The intricate machinery behind modern farming equipment plays a crucial role in enhancing productivity and efficiency. Knowledge of each element’s function and arrangement can greatly aid operators and technicians in maintaining and repairing their devices. This section delves into the specifics of a well-known tractor model, providing valuable insights into its mechanical structure.

By examining the layout of its components, users can identify not only the location of each section but also the relationships between them. This understanding is essential for troubleshooting and ensuring optimal performance. Accurate information about these elements can save time and resources, allowing for more effective management of agricultural tasks.

Whether you are a seasoned professional or a novice in the field, grasping the organization of these vital machine parts will empower you to make informed decisions. Knowledge is a powerful tool in the world of agriculture, leading to improved practices and results.

Understanding the John Deere 4310

The machine in question is a versatile piece of agricultural equipment designed for various tasks in farming and land management. Known for its durability and performance, it is often used in a wide range of applications due to its adaptable features. This section will explore its core functionalities and capabilities, highlighting how it can be used effectively in different scenarios.

Key Features and Benefits:

This model offers a robust engine that ensures efficiency even in demanding conditions. Its advanced hydraulics system supports multiple attachments, making it suitable for plowing, mowing, and lifting tasks. The compact design allows for easy maneuverability, which is essential when working in tight spaces.

Practical Applications:

From landscaping to small-scale construction projects, this equipment excels in both power and precision. It is well-suited for operators looking to handle tasks such as grading, soil preparation, or debris removal. Its reliability in various weather conditions adds to its appeal for those in need of a machine that can operate year-round.

Importance of Accurate Parts Diagrams

Ensuring that mechanical components are properly illustrated is critical for maintenance, repair, and efficient assembly. Diagrams that precisely display the structure and placement of each component help avoid confusion, reduce errors, and improve overall efficiency in any technical process.

Benefits of Well-Defined Illustrations

Clear illustrations save time by allowing users to identify specific components more easily. Whether it’s during a repair process or routine maintenance, having a detailed representation of every element reduces the chance of misassembly or incorrect part usage. Additionally, it ensures that replacements and repairs are done correctly the first time.

Ensuring Compatibility and Efficiency

Accurate visuals also help ensure compatibility with the surrounding system. They make it easier to choose the right part for a specific function, reducing downtime and preventing potential damage to the machine.

| Advantage | Impact | |||||||

|---|---|---|---|---|---|---|---|---|

| Faster Identification | Speeds up repair and maintenance | |||||||

| Reduced Errors | Minimizes misassembly or incorrect part use | |||||||

| Improved Compatibility | Ensures correct function with other components |

| Issue | Description | Solution |

|---|---|---|

| Hydraulic Leaks | Fluid leakage from the hydraulic system can lead to performance issues, including weak or slow implement movement. | Check hoses and seals for wear and replace any damaged parts. Regularly monitor fluid levels to prevent further problems. |

| Transmission Trouble | Difficulty shifting gears or unusual noises during operation are common concerns related to the transmission. | Inspect fluid levels and ensure the proper type of transmission oil is used. If the problem persists, consult a mechanic for further diagnosis. |

| Starter Failure | The engine may not start or take longer to turn over, especially in colder conditions. | Check the battery and starter connections. If the battery is in good condition, the starter motor may need replacement. |

Where to Find Replacement Parts

When it’s time to replace components for your machinery, it’s essential to know where to source reliable and compatible options. Numerous platforms and retailers offer a variety of solutions that meet the exact needs of your equipment.

| Source | Details |

|---|---|

| Authorized Dealers | Dealerships provide genuine items directly from manufacturers, ensuring compatibility and warranty support. |

| Online Marketplaces | Web platforms often offer a wide range of both new and used items, suitable for various machinery models. |

| Specialized Retailers | Stores focused on machinery offer high-quality alternatives that can serve as cost-effective replacements. |

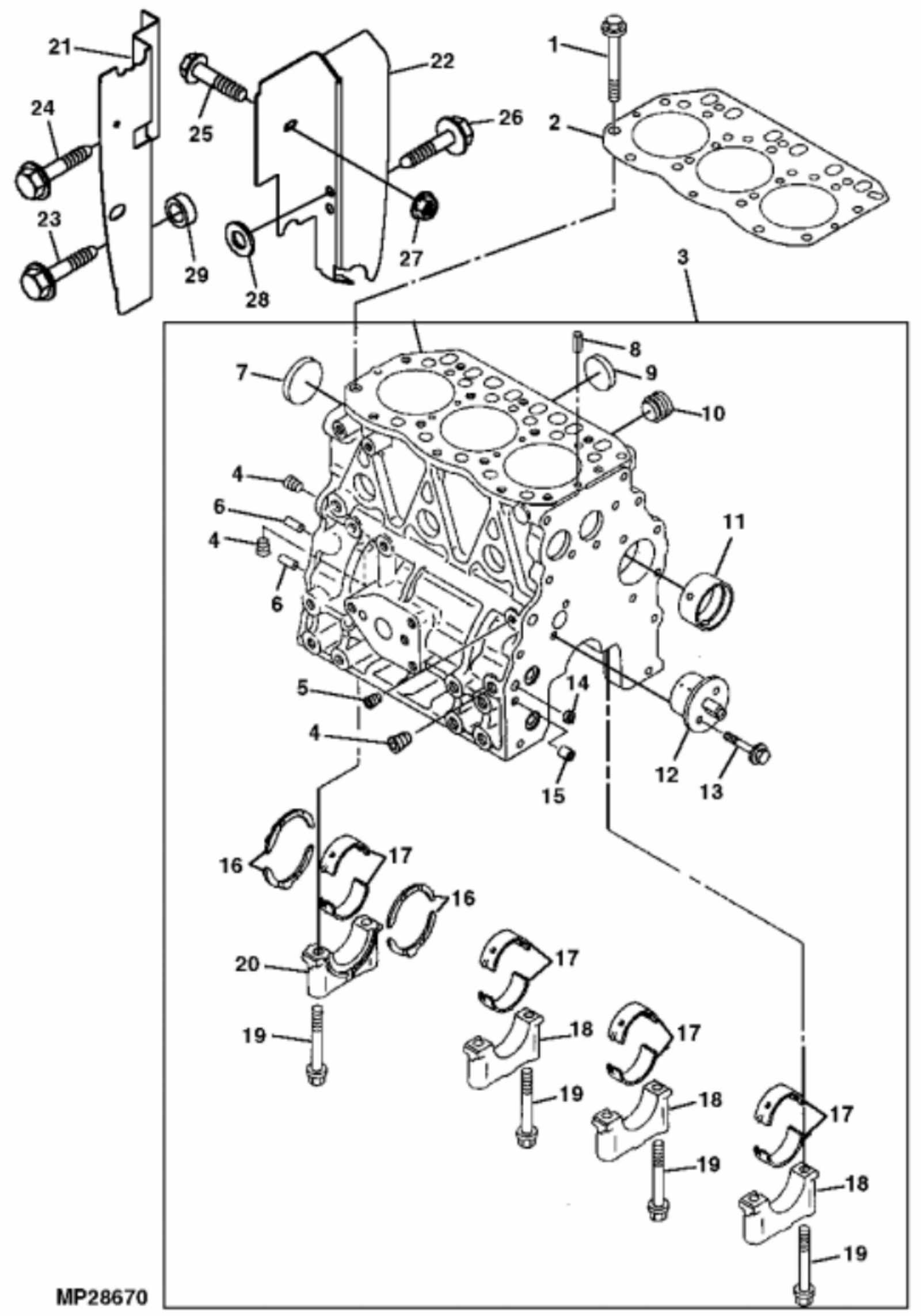

Overview of 4310 Components

This section provides a detailed examination of key elements that make up the 4310 machinery. Each component is essential to ensuring smooth functionality, contributing to the overall performance and durability of the equipment. Understanding how these parts work together will help in maintaining and troubleshooting issues.

Key Mechanical Elements

The machinery consists of several main mechanical units, including the engine, transmission, and hydraulic systems. These units are interconnected and designed to perform specific tasks efficiently. Proper maintenance of these systems is crucial to ensure optimal operation.

Electrical and Control Systems

The electrical systems power various functions, while control systems allow the operator to manage the equipment smoothly. The dashboard, wiring, and sensors are all vital components in maintaining precision and safety during operation.

| Component | Function | |||||||

|---|---|---|---|---|---|---|---|---|

| Engine | Generates power for all operations | |||||||

| Transmission | Ensures smooth movement and gear shifts | |||||||

| Aspect | Positive Reviews | Negative Reviews |

|---|---|---|

| Durability | 85% | 15% |

| Compatibility | 90% | 10% |