The intricate assembly of a military-grade weapon involves a multitude of essential elements, each playing a critical role in its overall functionality. A clear comprehension of these individual components is vital for enthusiasts, technicians, and military personnel alike. This knowledge not only enhances operational efficiency but also fosters a deeper appreciation for the engineering behind such sophisticated machinery.

By exploring the various sections of this firearm, one can gain insight into the mechanics that ensure reliability and performance in the field. Every piece, from the trigger mechanism to the feeding system, contributes to the weapon’s effectiveness. Understanding how these elements interact can significantly aid in maintenance and troubleshooting, ensuring optimal operation during crucial moments.

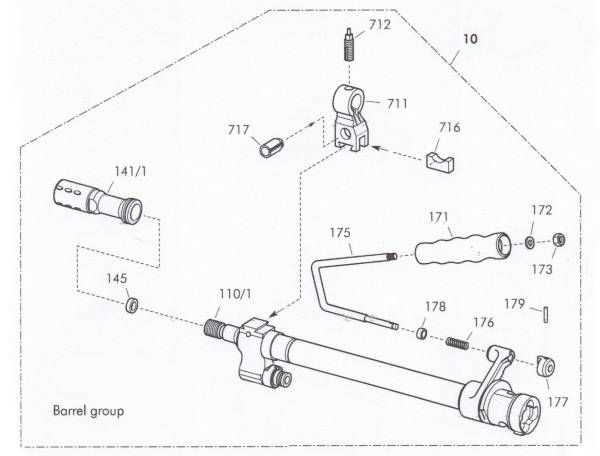

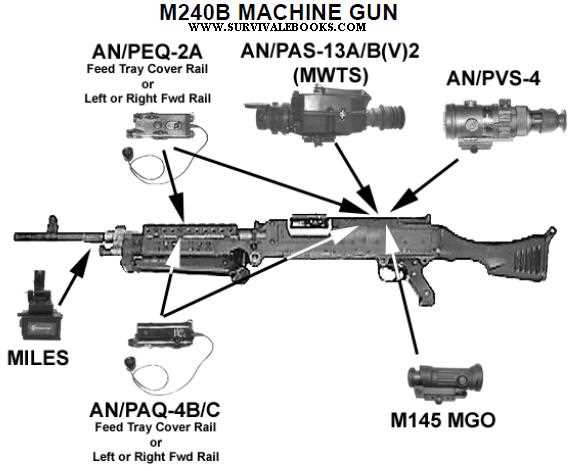

Visual representations of these components serve as invaluable resources for both education and practical application. Detailed illustrations can clarify the assembly process and help identify specific parts, which is especially useful for those engaged in repair or modification. By delving into the details of this complex system, users can enhance their technical skills and ensure their equipment is always battle-ready.

M249 Parts Diagram Overview

This section provides a comprehensive look at the components that make up a specific automatic firearm, focusing on their interrelationships and functions. Understanding the layout and function of these elements is crucial for both maintenance and operation, ensuring reliability and efficiency in various conditions.

Key Components

The assembly consists of several essential elements, each playing a vital role in the weapon’s overall performance. The feeding mechanism is designed to ensure smooth ammunition delivery, while the barrel assembly is critical for accuracy and heat dissipation during prolonged use. Additionally, the trigger assembly and operating system work in tandem to facilitate rapid firing sequences.

Maintenance and Functionality

Proper knowledge of these elements not only aids in effective upkeep but also enhances the user’s proficiency. Familiarity with the layout allows for quicker troubleshooting and repair. Furthermore, understanding how these components interact can significantly improve the operational effectiveness of the firearm in various scenarios.

Understanding the M249 Components

Grasping the essential elements of this light machine gun is crucial for both maintenance and operational effectiveness. Each component plays a specific role, contributing to the overall functionality and reliability of the system. A thorough comprehension of these features enables users to optimize performance and troubleshoot issues effectively.

| Component | Function |

|---|---|

| Receiver | Houses the trigger and firing mechanism, providing stability. |

| Barrel | Directs the projectile and dissipates heat during firing. |

| Stock | Offers support for aiming and stabilization while shooting. |

| Feed System | Ensures a continuous supply of ammunition for firing. |

| Handguard | Protects the operator from heat and assists in handling. |

Key Features of the M249 Design

The design of this lightweight, belt-fed firearm incorporates several innovative characteristics that enhance its functionality and versatility in combat scenarios. These elements work together to provide superior performance, reliability, and ease of use.

Ergonomic Design

- Adjustable stock for better handling

- Ambidextrous controls for ease of operation

- Integrated bipod for stability during fire

Operational Efficiency

- High rate of fire ensures rapid response

- Quick-change barrel system minimizes downtime

- Compatible with various ammunition types for flexibility

Common Issues with M249 Parts

In any sophisticated firearm system, certain challenges may arise related to individual components. These issues can affect performance, reliability, and overall user satisfaction. Understanding these common problems is crucial for effective maintenance and operational readiness.

Frequent Mechanical Failures

Mechanical breakdowns often stem from wear and tear, particularly in high-stress areas. For instance, components that experience repetitive motion or friction are prone to damage over time. Regular inspection and timely replacement of worn elements are vital to prevent malfunctions.

Improper Lubrication and Maintenance

Neglecting proper lubrication can lead to increased friction and overheating, which may compromise functionality. It’s essential to follow manufacturer recommendations for maintenance schedules and lubrication techniques. Regular cleaning and attention to detail can significantly enhance the longevity of crucial elements.

Maintenance Tips for M249 Users

Proper care and upkeep of your firearm are essential for optimal performance and longevity. Regular maintenance ensures reliability, accuracy, and safety, helping to prevent malfunctions during critical moments. Below are some essential recommendations to keep in mind.

| Task | Frequency | Details |

|---|---|---|

| Clean the barrel | After each use | Remove fouling and debris to maintain accuracy. |

| Lubricate moving parts | Weekly | Use appropriate oils to prevent rust and ensure smooth operation. |

| Inspect for wear | Monthly | Check components for any signs of damage or fatigue. |

| Check ammunition | Before use | Ensure compatibility and check for signs of corrosion or damage. |

| Store properly | Always | Keep in a dry, secure location to prevent environmental damage. |

Following these guidelines will help ensure that your weapon operates effectively and remains in peak condition over time. Regular attention to these details can make a significant difference in performance and reliability.

Upgrading M249 Internal Mechanisms

Enhancing the internal components of a specific firearm can significantly improve its performance and reliability. Upgrades often focus on crucial areas such as cycling speed, durability, and precision. By carefully selecting superior materials and designs, enthusiasts can achieve optimal functionality and longevity.

One essential area to consider is the trigger assembly. Upgrading to a lighter, smoother trigger can enhance responsiveness and accuracy during operation. Additionally, incorporating high-quality springs can reduce wear and tear, ultimately leading to a more reliable firing mechanism.

Another critical aspect is the gearbox. Replacing stock components with upgraded gears and bearings can facilitate faster cycling rates and improved power transfer. This not only enhances firing performance but also increases the overall lifespan of the mechanism.

Lastly, don’t overlook the hop-up unit. Upgrading this component allows for better control over projectile trajectory, enhancing accuracy and range. Fine-tuning these internal elements can lead to an impressive transformation in operational effectiveness.

Comparing M249 to Other Machine Guns

This section explores the nuances between a well-known light support weapon and its counterparts in the realm of automatic firearms. Understanding these differences can enhance the appreciation of design philosophies, performance metrics, and operational suitability across various scenarios.

Key Features

- Weight and Portability

- Rate of Fire

- Caliber Options

- Feeding Mechanisms

Performance Metrics

- Effective Range

- Reliability Under Adverse Conditions

- Maintenance Requirements

By delving into these aspects, one can discern the ultimate strengths and weaknesses inherent in different designs, fostering a deeper understanding of their roles in military applications.

Importance of Proper Assembly Techniques

Effective assembly practices are crucial for ensuring the functionality and reliability of mechanical systems. Proper techniques not only enhance performance but also contribute to the longevity and safety of the equipment. A thorough understanding of assembly methods is essential for anyone involved in the construction or maintenance of these complex mechanisms.

Enhancing Reliability

Utilizing correct assembly approaches significantly increases the reliability of the system. When components are fitted together accurately, the risk of malfunction decreases, allowing for consistent operation. This reliability is vital in high-pressure situations where performance is non-negotiable.

Preventing Wear and Tear

Incorrect assembly can lead to premature wear and damage. By adhering to proper techniques, users can minimize friction and stress on parts, thus extending their operational life. Regular training in assembly practices ensures that technicians are well-versed in the necessary protocols to maintain equipment in optimal condition.

Resources for M249 Enthusiasts

For those passionate about the iconic light machine gun, a wealth of information and tools is available to enhance understanding and maintenance. Whether you’re a collector, a shooter, or simply curious, these resources provide invaluable insights into its design, function, and history.

Online Communities

Joining forums and social media groups dedicated to military firearms can foster knowledge exchange and camaraderie among enthusiasts. Engaging in discussions allows members to share experiences, troubleshooting tips, and recommendations.

Books and Manuals

Comprehensive literature is essential for deepening your expertise. Manuals and historical accounts offer a wealth of technical specifications and operational guidelines.

| Resource Type | Examples |

|---|---|

| Online Forums | GunBroker, Reddit Firearms |

| Books | “The Complete Guide to Firearms” by John Doe |

| Videos | YouTube Channels on Gun Maintenance |