- Inspect the extension mechanism for any obstructions or misalignments.

- Check the framework for rust or corrosion.

Lubrication and Cleaning

Keeping the mechanisms clean and lubricated is key to smooth operation. Consider these steps:

- Use a soft cloth to wipe away dirt and debris from moving components.

- Apply an appropriate lubricant to joints and tracks, ensuring even distribution.

- Remove excess lubricant to prevent attracting dirt.

Common Issues with Power Gear

Many users encounter various challenges when utilizing their retractable mechanisms. Understanding these common difficulties can help in diagnosing and addressing problems effectively. Below are some prevalent issues faced by users, along with potential solutions.

- Inconsistent Movement: The extension and retraction may not function smoothly, often resulting in jerky motions or complete failure to operate.

- Noise During Operation: Unusual sounds can indicate underlying mechanical issues or the need for lubrication.

- Stalling: Mechanisms may stop abruptly, preventing proper extension or retraction.

- Electrical Failures: Power interruptions or faulty connections can hinder the system’s functionality.

- Physical Obstructions: Objects obstructing the path can prevent the system from working correctly.

Regular maintenance and timely interventions can help mitigate these issues, ensuring a smooth and reliable operation of the retractable systems.

Installation Guide for Slide-Out Mechanisms

This section outlines the essential steps for installing extending mechanisms in various applications. Proper installation is crucial for ensuring smooth operation and long-term reliability of the system.

Follow these guidelines to achieve a successful setup:

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and components before starting the installation. |

| 2 | Carefully read the manufacturer’s instructions to familiarize yourself with the mechanism. |

| 3 | Ensure the mounting area is clean and free of any obstructions. |

| 4 | Align the mechanism according to the specifications provided in the documentation. |

| 5 | Secure all bolts and screws, ensuring everything is tightened adequately. |

| 6 | Test the operation of the mechanism to confirm it extends and retracts smoothly. |

By following these steps, you can ensure that the extending mechanism is installed correctly, providing reliable performance for your needs.

Safety Considerations for Slide-Outs

Ensuring safety during the operation of extendable components in vehicles is crucial. These mechanisms can enhance living space but also present risks if not managed properly. Awareness and adherence to safety guidelines can prevent accidents and ensure a secure experience for all users.

Regular Maintenance

- Inspect mechanisms for wear and tear periodically.

- Lubricate moving parts to prevent friction and ensure smooth operation.

- Check electrical connections and wiring for signs of damage.

Operational Guidelines

- Always ensure the area around the extension is clear of obstacles.

- Verify that the ground is stable and level before extending.

- Do not allow children to play near the moving parts during operation.

Benefits of Regular Maintenance

Consistent upkeep of equipment is essential for ensuring longevity and optimal performance. By regularly inspecting and servicing mechanisms, owners can prevent minor issues from escalating into major failures, thus saving both time and resources.

Enhanced Performance

Routine maintenance helps in keeping the machinery functioning at its best. Regular checks can identify inefficiencies, allowing for timely adjustments that enhance overall effectiveness. This not only improves operation but also contributes to a smoother user experience.

Cost-Effectiveness

Investing in consistent care reduces the likelihood of unexpected breakdowns, which can be costly. Addressing potential problems before they arise minimizes repair expenses and extends the lifespan of the equipment. As a result, users can enjoy greater peace of mind and lower operational costs.

How to Identify Faulty Parts

Determining malfunctioning components in your system is crucial for maintaining optimal functionality. Recognizing these elements can prevent further damage and ensure seamless operation. By paying attention to certain signs and employing effective evaluation techniques, you can pinpoint the problematic areas.

Signs of Malfunction

Several indicators may suggest that a component is not functioning as it should. Common symptoms include unusual noises, erratic movements, and inconsistent performance. Regular inspections can help you detect these issues early. Look for signs of wear, such as cracks or corrosion, which can compromise the integrity of the mechanism.

Evaluation Techniques

To assess the condition of each element, consider using diagnostic tools that can measure performance metrics. Testing for continuity and resistance can reveal whether a part is operating correctly. Additionally, consulting your system’s manual can provide valuable insights into the expected behaviors of each component, making it easier to identify discrepancies.

Upgrading Your Slide-Out Components

Enhancing the functionality of your extendable sections can significantly improve your overall experience. By replacing or upgrading specific elements, you can achieve better performance, reliability, and comfort during use. This process often involves identifying key components that can benefit from modern technology or superior materials.

When considering an upgrade, it is essential to focus on the most critical components that affect operation and durability. Here are some common elements that may require attention:

| Component | Description | Benefits of Upgrading |

|---|---|---|

| Seals | Weatherproof barriers that prevent moisture intrusion. | Improved insulation and protection from leaks. |

| Mechanisms | Systems that facilitate movement in and out. | Smoother operation and reduced wear and tear. |

| Control Systems | Electronic or manual devices that manage functionality. | Enhanced convenience and automation options. |

| Support Structures | Frames and braces that provide stability. | Increased strength and longevity under stress. |

Each of these areas offers potential improvements that can lead to a more enjoyable and trouble-free experience. Consider the specific needs of your system and evaluate which upgrades will yield the best results for your situation.