In the world of metal fabrication, the efficiency and reliability of equipment are paramount. Each device consists of various elements that work in unison to ensure optimal performance. A thorough comprehension of these components can significantly enhance both operation and maintenance. This section delves into the intricate details of a specific model’s configuration, allowing users to navigate its assembly with confidence.

By familiarizing oneself with the structure and functionality of essential components, operators can not only troubleshoot issues more effectively but also optimize their techniques. This exploration serves as a valuable resource for those looking to deepen their understanding of their equipment. Whether you are a seasoned professional or a novice, having a clear view of the internal workings can elevate your skill set and improve outcomes.

In addition, this guide emphasizes the importance of regular inspection and replacement of worn elements to prolong the lifespan of the machine. Recognizing when and how to make these adjustments is crucial for maintaining productivity and ensuring safety in the workspace. Armed with this knowledge, users can achieve greater precision and efficiency in their projects.

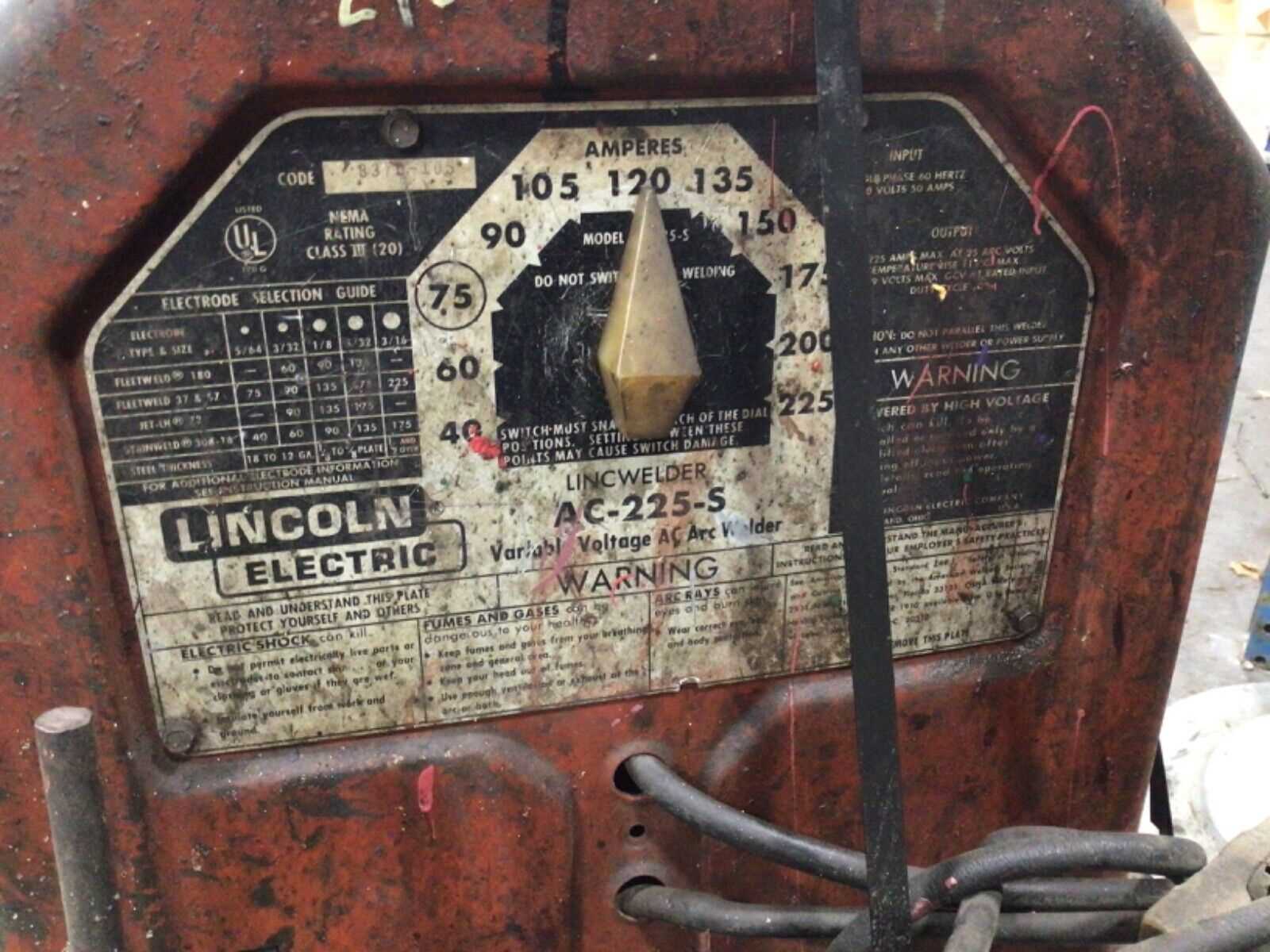

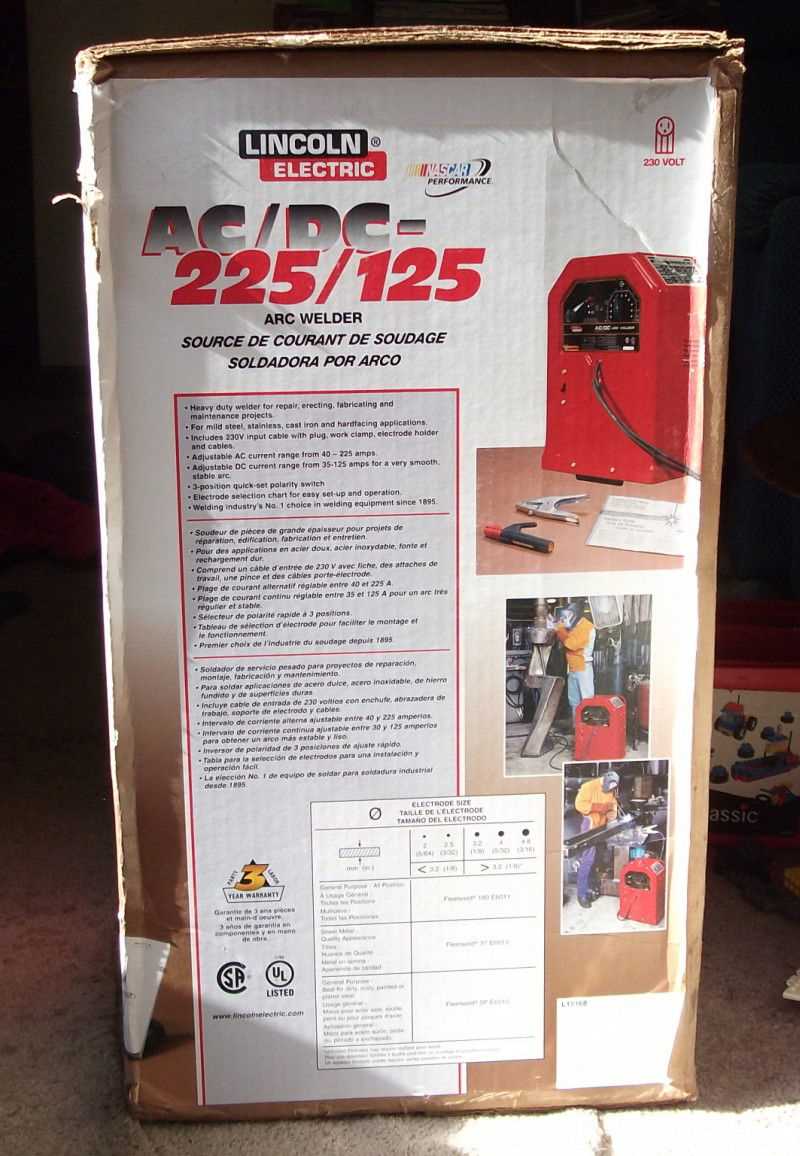

Understanding Lincoln AC-225 Arc Welder

This section explores the intricacies of a specific type of welding equipment that is essential for various metal fabrication tasks. Recognizing its components and functionalities can enhance the user experience and improve the overall effectiveness of the device.

- Power Source: The device operates on alternating current, providing reliable performance.

- Electrode Holder: This component secures the electrode, enabling efficient arc initiation.

- Ground Clamp: Ensures proper electrical grounding, which is crucial for safety and performance.

- Control Settings: Adjustments for voltage and amperage allow for versatility in different welding scenarios.

Understanding these elements is the ultimate step towards mastering the use of this equipment, facilitating better results and enhanced skills in welding projects.

Key Components of the Welder

Understanding the essential elements of a welding machine is crucial for both novices and experienced operators. Each component plays a significant role in ensuring effective operation and achieving high-quality results. A comprehensive grasp of these parts allows for better maintenance and troubleshooting.

Power Supply: This is the heart of the device, responsible for converting electrical energy into the form required for the welding process. It delivers the necessary current to generate the heat required for fusing materials.

Electrode Holder: This tool securely grips the electrode while allowing it to conduct electricity to the workpiece. Proper handling of this component is vital for achieving a stable arc and ensuring safety during operation.

Ground Clamp: This component connects the workpiece to the machine, completing the electrical circuit. A good connection is essential for effective performance and helps prevent unwanted electrical resistance.

Cooling System: Many devices incorporate a cooling mechanism to prevent overheating during extended use. This system can include fans or liquid cooling, which is critical for maintaining optimal operating temperatures.

Control Panel: This interface allows the user to adjust settings such as current and voltage. Understanding how to navigate and utilize the control panel effectively can greatly enhance the quality of the welds produced.

Protective Housing: This structure encloses the internal components, providing safety for the user and protection against environmental factors. A robust housing also contributes to the longevity of the equipment.

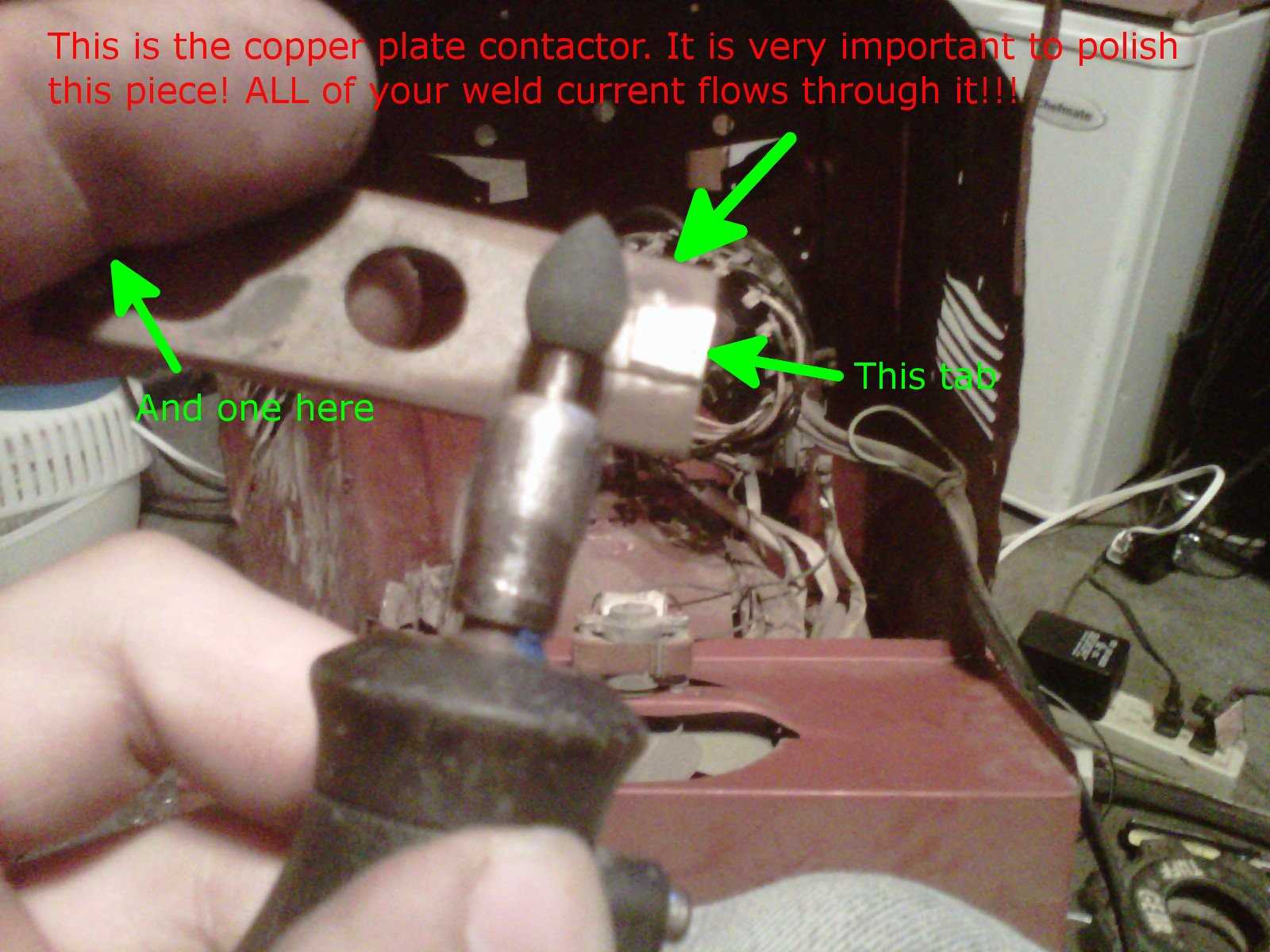

Importance of Accurate Parts Diagram

An effective representation of components is crucial for ensuring optimal functionality and maintenance of equipment. A precise illustration not only aids in identifying each element but also facilitates smoother repairs and replacements.

Clarity in visual references minimizes the risk of errors during assembly or troubleshooting, promoting efficiency. When users can easily discern each part’s location and function, they can swiftly address issues without unnecessary delays.

Moreover, having an accurate reference enhances safety by preventing misuse or incorrect handling of equipment. A well-detailed schematic can serve as an educational tool, enabling operators to familiarize themselves with the machine’s inner workings.

Ultimately, investing time in creating and maintaining high-quality component illustrations can lead to prolonged equipment lifespan and increased reliability.

Common Issues and Solutions

In the realm of electrical fabrication tools, various challenges can arise that impact performance and efficiency. Understanding these common problems and their remedies is essential for maintaining optimal functionality and achieving desired results.

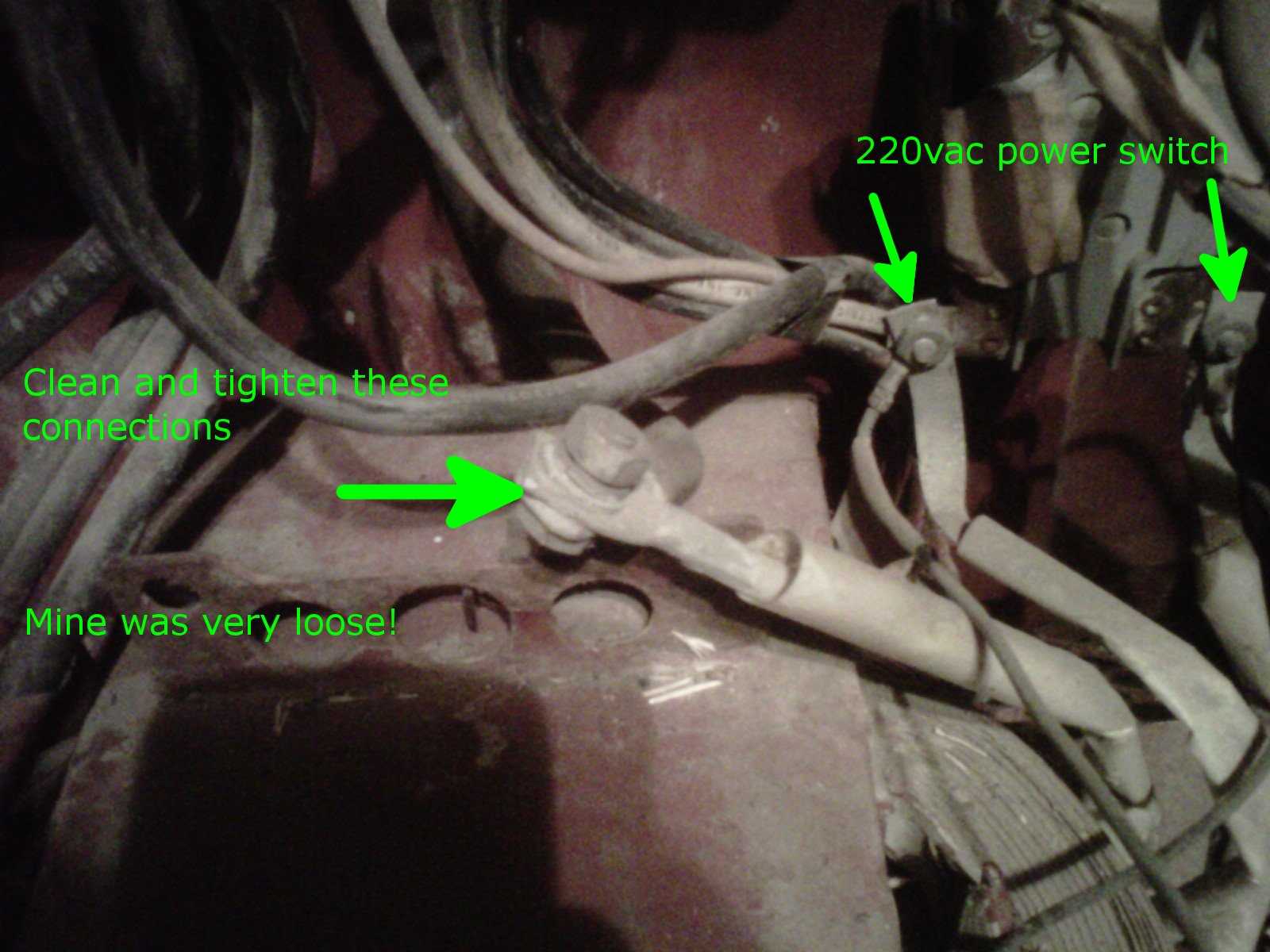

One frequent issue is inconsistent output, which may stem from improper connections or worn components. Regular inspection and timely replacement of faulty parts can restore reliable performance.

Another common concern is overheating, often caused by prolonged use or inadequate ventilation. Ensuring proper cooling and taking breaks during operation can help mitigate this risk.

Lastly, difficulties with starting can be attributed to power supply fluctuations or internal malfunctions. Verifying power sources and conducting routine maintenance can prevent such occurrences, ensuring smooth operation.

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your equipment, regular upkeep is essential. Implementing a consistent maintenance routine can prevent wear and tear, leading to fewer repairs and enhanced efficiency. Here are some key practices to consider.

Regular Inspections

Conduct thorough examinations of the machinery on a scheduled basis. Look for signs of wear, loose connections, or damaged components. Early detection of issues can save time and resources in the long run.

Cleaning and Lubrication

Keep the equipment clean to prevent dust and debris accumulation, which can affect functionality. Additionally, ensure that all moving parts are well-lubricated to reduce friction and enhance performance. Using high-quality lubricants will provide better protection and efficiency.

How to Replace Faulty Parts

Maintaining your equipment in optimal condition is essential for ensuring its longevity and performance. When components fail, timely replacement is crucial. This guide outlines the steps to effectively identify and substitute defective elements in your apparatus.

Identifying Faulty Components

Before proceeding with any replacements, it is vital to determine which parts are malfunctioning. Common signs of failure include:

- Unusual noises during operation

- Inconsistent performance or output

- Visible signs of wear or damage

- Frequent overheating

Utilizing a multimeter can also assist in diagnosing electrical issues, ensuring that you address the correct part.

Steps for Replacement

Once the problematic components have been identified, follow these steps to perform a replacement:

- Ensure the device is powered off and disconnected from any power source.

- Gather the necessary tools, including screwdrivers, wrenches, and replacement components.

- Carefully disassemble the housing to access the faulty component. Take note of the assembly for reinstallation.

- Remove the defective part, paying attention to any connectors or screws.

- Install the new component, ensuring a secure fit and proper alignment.

- Reassemble the device, reversing the disassembly steps.

- Test the equipment to confirm that the replacement has resolved the issue.

Regular maintenance and timely replacements can significantly enhance the efficiency and lifespan of your machinery.

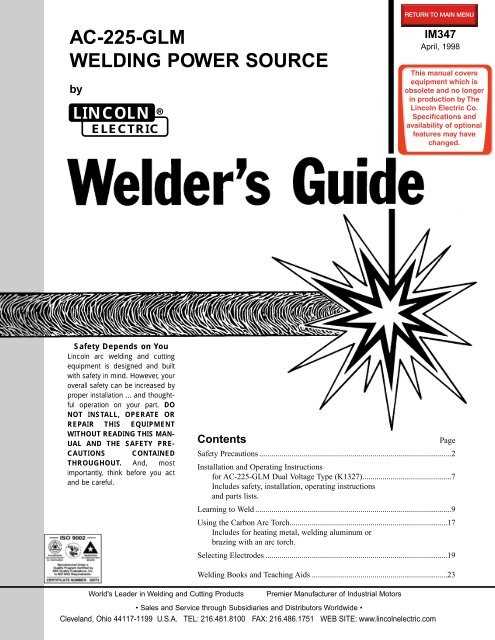

Safety Precautions When Welding

Ensuring safety during metal joining processes is essential to prevent injuries and accidents. The environment must be carefully assessed, and appropriate measures should be taken to protect both the operator and those nearby. Proper equipment, personal protective gear, and adherence to safety guidelines play a crucial role in creating a secure workspace.

Personal Protective Equipment

Wearing suitable protective gear is vital. This includes helmets with appropriate shading, gloves, and clothing made from flame-resistant materials. Safety glasses are necessary to shield the eyes from sparks and harmful radiation, while respiratory protection may be needed to avoid inhaling harmful fumes.

Workspace Safety

The work area should be well-ventilated and free from flammable materials. Keeping a fire extinguisher nearby and knowing how to use it can be lifesaving. Additionally, ensuring that the ground is dry and free of tripping hazards will reduce the risk of accidents significantly.

Upgrades and Modifications Available

Enhancing equipment performance can significantly impact both efficiency and output quality. Numerous options exist for improving functionality and adapting tools to meet specific needs, whether for hobbyists or professionals in the industry. By exploring these enhancements, users can achieve optimal results and extend the lifespan of their devices.

Performance Enhancements

One of the most common modifications includes upgrading the power supply, which can provide increased output and stability. Additionally, installing advanced cooling systems can prevent overheating during prolonged use, ensuring that the equipment operates at peak efficiency.

Safety Features

Incorporating additional safety features is essential for protecting the user and equipment. Options such as automatic shut-off mechanisms and enhanced circuit protection can significantly reduce the risk of accidents. Investing in these modifications not only improves safety but also boosts overall performance.

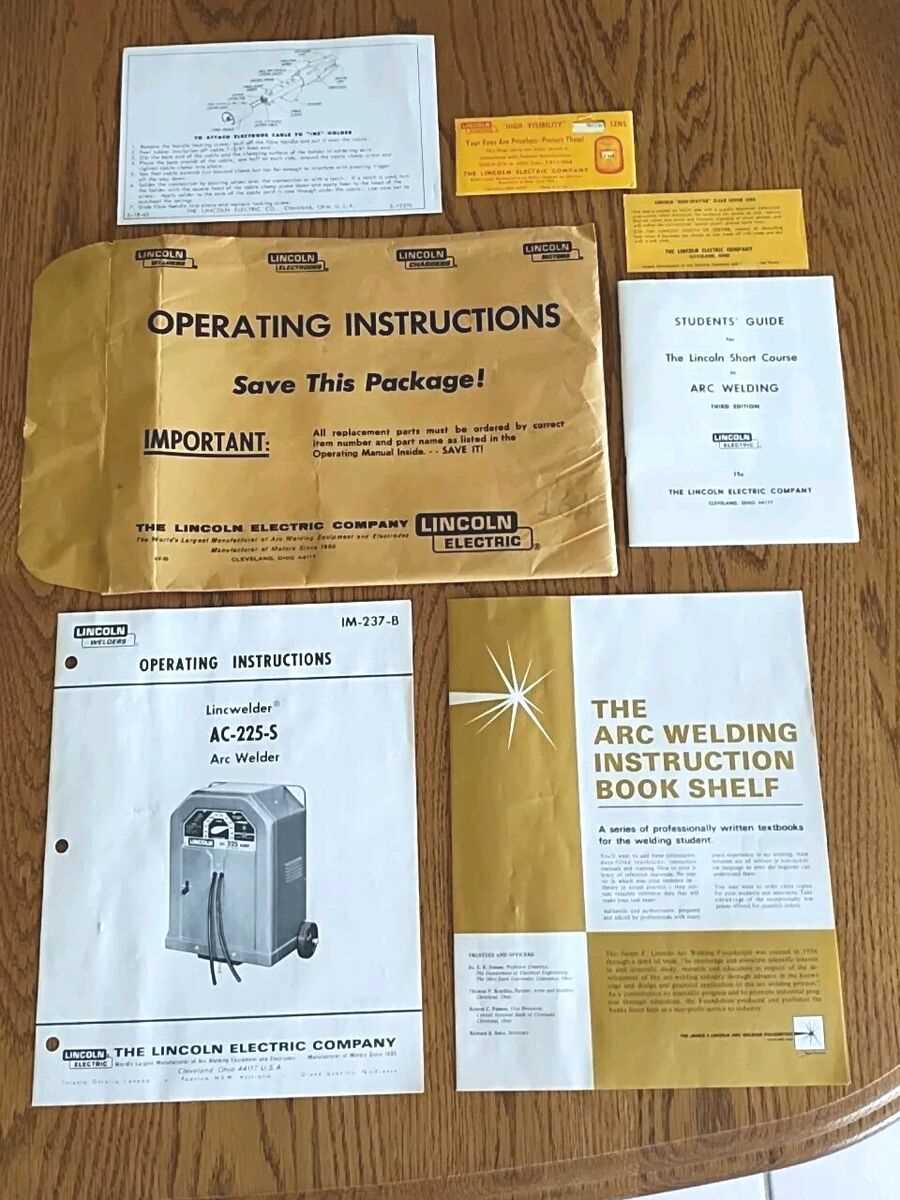

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its functionality and performance. Whether you’re seeking replacements for maintenance or repairs, there are various avenues to explore that can lead you to the right solutions.

Here are some reliable sources for obtaining the necessary items:

- Manufacturer’s Website: Most brands offer a dedicated section for spare components, where you can find detailed information and ordering options.

- Authorized Dealers: Local distributors or authorized sellers often carry genuine items and can provide assistance with specific inquiries.

- Online Marketplaces: Platforms like eBay or Amazon feature a wide selection of components, but ensure to check seller ratings and product descriptions for authenticity.

- Specialty Stores: Stores focusing on industrial equipment may have a range of components tailored to your needs, along with knowledgeable staff to assist.

- Repair Shops: Local repair facilities might have spare parts available or can guide you to where to find them.

Always verify compatibility with your equipment before making a purchase to ensure optimal performance and longevity.