Modern diesel engines consist of various interconnected elements that work together to deliver optimal performance and efficiency. Each component plays a crucial role in ensuring that the engine functions smoothly, providing power and durability. Recognizing these elements and their interconnections can help in maintaining and troubleshooting the system effectively.

Within this intricate system, there are several essential components that interact with each other to ensure reliable operation. Some of these elements manage the flow of fuel, while others ensure the proper mixing of air and fuel. Their combined operation contributes to the overall efficiency and power output of the engine.

Understanding how these individual parts interact and support the engine’s operation is vital for anyone looking to maintain or repair this type of diesel system. This knowledge helps in identifying issues, performing routine maintenance, and ensuring that the engine continues to function at its best.

Powerstroke Parts Diagram

Understanding the layout and components of a complex engine system is crucial for maintaining optimal performance. This section provides an overview of the key elements that make up the engine’s structure, focusing on how various components interact and support the engine’s operation. It is essential for anyone working with these systems to have a clear mental image of how each element fits together.

Key Structural Elements include a variety of components that collaborate to ensure smooth functionality. From the heart of the engine to peripheral systems, each part has a role in maintaining power and efficiency. This cooperation between different sections ensures reliability during diverse conditions.

Maintenance Considerations often depend on knowing where each element is located within the system. Regular inspections can help identify potential wear and tear, preventing larger issues before they arise. An organized understanding of these components aids in making informed decisions about repairs and adjustments.

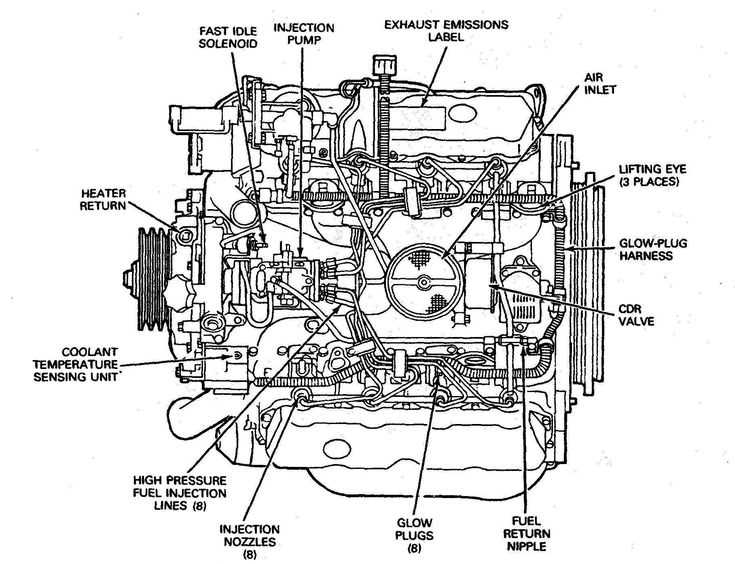

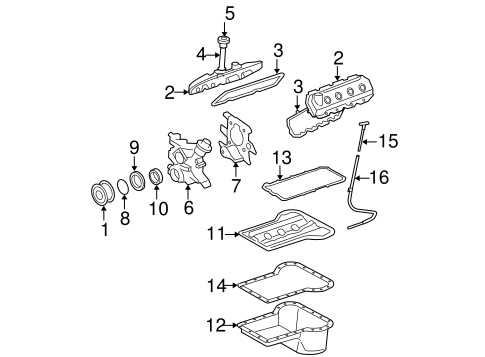

Overview of Engine Components

The intricate system of a vehicle’s engine relies on a variety of interconnected elements, each playing a vital role in ensuring smooth operation. These elements collaborate to convert energy into motion, maintaining efficiency and performance. Understanding their interactions helps in recognizing the importance of each part in the engine’s overall functionality.

Main Mechanical Elements

The engine comprises several key mechanical elements that work in harmony. The cylinder block forms the core structure, housing critical components that enable energy conversion. Alongside, the crankshaft transforms linear energy into rotational force, driving the vehicle’s movement. The pistons, moving in rhythm, ensure that this transformation is seamless and balanced.

Fuel and Air System

An efficient fuel delivery system is crucial for optimal engine performance. It includes parts that precisely manage the flow of fuel and air, ensuring the right mixture reaches the combustion chamber. The intake manifold directs air into the engine, while the fuel injectors ensure a controlled fuel supply. This balance is key to maintaining power and efficiency.

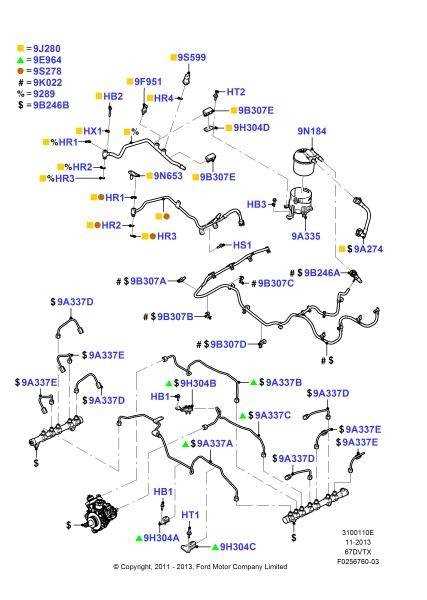

Critical Elements in Fuel System

The fuel system plays a vital role in ensuring efficient performance by delivering the necessary fuel to the engine with precision. A well-maintained system guarantees smooth operation and reliability, making it essential for vehicles to function optimally. Understanding the key components helps in identifying potential issues and maintaining overall system integrity.

Fuel Delivery Components

Among the primary elements are those responsible for transporting fuel from the tank to the engine. This includes devices that maintain appropriate pressure and ensure a steady flow. These components work together to prevent interruptions and maintain consistent power during operation, supporting both performance and durability.

Filtration and Pressure Management

Proper filtration is critical to prevent contaminants from entering the engine, safeguarding it from damage. Equally important is maintaining stable pressure, which allows the system to deliver the right amount of fuel under various conditions. Together, these aspects ensure the engine runs smoothly and remains protected over time.

Cooling System and Its Key Parts

The cooling system is essential for maintaining optimal engine performance, ensuring that temperature levels remain stable during operation. By circulating coolant through various components, it helps to prevent overheating and promotes efficiency in diverse driving conditions. The structure of this system is intricate, comprising multiple interconnected elements that work together seamlessly.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant, allowing it to release absorbed warmth into the surrounding air. |

| Thermostat | Regulates the flow of coolant based on temperature, ensuring that the engine reaches its ideal working conditions. |

| Water Pump | Facilitates the continuous flow of coolant through the engine and back to the radiator, maintaining a balanced temperature. |

| Coolant Reservoir | Acts as a storage unit for excess coolant, preventing overflow and accommodating thermal expansion. |

| Cooling Fans | Enhance airflow across the radiator, especially during low-speed operation or when additional cooling is needed. |

Each of these components has a unique role, working collectively to ensure the system’s efficiency. Together, they form a mechanism that keeps the engine running smoothly, regardless of external conditions or demands on performance.

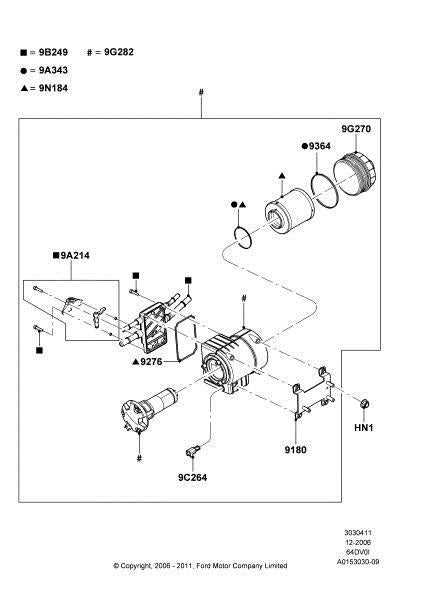

Understanding the Turbocharger Assembly

The turbocharger assembly plays a crucial role in enhancing the overall performance and efficiency of an engine. It is designed to increase airflow, allowing for better combustion, which results in improved power output. This component is essential for optimizing the engine’s responsiveness and ensuring a smoother driving experience, particularly during acceleration.

Main Components of the Turbo System

The turbo system consists of various interconnected parts that work together to compress and direct air into the engine. Key elements include the turbine, compressor, and intercooler, each contributing to the smooth flow of air and efficient operation. The turbine harnesses exhaust gases to drive the compressor, which in turn pushes more air into the combustion chamber.

How the Turbocharger Operates

The operation begins when the turbine spins due to the force of exhaust gases, driving the compressor to draw in more air. This process results in a higher density of air entering the engine, leading to better fuel combustion. The intercooler helps to cool down the compressed air, ensuring that the engine runs efficiently and stays within optimal temperature ranges.

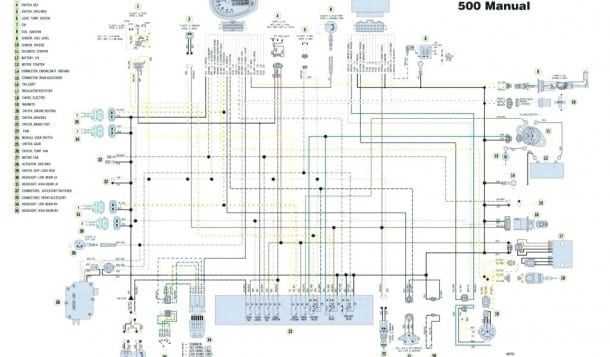

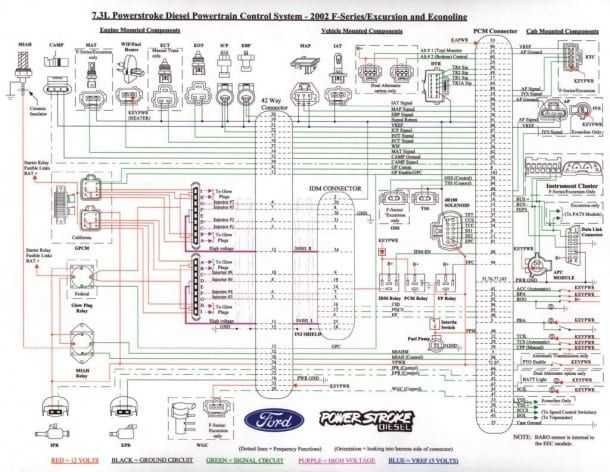

Electrical Connections and Sensors

This section explores the vital components involved in the electrical system of an engine, focusing on the connections and sensors that ensure optimal performance and reliability. Proper understanding and maintenance of these elements are crucial for efficient operation.

The electrical connections facilitate communication between various engine components and the control unit. These connections are essential for transmitting signals and power, enabling the engine to function smoothly. Here are some key aspects to consider:

- Connector Types: Different types of connectors are utilized, including weatherproof and sealed connectors, which prevent moisture ingress and ensure longevity.

- Wiring Harness: The wiring harness organizes and protects the electrical wires, helping to prevent damage and maintain clear pathways for electrical flow.

- Ground Connections: Proper grounding is essential for reducing electrical noise and ensuring that all components operate effectively.

Sensors play a critical role in monitoring various parameters within the engine. These devices collect data and send it to the control unit for processing, helping to optimize performance. Important sensors include:

- Temperature Sensors: Monitor the temperature of the engine and its components, providing essential information for maintaining safe operating conditions.

- Pressure Sensors: Measure oil and fuel pressure, alerting the system to potential issues that may arise.

- Position Sensors: Track the position of components, ensuring that the engine functions correctly and efficiently.

Regular inspection and maintenance of electrical connections and sensors are crucial to prevent failures and ensure the longevity of the engine. Proper care will contribute to the overall health and performance of the system.

Exhaust System Layout Explained

The configuration of the exhaust system plays a crucial role in the overall performance of a vehicle. It serves to direct harmful gases away from the engine while ensuring efficient airflow. A well-designed exhaust system not only enhances power output but also contributes to optimal fuel efficiency.

Key Components

Essential elements of the exhaust system include the manifold, catalytic converter, and muffler. Each component has a specific function in controlling emissions and managing sound levels. The manifold collects exhaust gases from the engine cylinders, while the catalytic converter reduces harmful emissions before they exit the system. The muffler, on the other hand, minimizes noise, creating a more pleasant driving experience.

Flow Dynamics

Understanding the flow dynamics within the exhaust system is vital for maximizing engine efficiency. Proper routing and sizing of pipes ensure that exhaust gases move freely, reducing backpressure and enhancing performance. A carefully engineered layout can significantly impact torque and horsepower, leading to an overall improvement in vehicle responsiveness.

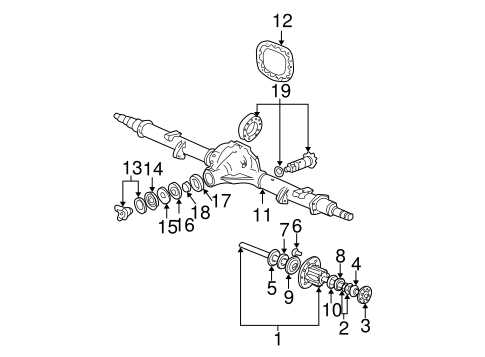

Internal Mechanisms and Moving Parts

The intricate assembly of an engine relies heavily on its internal components and their harmonious interaction. These essential elements work together to ensure the smooth operation and efficiency of the overall system. Understanding these mechanisms is crucial for anyone involved in maintenance or troubleshooting.

Key Components and Their Functions

Various vital elements contribute to the engine’s performance, including pistons, crankshafts, and camshafts. Each component plays a specific role in the conversion of fuel into energy, facilitating the movement and generating the necessary power for operation.

Importance of Proper Maintenance

Regular upkeep of these internal mechanisms is vital to prevent wear and tear. Neglecting maintenance can lead to significant issues, affecting the overall functionality. Timely inspections and replacements of worn parts can help extend the lifespan of the engine and maintain optimal performance.

Maintenance Tips for Engine Components

Regular upkeep of engine elements is crucial for optimal performance and longevity. Proper maintenance not only enhances efficiency but also helps in preventing costly repairs in the future. By following specific guidelines, vehicle owners can ensure that their machinery remains in excellent condition.

Routine Inspections

Conducting frequent assessments of engine components is essential. Here are some key areas to focus on:

- Check fluid levels, including oil and coolant.

- Inspect belts and hoses for signs of wear or damage.

- Examine electrical connections for corrosion or loose fittings.

Regular Cleaning

Keeping engine parts clean can significantly improve performance. Consider these cleaning practices:

- Use a gentle cleaner to remove grime and debris.

- Ensure air filters are free from dust and blockages.

- Clean fuel injectors to promote efficient combustion.