When working with outdoor power tools, especially those designed for cutting and trimming, familiarity with the various elements is essential. Knowing how each piece functions and interacts can significantly enhance performance and maintenance. This section aims to provide a comprehensive overview of the intricate design and layout of a popular model, aiding users in identifying and understanding its core components.

Exploring the Assembly of your cutting device can uncover insights into its efficient operation. Every individual element plays a crucial role, contributing to the overall effectiveness and reliability of the machine. By examining the arrangement and purpose of these sections, operators can better appreciate the engineering behind their tool.

Furthermore, having a clear visual representation of the configuration aids in troubleshooting and repairs. Recognizing how different parts fit together can simplify maintenance tasks and ensure the tool remains in optimal working condition. Knowledge is power, and being well-informed about your equipment is the first step toward proficient use and care.

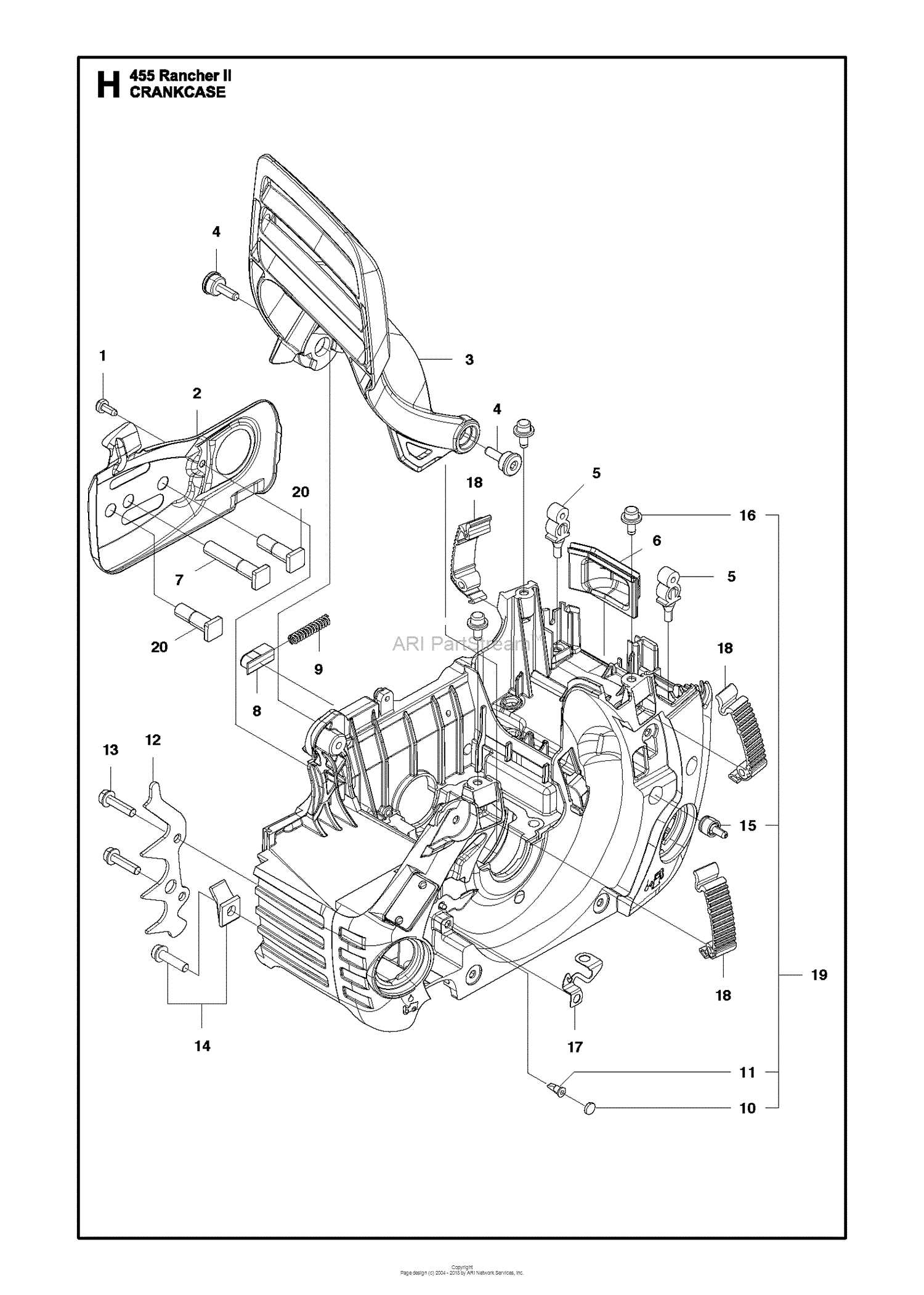

Understanding the Husqvarna 455 Diagram

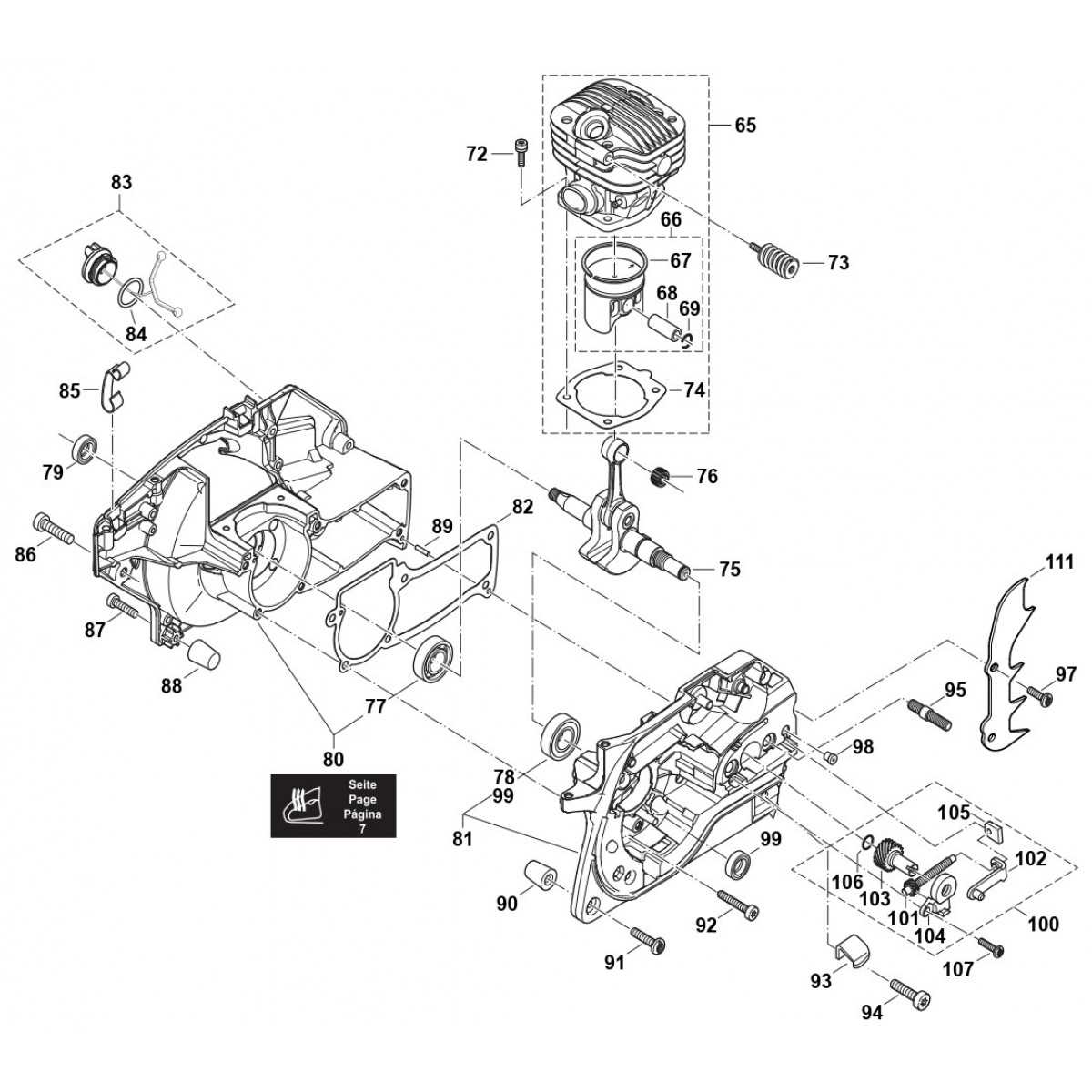

When working with machinery, a detailed illustration can be invaluable for understanding its components and assembly. These visual guides serve as a roadmap, helping users identify individual elements and comprehend how they interact within the system. This knowledge is essential for maintenance, repairs, and effective operation.

Familiarity with each component is crucial. By analyzing the schematic representation, one can gain insights into the functionality of various sections. This not only aids in troubleshooting but also enhances the user’s ability to perform adjustments and replacements as needed.

Moreover, visual references simplify the complex relationships between parts, making it easier to follow instructions during repairs. Understanding these relationships can lead to better performance and longevity of the equipment. Consequently, a thorough grasp of the illustration is an important step in mastering the machinery.

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool can significantly enhance its efficiency and longevity. Each part plays a crucial role in the overall functionality, contributing to the tool’s performance and safety during operation. Familiarity with these components not only aids in proper maintenance but also helps users troubleshoot common issues.

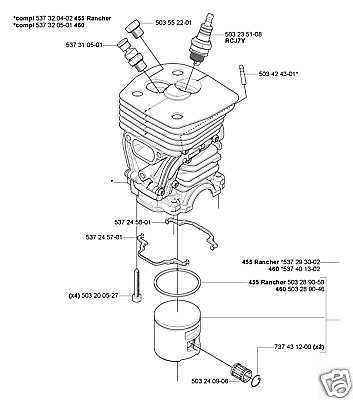

Engine and Power System

The engine serves as the heart of the tool, providing the necessary power to operate the chain. Typically, two-stroke engines are prevalent, known for their lightweight design and strong output. The power system, including the fuel tank and air filter, ensures optimal combustion and airflow, crucial for maintaining performance levels.

Cutting Mechanism

The cutting mechanism consists of the guide bar and the chain. The guide bar supports the chain as it moves around, while the sharp teeth of the chain perform the actual cutting. Regular inspection and maintenance of these components are vital for effective cutting and safety. Ensuring the chain is well-lubricated and properly tensioned can prevent wear and tear, extending the tool’s lifespan.

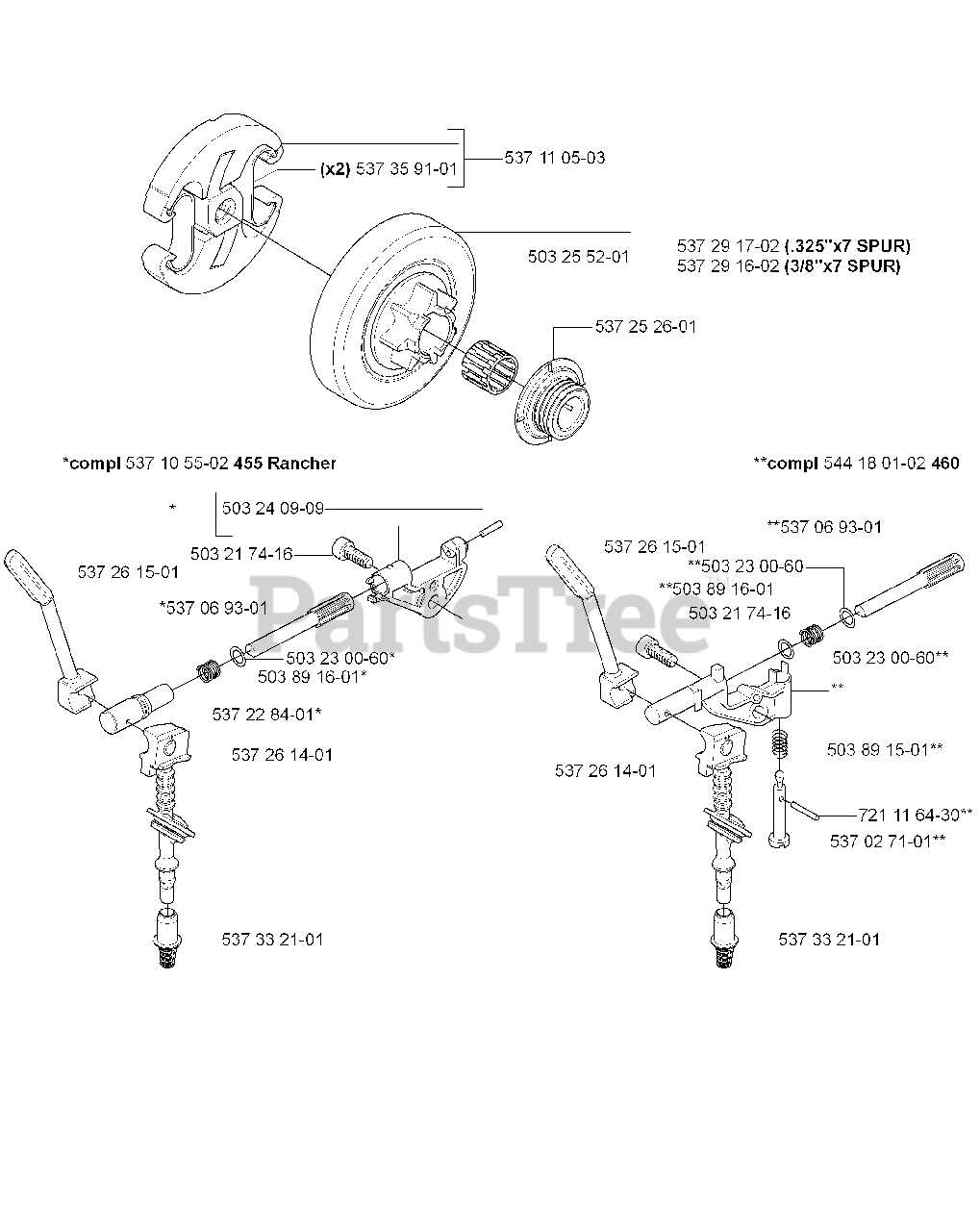

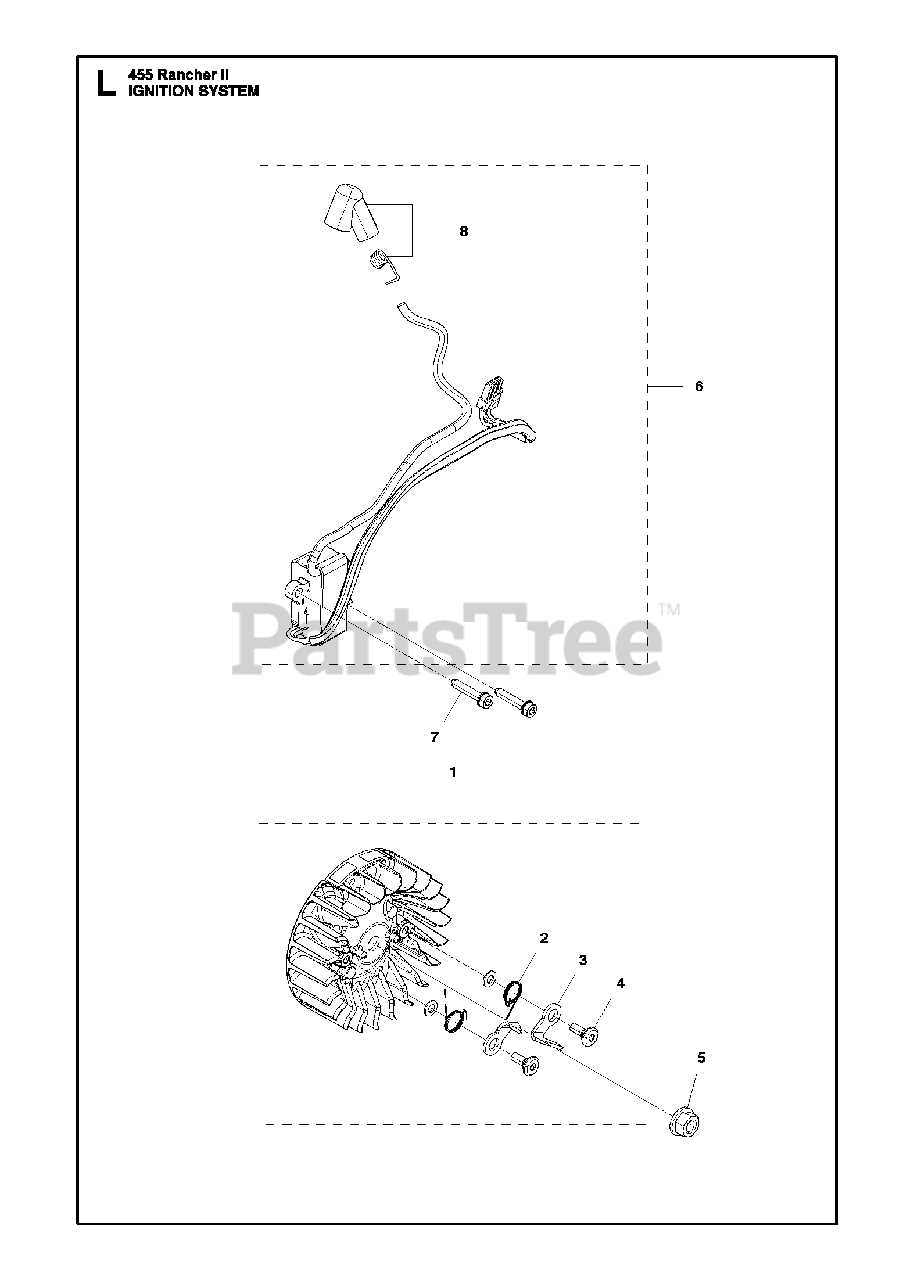

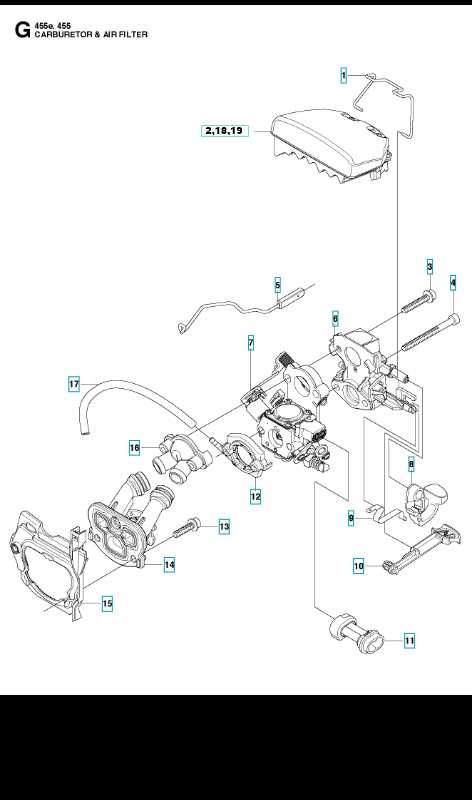

How to Read the Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear overview of the various elements, allowing users to identify, locate, and manage the necessary components efficiently.

Key Elements to Identify

- Labels: Most visuals include specific labels for each part, which help in pinpointing the exact components needed for repairs.

- Numbers: Components are often numbered sequentially, corresponding to a parts list for easy reference.

- Connections: Arrows or lines may indicate how parts are connected or interact with one another.

Steps for Effective Reading

- Start by examining the overall layout to get a sense of the assembly.

- Locate the legend or key that explains any symbols used in the representation.

- Refer to the accompanying list to match numbers with specific components.

- Take note of any highlighted areas that may require special attention during disassembly or reassembly.

By following these guidelines, you can efficiently navigate the visual representation and ensure proper handling of the equipment. Understanding this format will enhance your ability to perform necessary tasks with confidence and accuracy.

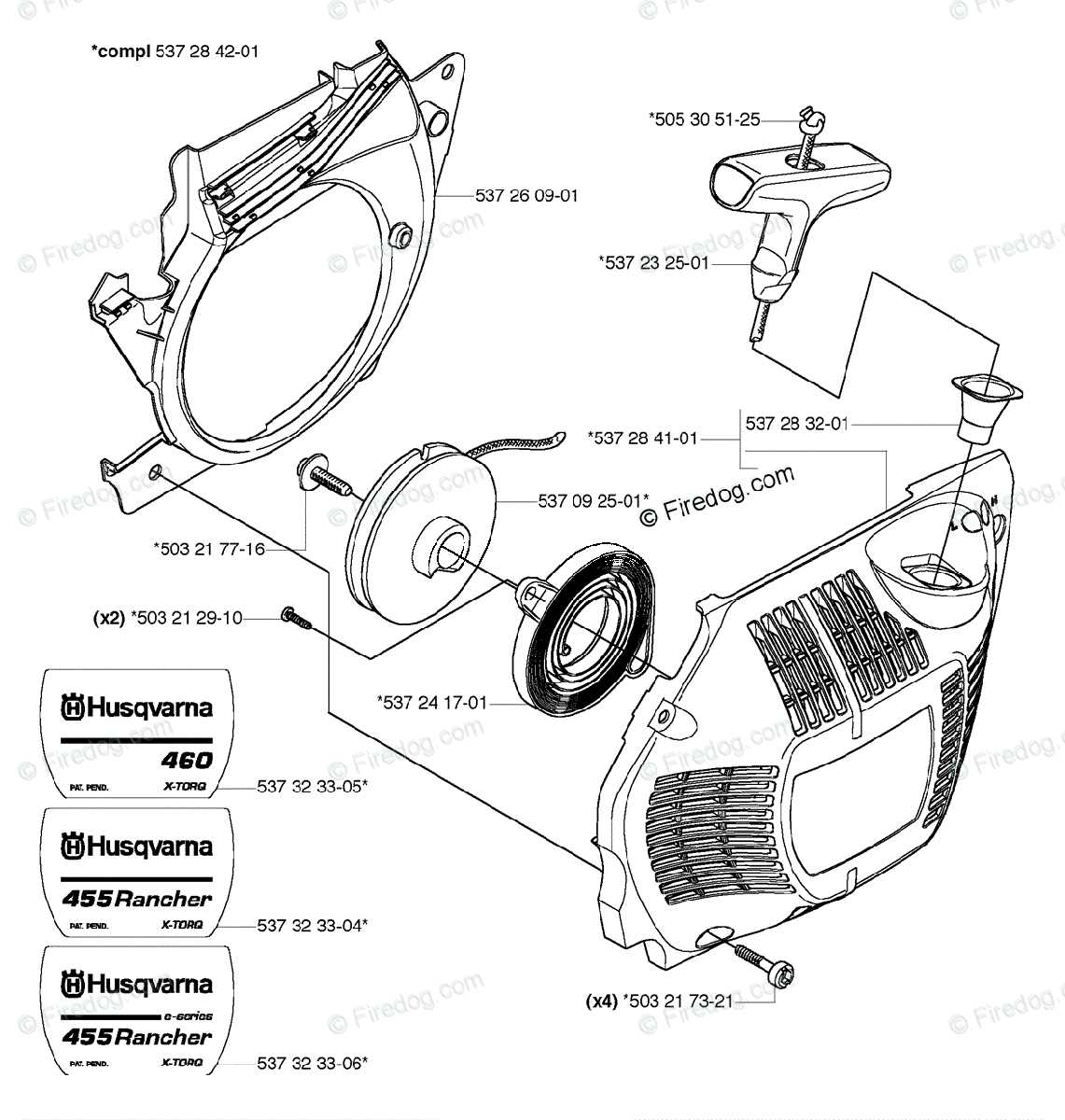

Replacement Parts Availability

When maintaining outdoor power equipment, ensuring access to quality components is essential for optimal performance and longevity. Various suppliers and retailers provide a wide array of essential elements, allowing users to replace worn or damaged items efficiently. Understanding the availability of these components can significantly influence the upkeep and functionality of the machinery.

Numerous authorized dealers and online platforms offer a comprehensive selection of necessary items, catering to diverse needs. Users can find everything from small fittings to larger assemblies, ensuring that repairs can be conducted with ease. Additionally, many resources provide detailed specifications and compatibility information, helping users make informed decisions when sourcing replacements.

For those seeking alternatives, aftermarket options are also widely available. These alternatives can provide cost-effective solutions without sacrificing quality. However, it is crucial to verify the reliability of the sources and ensure that any chosen replacements meet the required standards for performance and safety.

Staying informed about new product releases and potential updates can also enhance the maintenance experience. Regularly checking with suppliers and forums can reveal valuable insights and tips from other users, facilitating better care and prolonged service life for your equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of your equipment. Regular attention to detail can prevent premature wear and ensure efficient operation over time.

1. Regular Cleaning: Keep your device free from debris and dirt. This not only improves performance but also prevents damage.

2. Routine Lubrication: Ensure moving parts are adequately lubricated to reduce friction and wear, enhancing overall functionality.

3. Inspect and Replace Components: Regularly check critical components for signs of wear. Prompt replacement can avoid more significant issues down the line.

4. Proper Storage: Store the equipment in a dry, protected area to shield it from the elements and potential damage.

5. Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule will optimize performance and longevity.

By implementing these strategies, you can ensure that your device remains reliable and efficient for years to come.

Common Issues and Solutions

When working with outdoor power equipment, various challenges may arise that can hinder performance. Understanding these common problems and their remedies can enhance efficiency and prolong the life of your machinery.

Frequent Challenges

- Difficulty starting the engine

- Reduced power during operation

- Excessive vibration

- Fuel leaks

Possible Solutions

- Check the fuel system for clogs or old fuel.

- Inspect spark plugs for wear and replace if necessary.

- Tighten or replace loose components to minimize vibrations.

- Examine seals and gaskets to fix any leaks.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your equipment can significantly impact its overall performance. By focusing on key enhancements, users can achieve better power, reliability, and user experience. Whether for professional use or personal projects, strategic upgrades make a substantial difference.

Engine Optimization

One of the most effective ways to boost performance is through engine optimization. Upgrading components such as the air filter or fuel system can enhance combustion efficiency, leading to increased power output. Regular maintenance also plays a crucial role in ensuring the engine operates at peak performance.

Cutting Equipment Enhancements

Another vital area for improvement is the cutting mechanism. Investing in high-quality blades or bars can improve cutting speed and precision. Choosing the right material and design tailored to specific tasks can maximize effectiveness and durability, ultimately enhancing your overall cutting experience.

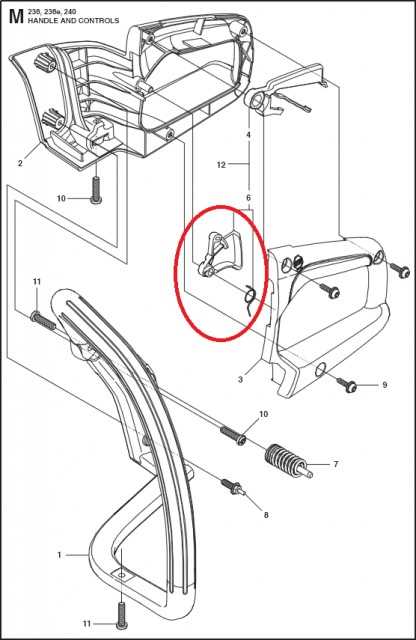

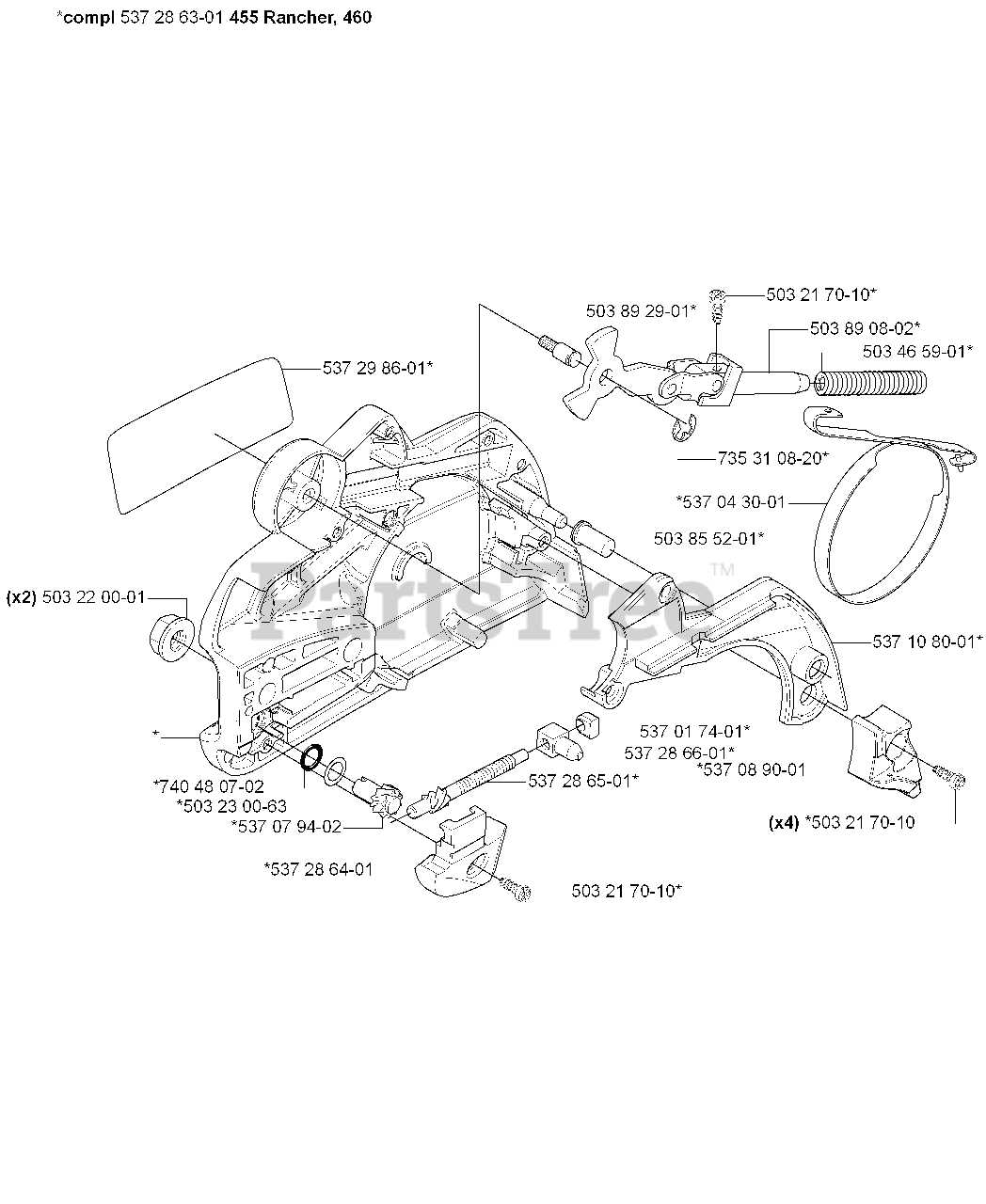

Visual Guide to Assembly Process

This section aims to provide a comprehensive overview of the assembly process for outdoor power equipment. By utilizing a visual approach, users can better understand the sequence and relationship between various components, ensuring a smooth assembly experience.

Step-by-Step Breakdown

Each stage of the assembly is outlined with clear visuals, allowing users to follow along easily. Understanding the orientation of each element is crucial, as improper placement can lead to operational issues. Pay close attention to the alignment of the pieces during assembly.

Common Challenges

While assembling, one may encounter typical hurdles such as misalignment or missing components. Referencing the visual guide can help troubleshoot these issues effectively. Ensuring all parts are present before starting will minimize complications and enhance efficiency.

Expert Recommendations for Use

To maximize the performance and longevity of your outdoor equipment, it’s crucial to follow specific guidelines that enhance both efficiency and safety. Understanding the intricacies of your machine can lead to more effective usage and reduce the likelihood of malfunctions.

Regular Maintenance: Consistent upkeep is essential. Clean the components frequently and check for any signs of wear. This proactive approach will help identify potential issues before they escalate.

Proper Usage: Always operate the equipment according to the manufacturer’s instructions. Using the right techniques not only improves performance but also ensures your safety and that of those around you.

Quality Fuel: Using high-quality fuel can significantly impact the machine’s efficiency. It is advisable to avoid low-grade options that may lead to engine problems.

Storage Practices: When not in use, store your equipment in a dry, protected area to prevent rust and deterioration. This simple step can extend the lifespan of the machine significantly.

By adhering to these expert recommendations, you can ensure optimal performance and reliability of your outdoor tools, allowing you to tackle tasks with confidence.