Exploring the intricate assembly of garden machinery reveals the essential elements that contribute to efficient soil management. Each component plays a pivotal role in ensuring optimal performance, allowing for a seamless cultivation experience.

Identifying individual elements within these machines not only enhances operational knowledge but also aids in troubleshooting and maintenance. By gaining insights into the various sections, users can make informed decisions about repairs and upgrades.

Moreover, a comprehensive overview of these mechanisms empowers gardeners to maximize their productivity. Whether for home gardens or larger agricultural endeavors, understanding how each part functions is key to achieving ultimate success in soil preparation.

Understanding MTD Tiller Components

Exploring the intricacies of garden cultivation machinery reveals a variety of essential elements that work in harmony to enhance soil preparation. Each component plays a significant role in ensuring optimal performance, contributing to efficiency and effectiveness in gardening tasks. A solid grasp of these elements allows users to maintain and operate their equipment more effectively.

Key Elements of the Machinery

At the core of the operation lies the engine, providing the necessary power to drive the unit. Coupled with this are the cutting implements, which are crucial for breaking up the earth and turning the soil. Additionally, the transmission system facilitates the movement and control, allowing the operator to navigate various terrains with ease.

Maintenance and Care

Regular upkeep of these essential components is vital for longevity and optimal functionality. Routine checks on the engine, lubrication of moving parts, and inspection of the cutting tools can significantly enhance performance. Understanding the roles of each element not only aids in effective operation but also empowers users to troubleshoot potential issues.

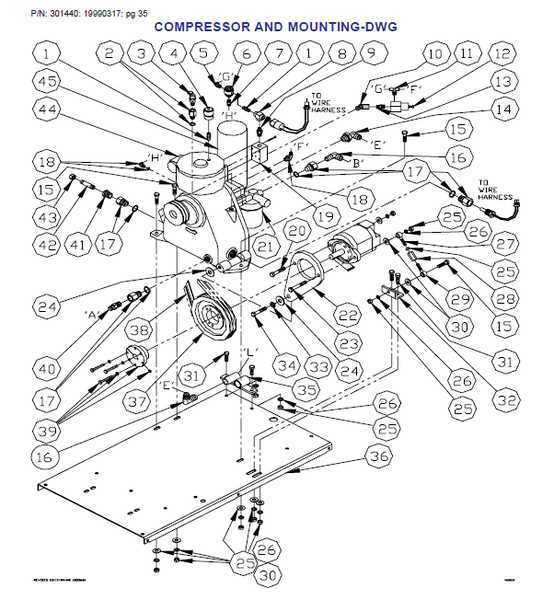

Importance of Tiller Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements help users identify each section, facilitating troubleshooting and ensuring optimal performance. By familiarizing oneself with the layout and function of individual components, operators can address issues more swiftly and efficiently.

Moreover, having a clear reference guide supports proper assembly and disassembly, reducing the risk of errors during repairs. It promotes a deeper understanding of how each segment interacts, ultimately enhancing the lifespan of the equipment. For both novice and experienced users, these illustrations serve as an invaluable resource in achieving the highest standards of care and functionality.

Common MTD Tiller Issues Explained

Understanding the typical problems that can arise with gardening equipment is essential for effective maintenance and repair. This section highlights some frequent challenges users may encounter, providing insights into their causes and potential solutions.

Engine Performance Problems: One of the most common issues involves the engine not starting or running poorly. This can be attributed to fuel contamination, old spark plugs, or clogged air filters. Regular maintenance, including changing the fuel and checking the spark plug, can help prevent these issues.

Transmission Difficulties: Users often face challenges with the transmission, such as slipping or not engaging. This may be due to worn belts or misaligned components. Inspecting and replacing worn parts promptly can ensure smooth operation.

Uneven Tilling: When the equipment does not till evenly, it can result from improper adjustment of the tines or worn-out blades. Ensuring that the tines are correctly positioned and checking for damage can restore even performance.

Overheating: Overheating is another prevalent issue, often caused by insufficient lubrication or debris buildup. Regularly checking oil levels and cleaning any accumulated debris can mitigate this problem.

Vibration and Noise: Excessive vibration or unusual noises can indicate loose or damaged components. Regular inspections and tightening of bolts can help reduce these symptoms, contributing to a smoother operation.

Addressing these common issues proactively can enhance the longevity and efficiency of your gardening machinery, ensuring it performs optimally for years to come.

How to Interpret Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations serve as a roadmap, guiding users through the assembly and functionality of machinery. By familiarizing yourself with the symbols and layout, you can enhance your troubleshooting skills and streamline the repair process.

First, identify the legend or key that explains various symbols used in the representation. This will provide clarity on what each element signifies. Next, focus on the arrangement of parts, noting how they interact within the larger system. Recognizing connections and relationships is crucial for understanding overall function.

Additionally, take note of any reference numbers or labels that correspond to replacement items, as these are vital for sourcing the correct components. Lastly, cross-reference these visuals with user manuals or guides to solidify your comprehension and ensure accurate assembly or disassembly.

Essential Maintenance Tips for Tillers

Proper upkeep of gardening machinery is crucial for ensuring efficiency and longevity. Regular maintenance not only enhances performance but also prevents costly repairs down the line. Here are key practices to keep in mind:

- Regularly check and change the oil to maintain engine health.

- Inspect the air filter frequently; a clean filter improves airflow and performance.

- Sharpen or replace blades to ensure effective soil cultivation.

- Keep the wheels and tines free of debris to prevent damage.

- Examine belts and cables for wear and replace them as necessary.

- Store the equipment in a dry, sheltered place to avoid rust and deterioration.

Following these essential steps will help you maintain optimal functionality and achieve the best results in your gardening endeavors.

Identifying Compatible Replacement Parts

Finding suitable substitutes for machinery components is crucial for maintaining performance and longevity. Understanding the compatibility of various elements ensures that your equipment operates efficiently without unnecessary disruptions. This process involves examining specifications, dimensions, and manufacturer recommendations to make informed choices.

Begin by consulting the user manual, which often contains valuable information regarding component compatibility. Pay close attention to the model number and serial information, as these details can lead you to the correct alternatives. Additionally, researching online or visiting local suppliers can provide insights into what options are available in the market.

Furthermore, consider engaging with community forums or support groups where enthusiasts share their experiences. Their insights can help you navigate challenges and discover reliable sources for replacements. Ultimately, taking the time to identify appropriate substitutes will enhance the efficiency and reliability of your machinery.

Step-by-Step Repair Guide for Tillers

This guide aims to assist you in effectively restoring your gardening equipment to optimal working condition. By following these systematic instructions, you will be able to troubleshoot common issues, replace worn components, and enhance overall performance. Each step is designed to be straightforward, ensuring you can handle repairs with confidence.

Begin by gathering essential tools and materials. A basic toolkit should include wrenches, screwdrivers, pliers, and replacement components as necessary. Having everything at hand will streamline the process and reduce downtime.

Next, perform a thorough inspection of the machine. Look for visible signs of wear, damage, or any parts that may be loose. Take notes of any irregularities you encounter; this will help you prioritize your repairs and replacements.

Once you have identified the issues, consult the manufacturer’s manual for specific guidelines on disassembly and reassembly. Carefully follow these instructions to avoid causing further damage during the repair process. Keep track of each component as you remove it to ensure everything is put back together correctly.

After addressing the identified problems, reassemble the equipment methodically. Double-check that all screws and bolts are securely fastened and that moving parts are properly aligned. Testing the machinery before returning it to regular use is crucial to ensure that your repairs were successful.

Finally, maintain your equipment regularly to prevent future issues. Routine checks and servicing can prolong the lifespan of your tools and enhance their efficiency. Remember, proactive care is key to avoiding extensive repairs down the line.

Where to Find MTD Tiller Diagrams

Locating detailed illustrations for outdoor equipment can be essential for maintenance and repairs. Understanding where to access these resources can significantly simplify the troubleshooting process and ensure efficient upkeep.

Online Resources

- Official Manufacturer Website: Most manufacturers provide a dedicated section for support and resources, including comprehensive guides and schematics.

- Online Retailers: Websites that specialize in outdoor machinery often have downloadable manuals and technical documents.

- DIY Forums: Community-driven platforms frequently host discussions and links to helpful visual aids shared by other users.

Printed Manuals

- Local Dealers: Authorized dealers may offer printed manuals and reference materials for various models.

- Library: Public libraries often maintain a collection of manuals and repair guides for different equipment.

Benefits of Regular Tiller Maintenance

Improved Performance

- Regular checks lead to smoother operation.

- Well-maintained machinery consumes less energy.

- Efficient tools allow for faster completion of tasks.

Cost Savings

- Reduces the likelihood of costly repairs.

- Extends the lifespan of your equipment.

- Minimizes the need for replacements.

By prioritizing maintenance, you ultimately enhance the reliability and effectiveness of your gardening tools, leading to a more fruitful and enjoyable gardening experience.