In any mechanical system, comprehending the layout of individual elements is crucial for optimal functionality and maintenance. A detailed representation serves as a guide, enabling users to identify and manage the various sections of the equipment effectively. By familiarizing oneself with these configurations, one can enhance the operational performance and longevity of the machinery.

Such schematics are invaluable tools for both novices and experienced technicians. They provide insights into how each segment interacts within the larger assembly, highlighting the relationships and dependencies that exist. With a clear understanding of this framework, maintenance tasks become more straightforward, ensuring that interventions are both timely and effective.

Moreover, having access to a comprehensive overview can significantly reduce downtime. By pinpointing specific areas that require attention, technicians can streamline their efforts and focus on resolving issues promptly. This proactive approach not only saves time but also minimizes the risk of further complications arising from overlooked components.

Z-Spray Parts Diagram Overview

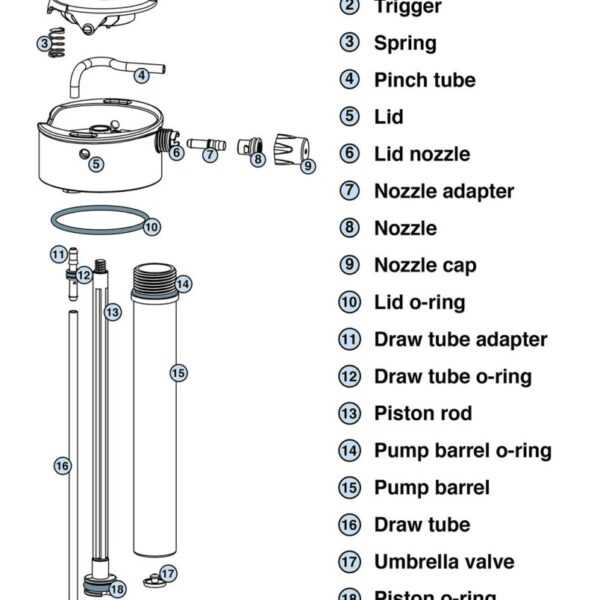

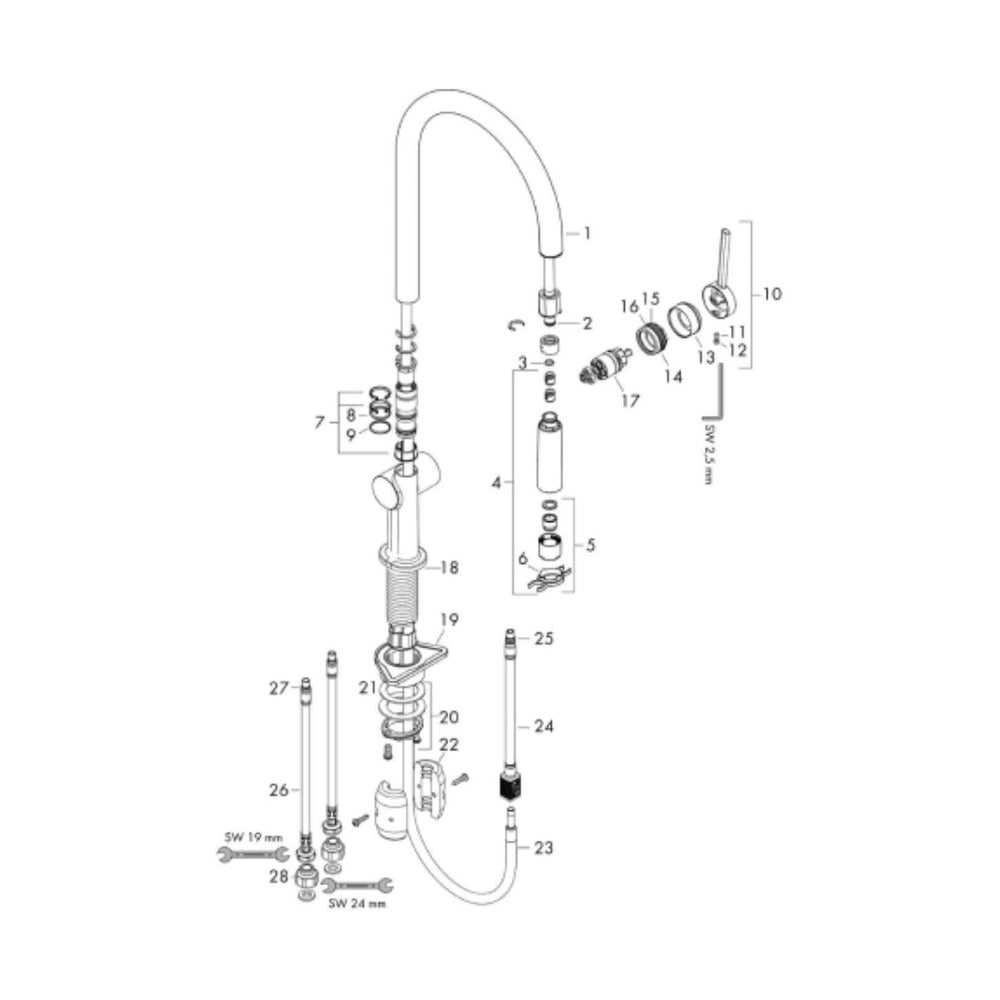

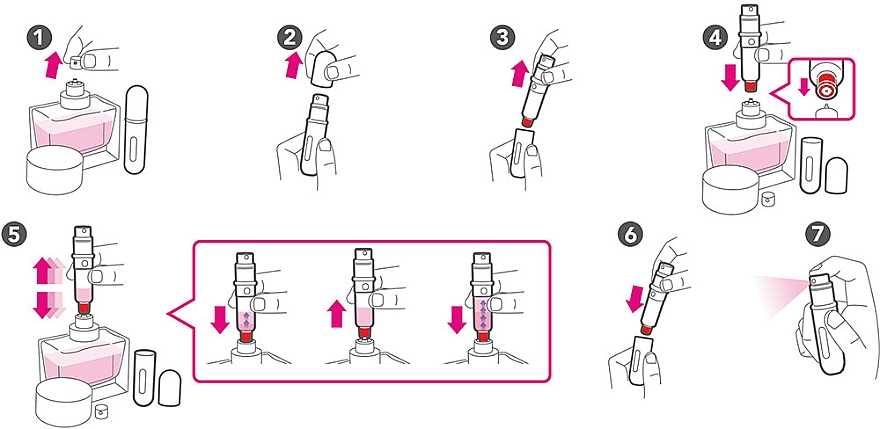

This section provides a comprehensive insight into the components of a specific spraying system. Understanding the configuration and functionality of each element is crucial for effective operation and maintenance.

Key elements within the system play vital roles in ensuring optimal performance. Familiarity with these components aids users in troubleshooting and enhancing efficiency.

By exploring the interconnections and purposes of each section, users can delve deeper into the mechanics, ultimately leading to better usage and care.

Understanding Z-Spray Components

In the world of advanced application systems, a comprehensive understanding of the various elements involved is crucial for optimal performance and maintenance. Each component plays a significant role, contributing to the overall efficiency and effectiveness of the equipment. Familiarity with these individual parts not only enhances operational knowledge but also aids in troubleshooting and repairs.

Key elements include the mechanisms responsible for distribution, control, and propulsion, each designed to work seamlessly together. For instance, the distribution system ensures an even application, while the control mechanisms allow for precision adjustments based on specific needs. Understanding these functionalities enables users to maximize the capabilities of their machinery.

Maintenance is another critical aspect that hinges on knowing the intricacies of these components. Regular inspections and timely replacements can prevent malfunctions and extend the lifespan of the equipment. A proactive approach to care not only safeguards investment but also ensures that operations remain smooth and efficient.

By delving into the specifics of each part, operators can gain valuable insights that enhance both performance and reliability, ultimately leading to improved outcomes in their applications.

Benefits of a Detailed Diagram

A comprehensive representation of components is essential for effective understanding and maintenance. Such visual aids not only clarify the relationships between various elements but also streamline processes, enhancing overall efficiency. Detailed illustrations serve as valuable tools for technicians and operators, providing insights that are crucial for effective troubleshooting and repair.

Enhanced Understanding

- Clear visualization of complex systems.

- Facilitates quicker comprehension of interrelated components.

- Reduces the likelihood of errors during assembly or disassembly.

Improved Communication

- Serves as a universal reference for team members.

- Bridges gaps in knowledge between different skill levels.

- Encourages consistent terminology and understanding across teams.

Incorporating detailed visual representations ultimately leads to smoother operations and better overall performance.

Common Issues with Z-Spray Parts

In the realm of specialized equipment maintenance, several challenges frequently arise that can hinder optimal performance. Identifying these issues is essential for ensuring efficiency and prolonging the lifespan of the machinery. This section explores the prevalent difficulties encountered, along with potential solutions to mitigate them.

Wear and Tear: Regular usage can lead to the deterioration of components. This wear may result in reduced efficacy, requiring timely replacements to maintain functionality.

Clogging: Debris accumulation in critical areas can obstruct fluid flow, causing malfunctions. Regular cleaning and inspection are vital to prevent this problem from escalating.

Corrosion: Exposure to chemicals can lead to rust and deterioration of metallic surfaces. Employing protective coatings and choosing corrosion-resistant materials can significantly extend the equipment’s life.

Improper Calibration: Misalignment or incorrect settings can affect performance. Regular checks and adjustments are necessary to ensure precision in operation.

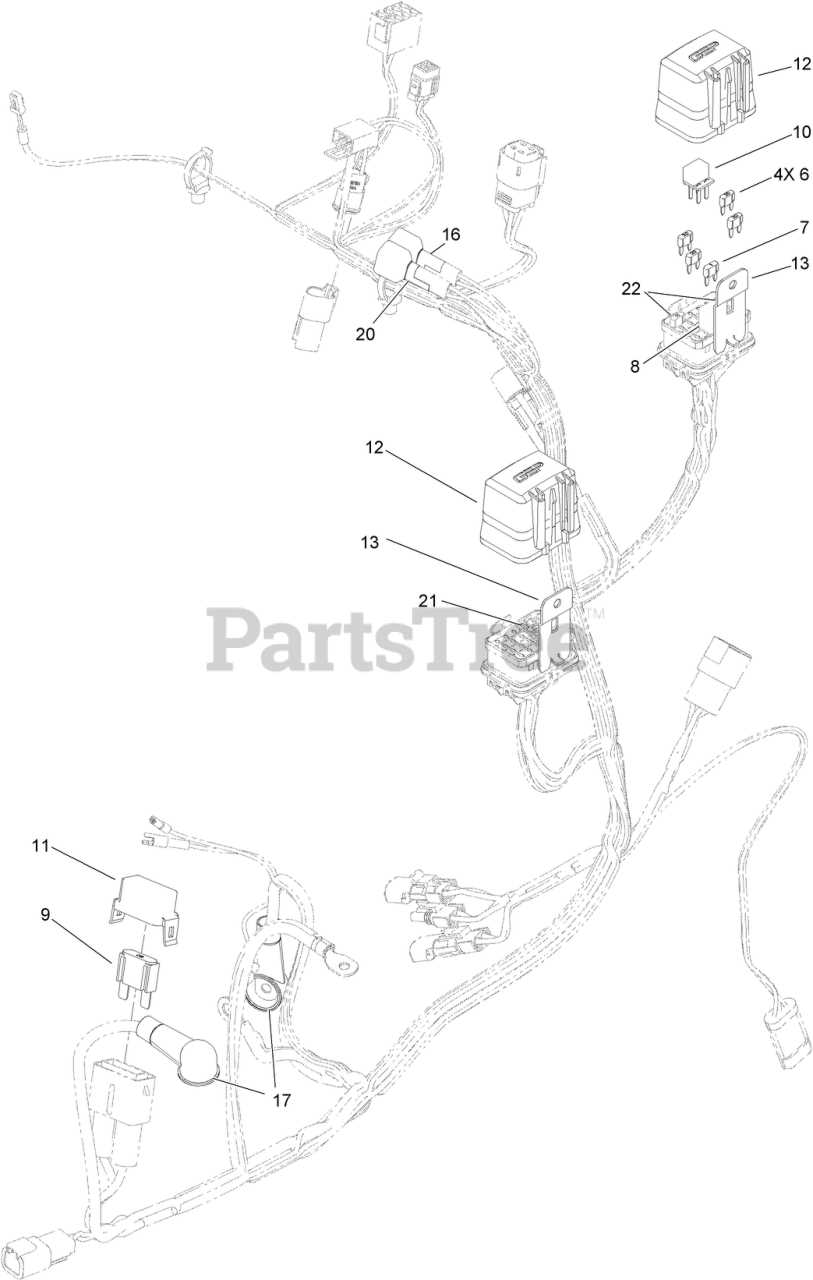

Electrical Failures: Wiring issues or component failures can disrupt functionality. Routine electrical inspections can help identify and resolve these problems before they lead to significant downtime.

By recognizing these common challenges, operators can take proactive measures to enhance the performance and longevity of their machinery, ensuring reliable operation in demanding environments.

How to Read the Diagram

Understanding a schematic representation of equipment can greatly enhance your ability to operate and maintain the machinery effectively. A clear grasp of this visual tool allows users to identify components, their functions, and how they interconnect. By following a systematic approach, you can extract valuable insights that will aid in troubleshooting and optimizing performance.

Key Elements to Focus On

Begin by familiarizing yourself with the legend or key, which usually explains the symbols and markings used throughout the representation. Colors and lines often indicate different types of components and their relationships. Pay attention to any annotations or notes, as they can provide additional context about specific functions or precautions.

Interpreting Connections and Flow

Next, examine how the various elements are connected. Look for arrows or lines that indicate the direction of flow or the sequence of operation. Understanding these connections is crucial for diagnosing issues or planning maintenance tasks. Take your time to follow each path carefully, ensuring you comprehend how each part influences the overall system.

Maintenance Tips for Z-Spray Machines

Regular upkeep of your spraying equipment is crucial for ensuring its longevity and optimal performance. By following a few simple guidelines, you can keep your machine in excellent condition, reducing the risk of breakdowns and enhancing its efficiency.

Routine Checks

Implementing routine inspections can prevent minor issues from escalating into major problems. Consider the following:

- Inspect hoses for leaks or wear.

- Check connections and fittings for tightness.

- Examine the nozzles for clogs and clean them regularly.

- Look over the engine for signs of wear or damage.

Cleaning Procedures

Keeping your equipment clean is essential for maintaining its functionality. Follow these cleaning procedures:

- Rinse the tank thoroughly after each use to remove any residue.

- Wipe down exterior surfaces to prevent corrosion.

- Use appropriate cleaning solutions to avoid damaging components.

By adhering to these maintenance tips, you can ensure that your spraying machine operates smoothly and efficiently for years to come.

Identifying Replacement Parts Easily

When it comes to maintaining equipment, recognizing the necessary components is essential for seamless operation. By understanding the various elements involved, users can streamline the process of finding suitable alternatives or upgrades. This knowledge not only enhances efficiency but also minimizes downtime.

Visual aids play a crucial role in this identification process. Utilizing illustrations or schematics can help individuals quickly pinpoint specific elements, allowing for informed decision-making. When presented with a clear representation, it becomes significantly easier to locate the desired item among a multitude of options.

Additionally, familiarity with terminology related to the components can aid in communication with suppliers or service technicians. Having a solid grasp of the names and functions of various elements empowers users to ask targeted questions and obtain accurate replacements. This proactive approach reduces the chances of miscommunication and ensures that the correct items are sourced promptly.

Finally, keeping a detailed inventory of the components within the equipment allows for quick reference when replacements are needed. This organized method not only saves time but also ensures that maintenance can be performed efficiently, contributing to the longevity of the equipment.

Diagram Updates and Resources

This section focuses on the latest enhancements and tools available for visual representations of equipment and their components. Keeping these resources up-to-date is essential for efficient maintenance and understanding of the machinery.

Recent Enhancements

- Incorporation of new components based on user feedback.

- Improved clarity in visual layouts for easier navigation.

- Regular updates reflecting technological advancements.

Useful Resources

- Online manuals for detailed explanations.

- Community forums for sharing insights and experiences.

- Video tutorials for visual learners.

FAQs About Z-Spray Parts Diagrams

This section addresses common inquiries related to the visual representations of components used in specialized machinery. Understanding these illustrations is crucial for effective maintenance and operation.

Common Questions

- What information can I find in these illustrations?

- How can I use them to troubleshoot issues?

- Are there different types of visuals for various models?

- Where can I obtain the most accurate representations?

Helpful Tips

- Always refer to the manufacturer’s guidelines for the most reliable information.

- Familiarize yourself with common symbols used in the illustrations.

- Keep a digital copy for easy reference during maintenance tasks.

- Consult with professionals if you encounter unfamiliar elements.