In the realm of cooling appliances, grasping the intricate interplay of various elements is crucial for optimal performance and maintenance. Each component serves a unique function, contributing to the overall efficiency and reliability of the unit. Familiarity with these individual elements allows users to troubleshoot issues and enhance longevity.

Identifying the specific roles of each segment can demystify the functionality of the system. By visualizing the layout and connections, one can gain insights into how these interconnected features work together seamlessly. This knowledge not only aids in repairs but also empowers users to make informed decisions regarding upgrades and replacements.

Furthermore, a comprehensive understanding of these components facilitates better communication with technicians during service calls. When users can articulate the symptoms and issues related to specific elements, it leads to quicker resolutions and improved service outcomes. Emphasizing this interconnectedness underscores the importance of maintaining a well-functioning cooling apparatus.

Understanding Ice Machine Components

The operation of a refrigeration unit relies on various essential elements, each playing a crucial role in the overall functionality. Familiarizing oneself with these components enhances not only the maintenance process but also the efficiency and longevity of the system.

Key Elements in such systems include the condenser, which dissipates heat; the evaporator, where the cooling process occurs; and the compressor, responsible for circulating refrigerant. Each of these elements interacts harmoniously to produce the desired result.

Moreover, additional features such as water reservoirs, control boards, and filtration systems ensure optimal performance and quality. Understanding how these components work together can help troubleshoot common issues and facilitate effective repairs.

In conclusion, a comprehensive grasp of these integral components not only supports efficient operations but also empowers users to address potential challenges proactively, ensuring a smooth-running refrigeration experience.

Essential Parts of Ice Makers

Understanding the key components of these appliances is crucial for their efficient operation and maintenance. Each element plays a significant role in the overall functionality, contributing to the production and delivery of frozen products. A comprehensive knowledge of these essentials helps in troubleshooting and optimizing performance.

| Component | Description |

|---|---|

| Water Supply System | Responsible for providing the necessary liquid to create frozen formations. |

| Freezing Unit | This section cools the liquid to transform it into solid form. |

| Evaporator | Facilitates the freezing process by absorbing heat from the surrounding environment. |

| Condenser | Disperses heat away from the system to maintain optimal temperatures. |

| Control Panel | Allows users to adjust settings and monitor the operation. |

| Storage Bin | Holds the finished frozen products until needed. |

Functionality of Each Component Explained

This section aims to elucidate the roles and operations of various elements within the system, providing insight into how each contributes to the overall functionality. Understanding these components is essential for effective maintenance and troubleshooting.

Key Components

- Compressor: This element compresses refrigerant, raising its temperature and pressure to facilitate heat exchange.

- Condenser: Here, the refrigerant releases heat and transitions from gas to liquid, crucial for cooling processes.

- Expansion Valve: This part reduces refrigerant pressure, allowing it to expand and cool before entering the evaporator.

- Evaporator: The refrigerant absorbs heat, converting back into a gas, which is vital for the system’s cooling capability.

Supportive Elements

- Fans: These circulate air, enhancing heat exchange efficiency.

- Thermostats: They regulate temperature, ensuring optimal operation.

- Water Reservoir: This stores water, playing a key role in the freezing process.

- Control Panel: It serves as the interface for user adjustments and system monitoring.

Common Ice Machine Problems

Understanding the frequent issues that can arise in equipment designed for freezing water can help maintain optimal performance. By identifying and addressing these challenges promptly, users can ensure efficient operation and prolong the lifespan of their appliances.

| Problem | Possible Causes | Solutions |

|---|---|---|

| No output | Power supply issues, faulty thermostat, clogged water line | Check connections, replace thermostat, clear obstructions |

| Low production | Insufficient water supply, high ambient temperature | Ensure proper water flow, maintain cooler surroundings |

| Strange noises | Loose components, worn-out motor | Tighten parts, consider motor replacement |

| Unusual odors | Bacterial growth, stale water | Clean thoroughly, replace old water |

| Frozen components | Incorrect settings, blocked airflow | Adjust settings, ensure proper ventilation |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your cooling unit requires consistent care and attention. Regular maintenance not only extends its lifespan but also enhances efficiency, saving you time and resources in the long run.

1. Regular Cleaning: Frequent cleaning of all accessible components is essential. Dust and debris can accumulate, hindering performance. Use a soft cloth and appropriate cleaning solutions to keep surfaces pristine.

2. Check Connections: Inspect all electrical and water connections periodically. Loose or damaged connections can lead to malfunctions. Tighten or replace any faulty components immediately to avoid further issues.

3. Monitor Performance: Pay attention to any changes in functionality. Unusual noises, inconsistent output, or slow performance can indicate underlying problems. Addressing these signs early can prevent more significant repairs later.

4. Schedule Professional Servicing: Engaging a technician for routine check-ups can provide insights that you might miss. Professionals can identify potential issues and perform necessary adjustments to enhance efficiency.

5. Maintain Optimal Conditions: Ensure that the environment around your unit is conducive to performance. Avoid placing it in direct sunlight or near heat sources, and ensure proper ventilation to facilitate air circulation.

By following these guidelines, you can significantly enhance the reliability and effectiveness of your cooling system, ensuring it serves you well for years to come.

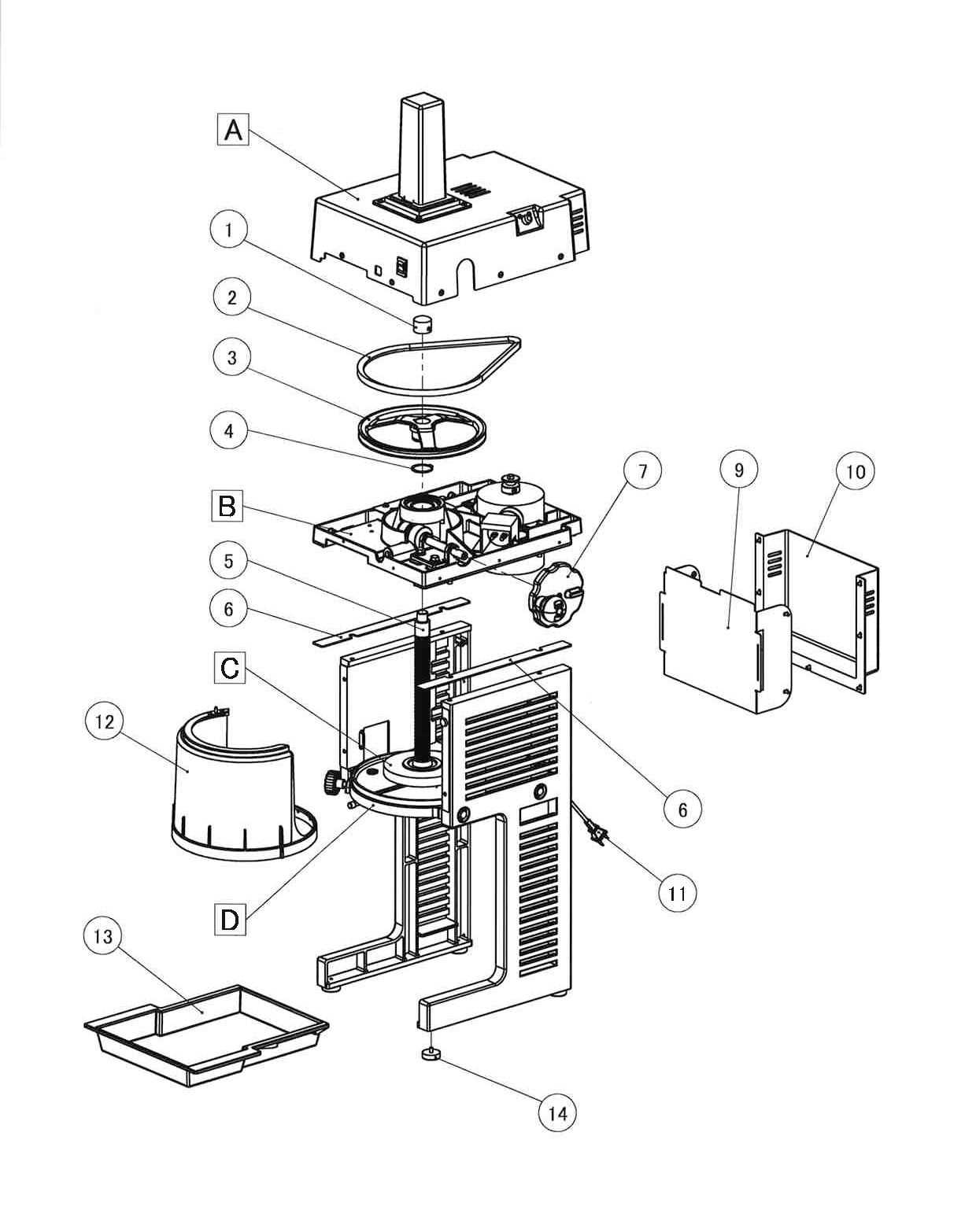

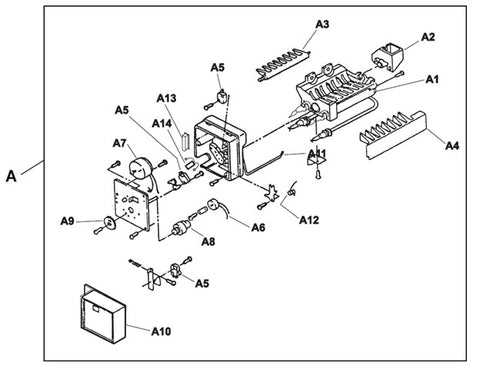

Visual Guide to Ice Machine Parts

This section aims to provide an insightful overview of the essential components found in a refrigeration unit designed for creating frozen cubes. Understanding these elements is crucial for efficient operation and maintenance.

Key Components

Each unit contains several vital elements, including a compressor, evaporator, and condenser. These work in harmony to produce and store frozen formations efficiently.

Maintenance Tips

Regular checks on the primary components can prevent breakdowns and enhance longevity. Ensure that connections are secure and that any build-up is addressed promptly for optimal functionality.

How to Identify Faulty Components

Recognizing malfunctioning elements within a cooling unit is essential for ensuring optimal performance. Understanding common symptoms and employing systematic approaches can aid in pinpointing issues effectively.

Common Symptoms of Malfunction

Be alert for unusual sounds, inconsistent temperature control, or excessive energy consumption. These signs often indicate underlying problems that require attention.

Testing Techniques

Utilize diagnostic tools to evaluate the functionality of individual elements. A multimeter can be particularly helpful for checking electrical components. Regular inspections and maintenance can prevent minor issues from escalating into major failures.

Replacing Parts: Step-by-Step Process

When it comes to ensuring optimal functionality, understanding how to replace specific components is essential. This guide will provide you with a systematic approach to tackle the replacement of crucial elements, enhancing overall performance and longevity.

Preparation and Tools

Before beginning the replacement process, gather the necessary tools such as screwdrivers, wrenches, and safety gear. Familiarize yourself with the components you’ll be working on to streamline the task and minimize complications.

Step-by-Step Replacement

1. Disconnect Power: Always ensure the device is unplugged or disconnected from the power source to avoid accidents.

2. Remove the Old Component: Carefully take out the faulty element, paying attention to any screws or connectors that may need to be released.

3. Install the New Element: Position the new component in place, securing it with the appropriate fasteners and ensuring it fits snugly.

4. Reconnect Power: Once everything is in place, restore the power and conduct a test run to confirm functionality.

Following these steps will help you achieve a successful replacement, ultimately prolonging the life of your equipment.

Upgrading Your Ice Machine Effectively

Enhancing your cooling apparatus can significantly improve efficiency and performance. By focusing on essential upgrades, you can achieve better output and lower energy consumption, ultimately leading to cost savings and improved reliability.

Assessing Your Needs: Before making any changes, evaluate your current setup. Consider factors such as output requirements, energy efficiency, and any recurring issues. This analysis will guide you in selecting the most effective enhancements.

Choosing Quality Components: Investing in high-quality replacements or additions is crucial. Opt for components that offer durability and compatibility with your existing framework. Doing so ensures that the system functions optimally and extends its lifespan.

Professional Assistance: Consulting with a technician can provide valuable insights. Their expertise allows for a thorough assessment and recommendations tailored to your specific needs, ensuring that upgrades are implemented smoothly and effectively.

Regular Maintenance: After upgrading, establish a maintenance routine. Regular checks and servicing will help maintain performance and prevent future breakdowns, ultimately protecting your investment.