Effective maintenance of machinery relies heavily on a thorough understanding of their individual components and how they interact within the overall system. Recognizing the specific elements involved in mechanical systems can enhance troubleshooting capabilities and streamline repair processes. This section aims to provide a comprehensive overview of the layout and relationships between various elements found in equipment.

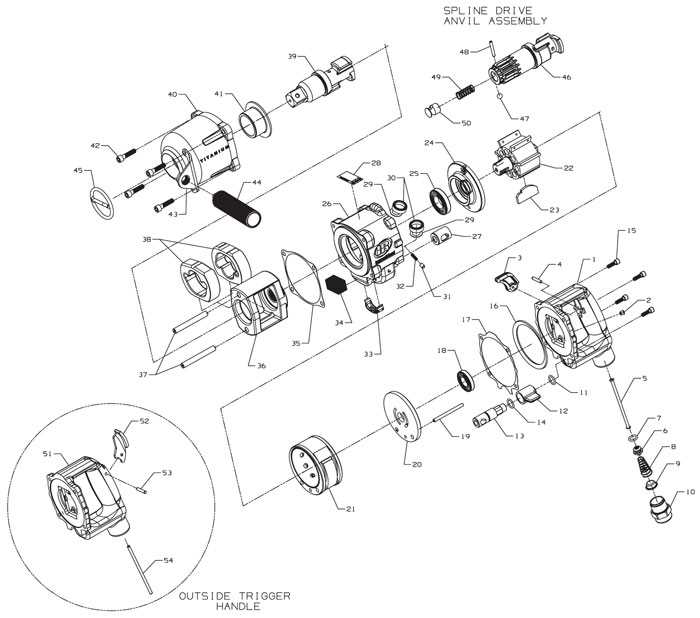

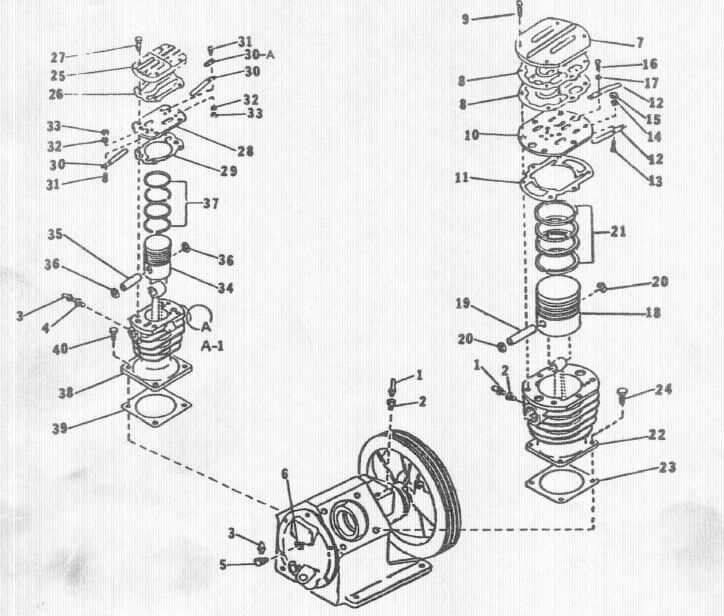

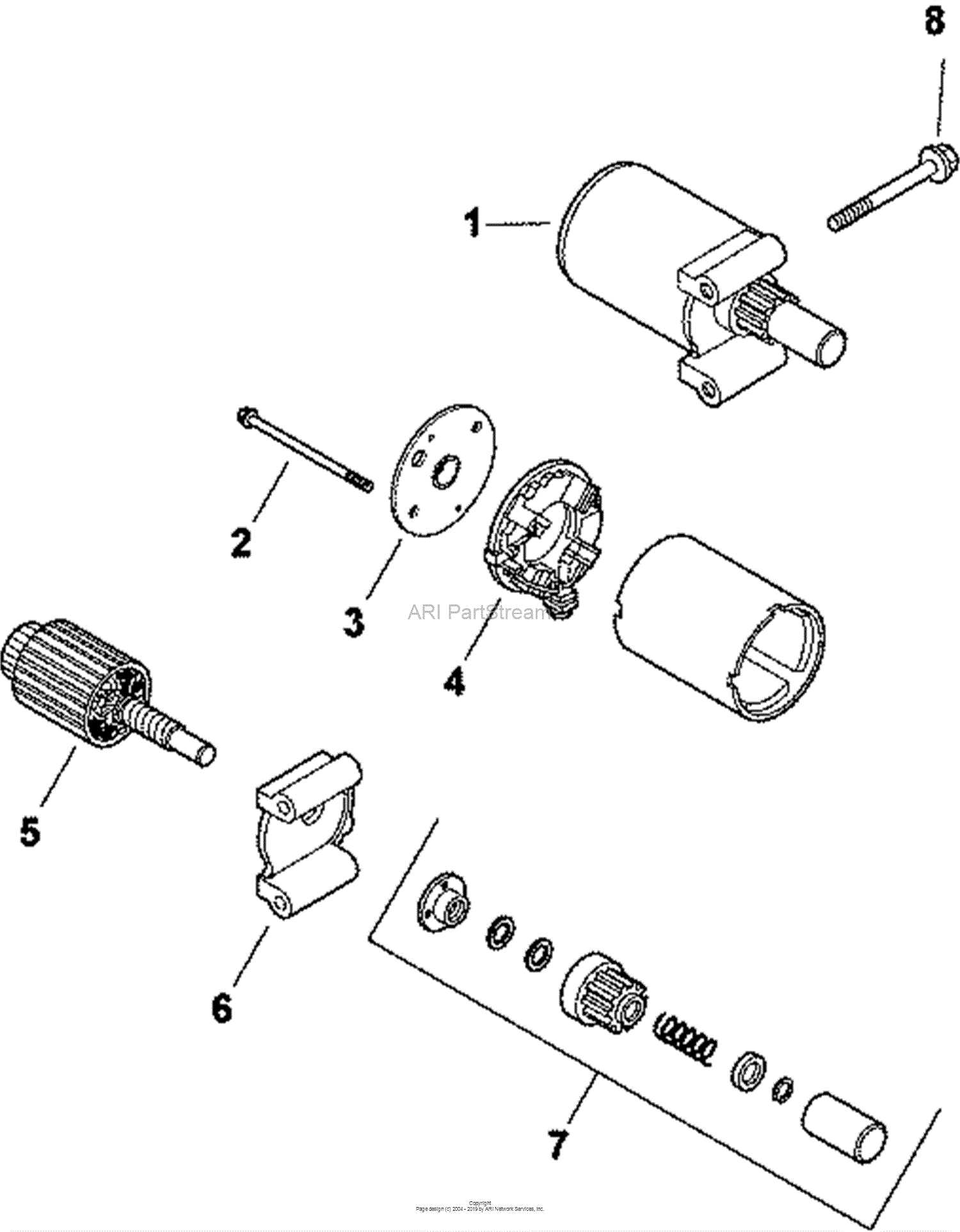

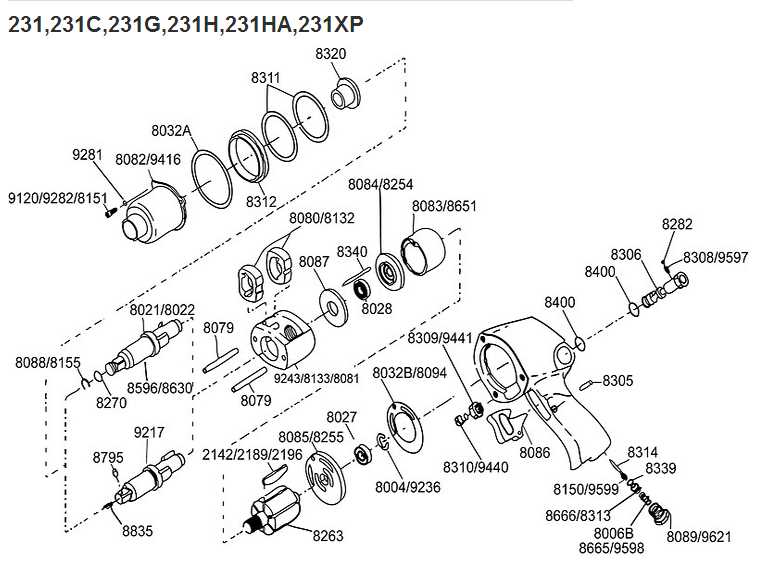

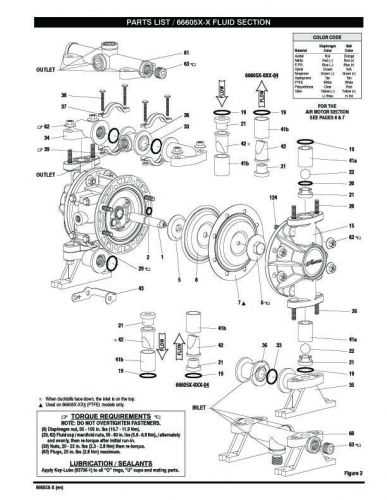

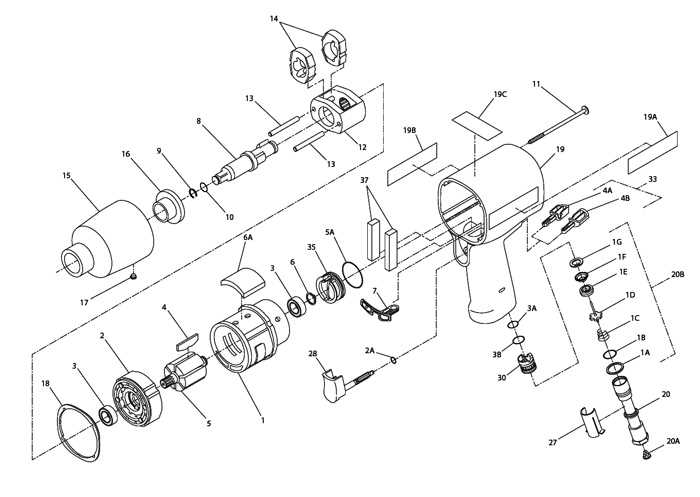

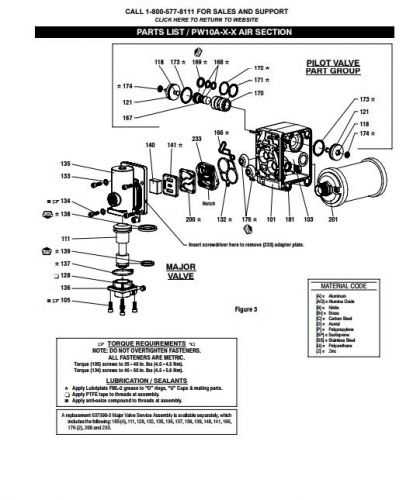

By examining the structure of these mechanisms, users can gain valuable insights into their functionality. Detailed illustrations serve as a vital tool for technicians, enabling them to identify each component’s role and facilitating efficient repairs. Moreover, having access to well-organized representations can significantly reduce downtime during maintenance tasks.

Furthermore, clarity in visual representations is essential for both seasoned professionals and newcomers in the field. It simplifies complex systems and promotes a deeper understanding of how different parts contribute to the overall operation of the machinery. This knowledge ultimately leads to improved performance and longevity of the equipment.

Understanding Ingersoll Rand Parts

When it comes to mechanical components, having a clear grasp of their individual roles is essential for efficient operation. Familiarity with these elements enables users to troubleshoot issues, perform maintenance, and enhance performance. This section delves into the fundamental aspects of these vital components.

Each element plays a unique role within the overall assembly. Understanding their functions can lead to improved efficiency and longevity of the equipment. Below are some key considerations:

- Functionality: Each component serves a specific purpose, contributing to the system’s overall performance.

- Interconnectivity: Elements work in tandem, meaning that the malfunction of one can affect the entire assembly.

- Maintenance: Regular inspection and servicing of each part can prevent costly breakdowns and prolong the lifespan of the equipment.

- Upgrades: Identifying the right components for upgrades can significantly enhance performance and efficiency.

In summary, a thorough understanding of these mechanical elements is crucial for anyone involved in maintenance or operation. Knowledge about their specific functions and interrelations aids in making informed decisions that can lead to optimal performance.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable resources, guiding users through complex assemblies and helping to identify individual elements and their functions. This clarity enhances the overall efficiency of service tasks.

Key benefits of utilizing visual schematics include:

- Enhanced Clarity: Illustrations simplify complex information, making it easier to comprehend how different components interact.

- Efficient Troubleshooting: By clearly indicating each part, these visuals enable quicker identification of issues, reducing downtime.

- Streamlined Maintenance: Detailed views assist technicians in performing routine checks and servicing, ensuring that machinery operates optimally.

- Effective Training Tool: Visual aids are essential for training new personnel, helping them grasp the mechanics of the equipment more quickly.

Incorporating visual guides into operational manuals is not just a convenience but a necessity for improving workflow and safety in technical environments.

Common Components in Ingersoll Rand Systems

Understanding the essential elements in air compression systems is crucial for optimal performance and reliability. Various components work together to ensure efficiency and effectiveness in operation. These parts play vital roles in maintaining functionality, minimizing downtime, and extending the lifespan of the entire system.

Key Elements

Among the significant components are compressors, which are responsible for increasing the pressure of the air. They work alongside filters that remove contaminants, ensuring the air is clean before entering other system parts. Regulators also play a critical role, controlling the pressure levels to prevent damage to the equipment.

Auxiliary Parts

In addition to the main elements, auxiliary parts like pressure switches and gauges are vital for monitoring and regulating the system’s performance. These components help maintain safety and efficiency, providing real-time feedback and ensuring that operations remain within specified parameters.

How to Read a Parts Diagram

Understanding a schematic representation of components is crucial for efficient maintenance and repair. These visual aids provide a clear overview of the elements involved, their arrangement, and the relationships between them. Grasping the information presented can significantly enhance troubleshooting efforts and streamline the assembly process.

To begin interpreting such a visual guide, familiarize yourself with the symbols and notations used. Each icon represents a specific component, while connecting lines illustrate the relationships or pathways between these elements. A legend or key is often included to clarify these representations, making it easier to identify each part’s function and importance.

Next, pay attention to the layout. Components are typically arranged logically, allowing you to trace connections from one element to another. This organization aids in understanding how different parts interact within the larger system. Additionally, observe any numerical annotations or color codes that may indicate size, model specifications, or compatibility, further assisting in your comprehension.

Lastly, take your time to cross-reference the visual representation with any accompanying documentation. Manuals and service guides often provide valuable context, instructions, and additional details that can deepen your understanding of the schematic. Combining these resources will equip you with the knowledge necessary for effective maintenance or repairs.

Maintenance Tips for Ingersoll Rand Equipment

Regular upkeep of machinery is essential for optimal performance and longevity. Implementing effective maintenance strategies ensures that equipment operates smoothly, reduces downtime, and prolongs its lifespan. Following best practices in care and servicing can lead to enhanced reliability and efficiency.

To maintain equipment effectively, consider the following guidelines:

| Maintenance Activity | Frequency | Description |

|---|---|---|

| Lubrication | Monthly | Ensure all moving parts are well-lubricated to reduce friction and wear. |

| Filter Replacement | Quarterly | Replace air and oil filters to maintain clean operation and prevent blockages. |

| Visual Inspections | Weekly | Check for leaks, wear, or damage to components to catch issues early. |

| Calibrations | Annually | Perform necessary calibrations to ensure accurate performance of all systems. |

| Fluid Levels | Monthly | Monitor and maintain appropriate levels of hydraulic and lubricant fluids. |

By adhering to these maintenance practices, users can significantly enhance the performance and reliability of their equipment, ensuring it remains in top condition for years to come.

Identifying Replacement Parts Easily

When it comes to maintaining equipment, recognizing the correct components for replacement can significantly streamline the process. Understanding how to identify these elements not only enhances efficiency but also ensures the longevity of your machinery. This section aims to provide practical strategies for effortlessly locating the necessary items for your maintenance needs.

Utilizing Visual References

One of the most effective methods for recognizing necessary components is to use visual references. Diagrams and illustrations serve as invaluable tools, allowing users to match the appearance of items directly with their counterparts. By consulting detailed graphics, you can quickly ascertain the specific features and shapes of the components you require.

Consulting Manuals and Documentation

Another essential approach involves referring to manuals and technical documents. These resources often include comprehensive lists of components along with their specifications. By familiarizing yourself with these details, you can efficiently pinpoint the correct items needed for replacements, minimizing the risk of ordering incorrect parts.

Resources for Parts Diagrams Online

Finding reliable resources for component illustrations is essential for maintenance and repair tasks. Various platforms offer detailed visuals and information to assist users in identifying and obtaining the necessary items for their machinery.

Here are some valuable online resources:

- Manufacturer Websites: Official websites often provide access to comprehensive resources, including technical documents and visual aids for their equipment.

- Online Marketplaces: E-commerce platforms frequently have sections dedicated to manuals and technical illustrations, helping users locate specific components.

- Technical Forums: Community-driven forums allow users to share resources, insights, and diagrams, making them an excellent source for troubleshooting and guidance.

- Specialized Parts Retailers: Retailers that focus on machinery components often have extensive catalogs, complete with visual references for easy identification.

- Educational Resources: Online courses and webinars can provide insights into understanding component layouts and their functionality, enhancing users’ technical knowledge.

Utilizing these resources can significantly streamline the process of locating necessary components and ensuring efficient operation.

Benefits of Using Genuine Parts

Opting for original components ensures that your equipment maintains optimal performance and reliability. Genuine replacements are specifically designed to fit and function seamlessly, which helps extend the lifespan of machinery and minimize the chances of malfunctions.

Improved Efficiency and Longevity

When you choose authentic elements, the equipment operates at its intended efficiency. These items are manufactured to precise standards, ensuring that they deliver the same level of performance as the original setup. As a result, they reduce the likelihood of wear and tear, which can increase the overall lifespan of the system.

Safety and Warranty Protection

Using factory-approved components not only enhances the safety of the equipment but also helps maintain any existing warranties. Unauthorized alternatives might not meet the safety requirements, leading to potential risks. Staying within the manufacturer’s guidelines ensures that the warranty remains valid and that your machinery stays safe to use.

Frequently Asked Questions About Parts

This section addresses the most common inquiries related to various components used in equipment. Whether you are looking to understand specific elements or need clarification about replacement options, the answers provided here will help you make informed decisions.

How Do I Identify the Correct Replacement?

To ensure compatibility, it’s important to match the specifications of your equipment with the available replacement. Always verify dimensions, functionality, and any manufacturer guidelines before making a decision.

What Should I Consider When Choosing Components?

When selecting components, consider the durability, performance, and cost-effectiveness of each option. It’s crucial to ensure that the part will meet the operational demands of your equipment while providing long-term reliability.