Maintaining the efficiency of your lawn equipment is essential for achieving a pristine outdoor space. This section delves into the various elements that make up the cutting apparatus, ensuring that you have a comprehensive understanding of each component’s role. Knowledge of these integral parts enhances your ability to diagnose issues and carry out repairs effectively.

Identifying individual components is crucial for anyone looking to enhance their machinery’s performance. Familiarizing yourself with the specific functions and arrangements of these items can lead to more informed maintenance practices. Proper care not only extends the lifespan of your equipment but also ensures optimal functionality.

Furthermore, having access to clear representations of these elements aids in visualizing their interconnections. Such insights empower users to manage their tools with confidence, paving the way for a more enjoyable and productive experience. Embrace the opportunity to learn about these vital components and elevate your lawn care routine.

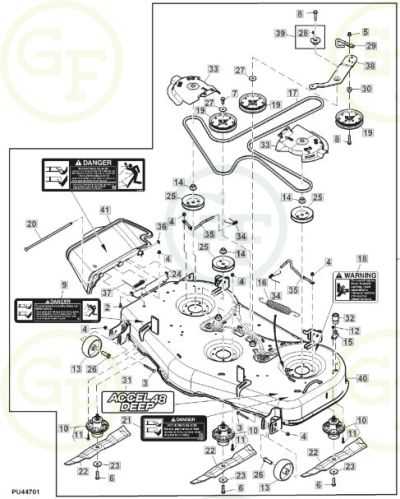

Understanding the 48 Edge Mower Deck

This section provides insights into a specific cutting assembly designed for effective grass management. It encompasses various components that work in harmony to achieve optimal performance and longevity. By familiarizing oneself with these elements, users can enhance their maintenance practices and ensure the equipment operates efficiently.

At the heart of this assembly lies a robust structure, engineered for durability and precision. Each component plays a crucial role in delivering a clean and even cut. Regular inspection and understanding of these features can prevent wear and improve overall functionality. Additionally, recognizing the significance of each part aids in troubleshooting common issues that may arise during operation.

Furthermore, maintaining this assembly not only prolongs its lifespan but also contributes to achieving the best results in lawn care. Employing appropriate care techniques, such as cleaning and timely replacements, ensures that the equipment remains in top condition, ultimately enhancing the user experience.

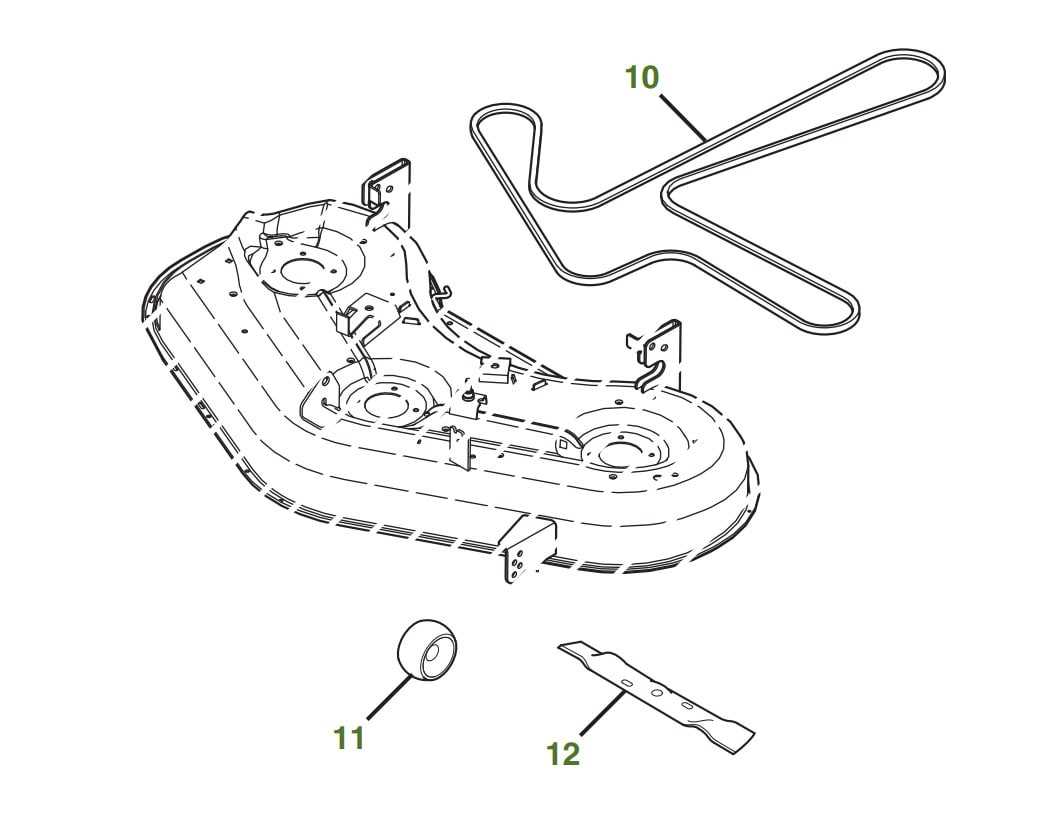

Key Components of the Mower Deck

The efficiency and performance of a cutting apparatus rely heavily on its integral elements. Understanding these crucial components is essential for effective maintenance and operation. Each part plays a vital role in ensuring optimal functionality and achieving a pristine lawn finish.

Cutting Blades

Blades are the primary tools responsible for executing the cutting action. Their design and sharpness directly influence the quality of the cut, making regular inspection and sharpening essential for maintaining effectiveness.

Spindles and Bearings

The spindles house the bearings that allow the blades to rotate smoothly. Proper lubrication and maintenance of these components are crucial to prevent wear and ensure longevity, which ultimately affects the cutting performance.

Assembly Process for Replacement Parts

When it comes to restoring equipment functionality, understanding the reassembly procedure for new components is essential. This section outlines the systematic approach to ensure optimal integration of new elements, enhancing performance and longevity.

Follow these steps for a successful assembly:

- Gather necessary tools and components to ensure a smooth process.

- Begin by clearing the work area, providing ample space for assembly.

- Refer to the manufacturer’s specifications to understand the required components and their arrangement.

- Start with the installation of the main assembly, ensuring that it is securely positioned.

- Progress to attaching secondary components, verifying alignment and tightness at each stage.

- Once all elements are in place, perform a thorough inspection to confirm correct installation.

- Finally, conduct a functional test to ensure everything operates as intended.

By adhering to this structured approach, users can facilitate a seamless transition from old to new, promoting efficiency and reliability in equipment operation.

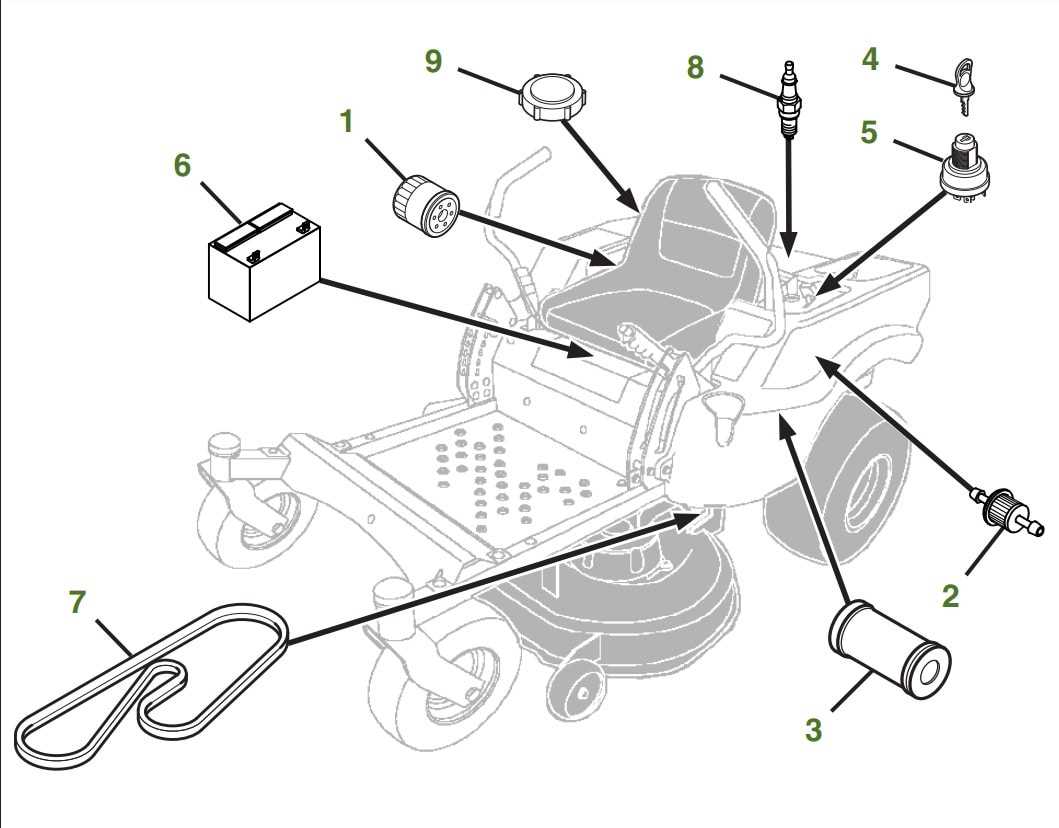

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires consistent care and attention. Regular upkeep not only enhances performance but also prevents potential issues that could lead to costly repairs. Implementing best practices can significantly improve operational efficiency and extend the lifespan of your machinery.

Here are essential maintenance suggestions to keep your system running smoothly:

| Task | Frequency | Description |

|---|---|---|

| Clean Components | After each use | Remove debris and dirt from all surfaces to prevent buildup and corrosion. |

| Inspect Belts and Cables | Monthly | Check for wear, fraying, or damage to ensure optimal tension and functionality. |

| Sharpen Blades | Every 20-25 hours | Keep blades sharp for effective cutting performance and to reduce strain on the engine. |

| Change Oil | Every season | Replace engine oil to ensure proper lubrication and prevent overheating. |

| Check Tire Pressure | Bi-weekly | Maintain correct tire pressure for stability and improved traction during operation. |

| Replace Air Filter | Every season | Ensure clean air intake for efficient engine performance. |

By adhering to these recommendations, you can achieve optimal functionality and reliability from your equipment, ultimately saving time and resources.

Common Issues and Troubleshooting Guide

This section addresses frequent challenges encountered with lawn maintenance equipment and offers practical solutions. Understanding these common problems can help in maintaining optimal performance and prolonging the life of the equipment.

Identifying issues early can prevent further complications. Below are some typical problems and their troubleshooting steps:

| Issue | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Uneven Cutting | Incorrect height adjustment | Check and adjust the cutting height on all sides to ensure they are level. |

| Excessive Vibration | Damaged or unbalanced blades | Inspect blades for wear or damage and replace or sharpen as necessary. |

| Engine Won’t Start | Fuel issues | Check fuel level and ensure it is fresh. Inspect fuel lines for leaks or clogs. |

| Clogged Chassis | Debris accumulation | Clean under the equipment and remove any accumulated grass or dirt. |

| Inconsistent Power | Air filter blockage | Inspect and clean or replace the air filter to improve airflow. |

Where to Purchase Replacement Parts

Finding the right components for your equipment can enhance its performance and longevity. There are several avenues to explore when seeking quality replacements that fit your machine’s specifications.

Online retailers offer a vast selection of components, often at competitive prices. In addition to dedicated websites, major e-commerce platforms provide various options from multiple sellers. Local dealerships typically carry genuine components and can offer expert guidance on your equipment’s requirements.

Consider checking out the following options for sourcing replacements:

| Source | Description |

|---|---|

| Authorized Dealers | These establishments provide genuine components, ensuring compatibility and quality. |

| Online Marketplaces | Platforms like Amazon and eBay feature numerous sellers offering a wide range of components. |

| Local Hardware Stores | Some local stores may stock compatible components or can order them for you. |

| Specialty Retailers | These stores focus on equipment components and may offer expert advice on your needs. |

| Manufacturer’s Website | Visiting the official site can provide access to specific components and additional resources. |

Comparing Different John Deere Models

When evaluating various models from a renowned agricultural machinery manufacturer, it’s essential to consider their unique features and specifications. Each variant is designed to cater to specific needs, ensuring efficiency and effectiveness in various tasks. This comparison will highlight the strengths and functionalities that distinguish these machines from one another.

Model A offers exceptional maneuverability, making it ideal for smaller residential properties. Its compact size allows for easy navigation in tight spaces, while its robust engine provides reliable power for various landscaping tasks.

Model B, on the other hand, is built for larger areas and commercial use. With a wider cutting width and enhanced durability, this version can handle extensive terrain with ease. Its advanced technology improves overall performance, making it a favorite among professionals.

Finally, Model C strikes a balance between power and versatility. Equipped with multiple attachments, it can tackle a wide range of tasks, from basic trimming to more complex landscaping projects. This adaptability makes it an excellent choice for users seeking a multifunctional solution.

Ultimately, selecting the right model depends on individual requirements and the specific tasks at hand. Understanding the differences among these machines will enable buyers to make informed decisions, optimizing their investment in outdoor equipment.

Essential Tools for Repair Work

When it comes to performing maintenance and repair tasks, having the right tools is crucial for achieving effective results. The proper equipment not only enhances efficiency but also ensures safety and precision during the process. Familiarizing yourself with the essential instruments will significantly improve your overall experience and outcome.

Commonly Used Instruments

Some of the most frequently utilized instruments include wrenches, screwdrivers, and pliers. Wrenches come in various sizes and types, allowing you to tackle different fasteners with ease. Screwdrivers, both flathead and Phillips, are indispensable for assembling and disassembling components. Pliers are versatile tools that assist in gripping, twisting, and cutting tasks.

Specialized Equipment

In addition to the basic tools, certain specialized equipment can enhance your repair capabilities. Torque wrenches are essential for ensuring that fasteners are tightened to the manufacturer’s specifications, preventing damage. A multimeter is invaluable for diagnosing electrical issues, providing accurate readings of voltage, current, and resistance. Investing in high-quality tools will not only make your work easier but also extend the lifespan of your equipment.

DIY vs. Professional Repair Services

When it comes to maintaining and fixing equipment, individuals often face the decision between tackling repairs themselves or hiring skilled technicians. Each option has its own set of advantages and disadvantages, influencing both cost and the quality of the outcome. Understanding these factors can help in making an informed choice that best suits one’s needs.

For those inclined towards hands-on projects, DIY repairs can be a fulfilling experience. It allows for a deeper understanding of the machinery and the satisfaction of completing a task independently. However, this route may require a significant investment of time and effort, and the outcome can vary based on the individual’s skill level and access to proper tools.

On the other hand, enlisting the expertise of professional services can ensure that repairs are conducted efficiently and effectively. Technicians possess specialized knowledge and experience, which can lead to quicker resolutions and higher-quality results. While this option often incurs a higher initial cost, it may ultimately save money in the long run by preventing further issues caused by improper repairs.

| Criteria | DIY Repairs | Professional Services |

|---|---|---|

| Cost | Generally lower, but may require tools | Higher upfront cost |

| Time Investment | Can be significant, depending on skill level | Typically quicker due to expertise |

| Quality of Work | Varies based on experience and techniques | Consistently high quality |

| Learning Opportunity | Valuable experience gained | Limited personal skill development |

| Follow-up Support | None typically provided | Often includes warranties or guarantees |