When maintaining outdoor cutting machines, it’s crucial to grasp the inner workings of their various elements. These devices rely on a set of mechanical and structural units that work together to deliver precision and efficiency. Ensuring proper upkeep and knowing how each element contributes to the overall performance is key to prolonging the lifespan of the equipment.

Each assembly has a specific function, whether it’s related to movement, cutting capability, or power distribution. By breaking down these components and their connections, it becomes easier to identify potential issues and perform necessary adjustments or replacements. Whether you’re a seasoned technician or a beginner, familiarizing yourself with the structure of these devices can save time and effort during maintenance.

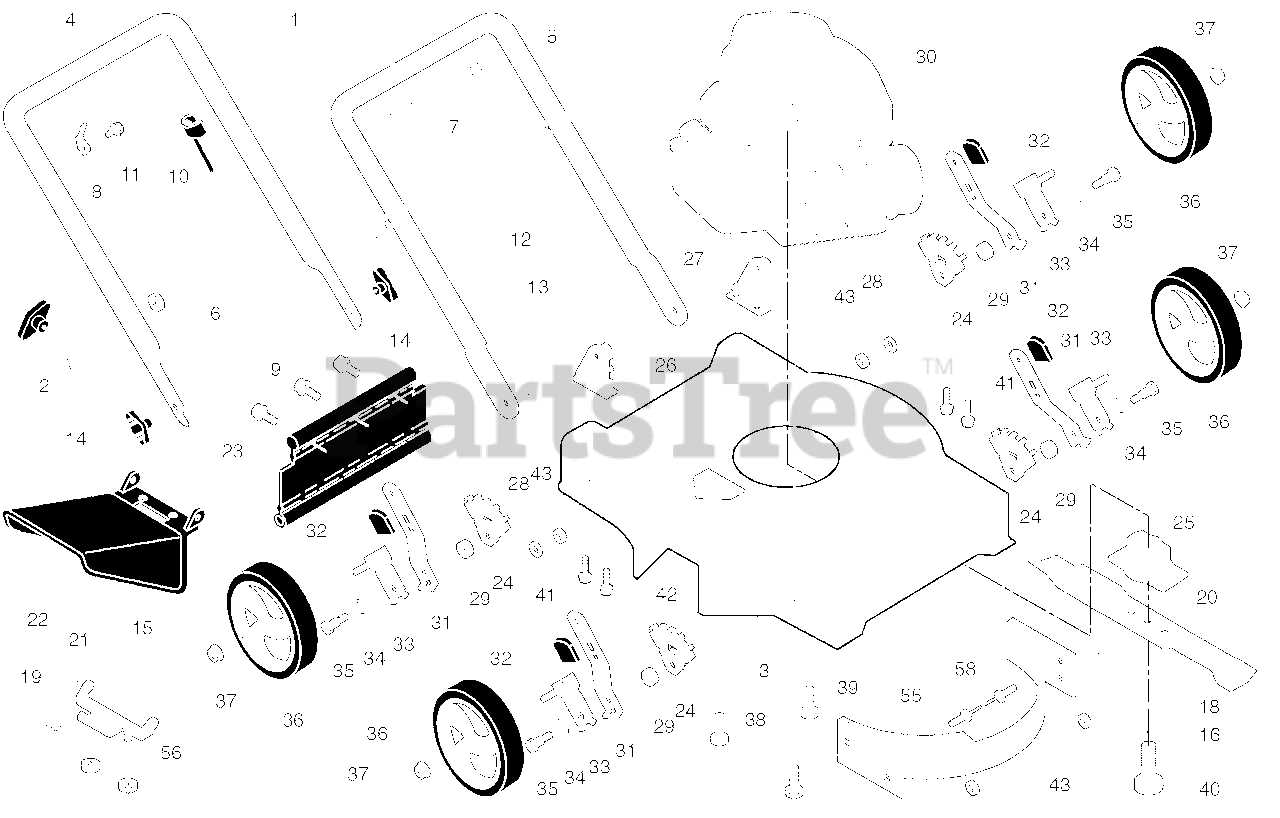

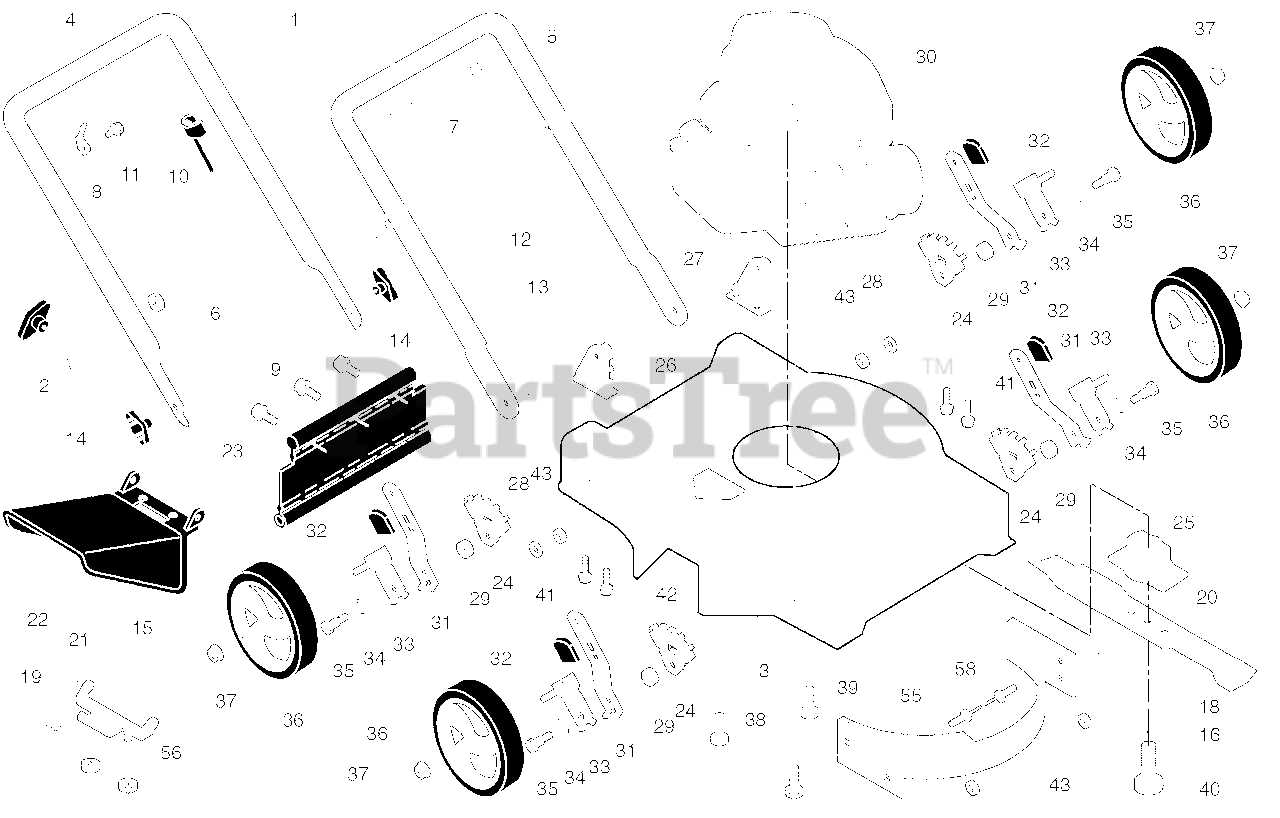

Weed Eater Lawn Mower Components Overview

Understanding the various elements of a typical cutting machine is essential for efficient maintenance and performance. Each component plays a crucial role in ensuring that the entire system operates smoothly and delivers the desired results during operation. Familiarizing yourself with these individual elements helps in troubleshooting issues and optimizing the overall functionality of the equipment.

Engine and Drive Mechanism

The engine serves as the core power source, converting fuel or electricity into the force needed to turn the blades and drive the machine. Connected to the drive mechanism, it ensures smooth motion across different terrains. Regular upkeep of this core component is vital for reliable and consistent operation.

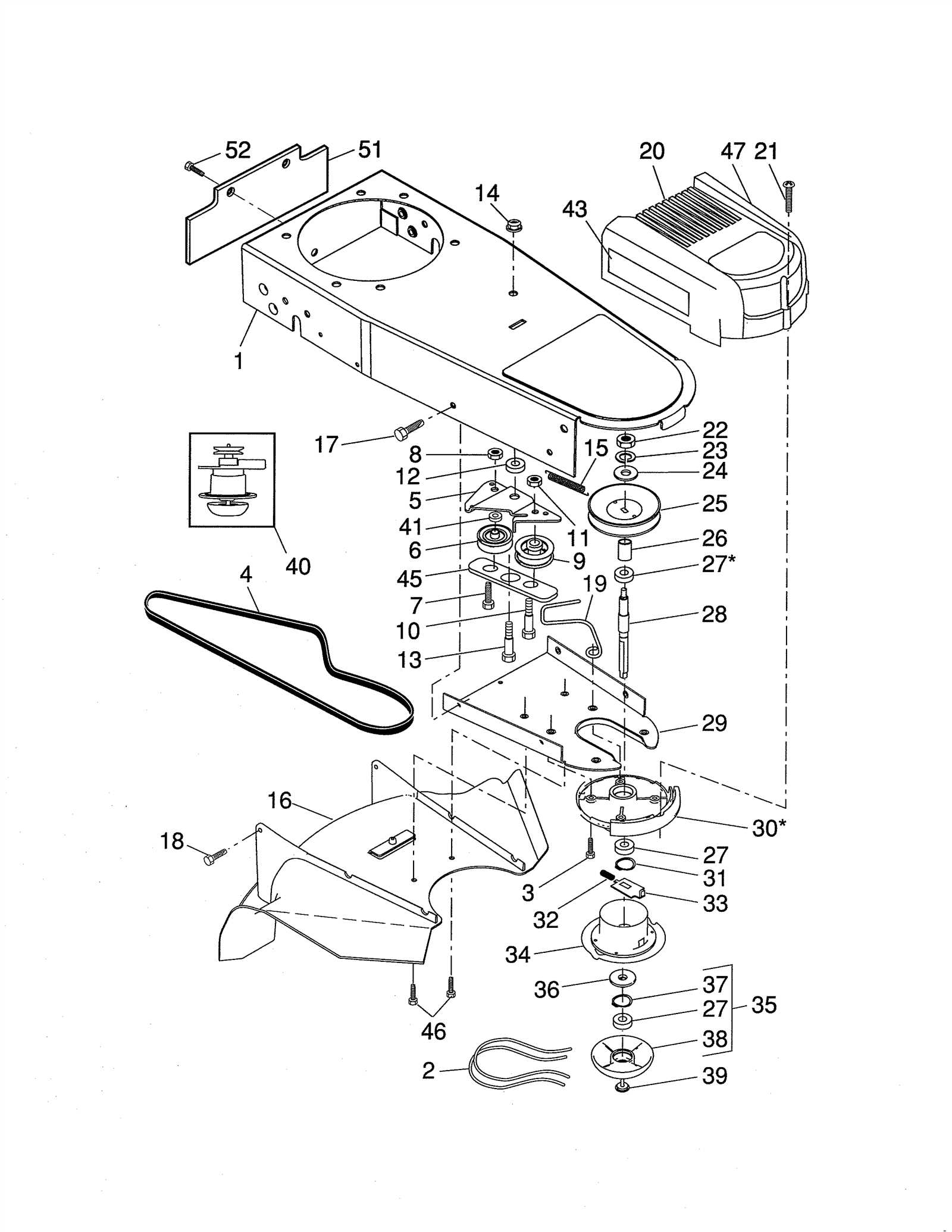

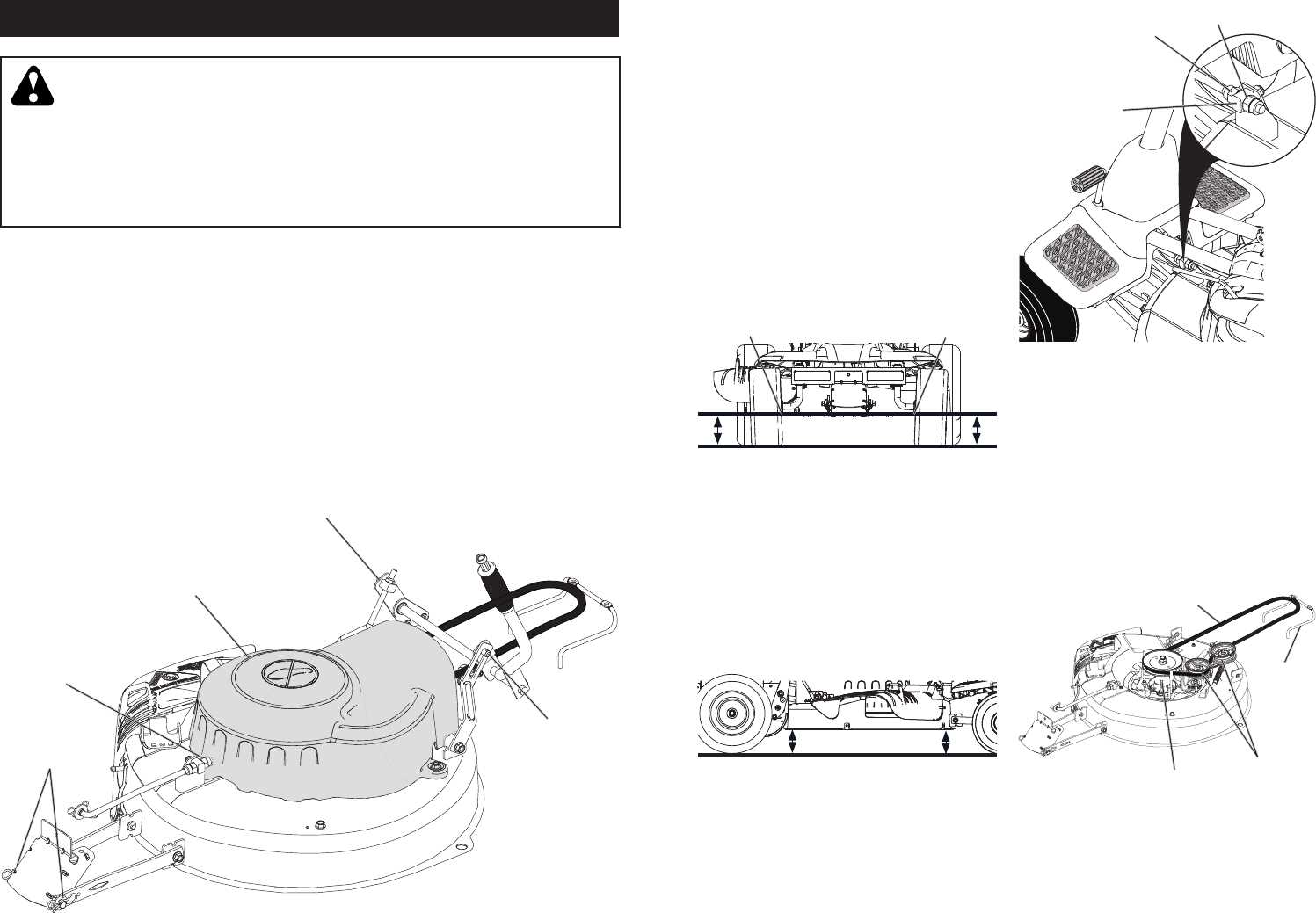

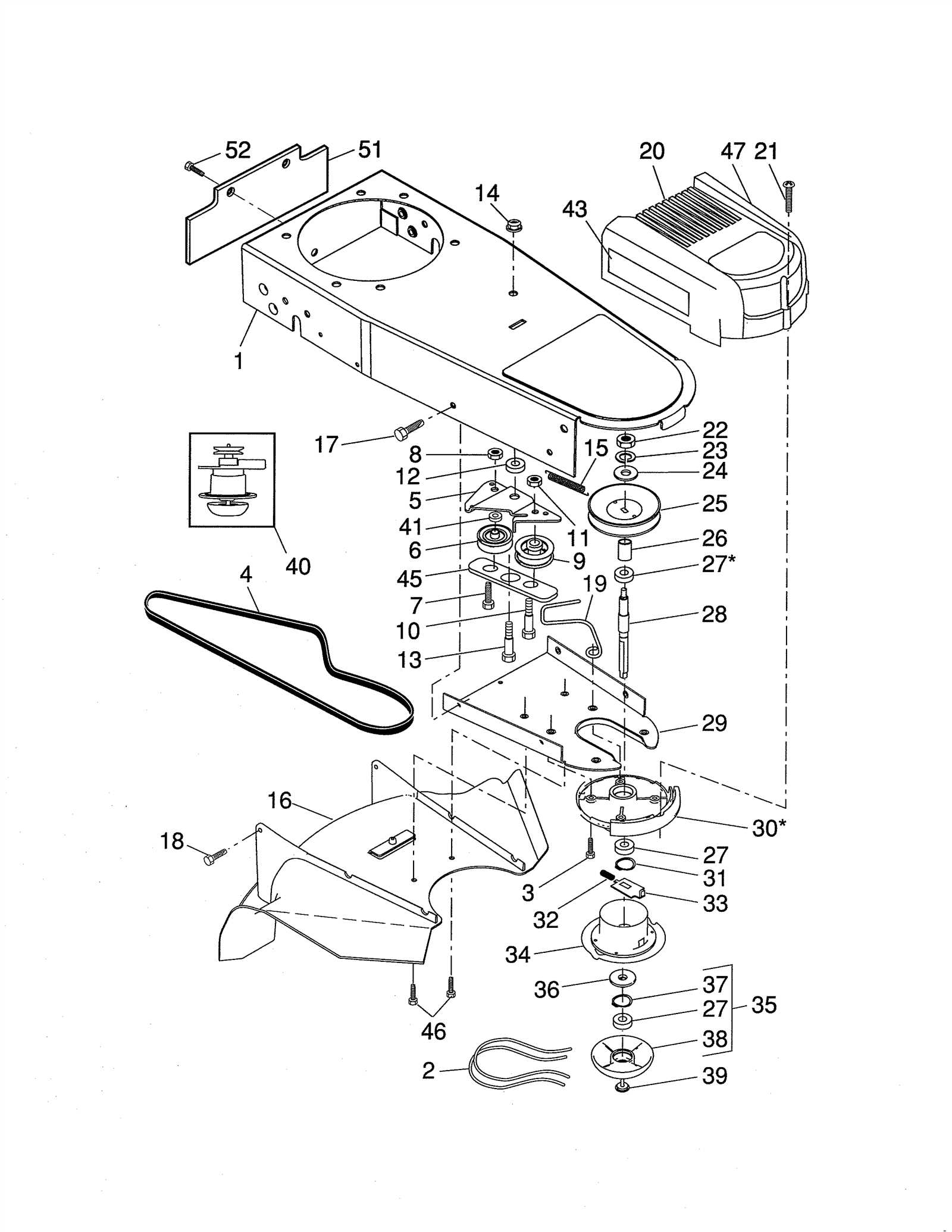

Cutting System

The cutting mechanism consists of sharp, rotating blades designed to trim surfaces to the desired height. Whether made from metal or composite materials, these blades require regular sharpening and occasional replacement to maintain effectiveness. A properly maintained cutting system ensures clean, precise trimming and a well-groomed result.

Identifying Essential Parts for Maintenance

Regular upkeep of outdoor power tools requires a solid understanding of their critical components. Knowing which elements demand routine attention ensures efficient operation and prolongs the equipment’s lifespan.

Among the key elements, certain mechanical and electrical components are more prone to wear due to frequent use. These require close inspection during routine check-ups to maintain optimal performance.

Bolts, screws, and fasteners secure various moving elements and must be regularly checked to ensure they are tightly fitted and in good condition. Belts and pulleys, which transfer power across the machine, are also subject to wear and may need replacement if damaged.

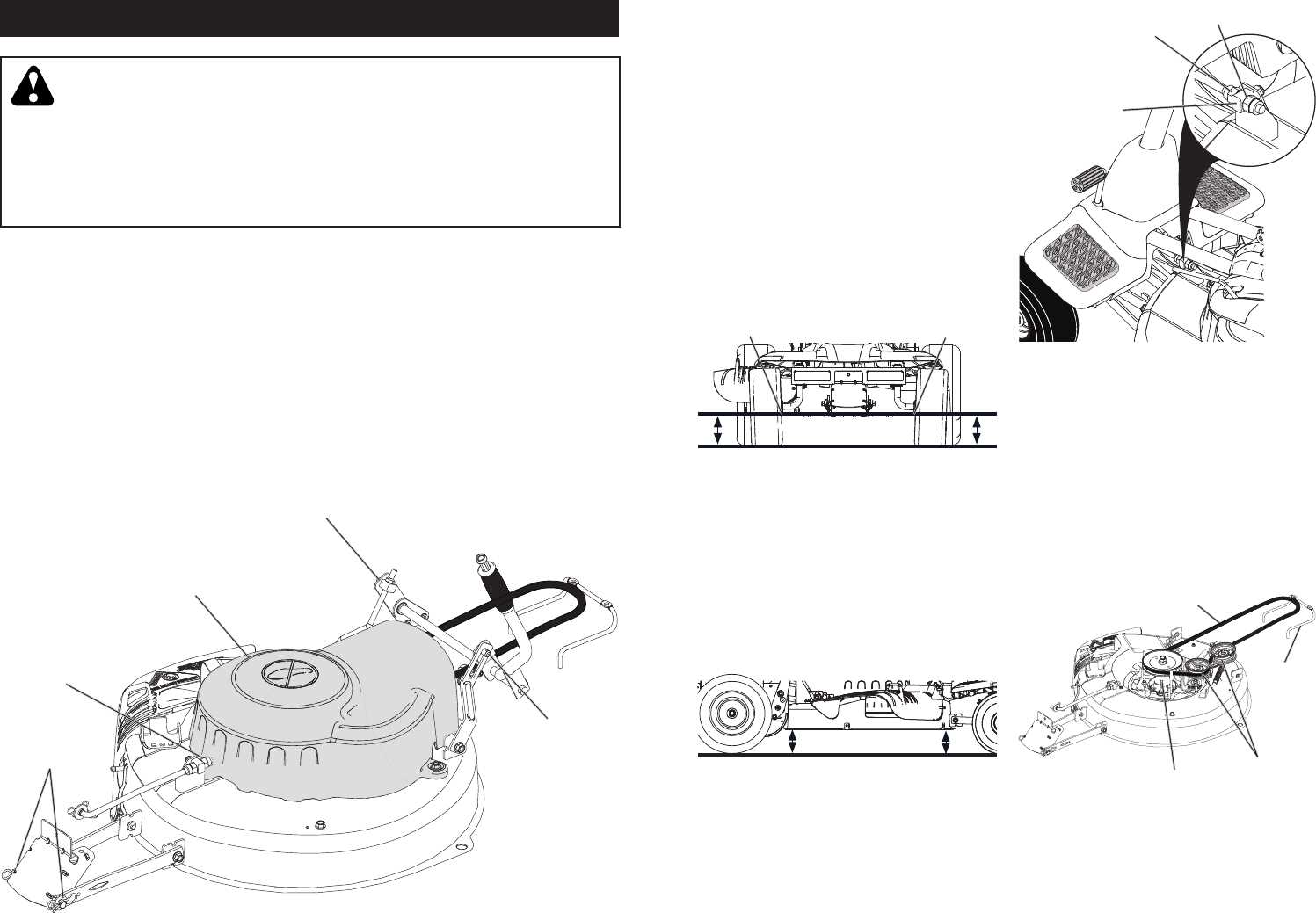

Exploring Blade and Cutting Mechanism

The effectiveness of any cutting tool relies heavily on the design and functionality of its blade system. Understanding how the cutting mechanism operates helps to improve overall performance and ensure smooth operation, especially in tough conditions. The interaction between the rotating blades and the surface being trimmed is critical to achieving precision.

Blade Design and Material

The construction of the cutting blades, including their shape, sharpness, and material composition, plays a significant role in performance. Durable metals like hardened steel are often used for crafting blades, ensuring longevity and resistance to wear. The shape and edge angle of the blade also affect the precision and efficiency of the cut, allowing for clean slices through even dense vegetation.

Rotation Speed and Cutting Action

The speed at which the cutting mechanism rotates determines the efficiency of the trimming process. Higher speeds provide a finer cut, while lower speeds are more suited for heavier, thicker growth. Proper maintenance of the blades, including sharpening and balance, ensures that the cutting action remains effective over time, preventing uneven cuts and potential damage to the mechanism.

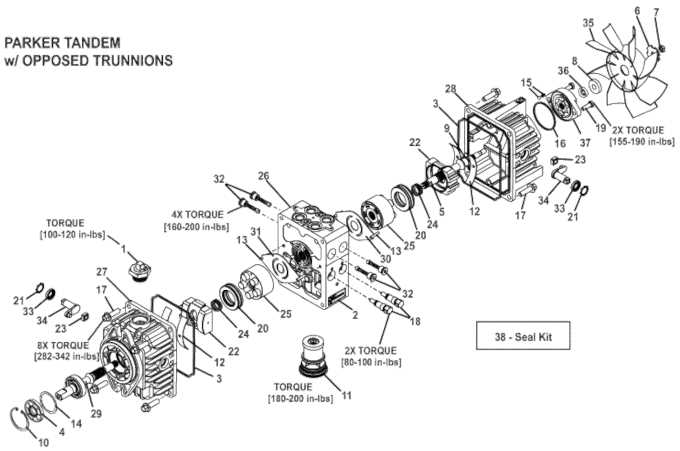

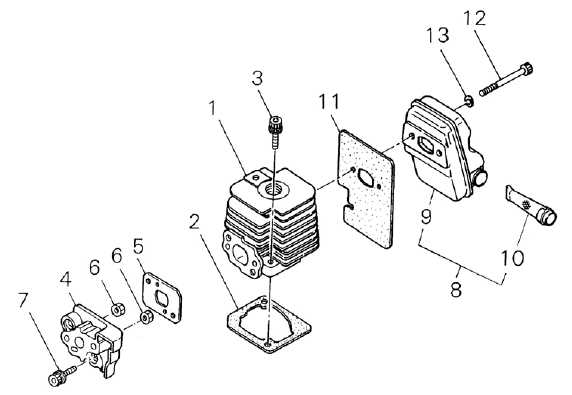

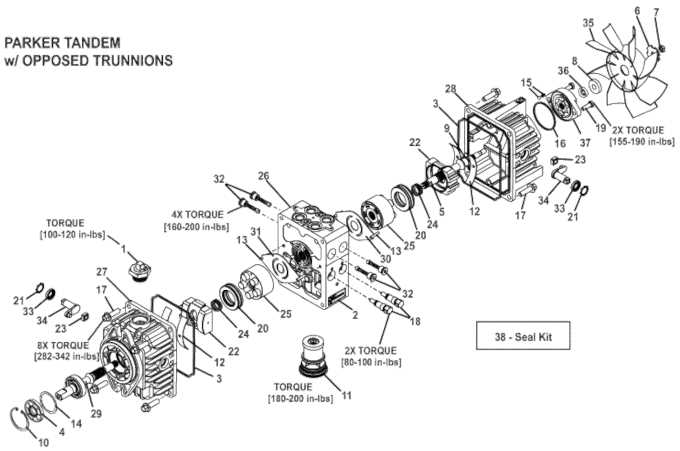

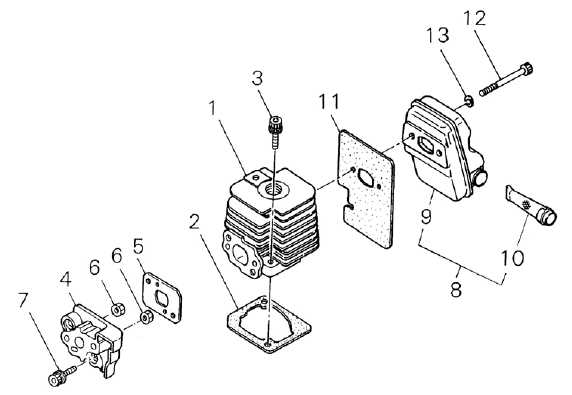

Understanding Engine and Power Transmission

The mechanism that drives cutting and trimming equipment is a crucial aspect of its overall functionality. At its core, this system converts energy into motion, allowing for efficient and smooth operation. By analyzing the flow of power from the source to the working components, we can understand how different parts work in harmony to achieve the desired output.

Central to this operation is the engine, which generates the necessary force, and the transmission, responsible for directing that force to the mechanical components. This coordinated effort is vital for optimal performance and durability.

| Component |

Function |

| Engine |

Generates power for the entire system. |

| Transmission |

Transfers generated power to moving parts. |

| Drive Shaft |

Connects the engine to the transmission system. |

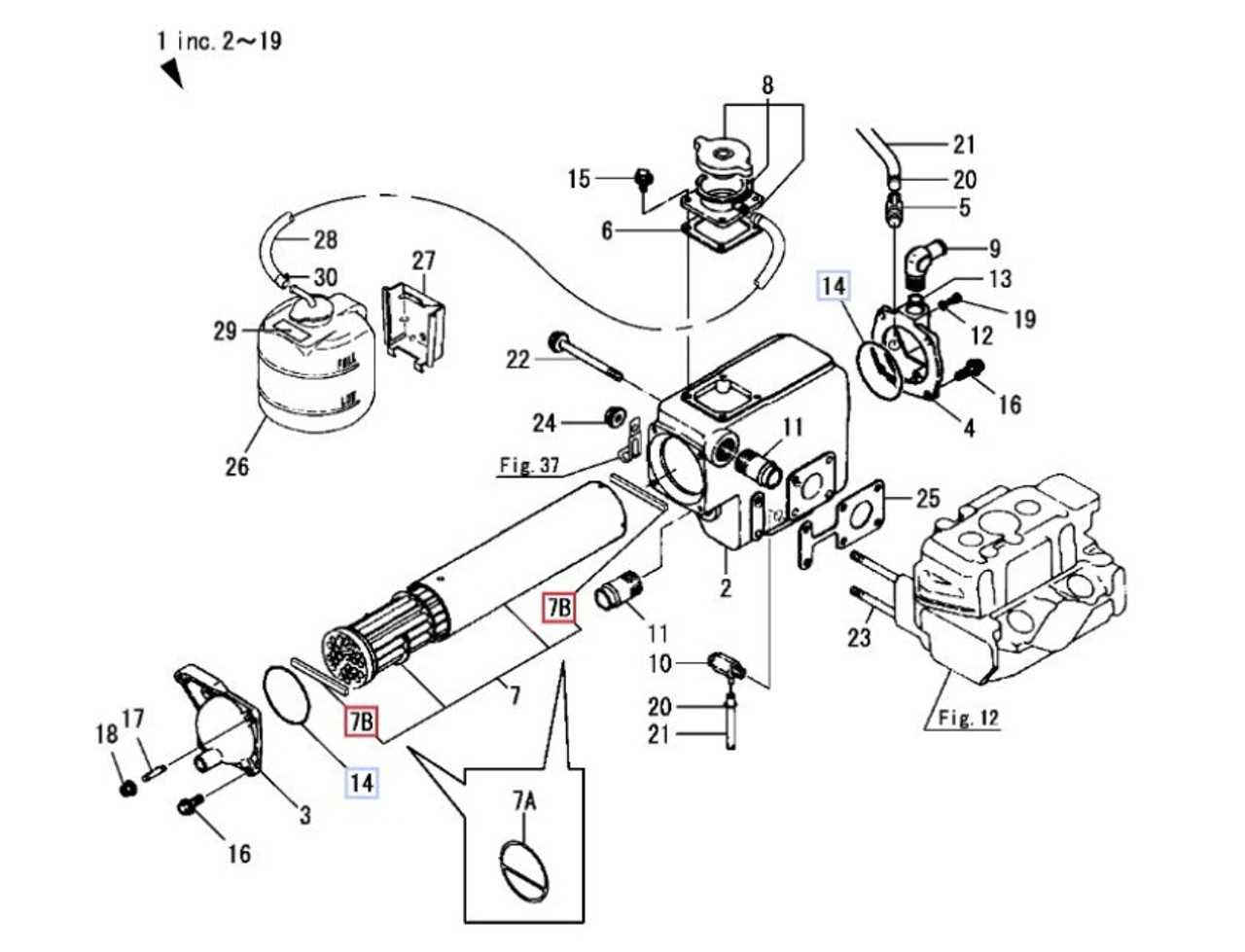

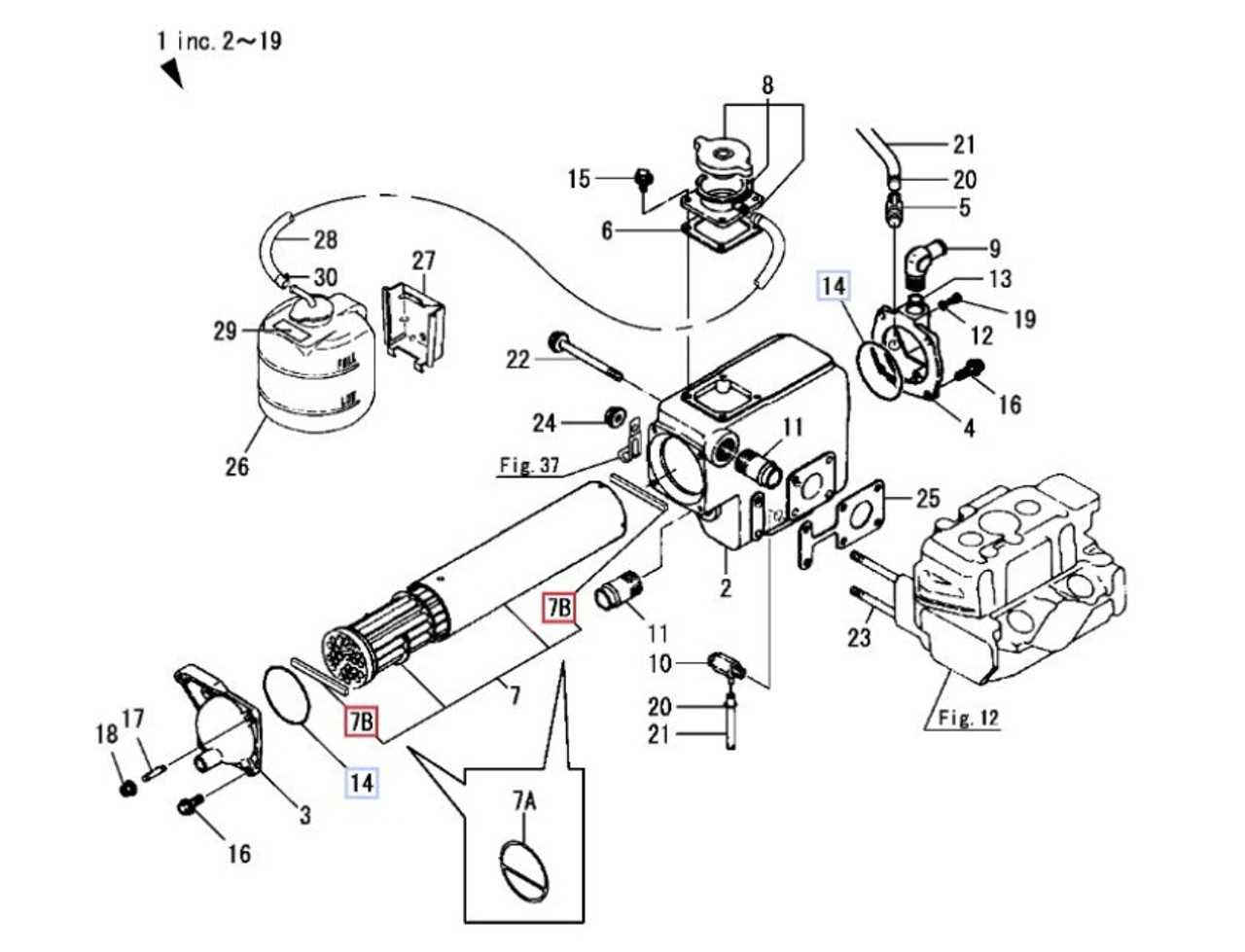

Fuel System and Ignition Key Features

The efficiency and functionality of outdoor equipment depend heavily on how well its power mechanisms are designed and maintained. The fuel system and ignition are two vital components that ensure smooth operation, delivering consistent power and reliable performance. Understanding their roles and distinguishing characteristics is essential for optimal use.

Fuel System Overview

The fuel mechanism ensures a stable supply of energy by regulating the mixture of air and fuel. Proper airflow, combined with accurate fuel delivery, guarantees efficient combustion. Key elements such as filters and valves help maintain this balance, ensuring smooth energy transfer.

Ignition Key Characteristics

The ignition setup is crucial for initiating the equipment’s power cycle. It consists of key elements like spark mechanisms, switches, and wiring systems that deliver electrical impulses at the right time. These components work together to ignite the fuel and power the equipment.

Wheels and Drive Mechanism Explained

The functionality of outdoor cutting machines relies heavily on their wheel system and drive mechanism. These components work together to ensure smooth movement and efficient operation across various terrains. Understanding how these elements interact can significantly enhance the user experience and maintenance practices.

The wheels are designed to provide stability and traction, allowing the device to navigate uneven surfaces without losing grip. Typically, they come in different sizes and materials to cater to specific environmental conditions. Meanwhile, the drive mechanism, often a combination of gears and belts, transmits power from the engine to the wheels, enabling controlled movement. The interplay between these parts is crucial for achieving optimal performance and maneuverability.

Regular inspection and maintenance of the wheels and drive system are essential for longevity. Ensuring that the wheels are free from debris and that the drive mechanism is properly lubricated can prevent unnecessary wear and tear. Users should familiarize themselves with these components to troubleshoot issues effectively and enhance the overall functionality of their equipment.

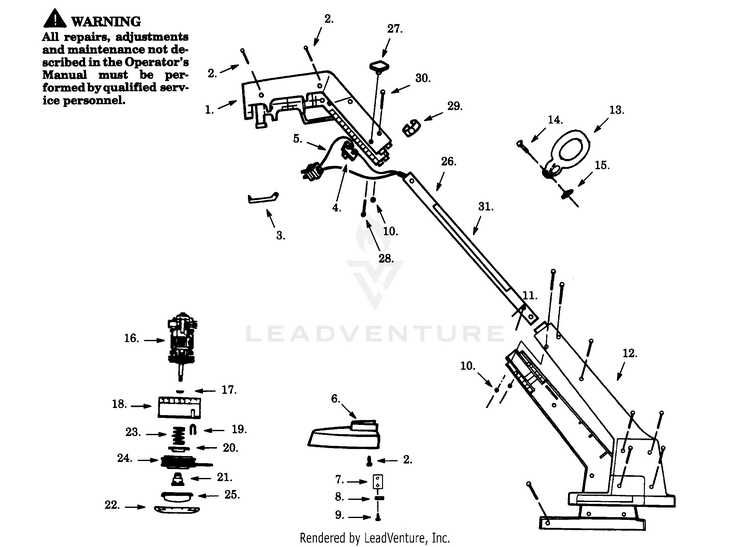

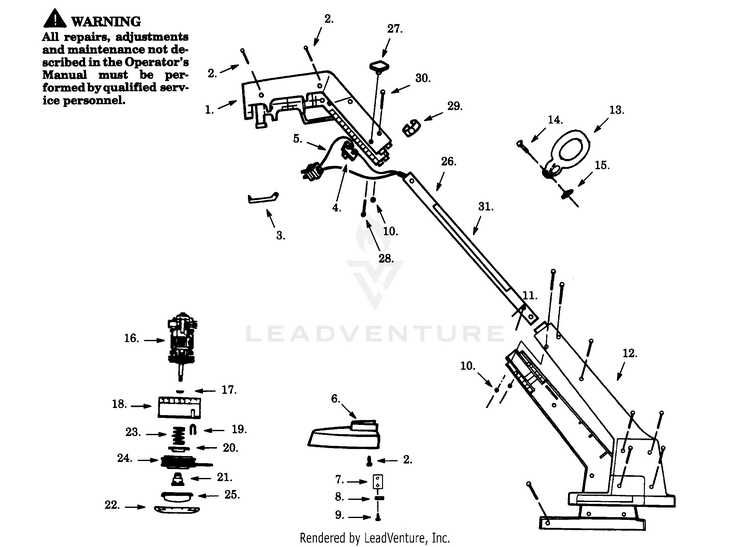

Exploring Handle and Control System

In the realm of outdoor maintenance equipment, the significance of the handle and control mechanisms cannot be overstated. These components serve as the primary interface between the user and the machine, ensuring ease of operation and effective maneuverability. A thorough understanding of these systems enhances both the functionality and safety of the equipment during use.

Importance of Ergonomics

Ergonomic design plays a crucial role in the overall user experience. A well-designed handle allows for a comfortable grip, reducing strain on the hands and arms during extended use. Features such as adjustable heights and padded grips can significantly enhance comfort, making tasks less labor-intensive. Additionally, a well-positioned control system contributes to intuitive operation, allowing users to focus on their work rather than struggling with awkward controls.

Control Mechanisms Overview

The control system typically comprises various levers and switches that manage the equipment’s functions. Understanding how these controls interact with the machinery is essential for efficient operation. Some systems feature safety mechanisms to prevent accidental activation, ensuring the user’s safety during operation. Familiarity with these controls enables users to respond swiftly and effectively, optimizing performance while minimizing the risk of accidents.

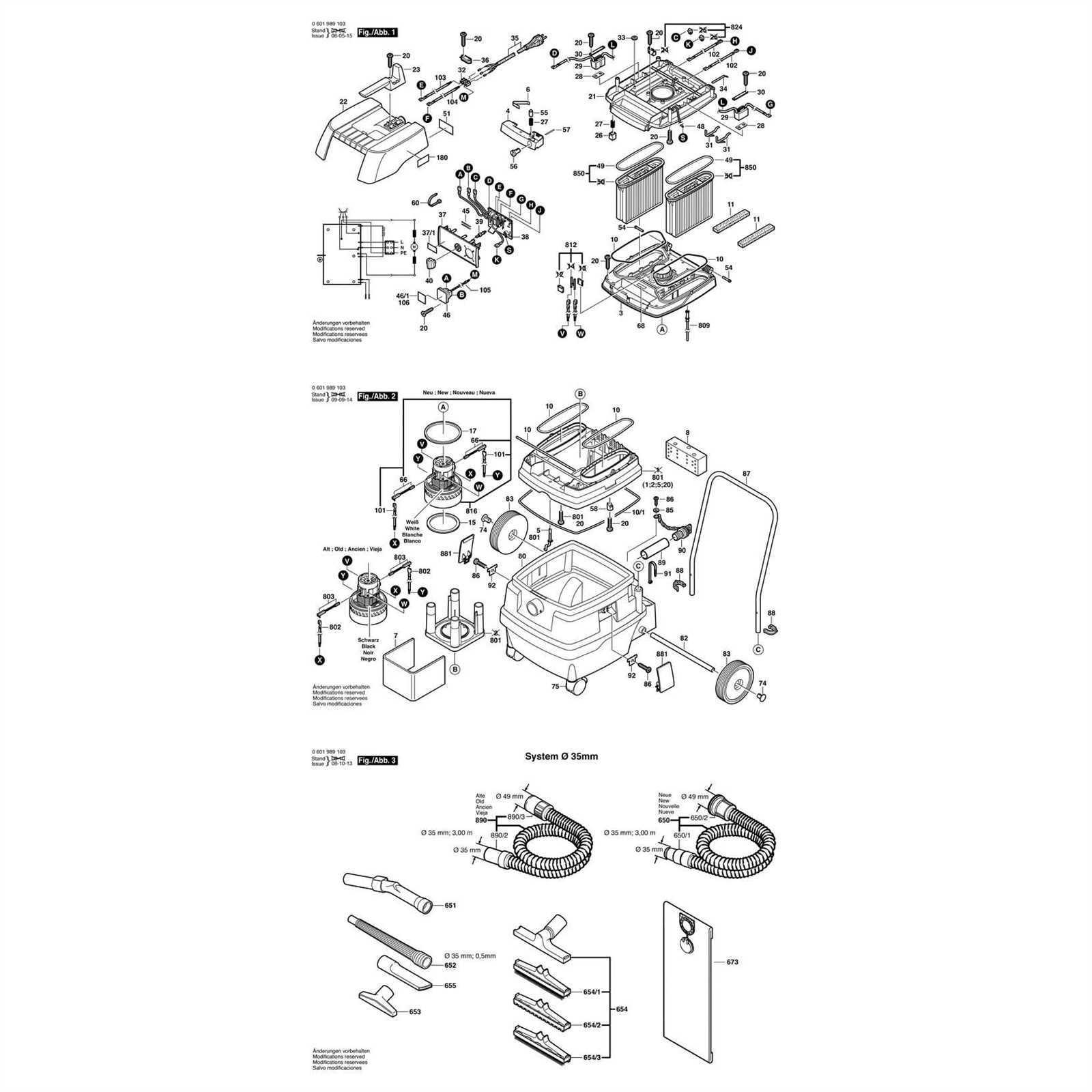

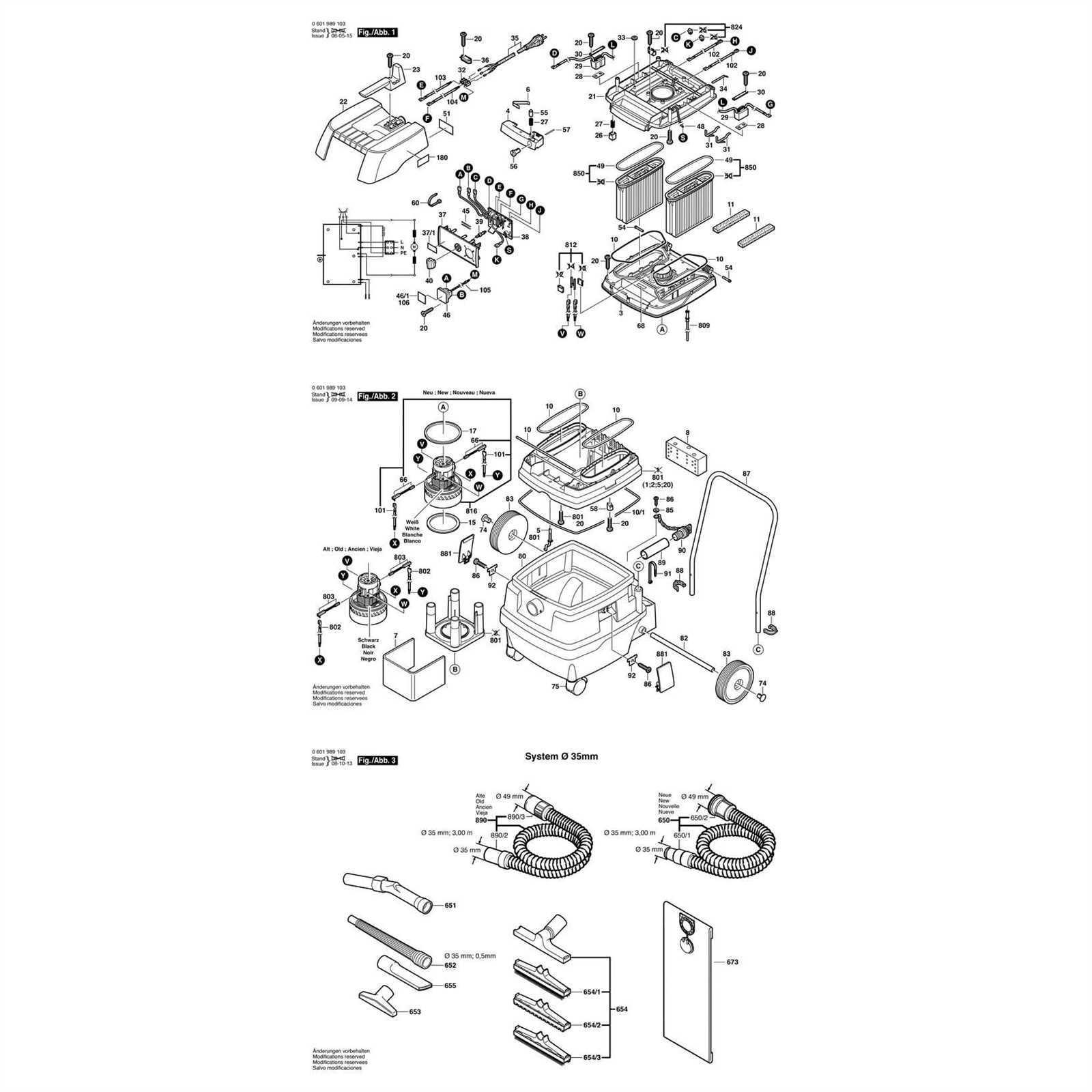

Air Filter and Cooling System Layout

The efficiency of any machinery is significantly influenced by its air filtration and thermal management systems. These components work in harmony to ensure optimal performance and longevity of the equipment. A well-structured layout not only facilitates smooth airflow but also aids in maintaining the right temperature during operation.

Air Filter Configuration plays a critical role in maintaining the purity of the air entering the engine. This element captures debris and contaminants, preventing them from causing damage. Proper positioning and accessibility of the air filter are essential for regular maintenance, ensuring that it functions effectively over time.

Cooling Mechanism is equally important, as it prevents overheating during extended use. The layout typically includes strategically placed vents and ducts that promote efficient airflow around the engine, dissipating heat effectively. Understanding this system helps in identifying potential issues before they escalate, leading to a more reliable and durable machine.

Safety Features and Shielding Components

Ensuring user protection is paramount when operating outdoor machinery. Various features are integrated into these devices to minimize risks and enhance safety during use. Understanding the role of these protective elements is essential for both novice and experienced users alike.

Key Protective Mechanisms

Modern equipment is equipped with several mechanisms designed to shield users from potential hazards. These include:

- Safety Guards: These barriers prevent accidental contact with moving components, significantly reducing the chance of injury.

- Emergency Shut-off: A quick-access button or lever that allows for immediate cessation of operations in case of an emergency.

- Noise Dampening: Components designed to minimize sound levels, protecting the operator’s hearing.

Importance of Shielding Components

The inclusion of shielding components not only protects users but also extends the lifespan of the machinery. Properly placed shields can prevent debris from entering critical areas, thus reducing wear and tear on internal mechanisms. Regular inspection and maintenance of these features are essential for optimal performance and safety.