When it comes to maintaining and repairing riding mowers, having a clear understanding of their various elements is essential for efficiency and performance. This section aims to break down the intricate details of the machinery involved, enabling users to navigate their upkeep with confidence.

By examining the layout and function of each segment, owners can better appreciate how these components work together to achieve optimal results. From the engine to the transmission, every piece plays a pivotal role in the overall functionality.

Whether you’re looking to replace a worn-out component or simply curious about the construction of your mower, a comprehensive overview will enhance your ability to troubleshoot and maintain your equipment. Dive deep into the essential elements to unlock the full potential of your riding machine.

Understanding the Troy-Bilt Mustang 50

This section delves into the features and components of a popular riding mower model. With an emphasis on efficiency and durability, this machine has become a favorite for homeowners seeking to maintain their lawns effortlessly. By exploring its functionality and construction, users can gain insights into optimizing their mowing experience.

The mower is designed with a robust engine and a user-friendly interface, making it accessible for both novice and experienced users. Key elements include a comfortable seating arrangement and intuitive controls, which enhance the overall usability. Additionally, the machine boasts various attachments that extend its versatility for different landscaping tasks.

| Component | Description |

|---|---|

| Engine | Powerful motor that provides reliable performance for extended periods. |

| Deck | Durable housing that protects the blades while ensuring optimal cutting performance. |

| Wheels | Sturdy tires designed for traction and stability on various terrains. |

| Controls | Ergonomically positioned levers and pedals that allow for precise maneuvering. |

Understanding these key components is essential for maintenance and troubleshooting. Regular care can significantly extend the lifespan of the machine, ensuring that it continues to perform efficiently for years to come. By familiarizing oneself with the structure and function, users can enhance their mowing capabilities and achieve a well-manicured lawn with ease.

Key Features of Mustang 50 Model

This model stands out for its innovative design and exceptional performance, tailored to meet the needs of both homeowners and professionals. Users appreciate the robust construction, ensuring longevity and reliability in various conditions.

Powerful Engine: The machine is equipped with a high-performance engine that provides ample power for tackling challenging tasks efficiently.

User-Friendly Controls: Intuitive controls enhance the user experience, making operation straightforward even for beginners.

Durable Build: Constructed with high-quality materials, the unit promises durability and resistance to wear and tear over time.

Versatile Functionality: Designed for a range of applications, this model excels in diverse environments, from residential lawns to larger landscapes.

Enhanced Maneuverability: With its compact design, it offers excellent maneuverability, allowing users to navigate tight spaces effortlessly.

Maintenance Accessibility: Easy access to key components simplifies routine maintenance, ensuring optimal performance throughout its lifespan.

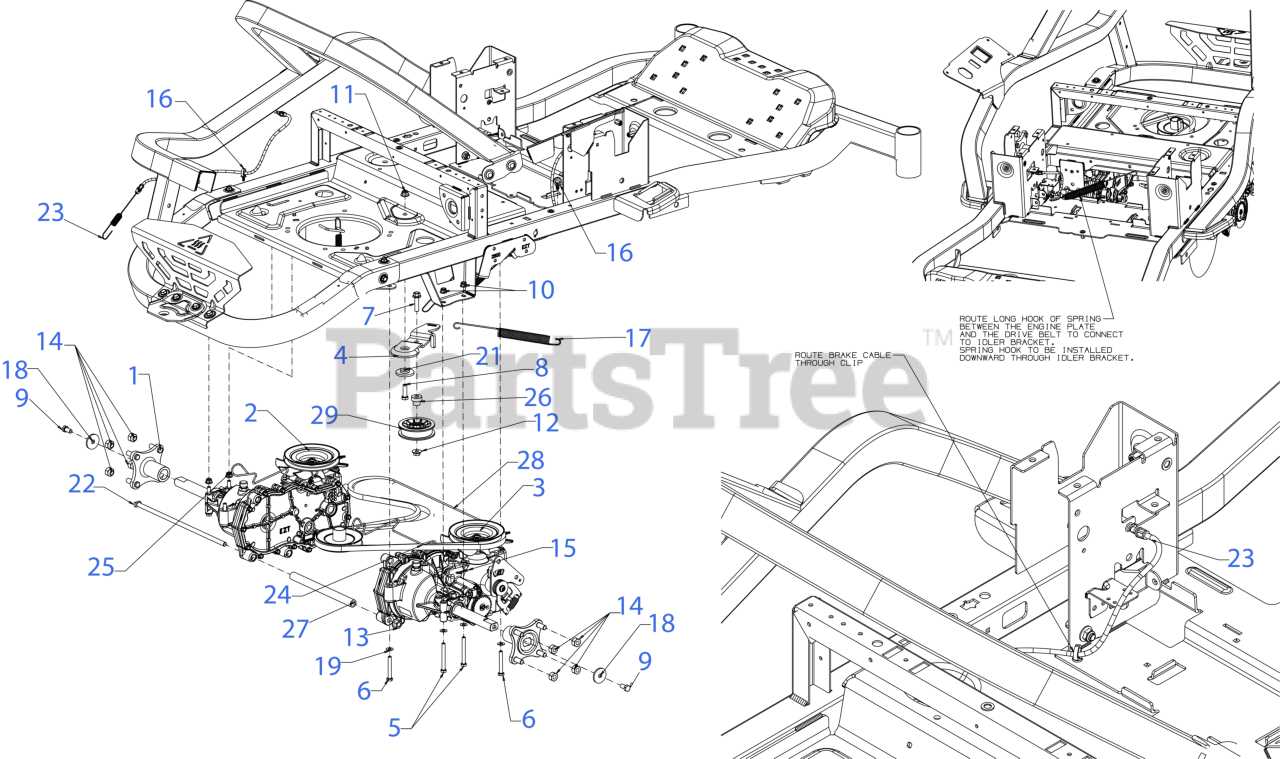

Importance of Parts Diagram

Understanding the components of machinery is crucial for effective maintenance and repair. A clear visual representation aids users in identifying individual elements, facilitating easier troubleshooting and part replacement.

Benefits of Visual References

- Enhances comprehension of assembly.

- Simplifies identification of damaged or worn items.

- Streamlines the repair process, saving time and effort.

Facilitating Efficient Maintenance

- Ensures accurate reassembly of equipment.

- Promotes proactive maintenance by recognizing wear patterns.

- Encourages informed purchasing decisions for replacements.

Common Issues with Mustang 50 Parts

When maintaining outdoor power equipment, users often encounter a variety of challenges that can affect performance and longevity. Understanding these common problems can help in troubleshooting and ensuring optimal functioning. Many issues arise from wear and tear, improper maintenance, or even incorrect usage of the machinery.

Wear and Tear

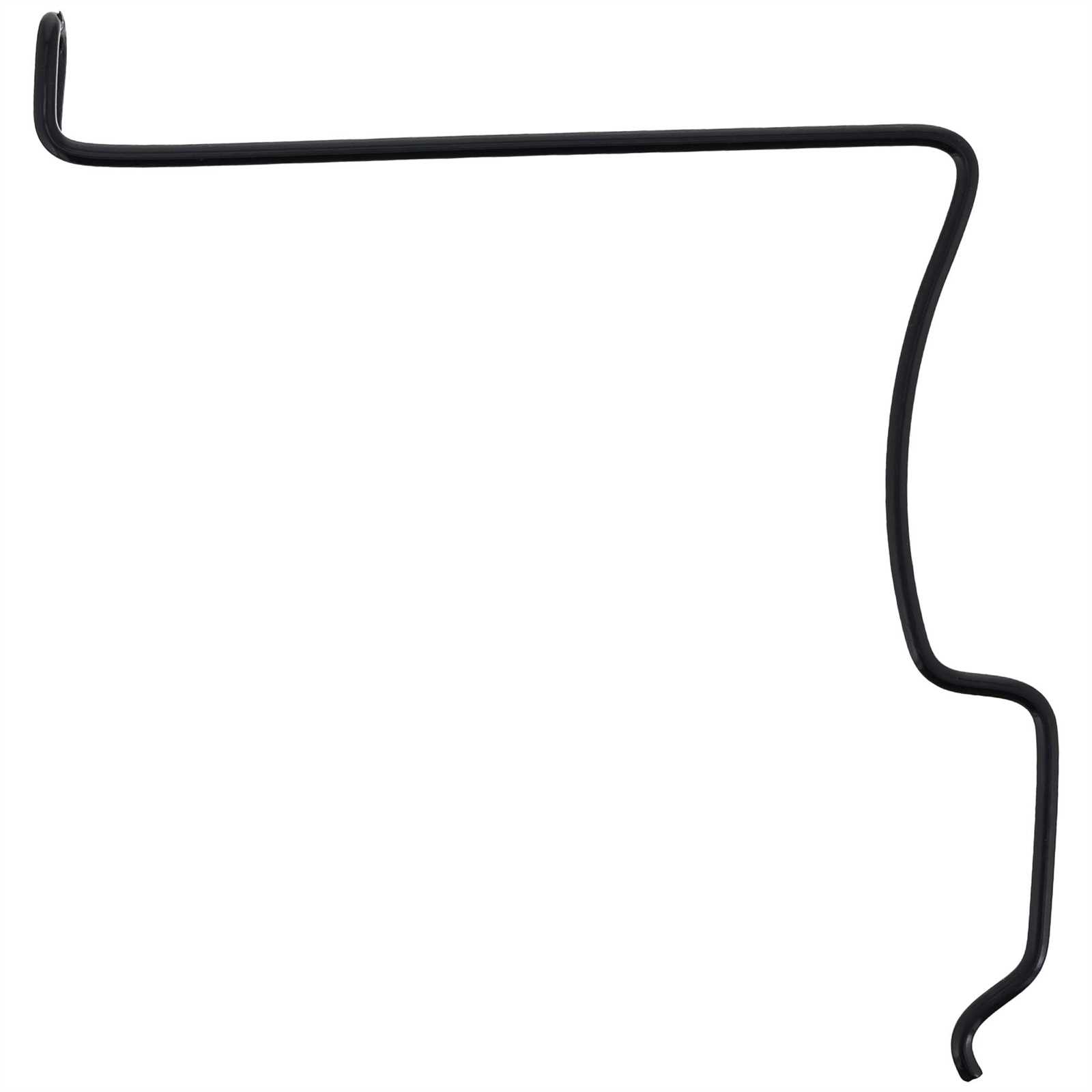

Over time, components experience significant wear due to continuous operation. This can lead to decreased efficiency and performance. Belts may fray or stretch, resulting in slippage, while blades can dull, affecting cutting quality. Regular inspections can help identify these issues before they escalate.

Maintenance Neglect

Neglecting routine maintenance can cause minor issues to develop into major malfunctions. Filters may clog, leading to reduced airflow and engine performance, while fluids can degrade, impacting lubrication and cooling. Implementing a consistent maintenance schedule is essential for preventing these problems.

Where to Find Replacement Parts

Locating components for maintenance or repair can be essential for keeping your equipment running smoothly. Various sources offer an array of options, ensuring you can find what you need efficiently.

Online Retailers provide convenience and a wide selection. Websites dedicated to machinery often stock a comprehensive range of items suitable for different models.

Local Dealers are another viable option. Visiting a dealership allows you to consult with experts who can help you identify the correct components.

Salvage Yards may also have valuable resources. Searching through these facilities can yield affordable alternatives for older or less common items.

For more detailed guidance, manufacturer websites often have specific recommendations and may even offer manuals that include essential information for your repairs.

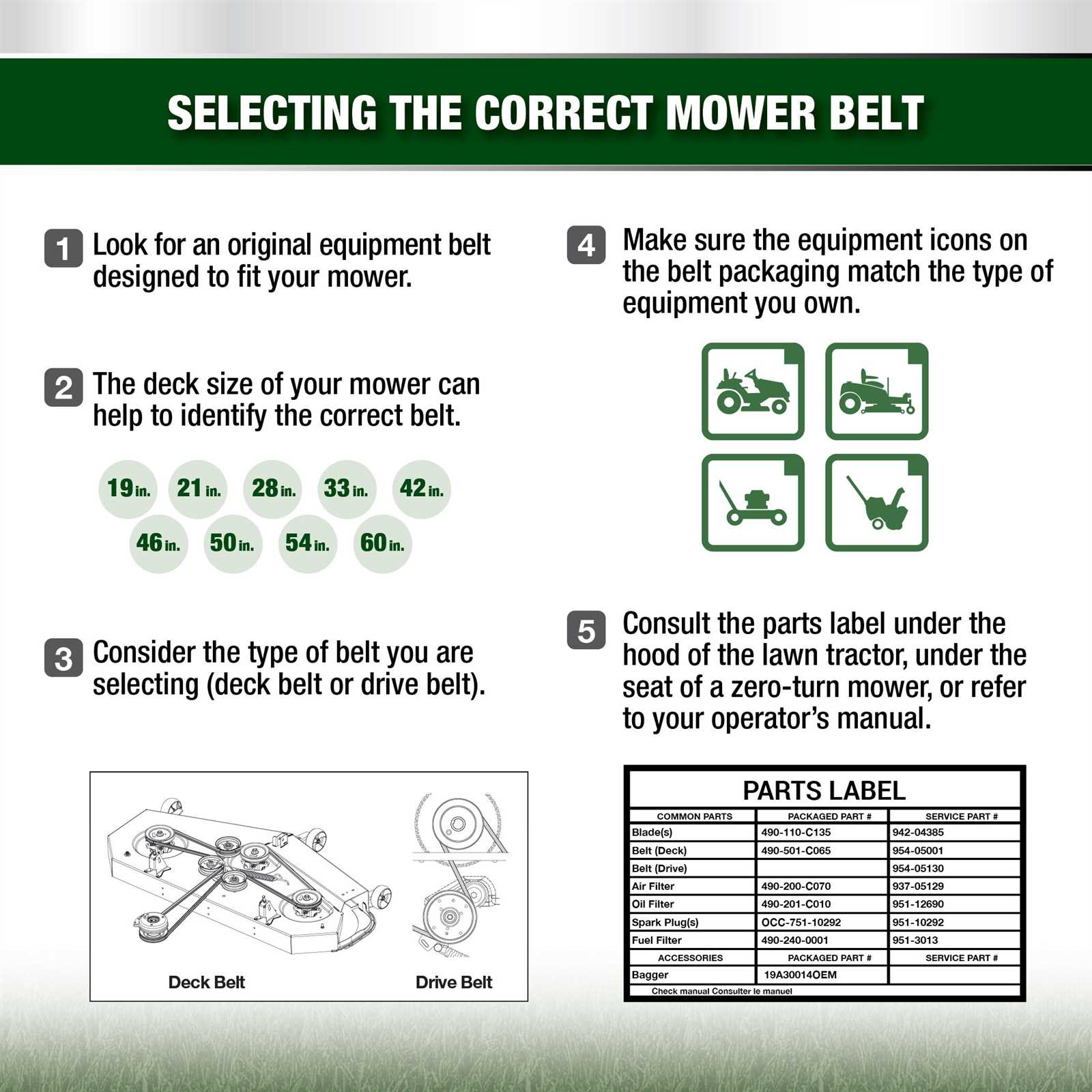

How to Use the Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair of machinery. This guide will help you navigate through the intricate layout, allowing you to identify essential elements and ensure proper functionality of your equipment.

Step 1: Begin by familiarizing yourself with the overall layout. Each section typically corresponds to a specific area of the machine, making it easier to locate various pieces. Take your time to understand how the elements are organized.

Step 2: Pay attention to the labeling. Components are often marked with numbers or letters, which correspond to a list detailing their specifications. This cross-reference is invaluable when sourcing replacements or making repairs.

Step 3: When troubleshooting issues, refer back to the visual guide to pinpoint potential areas of concern. This method allows for efficient diagnosis and can save you time and resources in the long run.

Step 4: If you’re looking to replace a specific item, use the illustration to find the exact reference number. This ensures that you acquire the correct part, minimizing the risk of compatibility problems.

In summary, leveraging a visual guide enhances your understanding and management of mechanical systems. By following these steps, you can navigate the complexities with confidence.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. By implementing a few key practices, you can significantly enhance performance and durability.

- Regularly inspect and clean all components to prevent buildup and corrosion.

- Change fluids and filters as recommended to keep the machinery running smoothly.

- Sharpen blades and check alignment to improve cutting efficiency.

- Store the equipment in a dry, sheltered location to protect it from the elements.

- Follow the manufacturer’s guidelines for usage and maintenance schedules.

Incorporating these habits into your routine can ultimately lead to better performance and longer lifespan of your machinery.

Comparing Parts with Other Models

When evaluating components across various models, it’s essential to recognize both similarities and differences that can impact performance and compatibility. A thorough analysis helps users make informed decisions about maintenance and upgrades, ensuring optimal functionality.

Understanding Variations: Different designs may incorporate unique features tailored to specific applications. By examining these distinctions, one can identify enhancements or potential shortcomings in certain configurations. For example, a component in one model might offer improved durability, while another could excel in ease of replacement.

Cross-Referencing Specifications: It is beneficial to create a reference guide that outlines the specifications of various models. This approach allows for quick identification of interchangeable items, potentially reducing downtime during repairs. Users can benefit from this comparative analysis when sourcing replacements or considering aftermarket options.

In conclusion, a detailed comparison not only aids in identifying the right fit for existing equipment but also enhances overall understanding of how different models perform under various conditions. By leveraging this knowledge, users can achieve better efficiency and reliability in their operations.

Frequently Asked Questions About Mustang 50

This section addresses common inquiries related to the mower model in question. Understanding these key points can help users maximize their experience and maintain their equipment effectively.

- What is the typical maintenance schedule for this mower?

- Regular oil changes every 50 hours of operation.

- Inspecting and replacing air filters as needed.

- Sharpening blades at least once a season.

- Where can I find replacement components?

- Authorized dealers and service centers.

- Online retailers specializing in outdoor equipment.

- Local hardware stores with a lawn care section.

- What are common troubleshooting steps?

- Check the fuel level and quality.

- Inspect the battery connections and charge.

- Examine belts for wear and proper tension.

- How do I store the equipment during off-season?

- Clean the mower thoroughly to remove debris.

- Drain or stabilize fuel to prevent corrosion.

- Store in a dry, covered area to protect from the elements.