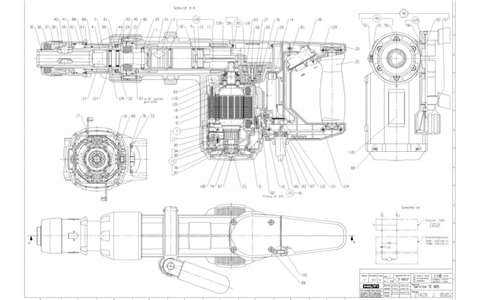

In the world of heavy-duty machinery, a thorough comprehension of the internal mechanisms is essential for optimal performance and maintenance. Each component plays a vital role in the overall functionality, contributing to the efficiency and reliability of the equipment. This section will delve into the intricate relationships between these elements and their significance in ensuring smooth operation.

By examining the layout and arrangement of the various segments, users can better appreciate how these parts interact to achieve desired outcomes. Knowledge of this structure not only aids in troubleshooting issues but also enhances the ability to execute effective repairs and upgrades. Understanding these connections empowers operators to maximize the equipment’s potential and longevity.

Moreover, a detailed exploration of the individual elements provides insights into their specific functions and how they integrate with other components. This understanding fosters a more informed approach to equipment management, leading to improved operational efficiency and reduced downtime. A comprehensive grasp of these internal workings ultimately supports users in making informed decisions regarding maintenance and enhancements.

Ensuring the prolonged functionality of your tools requires regular upkeep and care. Adopting best practices not only enhances performance but also minimizes the risk of unexpected breakdowns. This section outlines essential strategies to maintain your equipment effectively.

- Regular Cleaning: Keep the device free from dust, debris, and residue. Use appropriate cleaning agents to avoid damage to sensitive components.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and wear. Regular lubrication can significantly extend the lifespan of mechanical elements.

- Routine Inspections: Conduct frequent checks on all components to identify signs of wear or damage early. This proactive approach helps prevent major repairs down the line.

- Proper Storage: Store the equipment in a dry and clean environment. Ensure it is protected from extreme temperatures and humidity, which can adversely affect performance.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule and guidelines provided by the manufacturer. This ensures that your tools remain in optimal working condition.

By implementing these maintenance strategies, you can enhance the durability and reliability of your tools, ensuring they serve you well for years to come.

How to Identify Spare Parts

Recognizing the components necessary for the maintenance and repair of equipment is crucial for ensuring optimal functionality. Understanding the various elements involved allows for effective troubleshooting and replacement, ultimately extending the lifespan of the machinery. This section outlines key strategies for accurately determining the required components.

Understanding Component Types

Familiarizing yourself with the different classifications of elements can streamline the identification process. Consider the following categories:

- Electrical Components: These include switches, connectors, and circuit boards.

- Mechanical Elements: Gears, bearings, and housings fall under this category.

- Consumables: Items such as filters, belts, and blades should be regularly monitored for replacement.

Utilizing Resources for Identification

Leveraging available resources can significantly enhance the accuracy of your identification efforts:

- Consult the user manual or product documentation for detailed specifications.

- Use online databases or manufacturer websites for reference images and part numbers.

- Engage with customer support or forums for insights from experienced users.

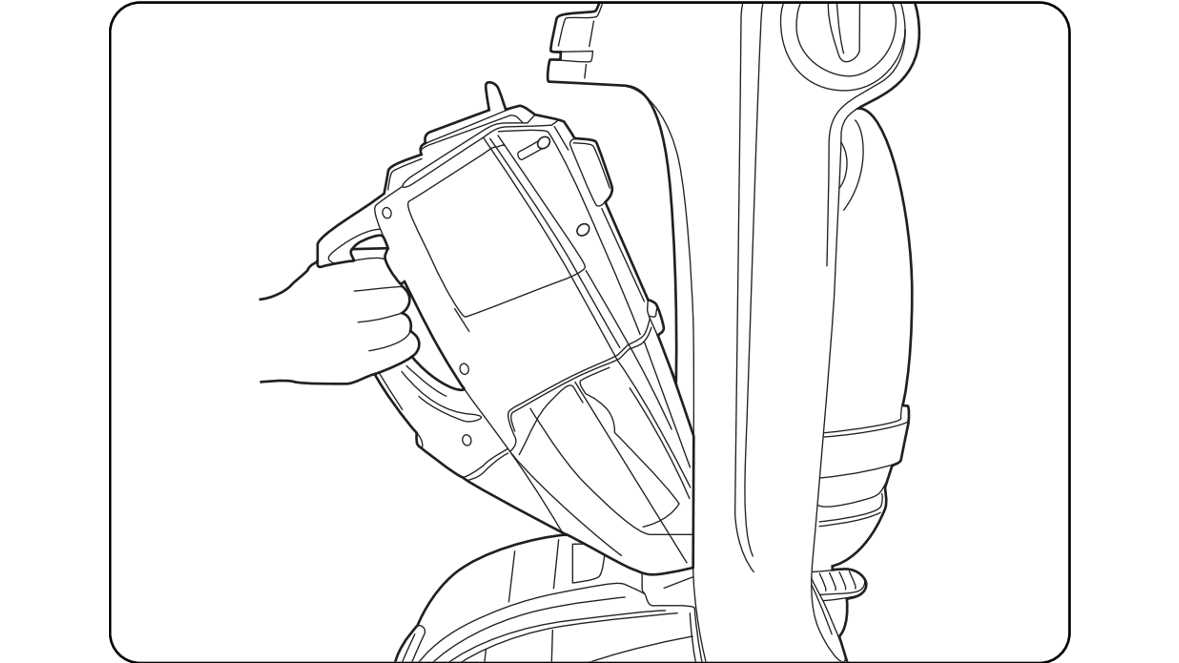

Replacement Procedures for Major Parts

Maintaining the efficiency and longevity of any mechanical device often requires the timely substitution of essential components. This section outlines the systematic methods for replacing significant elements, ensuring optimal functionality and performance. Understanding these procedures is crucial for both novice users and experienced technicians alike.

Preparation for Replacement

Before initiating any replacement process, it is vital to follow a set of preparatory steps:

- Gather the necessary tools and replacement components.

- Review the user manual for specific instructions related to the model in use.

- Ensure the device is powered off and disconnected from any power sources.

- Work in a well-lit area to enhance visibility and safety.

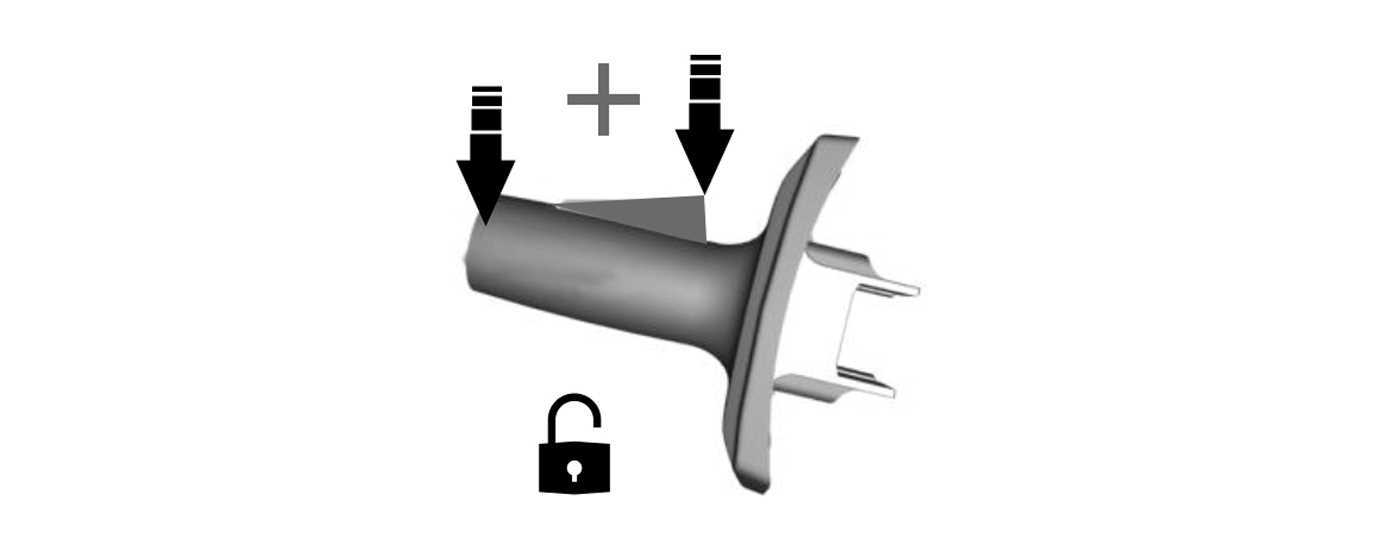

Step-by-Step Replacement Guide

To effectively replace major components, adhere to the following steps:

- Identify the component that needs to be replaced.

- Carefully remove any protective covers or housings to access the defective part.

- Disconnect any electrical connections or fasteners that secure the component.

- Remove the faulty part, taking care not to damage surrounding elements.

- Install the new component by reversing the removal steps, ensuring all connections are secure.

- Reattach any protective covers and perform a functional test to confirm proper operation.

Following these guidelines will facilitate a smooth replacement process, helping to maintain the overall performance of the equipment.

Troubleshooting Common Issues

When working with complex machinery, encountering problems is a common occurrence. Identifying and resolving these issues can ensure smooth operation and enhance performance. Understanding the typical challenges and their solutions is essential for effective maintenance and longevity of the equipment.

Here are some frequent problems and their potential fixes:

- Power Failure: If the device does not turn on, check the following:

- Ensure the power source is functioning.

- Inspect cables and connections for damage.

- Verify that the power switch is engaged.

- Overheating: Excessive heat can lead to performance issues. Consider these steps:

- Allow the machine to cool down before use.

- Check for blocked ventilation openings.

- Make sure the cooling system is operational.

- Vibration Problems: Unusual vibrations may indicate misalignment or wear. To address this:

- Inspect for loose components or fasteners.

- Assess the condition of internal parts for wear.

- Ensure proper alignment of all moving parts.

- Noise Issues: Excessive noise can be a sign of underlying issues. To troubleshoot:

- Examine the machine for any foreign objects.

- Listen for unusual sounds that may indicate wear.

- Lubricate moving parts as necessary.

By systematically addressing these common issues, operators can significantly improve the reliability and performance of the machinery. Regular maintenance and prompt troubleshooting are key to avoiding more severe complications in the future.

Where to Buy Authentic Parts

Finding genuine components for your equipment is crucial for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality items that meet the required specifications. By choosing reputable vendors, you can avoid the risks associated with counterfeit products that may compromise safety and efficiency.

Authorized Distributors: The most dependable option is to purchase from authorized distributors. These suppliers have direct access to the manufacturer’s inventory and can guarantee the authenticity of the items they offer. Check the manufacturer’s website for a list of approved retailers in your region.

Online Marketplaces: Reputable online marketplaces also provide a wide selection of genuine components. Always verify the seller’s ratings and reviews before making a purchase. Look for listings that explicitly state the authenticity of the items, as well as return policies in case the products do not meet your expectations.

Local Service Centers: Visiting local service centers or workshops can be beneficial. Many of these facilities are equipped to source authentic components directly from the manufacturer. Engaging with professionals in person allows you to ask questions and gain insights into the best practices for installation and maintenance.

In conclusion, selecting the right source for your components is essential for ensuring the longevity and efficiency of your equipment. By opting for authorized distributors, reputable online platforms, and local service centers, you can ensure that you are investing in quality items.