The intricacies of a combustion system are essential to its overall performance and efficiency. Each element plays a crucial role in ensuring optimal functionality, contributing to the power output and operational reliability.

By exploring the various components involved, one can gain insight into how these mechanisms interact harmoniously. This examination not only highlights the significance of each segment but also illuminates the ultimate purpose of the entire assembly.

From the initiation of fuel ignition to the expulsion of exhaust gases, understanding these elements is key for enthusiasts and professionals alike. This knowledge empowers individuals to delve deeper into the workings of a combustion system, enhancing their appreciation for this complex technology.

Understanding Diesel Engine Components

Grasping the intricacies of a combustion mechanism reveals the synergy of various elements working harmoniously to convert fuel into motion. Each component plays a crucial role, contributing to the overall functionality and efficiency of the system. A comprehensive understanding of these elements can enhance maintenance practices and improve performance.

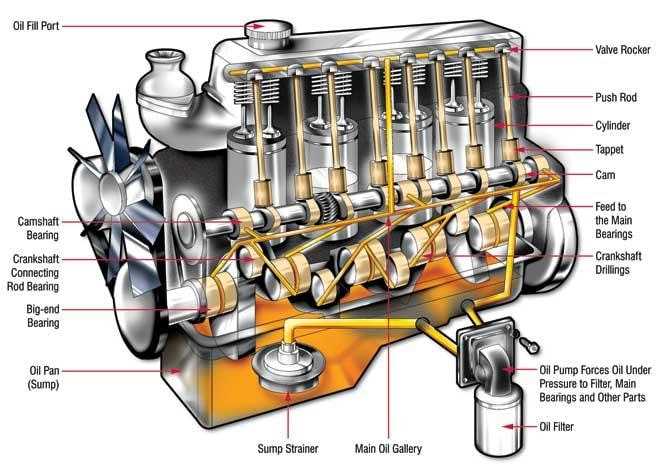

The core of the mechanism consists of the combustion chamber, where the fuel-air mixture ignites, generating the necessary force. Surrounding this chamber are elements responsible for intake and exhaust processes, ensuring optimal airflow. Additionally, the mechanism relies on a robust structure that houses moving parts, facilitating smooth operation and minimizing friction.

Furthermore, auxiliary systems such as lubrication and cooling are essential for sustaining optimal temperatures and preventing wear. By delving into each component’s purpose and interrelation, one can appreciate the ultimate complexity and sophistication of this technology.

Key Parts of a Diesel Engine

This section explores the essential components that contribute to the efficient functioning of a robust power unit. Each element plays a critical role in the overall operation, ensuring reliability and performance under various conditions.

Combustion Chamber

The combustion chamber is where the fuel-air mixture ignites, creating the force needed to drive the pistons. Its design affects efficiency, power output, and emissions, making it a focal point in optimizing performance.

Fuel Injection System

This system is crucial for delivering fuel into the combustion chamber at precise intervals. The accuracy of fuel delivery directly influences power generation, fuel efficiency, and overall operational smoothness, highlighting its significance in any power unit.

How Diesel Engines Operate

This section explores the fundamental principles behind the operation of a specific type of internal combustion mechanism, emphasizing the unique process of fuel combustion and energy conversion. Understanding this system reveals the intricate interplay of various components that contribute to its efficiency and functionality.

Basic Operation Principles

The cycle begins with air intake, followed by compression, where the air is pressurized to raise its temperature. This high-pressure environment facilitates the injection of fuel, leading to spontaneous ignition. The rapid expansion of gases generates power, which is then harnessed to perform work.

Key Components and Their Functions

| Component | Function |

|---|---|

| Intake Valve | Allows air to enter the combustion chamber. |

| Piston | Moves up and down to compress air and generate power. |

| Fuel Injector | Delivers fuel into the high-pressure air for combustion. |

| Exhaust Valve | Releases spent gases from the combustion process. |

Fuel Delivery Systems Explained

The mechanism of delivering energy sources to combustion chambers is crucial for optimal performance. This system ensures that the appropriate amount of fuel reaches the combustion area, facilitating efficient operation and minimizing waste. Understanding how this process functions is essential for improving overall efficiency and reliability.

Components of these systems include various elements such as pumps, filters, and injectors, each playing a vital role in maintaining a steady flow. Pumps create the necessary pressure to transport fuel, while filters remove impurities that could hinder performance. The injectors then precisely meter the fuel into the combustion chamber, ensuring a well-mixed charge for ignition.

Moreover, modern advancements have led to the integration of electronic controls, allowing for real-time adjustments based on operating conditions. This enhances not only efficiency but also reduces emissions, contributing to a more sustainable approach. Delving into the intricacies of these systems reveals their ultimate importance in achieving peak performance.

Importance of the Cylinder Block

The cylinder block serves as a fundamental structure in various internal combustion systems, providing essential support and housing for critical components. Its design and material directly influence overall performance and durability.

Structural Integrity: This component ensures that all moving parts are securely held in place, allowing for efficient operation under high pressures and temperatures. A robust design prevents deformation and maintains alignment, which is crucial for optimal functionality.

Heat Management: The cylinder block plays a vital role in dissipating heat generated during combustion. Effective heat distribution helps maintain optimal operating temperatures, reducing the risk of overheating and enhancing reliability.

Efficiency and Power Output: The design and construction of the block can significantly impact the efficiency and power output of the system. A well-engineered block contributes to smoother operation and improved performance, maximizing the overall effectiveness of the unit.

Role of the Crankshaft in Functionality

The crankshaft is a pivotal component that transforms linear motion into rotational movement, playing a crucial role in the overall mechanics of machinery. Its design and operation are fundamental to achieving efficient performance and power generation.

| Function | Description |

|---|---|

| Energy Conversion | Transforms linear forces from pistons into rotational energy. |

| Balance | Ensures smooth operation by distributing weight and forces evenly. |

| Torque Generation | Creates the necessary torque to drive associated systems. |

| Synchronization | Works in harmony with other components to maintain timing. |

Cooling Systems in Diesel Engines

Effective thermal management is crucial for optimal performance and longevity of internal combustion systems. These systems generate significant heat during operation, necessitating efficient methods to dissipate excess warmth and maintain suitable operating temperatures. A well-designed cooling mechanism not only enhances efficiency but also minimizes the risk of overheating and potential damage.

Types of Cooling Systems

There are primarily two types of cooling mechanisms utilized in these power-producing units: liquid and air cooling systems. Each method has its own advantages and is chosen based on specific operational needs and environmental conditions.

| Type | Advantages | Disadvantages |

|---|---|---|

| Liquid Cooling | Efficient heat absorption, consistent temperature control | More complex, requires regular maintenance |

| Air Cooling | Simpler design, lower maintenance | Less effective in extreme conditions, temperature fluctuations |

Components of Cooling Systems

The main components of these thermal regulation systems include radiators, pumps, thermostats, and cooling fans. Each component plays a vital role in ensuring that the temperature remains within the optimal range, thereby enhancing performance and preventing damage from excessive heat.

Common Issues with Diesel Engine Parts

When dealing with complex machinery, various challenges can arise, often leading to diminished performance and increased maintenance costs. Identifying and understanding these prevalent problems can significantly enhance the longevity and efficiency of the system. Here, we explore some frequent complications associated with critical components.

Fuel System Challenges

One of the primary areas where difficulties can occur is within the fuel delivery system. Clogged filters and contaminated fuel are common issues that can lead to subpar operation. These obstacles restrict the flow of fuel, causing misfires and reduced power output. Regular maintenance and timely replacement of filters can help mitigate these risks.

Cooling System Failures

Another significant concern lies in the cooling mechanism. Overheating can result from coolant leaks or a malfunctioning thermostat. Such failures can lead to serious damage if not addressed promptly. Ensuring that all components are functioning correctly and routinely checking coolant levels can prevent overheating and maintain optimal operating conditions.