In the world of farming and gardening, maintaining the efficiency of machinery is crucial for optimal performance. Every piece of equipment consists of various elements that work together to ensure smooth operation. Familiarity with these components not only aids in effective maintenance but also enhances overall productivity.

When exploring the intricate workings of agricultural machinery, visual aids can be invaluable. Detailed representations provide clarity on how each segment interacts and contributes to the whole system. This understanding empowers users to troubleshoot issues and perform necessary repairs with confidence.

In this section, we delve into the specifics of a popular brand’s machinery, breaking down the essential components and their functions. By dissecting these elements, we aim to equip operators with the knowledge needed to keep their equipment running efficiently, minimizing downtime and maximizing yield.

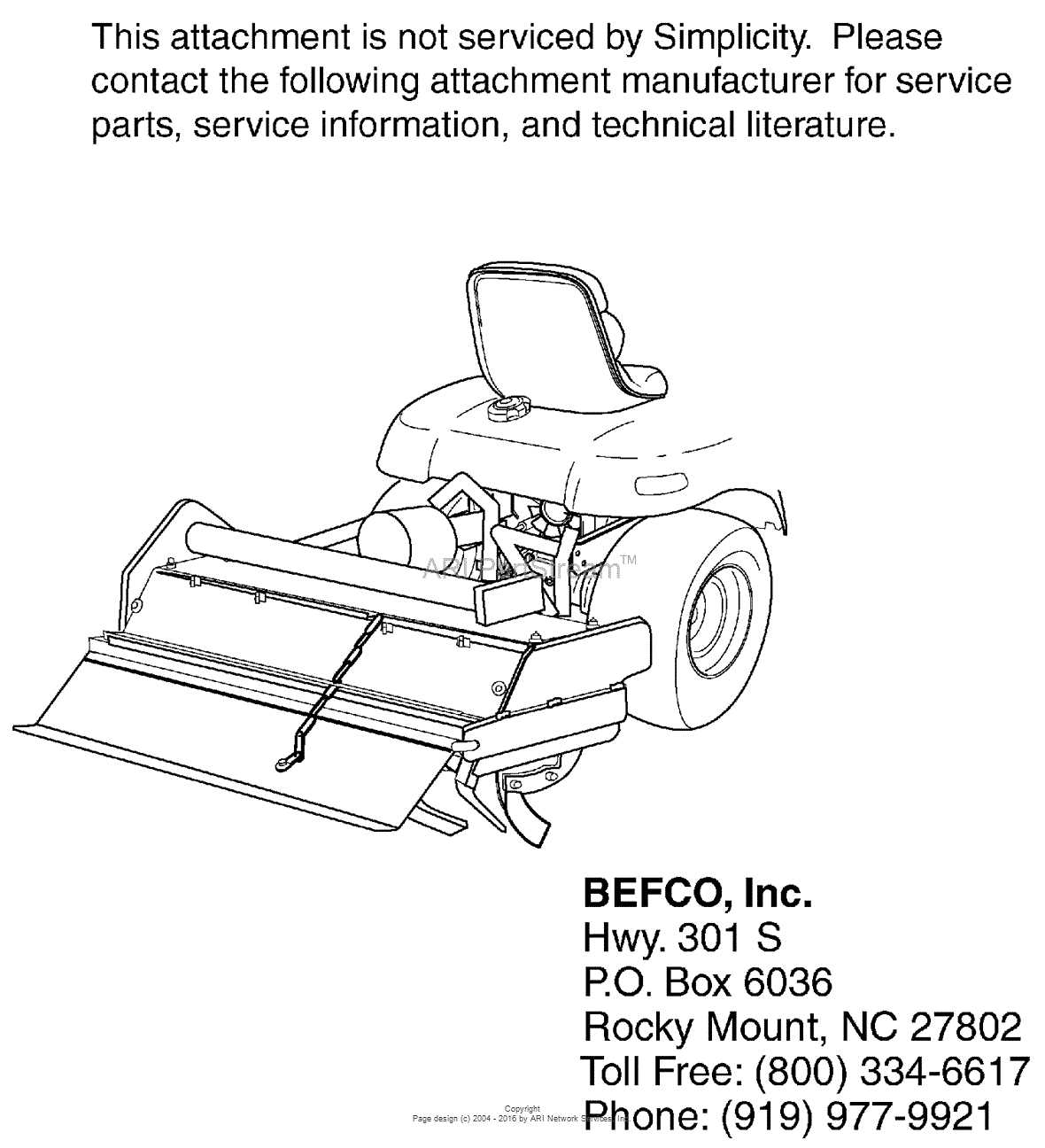

Understanding Befco Tillers

This section explores the essential components and mechanisms behind cultivation machinery, focusing on their design and functionality. Knowledge of these elements is crucial for effective maintenance and operation.

Key Features:

- Engine Types

- Transmission Systems

- Cutting Mechanisms

- Handle Design

Maintenance Tips:

- Regular inspection of the engine

- Lubrication of moving parts

- Sharpening or replacing cutting blades

- Checking and adjusting belts

Understanding these aspects can greatly enhance the performance and longevity of your equipment, ensuring optimal results in soil preparation tasks.

Components of Befco Tiller Systems

The machinery used for soil cultivation comprises various essential elements that work in harmony to achieve optimal performance. Understanding these components is crucial for effective maintenance and operation, ensuring longevity and efficiency in the field.

Engine serves as the powerhouse, providing the necessary energy to drive the entire system. Its reliability directly influences the overall effectiveness of the equipment.

Transmission facilitates the transfer of power from the engine to the working components. This system includes gears and belts that adjust speed and torque, allowing for adaptability to different soil conditions.

Cutting Tools are critical for soil engagement, featuring blades or tines that break up and aerate the ground. The design and material of these tools can significantly impact their performance and durability.

Chassis forms the structural foundation of the machinery, supporting all components while providing stability during operation. A robust chassis can withstand the stresses of heavy-duty use.

Controls encompass the user interface, allowing operators to adjust settings and monitor performance. Ergonomic design enhances usability, ensuring efficient operation during prolonged tasks.

Attachment System enables the integration of various implements, enhancing versatility. The ability to switch attachments allows users to customize their equipment for specific applications.

By understanding these integral components, operators can ensure their machinery functions optimally, leading to improved agricultural practices and productivity.

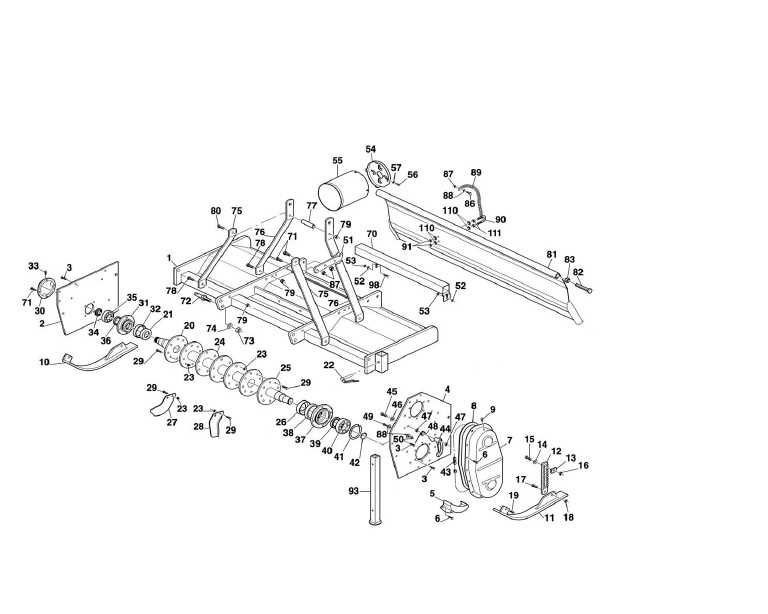

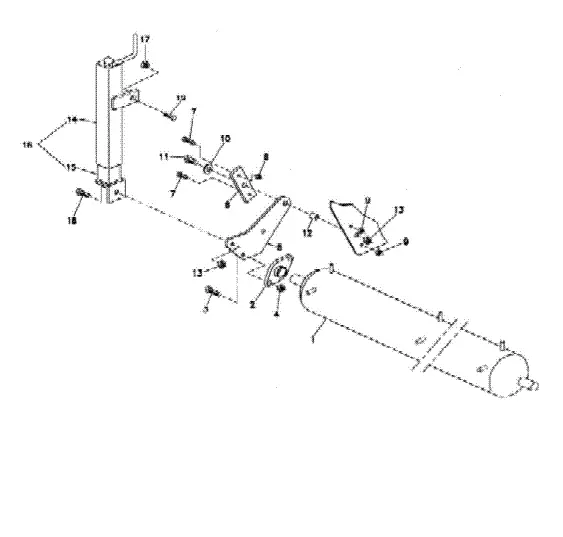

Importance of Accurate Parts Diagrams

Understanding the intricate layout of machinery components is essential for efficient maintenance and repair. Clear visual representations facilitate identification, ensuring that every element is correctly addressed during servicing. This accuracy not only saves time but also enhances the longevity of the equipment.

Precise illustrations serve as a vital resource for both professionals and DIY enthusiasts, enabling them to delve into the specifics of assembly and disassembly. They eliminate confusion, allowing for an ultimate understanding of how each piece interacts within the system.

Moreover, accurate schematics promote safety by guiding users in the correct handling of components. With a thorough grasp of each element’s function and placement, the risk of errors diminishes significantly, leading to a smoother operational experience.

Common Issues with Tiller Parts

When operating garden machinery, users often encounter various challenges that can hinder performance and efficiency. Understanding these common problems is essential for effective maintenance and repair, ultimately enhancing the lifespan of the equipment.

Wear and Tear: Over time, components may suffer from wear, leading to decreased functionality. Regular inspections can help identify parts that need replacement.

Clogging: Soil and debris can accumulate, obstructing movement and causing strain on the machine. Keeping the equipment clean is crucial for optimal operation.

Misalignment: Components that are not properly aligned can result in uneven performance and potential damage. Ensuring correct alignment during assembly and maintenance is vital.

Fluid Leaks: Leaks can occur in hydraulic or lubrication systems, impacting efficiency and potentially causing more significant issues. Prompt attention to any signs of leaking is necessary.

By addressing these common challenges, users can delve deeper into maintenance practices, ensuring their machinery operates at its ultimate best.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair of equipment. These visual guides provide a detailed overview of components, helping users identify, organize, and replace parts as needed. Mastering the interpretation of such illustrations can streamline the repair process and enhance overall efficiency.

Typically, these visuals are accompanied by a reference list that correlates each component with a unique identifier. This identifier often corresponds to a numerical or alphabetical code found on the illustration itself. By recognizing these symbols and their placements, one can easily locate and obtain the necessary items for repairs.

| Identifier | Description |

|---|---|

| 1 | Gear assembly |

| 2 | Drive shaft |

| 3 | Control lever |

| 4 | Housing cover |

| 5 | Mounting bracket |

Additionally, some illustrations include exploded views, which offer a clearer perspective of how components fit together. This can be particularly helpful when disassembling or reassembling machinery. Observing how each part interacts with others can provide insight into functionality and troubleshooting.

In summary, familiarizing oneself with an assembly illustration and its accompanying reference list can significantly simplify the process of identifying and acquiring components necessary for effective equipment maintenance.

Finding Replacement Parts for Befco

When it comes to maintaining agricultural equipment, locating suitable components is essential for ensuring optimal performance. Understanding the structure and functionality of your machinery can greatly aid in the search for quality substitutes that align with your needs.

Utilizing Resources

Many online platforms offer extensive catalogs and guides for identifying the necessary components. These resources can provide diagrams and lists that help clarify which items are required, facilitating a more efficient replacement process.

Connecting with Experts

Engaging with professionals or joining forums dedicated to agricultural tools can also prove invaluable. Experienced users often share insights and recommendations, making it easier to find the right solutions for your specific machinery.

Maintenance Tips for Tillers

Regular upkeep is essential to ensure optimal performance and longevity of your gardening machinery. By following a few straightforward practices, you can maintain efficiency and prevent costly repairs. This section outlines crucial maintenance strategies to keep your equipment running smoothly.

Routine Checks

- Inspect the engine oil regularly; change it according to the manufacturer’s recommendations.

- Clean or replace air filters to ensure proper airflow and engine efficiency.

- Examine the fuel system for leaks or blockages, and use fresh fuel to avoid issues.

Seasonal Maintenance

- Before winter, store your machinery in a dry place and drain fuel to prevent damage.

- Sharpen or replace cutting blades at the start of the season for effective soil cultivation.

- Check belts and cables for wear, adjusting or replacing them as necessary to ensure proper operation.

Adhering to these maintenance tips will enhance the performance and durability of your gardening tools, making your tasks easier and more efficient.

Upgrading Befco Tiller Features

Enhancing the capabilities of your gardening equipment can significantly improve its efficiency and performance. Upgrades not only increase productivity but also ensure that your machine adapts to various tasks and terrains. By implementing a few thoughtful modifications, you can transform your device into a more versatile and powerful tool.

One effective approach is to invest in advanced attachments. These accessories can extend the range of tasks your machinery can handle, from breaking up tough soil to creating finer tilth. Consider options such as specialized blades or different wheel types that cater to specific environments.

Another area for improvement is the engine. A more powerful or fuel-efficient engine can provide better performance and reduce downtime. Look into engine upgrades that align with your needs, ensuring they are compatible with your existing setup.

Maintenance is key to longevity and efficiency. Regularly replacing worn components not only prevents breakdowns but also enhances the overall operation of your equipment. Establish a routine check-up schedule to identify and address potential issues early on.

Finally, consider ergonomic modifications. Enhancing comfort during operation can lead to better handling and less fatigue. Look for adjustable controls or comfortable grips that suit your personal preferences, allowing for a more enjoyable working experience.

Comparative Analysis with Other Brands

When evaluating agricultural equipment, it is crucial to compare different manufacturers to understand their strengths and weaknesses. This analysis focuses on performance, durability, and user satisfaction, providing insights into how various brands stack up against one another.

Performance Metrics

Performance is a key factor in determining the efficiency of agricultural tools. The following table summarizes the performance ratings based on various criteria such as power output, speed, and operational ease.

| Brand | Power Output (HP) | Speed (mph) | Ease of Use (Rating/5) |

|---|---|---|---|

| Brand A | 5.5 | 4.0 | 4.5 |

| Brand B | 6.0 | 3.5 | 4.0 |

| Brand C | 5.0 | 4.2 | 4.8 |

Durability and Reliability

Durability is another essential aspect that impacts long-term investment. Brands are often judged on their materials, construction quality, and maintenance requirements. The following table presents a comparison of durability indicators.

| Brand | Material Quality (Rating/5) | Warranty Period (Years) | Maintenance Frequency (Months) |

|---|---|---|---|

| Brand A | 4.7 | 3 | 6 |

| Brand B | 4.5 | 2 | 4 |

| Brand C | 4.8 | 5 | 8 |

This comparative analysis highlights the importance of assessing multiple aspects when selecting agricultural machinery, enabling users to make informed decisions tailored to their needs.