When it comes to maintaining outdoor machinery, having a clear understanding of its various components is essential for optimal performance and longevity. This guide delves into the intricate assembly of a popular lawn care machine, highlighting the significance of each section in the overall functionality. By gaining insight into the arrangement and purpose of these individual elements, users can ensure their equipment operates smoothly and efficiently.

Moreover, familiarizing oneself with the layout of a machine’s essential parts not only aids in regular maintenance but also simplifies troubleshooting. Whether you’re a seasoned operator or a novice, comprehending how the different segments interact can empower you to tackle repairs and enhancements with confidence. This knowledge ultimately contributes to a more rewarding experience in lawn management.

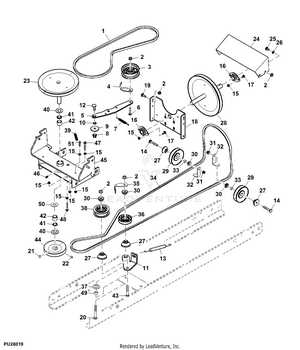

In this exploration, we will provide a detailed visual representation that outlines the various sections and components, making it easier to identify each piece’s role. From the power unit to the cutting mechanism, understanding these elements will enhance your ability to care for your equipment effectively and ensure it meets your gardening needs.

Understanding John Deere D125 Components

Exploring the various elements of a lawn care machine is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance, enhancing the overall efficiency of the equipment. Familiarity with these parts can aid in troubleshooting and repairs, ultimately extending the lifespan of the machinery.

Key Elements of the Machinery

Among the most vital components are the engine, which powers the entire unit, and the transmission system, responsible for the movement and speed control. Additionally, the cutting deck is essential for achieving a well-manicured lawn, while the wheels and tires provide stability and traction.

Importance of Regular Maintenance

Routine checks and servicing of these components are essential to prevent wear and tear. Understanding the functionality of each part allows operators to identify potential issues early, ensuring the machine operates at its best throughout the seasons.

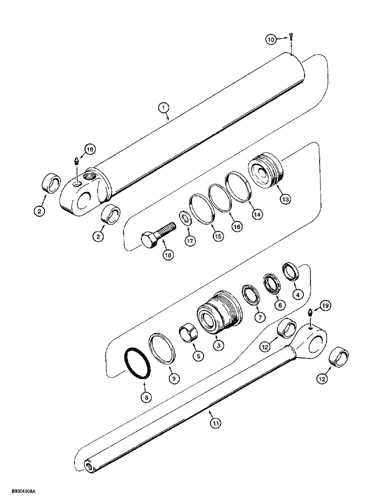

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that simplify complex systems, making it easier to identify and source individual elements. These illustrations not only aid in troubleshooting but also enhance the overall efficiency of repairs.

Clear visualization of each component allows technicians and enthusiasts alike to delve deeper into the mechanics involved. By providing a comprehensive overview, these illustrations become invaluable resources during maintenance sessions, ensuring that every part is accounted for and understood.

Moreover, having access to such resources minimizes the risk of errors during assembly or disassembly. With accurate representations at hand, users can confidently navigate through the intricate workings of machinery, ultimately leading to improved performance and longevity.

Key Features of the D125 Model

This model stands out in its category due to a combination of robust design and advanced functionalities, making it an ideal choice for various tasks around the yard. Users can expect a seamless experience with its innovative features tailored for efficiency and ease of use.

Powerful Engine: The machine is equipped with a reliable engine that ensures consistent performance, providing ample horsepower for tackling tough terrain and heavy workloads.

Ergonomic Design: The user-friendly layout allows for comfortable operation, featuring adjustable seats and controls that cater to operators of all sizes.

Cutting Efficiency: With a wide mowing deck, this model delivers a clean and precise cut, significantly reducing mowing time while enhancing the overall appearance of the lawn.

Durability: Constructed with high-quality materials, it is built to withstand the rigors of regular use, ensuring longevity and minimal maintenance requirements.

Versatile Attachments: The ability to utilize various attachments expands its functionality, making it suitable for tasks ranging from mulching to snow removal, adapting to seasonal needs.

Easy Maneuverability: Its compact size and responsive steering allow for effortless navigation around obstacles, ensuring efficient operation in tight spaces.

Where to Find Replacement Parts

Finding suitable components for your equipment is crucial for maintaining its performance and longevity. Whether you’re dealing with a lawn tractor or any similar machinery, locating the right substitutes can streamline repairs and ensure smooth operation. Here are some effective ways to source the necessary elements.

Online Resources

- Manufacturer’s Website: Most brands provide a dedicated section for accessories and components. These sites often include comprehensive catalogs and ordering options.

- Specialized Retailers: Numerous online stores focus on machinery components. Search for reputable retailers that offer a wide range of options.

- Marketplaces: Websites like eBay or Amazon can be valuable for finding both new and used items. Always check seller ratings and product reviews.

Local Options

- Authorized Dealers: Visiting a certified dealer can provide access to original equipment and expert advice on compatibility.

- Repair Shops: Local mechanics often have insights on where to source specific components and may have spare items available.

- Salvage Yards: For older models, salvage yards can be treasure troves for finding hard-to-locate elements at a lower cost.

Common Issues and Solutions

In the world of lawn maintenance machinery, users often encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their respective solutions is essential for keeping equipment in optimal condition and ensuring a smooth operation.

| Issue | Symptoms | Solution |

|---|---|---|

| Engine Won’t Start | Engine does not crank or make noise | Check the battery connections and replace the battery if necessary. Inspect the ignition system for faults. |

| Uneven Cutting | Grass appears uneven after mowing | Ensure the blades are sharp and properly adjusted. Check tire pressure and level the mower deck. |

| Overheating | Excessive heat and smoke from the engine | Inspect the cooling system for blockages and ensure the oil level is sufficient. Clean the air filter. |

| Stalling | Machine stops unexpectedly during operation | Examine fuel supply and ensure there are no clogs in the fuel line. Check the air filter for debris. |

| Transmission Issues | Difficulty in changing gears or slippage | Inspect the transmission fluid level and quality. Look for any signs of wear in the belts or cables. |

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure your equipment operates at its best. Implementing a systematic maintenance routine not only enhances efficiency but also extends the lifespan of your machinery.

1. Cleanliness is Key: Keep the exterior and interior of your equipment free from debris. Regularly wash off dirt and grass clippings to prevent rust and deterioration.

2. Check Fluid Levels: Regularly inspect and top off essential fluids, including oil and coolant. Maintaining appropriate levels is crucial for optimal functionality.

3. Inspect Belts and Cables: Periodically examine belts and cables for signs of wear. Replace any frayed or damaged components to avoid potential failures during operation.

4. Sharpen Cutting Edges: Ensure that blades are sharp for clean cuts. Dull blades can strain the engine and lead to uneven results.

5. Follow the Manual: Always refer to the manufacturer’s manual for specific maintenance guidelines. Adhering to recommended schedules and practices will yield the best results.

Comparison with Other John Deere Models

This section explores the differences and similarities among various models from the renowned manufacturer. By examining features, specifications, and overall performance, we can gain insights into how each unit caters to distinct user needs and preferences.

For instance, while some models may excel in maneuverability, others might prioritize power and efficiency. This variety allows users to choose a machine that aligns with their specific requirements, whether for residential use or larger agricultural tasks.

Ultimately, understanding these distinctions aids in making informed decisions when selecting equipment that best suits individual operational demands.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed look at various elements, helping users identify each part and its function within the overall system. Familiarity with the layout and symbols can significantly simplify the process of locating and replacing necessary items.

Key Elements to Look For

- Labels: Each component is usually labeled with a number or letter, corresponding to a reference list.

- Connections: Pay attention to how parts are connected, as this indicates how they interact during operation.

- Views: Diagrams may include multiple perspectives, so consider each angle to gain a complete understanding.

Tips for Effective Interpretation

- Start by familiarizing yourself with the reference list that accompanies the illustration.

- Break down the visual into sections to avoid feeling overwhelmed.

- Use a magnifying glass or digital zoom features for clarity on smaller elements.

- Cross-reference with user manuals or service guides for additional context.

Customer Reviews and Feedback

In this section, we explore the experiences and opinions of users regarding their equipment. Feedback plays a crucial role in understanding performance and reliability, offering valuable insights into product quality.

Overall Satisfaction: Many users express high satisfaction with their machinery, citing its durability and efficiency. They appreciate how well it handles various tasks, making their work easier.

Common Issues: Some customers report occasional challenges, such as maintenance concerns or specific component failures. However, these issues often vary based on usage and care.

Value for Money: Overall, users feel that the investment is justified, given the long-term benefits and capabilities of the machinery. The positive feedback highlights a strong recommendation for potential buyers.

User Testimonials: “This equipment has transformed my workflow,” one user notes, while another adds, “The reliability is unmatched.” Such testimonials underline the trust users place in their machinery.