The intricate design and functionality of agricultural machinery depend on a wide range of individual elements working together seamlessly. Each piece plays a crucial role in ensuring optimal performance and longevity, whether it’s during regular maintenance or a specific repair. Understanding how these components interact can significantly enhance the efficiency of your equipment.

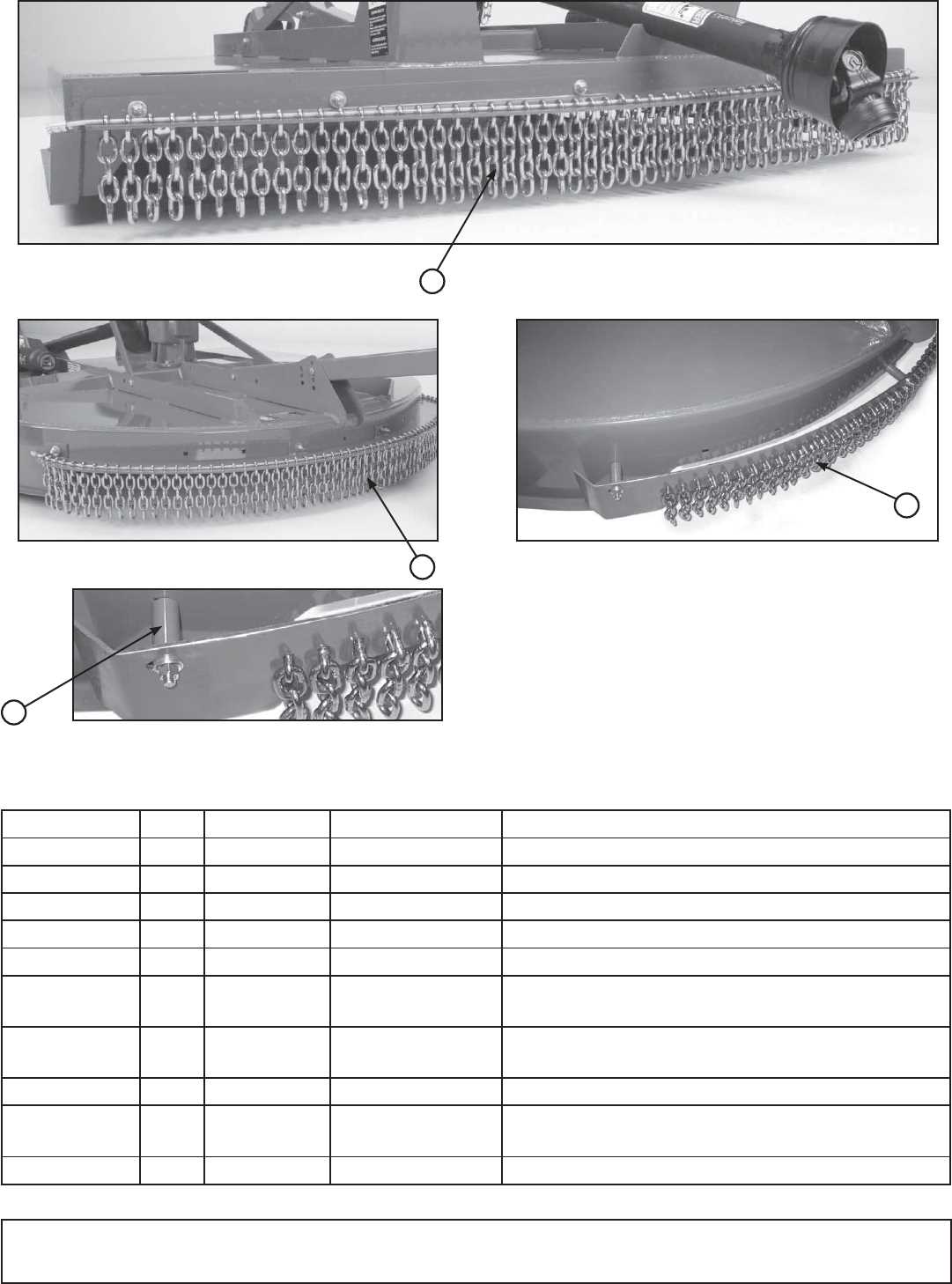

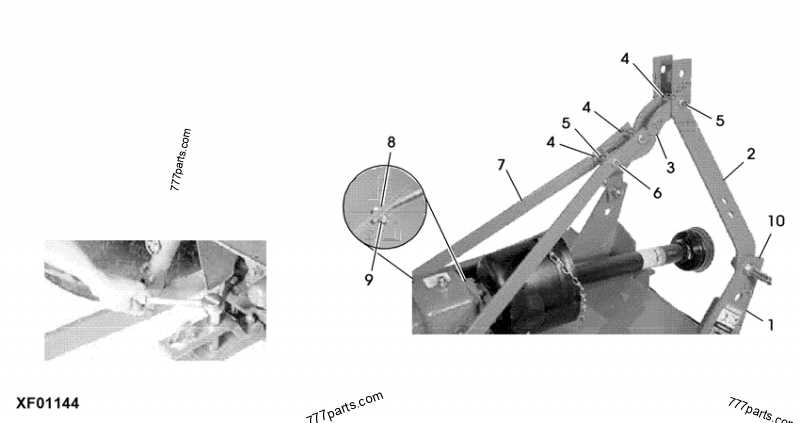

Detailed illustrations of the various parts and their connections provide an invaluable reference for anyone involved in the maintenance or assembly of machinery. These visuals offer clarity, allowing users to quickly identify and address any issues, ensuring that all systems are functioning as intended.

In this guide, we will explore the essential components of tractor attachments and provide insights into their structure. By familiarizing yourself with these elements, you’ll gain a deeper understanding of how they contribute to the overall functionality of your machinery.

Exploring the Frontier RC2060 Parts Diagram

Understanding the inner workings of a cutting machine can significantly improve maintenance and performance. Every component plays a crucial role in ensuring smooth operation, and knowing how they interconnect is essential for troubleshooting and repairs. A visual guide showcasing these elements provides clarity on how each part contributes to the overall functionality.

Detailed schematics offer a comprehensive view of the assembly, helping users identify individual components such as the drive system, cutting blades, and support structures. By carefully studying this guide, operators can better manage upkeep and replacements, ensuring that their equipment runs efficiently over time.

Efficient use of this reference can prevent potential issues by highlighting the most commonly worn parts and pinpointing areas that require regular inspection. With this knowledge, users are empowered to maintain optimal performance, reduce downtime, and extend the longevity of their machinery.

Key Components of the RC2060 Mower

The mower consists of several essential elements that work together to provide efficient cutting and handling. Each component plays a crucial role in ensuring the machine performs reliably under various conditions. Understanding the key parts allows for better maintenance and optimized operation.

Cutting Mechanism

The cutting system is at the heart of the mower’s functionality. It typically includes a set of rotating blades that are powered by the engine. These blades are designed to slice through grass and other vegetation with precision, ensuring a clean and uniform cut. Regular maintenance of this system is critical to avoid uneven results and potential damage to the blades.

Support and Stability

Stability and control are achieved through the frame and wheel assemblies. A well-designed frame provides the necessary structure for the mower, while the wheels offer the mobility required to navigate uneven terrain. Proper alignment and tire pressure are key to maintaining consistent performance and avoiding strain on the motor.

Understanding the Tractor Attachment System

The tractor attachment system is a crucial component that allows various implements and tools to be securely connected to the machine. This system enables the tractor to perform a wide range of tasks, from plowing to mowing and more. Understanding how this system works can help in selecting the right equipment for specific tasks and ensuring efficient operation in the field.

Key Components of the Attachment Mechanism

The system is composed of several parts that work together to facilitate easy mounting and detaching of implements. These components include the hitch, linkage, and hydraulic controls. The hitch is responsible for securing the implement to the tractor, while the linkage adjusts the position and movement of the attached tool. Hydraulic systems provide the necessary force for lifting and lowering implements, making tasks easier and more efficient.

Benefits of a Versatile Attachment System

A well-designed attachment system enhances the versatility of the tractor, allowing it to handle a variety of tasks. By switching out different implements, the machine can be used for a range of activities, from soil cultivation to hauling materials. This adaptability increases productivity and reduces the need for multiple specialized machines, making it a cost-effective solution for many farming and landscaping needs.

How to Read the Parts Diagram Effectively

Understanding technical visuals for machinery is crucial for proper maintenance and repair. These illustrations provide a detailed view of the components and their arrangement within the system. To make the most of these resources, it’s important to follow a systematic approach to interpret the symbols, labels, and connections accurately.

Key Elements to Focus On

The most effective way to read these visuals is by first identifying the key components. Each part will typically be labeled with a reference number or a specific code that corresponds to a list. Pay attention to these references, as they provide direct information about the part’s function and location.

Interpreting the Symbols and Numbers

Another critical element is understanding the symbols used. These symbols are universally recognized within the technical field and represent different types of components or actions. Numbers associated with each part guide you to its precise identification in a catalog or manual, which may be used for ordering or replacement.

| Component | Description | Reference Number |

|---|---|---|

| Wheel Assembly | Complete unit for rotational movement | W001 |

| Drive Shaft | Transmits power from the engine | S002 |

| Mounting Bracket | Secures the drive shaft to the frame | B003 |

Common Maintenance Tips for the RC2060

Regular upkeep of your equipment ensures its longevity and optimal performance. Proper care prevents wear and tear, reduces downtime, and helps maintain efficiency over time. By following these essential maintenance practices, you can keep your machinery in top condition and avoid costly repairs.

- Inspect the Blades: Regularly check the blades for any signs of damage, dullness, or wear. Sharp blades are crucial for effective operation and smooth cutting.

- Check Lubrication Levels: Ensure that all moving parts are well-lubricated to reduce friction and minimize wear. This helps extend the life of the machine and ensures smooth movement.

- Clean After Each Use: Remove debris and buildup from the equipment after every use. Keeping the surfaces clean helps prevent rust and corrosion.

- Examine the Belts: Inspect belts for tightness and wear. Loose or damaged belts can lead to inefficient operation and increased strain on the engine.

- Monitor Fluid Levels: Regularly check and maintain proper fluid levels, including hydraulic fluid and coolant. This ensures optimal machine performance and prevents overheating.

- Tighten Loose Parts: Periodically check bolts, screws, and other fasteners to ensure they are properly tightened. Loose parts can lead to malfunction or further damage.

Identifying Wear and Tear in Key Parts

Over time, essential components of machinery can experience gradual deterioration due to frequent use. Recognizing signs of wear early is crucial to prevent unexpected failures and to ensure the equipment operates efficiently. By carefully inspecting specific areas, you can address issues before they become serious problems, thus extending the lifespan of the machine.

Signs of Excessive Use

Components that endure regular strain, such as gears and bearings, are often the first to show signs of wear. Common indicators include looseness, increased noise, or difficulty in movement. Regular inspections for these symptoms will help maintain performance and avoid costly repairs.

Impact of Environmental Conditions

External factors like moisture, dirt, and extreme temperatures can accelerate wear on critical parts. In particular, seals and hoses may degrade faster in harsh environments. Keeping these parts clean and protected will reduce the risk of premature damage.

Frontier RC2060: Troubleshooting Common Issues

When operating a rotary cutter or mower, encountering technical problems is inevitable. Identifying and resolving these issues quickly can prevent unnecessary downtime and ensure smooth operation. In this section, we will explore some of the most frequently encountered challenges and offer solutions to help you get back to work efficiently.

Here are some common issues that operators may face, along with their potential causes and suggested remedies:

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Blade not cutting properly | Blades dull or damaged, improper height setting | Sharpen or replace the blades, adjust the cutting height |

| Excessive vibration | Loose parts, damaged blade or spindle, uneven terrain | Tighten all bolts and fasteners, check for blade or spindle damage, level the ground |

| Machine stalling or not starting | Fuel or oil issues, electrical problems, clogged filters | Check and top up fuel and oil levels, inspect and replace filters, examine the electrical system |

| Poor cutting performance in thick grass | Engine underperformance, worn-out components | Check engine power, replace worn parts, clean air filters |

Upgrading Components for Better Performance

Improving the key elements of your machinery can significantly enhance its overall efficiency and productivity. By focusing on upgrading specific components, you can boost power output, reduce wear, and extend the lifespan of your equipment. Strategic enhancements can make a noticeable difference in how well the system operates under various conditions.

Identifying critical upgrades is the first step towards maximizing performance. By evaluating the current parts and their functionality, you can determine which areas need improvement. For example, upgrading the cutting or drive mechanisms can result in smoother operation and reduced energy consumption.

Investing in higher-quality components often pays off in the long run. Not only does this contribute to more efficient work, but it also minimizes the likelihood of breakdowns, leading to less downtime and increased productivity. Consider researching options that provide better durability and enhanced capability.

Where to Find Replacement Parts for RC2060

When it comes to maintaining your equipment, finding the right components is essential for ensuring smooth operation. Whether you are in need of specific machinery elements or just looking for general upkeep, there are several reliable sources to consider. By sourcing the right replacements, you can restore the functionality and performance of your gear efficiently.

Online Retailers offer a wide range of options. Websites dedicated to machinery and agricultural equipment often stock everything you need, from basic hardware to more complex mechanical pieces. These platforms typically provide clear descriptions and images to assist in selecting the correct parts for your machine.

Authorized Dealers are another trusted source. They often carry official components, ensuring compatibility and durability. By reaching out to these dealers, you can get expert guidance and guarantees on the quality of the items you purchase.

Local Repair Shops may also be a good place to check. These establishments can offer hands-on support and may even stock the specific items you need. In addition, their technicians can offer personalized advice based on your equipment’s model and condition.