The intricate assembly responsible for transferring motion within a vehicle is essential for its functionality. Each element within this system plays a crucial role, contributing to overall performance and efficiency. A clear comprehension of these elements enhances our appreciation of automotive engineering.

From the central unit to auxiliary sections, each feature is designed to withstand significant stresses while ensuring seamless operation. Grasping the purpose and interrelation of these components allows enthusiasts and professionals alike to delve deeper into the mechanics behind automotive movement.

In this exploration, we will uncover the ultimate significance of each segment, shedding light on their unique functions and contributions. This knowledge not only enriches our understanding but also aids in maintenance and innovation within the automotive sector.

Understanding Drive Shaft Components

The intricate assembly within a vehicle’s propulsion system plays a crucial role in transferring energy from the engine to the wheels. A deep dive into this assembly reveals various elements that work in harmony to ensure smooth operation and efficient power distribution.

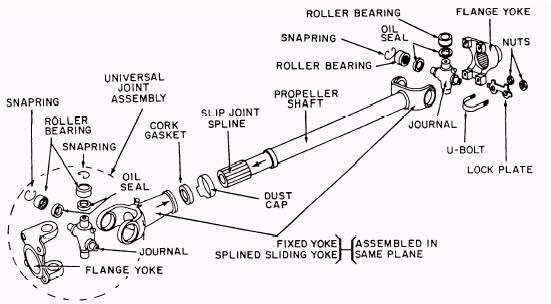

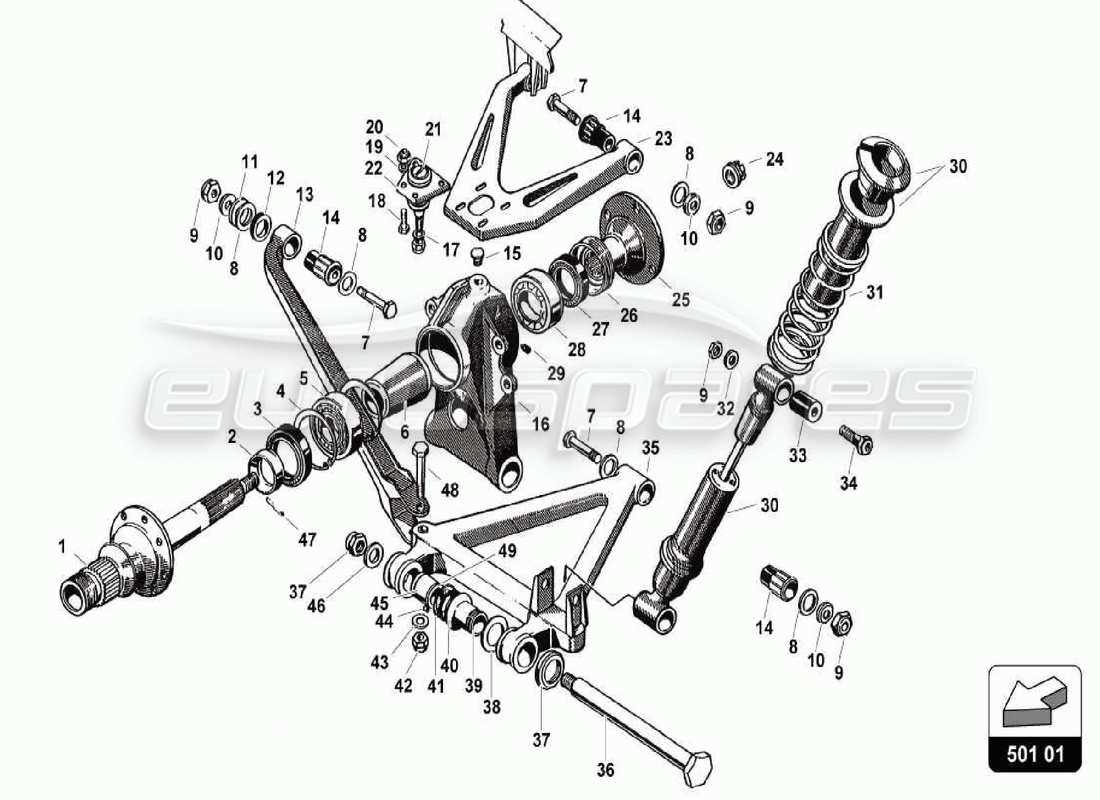

Key Elements: Central to this assembly is a robust cylindrical structure that allows for rotational movement. This component is complemented by joints that provide flexibility and accommodate changes in alignment during motion. Additionally, bearings support the entire mechanism, reducing friction and wear over time.

Another significant aspect includes couplings, which link different segments, allowing for seamless energy transfer. Moreover, insulation features are crucial in minimizing vibrations and enhancing comfort for passengers. Understanding these components and their functions is essential for anyone looking to grasp the mechanics of modern vehicles.

Functions of a Drive Shaft

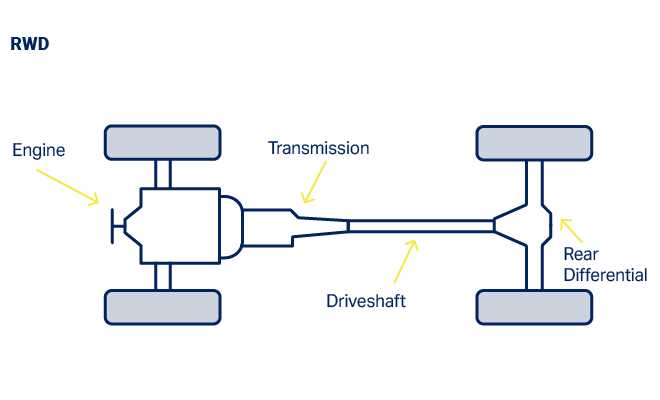

The central component of a vehicle’s transmission system plays a crucial role in transferring power from the engine to the wheels. This mechanism ensures that the vehicle can efficiently convert rotational energy into motion, enabling smooth acceleration and deceleration. Understanding its functions helps in appreciating the overall performance and reliability of automotive systems.

One primary function is to transmit torque, which is the rotational force generated by the engine. This force is essential for propelling the vehicle forward or backward. Additionally, this component allows for the necessary flexibility in the drivetrain, accommodating changes in angle and movement as the vehicle navigates various terrains.

Moreover, it helps to maintain balance and stability during operation. By connecting different parts of the transmission, it ensures that the power flow remains consistent, reducing vibrations and enhancing comfort for passengers. Overall, this element is vital for efficient vehicle operation, contributing to safety and performance on the road.

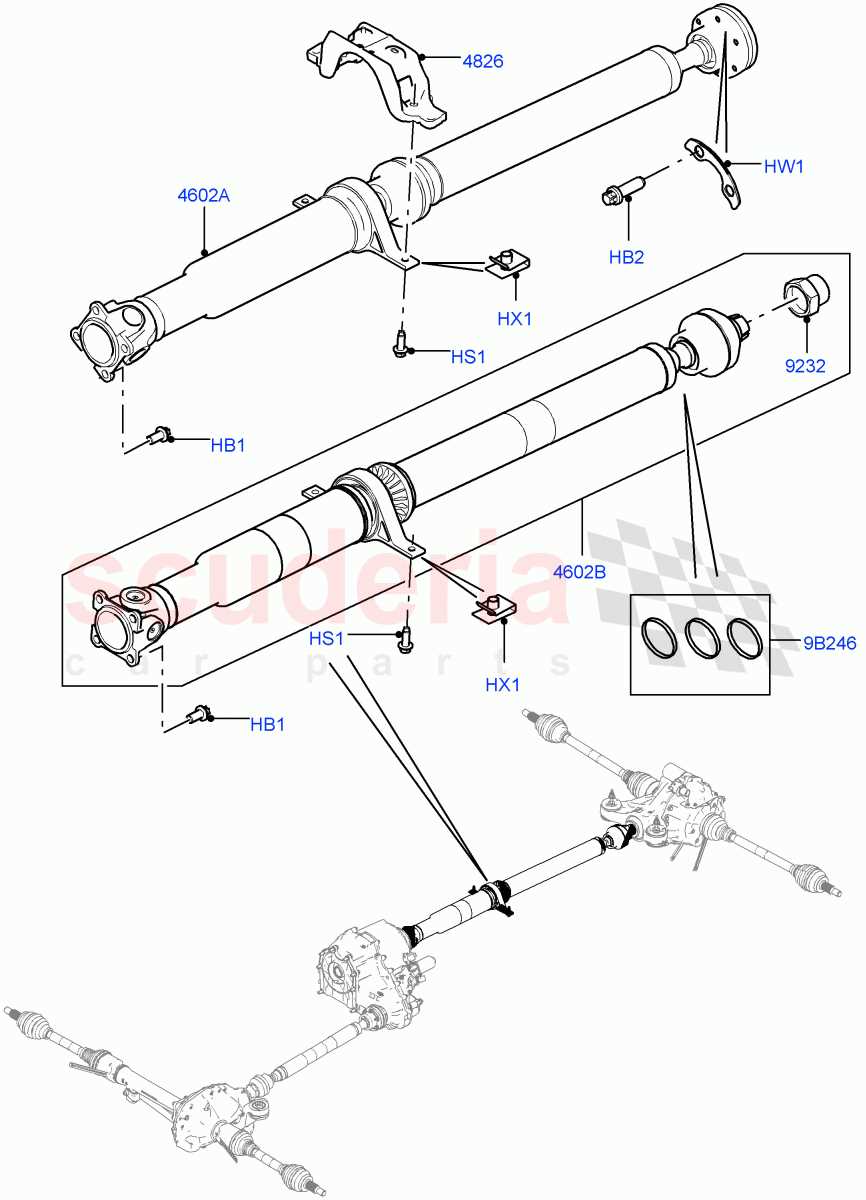

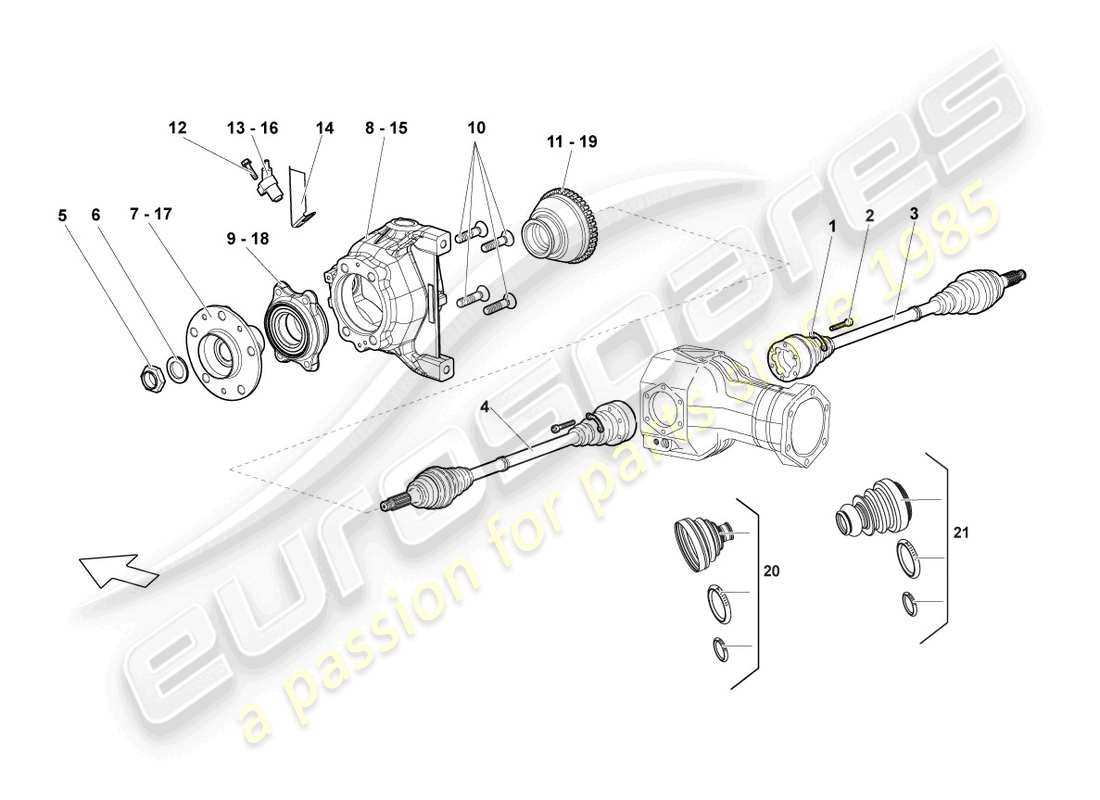

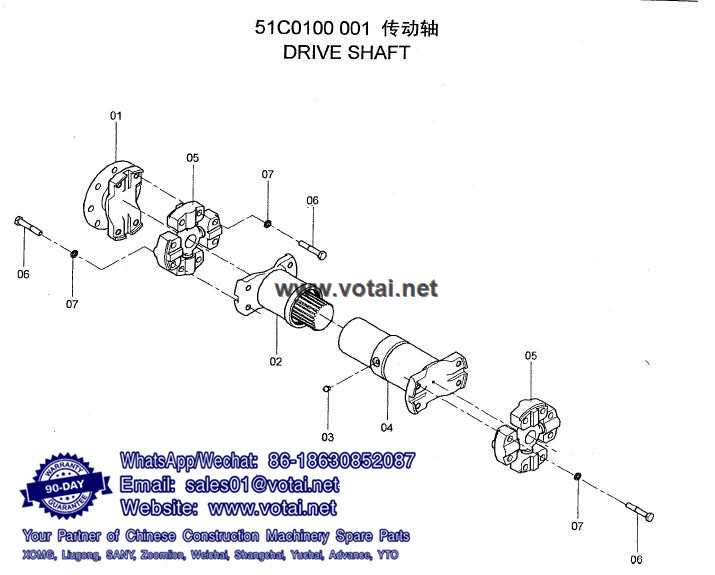

Key Parts of the Drive Shaft

This section explores the essential components that contribute to the functionality and efficiency of a mechanical connection in vehicles. Understanding these elements is crucial for grasping how power is transmitted through a system.

Transmission Elements

The transmission components are vital for transferring power from the engine to the wheels. These parts ensure that torque is effectively conveyed, facilitating smooth operation. Universal joints play a significant role in allowing flexibility while maintaining strength.

Support Structures

Support structures, such as bearings, are critical for stability and reducing friction during movement. These components help maintain alignment and ensure longevity, ultimately enhancing performance and reliability.

Materials Used in Drive Shafts

The choice of materials significantly influences the performance and durability of rotational components. Selecting the right substances ensures efficiency and resilience under various operating conditions.

- Steel: Known for its strength and toughness, steel is commonly utilized for its ability to withstand high torque and fatigue.

- Aluminum: Lightweight and resistant to corrosion, aluminum is often chosen for applications where weight reduction is critical.

- Composite materials: These materials offer a combination of low weight and high strength, making them suitable for specialized applications.

- Carbon fiber: Renowned for its stiffness and low density, carbon fiber is increasingly popular in high-performance contexts.

Each of these materials presents unique benefits and trade-offs, making them suitable for specific requirements in engineering and manufacturing.

How Drive Shafts Transfer Power

The transmission of energy from one component to another is a fundamental aspect of mechanical systems. This process ensures that power generated by the engine reaches the wheels, enabling movement and functionality. Understanding how this transfer occurs is crucial for comprehending the overall performance and efficiency of vehicles.

At the core of this mechanism lies a rotating element that connects various assemblies. When the engine produces torque, it rotates this element, which then engages with different gears and components. This interaction not only facilitates motion but also allows for the adjustment of speed and force, adapting to various driving conditions.

Additionally, the design of this connecting element plays a vital role. It must withstand significant forces while maintaining flexibility to accommodate changes in alignment. The materials and engineering involved are critical for ensuring durability and effective power transmission over time.

Ultimately, the efficiency of this energy transfer system greatly influences vehicle performance. Enhancements in technology continually improve the capability of this mechanism, leading to better fuel efficiency and smoother operation. Understanding the principles behind this process offers insight into the intricate workings of automotive engineering.

Importance of Universal Joints

Universal joints play a crucial role in transmitting torque and rotational motion between misaligned components. Their ability to accommodate various angles while maintaining a consistent power flow is essential for the smooth operation of machinery and vehicles. Without these joints, the efficiency and performance of mechanical systems would be severely compromised.

These versatile connectors allow for flexibility in alignment, making them vital in applications where components do not remain perfectly aligned due to vibration or shifting loads. The functionality they provide not only enhances operational reliability but also contributes to the overall lifespan of the machinery.

| Feature | Benefit |

|---|---|

| Flexibility | Accommodates misalignment |

| Torque Transmission | Ensures consistent power flow |

| Durability | Extends lifespan of components |

| Vibration Dampening | Reduces wear and tear |

In conclusion, universal joints are indispensable in many mechanical systems, providing essential flexibility and efficiency. Their design allows for the seamless integration of various components, ensuring optimal performance in diverse applications.

Common Issues with Drive Shafts

When it comes to the essential components that facilitate vehicle motion, several challenges can arise, leading to potential performance issues. Understanding these common problems is crucial for maintenance and safety, ensuring smooth operation and longevity of the vehicle.

Frequent Problems

- Vibration: Unwanted oscillations can occur due to misalignment or wear, impacting comfort and handling.

- Noise: Unusual sounds often indicate wear or damage, prompting immediate inspection to prevent further complications.

- Separation: A complete detachment can happen if components are not properly secured, leading to severe operational failures.

- Corrosion: Exposure to moisture and road salt can lead to rust, weakening structural integrity over time.

Preventative Measures

- Regular inspections to identify wear early.

- Timely lubrication to minimize friction and wear.

- Proper installation to ensure alignment and stability.

- Protective coatings to shield against environmental damage.

Maintenance Tips for Drive Shafts

Regular upkeep of crucial components in a vehicle is essential for ensuring smooth operation and longevity. Neglecting maintenance can lead to significant wear and potential failures, resulting in costly repairs and safety concerns. By following a few key practices, you can help keep these elements in optimal condition and enhance overall performance.

Regular Inspections

Routine checks are vital for identifying any signs of wear or damage early on. Look for unusual vibrations or noises while driving, as these may indicate underlying issues. Additionally, inspect the condition of rubber seals and joints for any signs of cracks or leaks, which could compromise functionality.

Lubrication and Cleaning

Proper lubrication is crucial for reducing friction and preventing premature wear. Ensure that all moving parts are adequately greased according to the manufacturer’s recommendations. Regular cleaning of these components can also help eliminate dirt and debris that may cause blockages or damage over time.