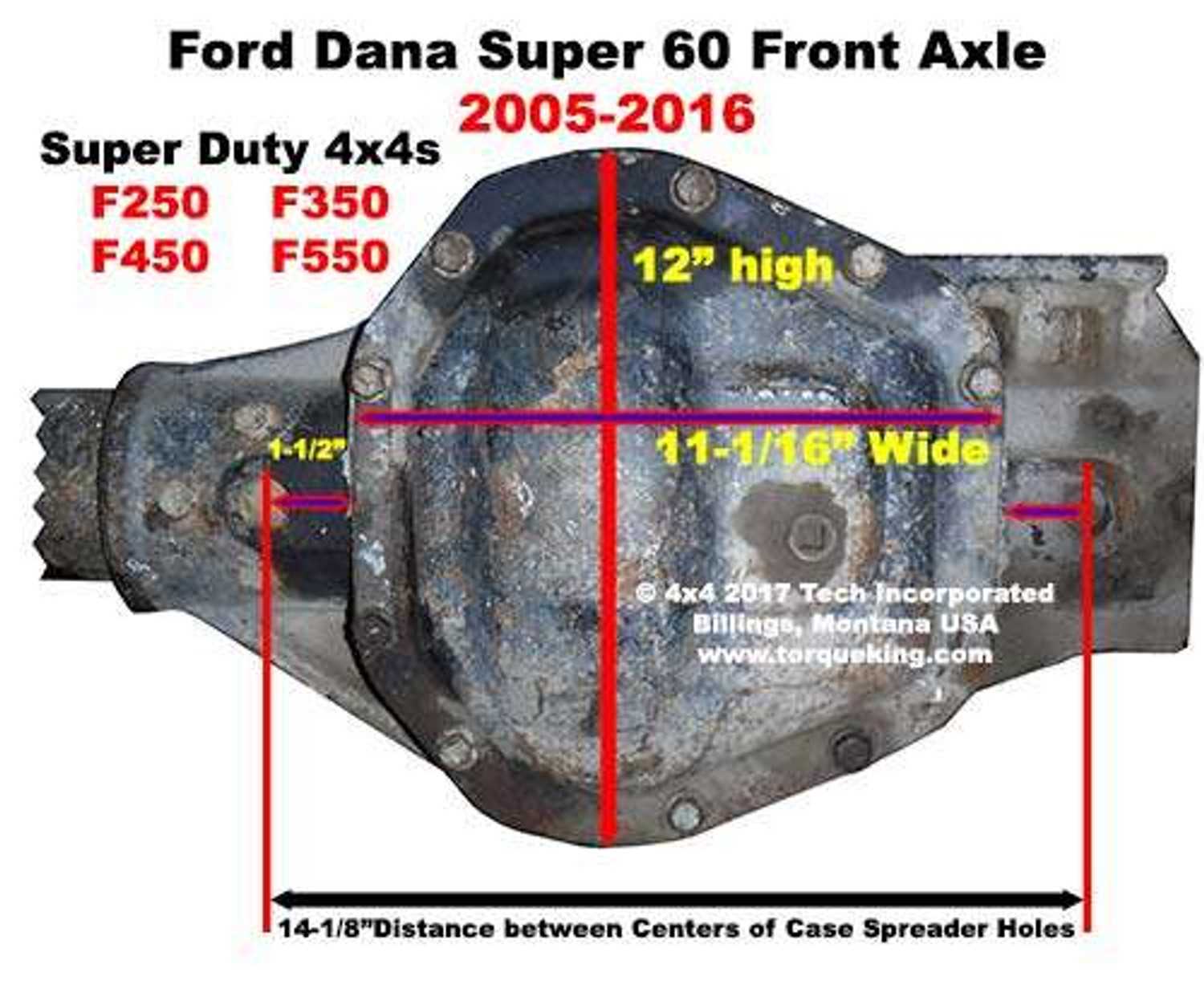

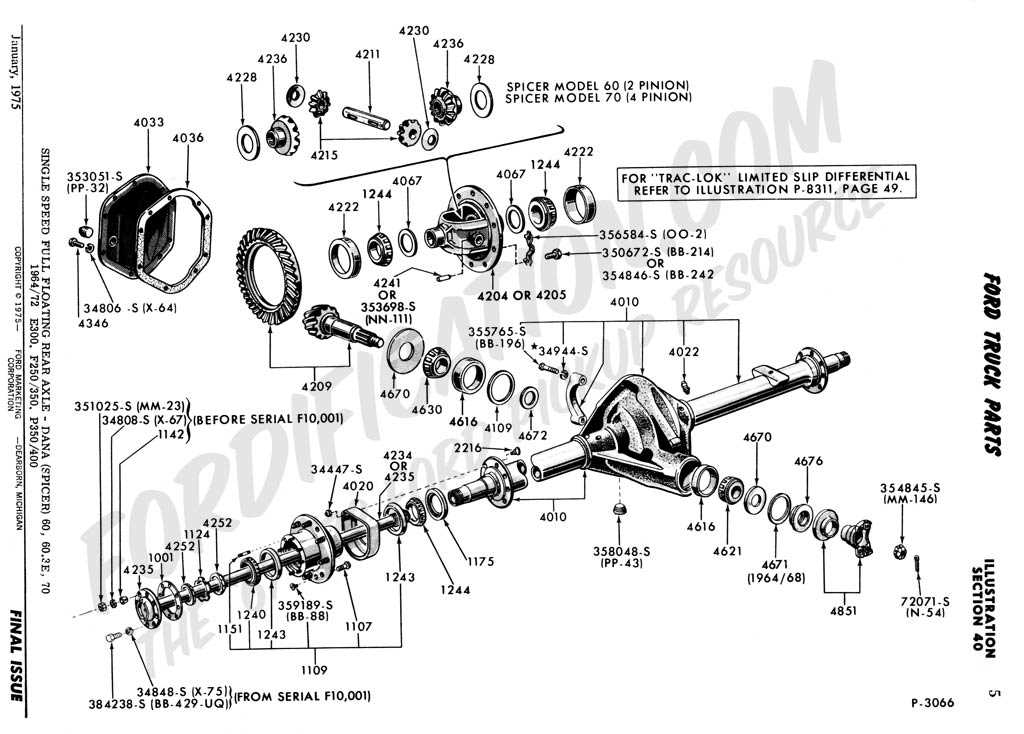

This section provides a detailed overview of the essential elements that constitute the front assembly of a heavy-duty vehicle. Understanding the configuration and functionality of these components is crucial for anyone engaged in maintenance or repair tasks. A clear representation helps in identifying each element’s role and how they interact to ensure optimal performance.

By exploring the arrangement of these critical structures, users can gain insights into their significance in the overall mechanics of the vehicle. This knowledge not only assists in troubleshooting issues but also enhances the effectiveness of any repair or replacement endeavors.

With a focus on clarity and accessibility, the information presented here serves as a valuable resource for enthusiasts and professionals alike. Grasping the intricacies of these components empowers individuals to make informed decisions regarding their maintenance and care.

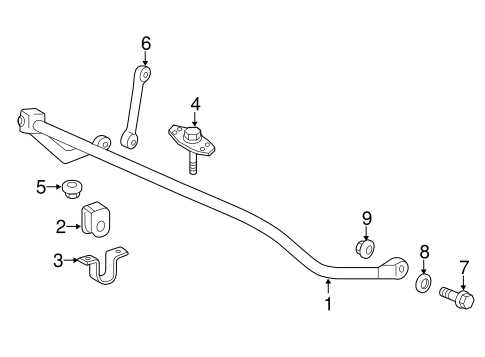

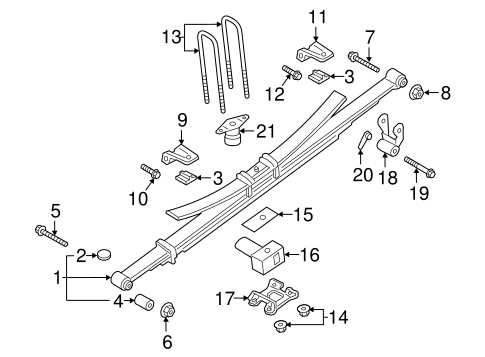

The suspension system plays a crucial role in maintaining vehicle stability, comfort, and handling. This complex assembly is designed to support the vehicle’s weight, absorb shocks from the road, and ensure optimal tire contact with the surface. A well-functioning suspension system contributes significantly to overall driving performance and safety.

Key Components of Suspension Systems

There are several essential elements within suspension systems that work together to achieve the desired performance. Each component serves a unique purpose, and understanding their functions can help in recognizing potential issues and ensuring proper maintenance.

- Shock Absorbers: These devices are responsible for dampening the impact of bumps and vibrations, providing a smoother ride.

- Springs: Springs support the vehicle’s weight and absorb shocks. They can be coil, leaf, or air types, each serving different applications.

- Control Arms: Control arms connect the suspension components to the vehicle’s frame, allowing for controlled movement and alignment.

Importance of Regular Inspection

Regular inspection of the suspension system is vital to ensure safe driving conditions. Over time, components can wear out or become damaged, leading to performance issues. Timely maintenance helps in identifying problems early and prolongs the lifespan of the system.

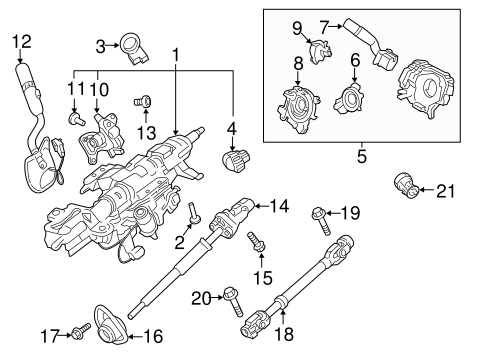

Steering Mechanisms Explained

Understanding the various components of steering systems is crucial for maintaining vehicle control and ensuring safety. These mechanisms play a vital role in enabling precise navigation and responsive handling, ultimately enhancing the driving experience.

The primary function of steering systems is to translate the driver’s input into the movement of the vehicle’s wheels. This process involves several key elements, including the steering wheel, column, and linkage that connect to the wheels. Each part contributes to the overall effectiveness of the system, allowing for smooth turns and adjustments while driving.

Modern steering mechanisms often incorporate advanced technologies, such as power assist features, to enhance responsiveness and reduce driver effort. By utilizing hydraulic or electric assistance, these systems provide greater control, particularly at low speeds or during tight maneuvers.

Regular maintenance and inspection of steering components are essential for ensuring optimal performance. Worn or damaged parts can lead to steering difficulties, negatively impacting vehicle handling and safety. Understanding the intricacies of these systems helps drivers appreciate the importance of timely repairs and replacements.

Brake System and Its Importance

The braking mechanism is a crucial component in any vehicle, responsible for ensuring safe and effective deceleration. This system plays a vital role in the overall safety of the automobile, as it allows the driver to control the speed and halt the vehicle when necessary. Understanding its significance can help in maintaining optimal performance and safety on the road.

Key Components of the Brake System

The braking mechanism consists of several essential elements that work together to facilitate smooth stopping. These components include:

- Brake Pads: These friction materials press against the rotors to slow down or stop the wheels.

- Rotors: These metal discs provide a surface for the brake pads to clamp down on, creating friction.

- Calipers: These components house the brake pads and utilize hydraulic force to press them against the rotors.

- Brake Lines: These tubes carry brake fluid from the master cylinder to the calipers, allowing for effective force transmission.

- Master Cylinder: This component converts the force applied on the brake pedal into hydraulic pressure, activating the braking mechanism.

Maintenance and Safety Tips

Regular inspection and maintenance of the braking system are essential for safe driving. Here are some tips to ensure its proper functionality:

- Check the brake fluid level frequently to avoid air in the system.

- Inspect brake pads for wear and replace them as needed to maintain stopping power.

- Examine rotors for grooves or warping, which can affect performance.

- Ensure all brake lines are free of leaks and damage to maintain hydraulic pressure.

- Have the entire system inspected by a professional periodically to catch any issues early.

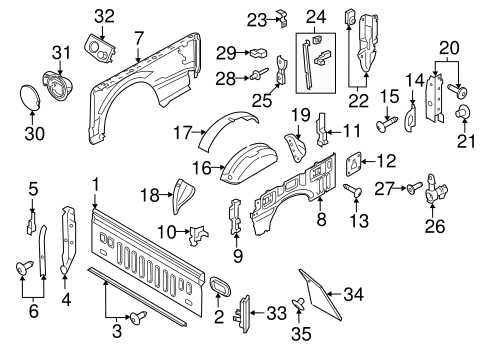

Body and Frame Interactions

The connection between the outer structure and the underlying support is crucial for vehicle integrity and performance. This relationship influences various aspects, including stability, handling, and overall durability. Understanding how these components interact can lead to better maintenance and enhancements, ultimately improving the driving experience.

Importance of Structural Integrity

A well-designed relationship between the outer shell and the frame contributes to the vehicle’s ability to absorb shocks and resist deformation during impacts. Key factors include:

- Weight Distribution: Balanced weight distribution enhances handling and stability.

- Material Strength: High-quality materials ensure both components can withstand stress and strain.

- Joint Design: Effective joints facilitate seamless interaction and reduce wear over time.

Impact on Performance

The synergy between the outer structure and frame directly affects various performance metrics:

- Driving Comfort: Improved interactions lead to a smoother ride.

- Handling Characteristics: Enhanced stability and cornering ability are achieved through solid connections.

- Longevity: Properly designed interactions extend the life of the vehicle by minimizing stress on both components.

Wiring and Electrical Components

This section provides an overview of the electrical systems and wiring found in heavy-duty trucks, highlighting their significance in vehicle functionality. Understanding these components is essential for proper maintenance and troubleshooting.

Key Electrical Systems

The electrical systems in trucks are designed to ensure optimal performance. They encompass various components that work in tandem to facilitate the vehicle’s operation. The major systems include the battery, alternator, and starter, each playing a vital role in energy distribution and functionality.

Wiring Configuration

The wiring configuration is crucial for connecting electrical components, ensuring that signals and power are transmitted effectively. A well-organized wiring system contributes to the reliability and safety of the vehicle.

| Component | Function |

|---|---|

| Battery | Stores and supplies electrical energy to start the engine and power accessories. |

| Alternator | Generates electricity while the engine runs, recharging the battery. |

| Starter | Engages the engine to initiate the combustion process. |

| Wiring Harness | Connects all electrical components, facilitating communication and power flow. |

Common Maintenance Tips and Advice

Proper upkeep is essential for ensuring the longevity and performance of any vehicle. Regular maintenance not only enhances reliability but also contributes to safety on the road. Below are several essential guidelines to follow for effective care.

Routine Inspections: Conducting frequent checks of vital components can prevent unexpected issues. Pay attention to fluid levels, tire condition, and brake functionality. Early detection of wear can save time and money.

Fluid Management: Keeping fluids at optimal levels is crucial for smooth operation. Regularly inspect and change engine oil, coolant, and transmission fluid as per the manufacturer’s recommendations. This practice helps maintain engine health and overall performance.

Tire Care: Proper tire maintenance is vital for safety and efficiency. Ensure tires are inflated to the recommended pressure, and regularly rotate them to promote even wear. Checking tread depth can also enhance grip and fuel efficiency.

Brake System Checks: The braking system is critical for safe driving. Regularly inspect brake pads, rotors, and fluid levels. If you notice any unusual noises or diminished responsiveness, seek professional assistance immediately.

Battery Maintenance: A well-maintained battery is key to reliable starts. Check connections for corrosion and ensure the battery is secure. Testing the battery periodically can prevent unexpected breakdowns.

By adhering to these maintenance tips, vehicle owners can ensure their automobiles operate optimally and remain safe on the roads.

Identifying Wear and Tear Signs

Regular inspection of vehicle components is crucial for ensuring optimal performance and safety. Over time, certain elements may show signs of degradation, which can affect functionality and lead to further complications if left unaddressed. Understanding the indicators of wear is essential for timely maintenance and repair.

Common Indicators of Degradation

One of the most visible signs of wear is unusual noise during operation. This can manifest as squeaking, grinding, or rattling sounds, often indicating that parts are not functioning harmoniously. Additionally, any noticeable vibrations or pulling sensations while driving can suggest misalignment or imbalance in the structure.

Visual Inspection Techniques

Conducting a thorough visual examination is vital. Look for cracks, fraying, or discoloration on components, as these can signify deterioration. Rust or corrosion is another major red flag, especially on metallic parts. Regularly checking for fluid leaks beneath the vehicle can also help identify potential issues before they escalate.

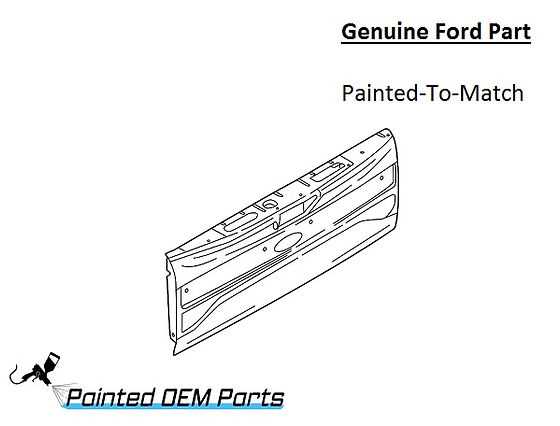

Replacement Options and Aftermarket Parts

When it comes to upgrading or repairing a vehicle’s structure, various alternatives and aftermarket components are available to enhance performance and reliability. Understanding these options can significantly impact maintenance decisions and long-term vehicle functionality.

Types of Replacement Components

Replacement components can be classified into several categories:

- OEM (Original Equipment Manufacturer) – These parts are made by the same manufacturer as the original components, ensuring compatibility and quality.

- Aftermarket Components – Produced by third-party manufacturers, these parts often offer competitive pricing and can include enhanced features.

- Rebuilt or Remanufactured Parts – These components are refurbished to meet original specifications, providing a cost-effective solution without sacrificing quality.

Benefits of Aftermarket Alternatives

Aftermarket alternatives provide several advantages:

- Cost-effectiveness, often available at lower prices than OEM parts.

- Variety of options, including performance enhancements and unique designs.

- Availability, making it easier to find suitable components for repairs or upgrades.

Choosing the right components for your vehicle can enhance its functionality and ensure a smoother driving experience.