When it comes to maintaining outdoor machinery, a comprehensive understanding of its components is essential for both novice and experienced users. Familiarity with the layout and functionality of these essential parts not only enhances the longevity of the equipment but also optimizes its performance. This exploration delves into the intricacies of various elements found in lawn care devices, providing clarity and insight.

With a detailed representation of the various sections and their interconnections, users can troubleshoot issues more effectively and carry out necessary maintenance tasks with confidence. Knowing where each element fits and how it interacts with others empowers operators to make informed decisions, ensuring their equipment remains in peak condition.

Whether you’re embarking on a repair journey or simply looking to deepen your knowledge, grasping the arrangement of components is invaluable. This article aims to shed light on these crucial aspects, offering a structured view that simplifies the complexities of lawn machinery.

Understanding John Deere Sabre Components

Exploring the essential elements of lawn care machinery can enhance both performance and longevity. A comprehensive grasp of these components allows users to optimize their equipment effectively. Each element plays a crucial role, ensuring smooth operation and maintenance.

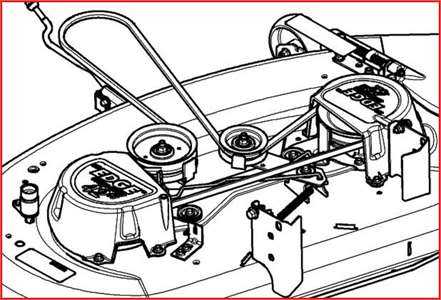

Key elements include the engine, transmission, and cutting system, which work in harmony to deliver efficient results. Understanding their functions and interconnections can empower operators to tackle issues proactively.

For ultimate performance, regular inspection and maintenance of these crucial parts are necessary. By doing so, one can ensure the machinery operates at its best, enhancing the overall experience.

Key Features of Sabre Lawn Tractors

Lawn tractors are designed to provide exceptional efficiency and ease of use for homeowners looking to maintain their yards. These machines combine power, comfort, and functionality to make lawn care a straightforward task. Understanding the main attributes can help users make informed decisions when choosing a suitable model for their gardening needs.

Power and Performance

- Robust Engines: Equipped with high-performance engines, these tractors ensure reliable operation, allowing for efficient mowing and handling of various terrains.

- Cutting Width: A wide cutting deck allows for faster mowing sessions, enabling users to cover larger areas in less time.

- Transmission Options: Many models feature easy-to-use transmission systems, providing smooth speed adjustments and greater control while navigating through different landscapes.

Comfort and Usability

- Ergonomic Seating: Comfortable seating designs reduce fatigue during extended use, making it easier for users to operate the machine over long periods.

- Intuitive Controls: User-friendly controls are strategically placed for easy access, enhancing the overall driving experience.

- Storage Solutions: Ample storage compartments allow for convenient storage of tools and personal items, keeping everything organized while working outdoors.

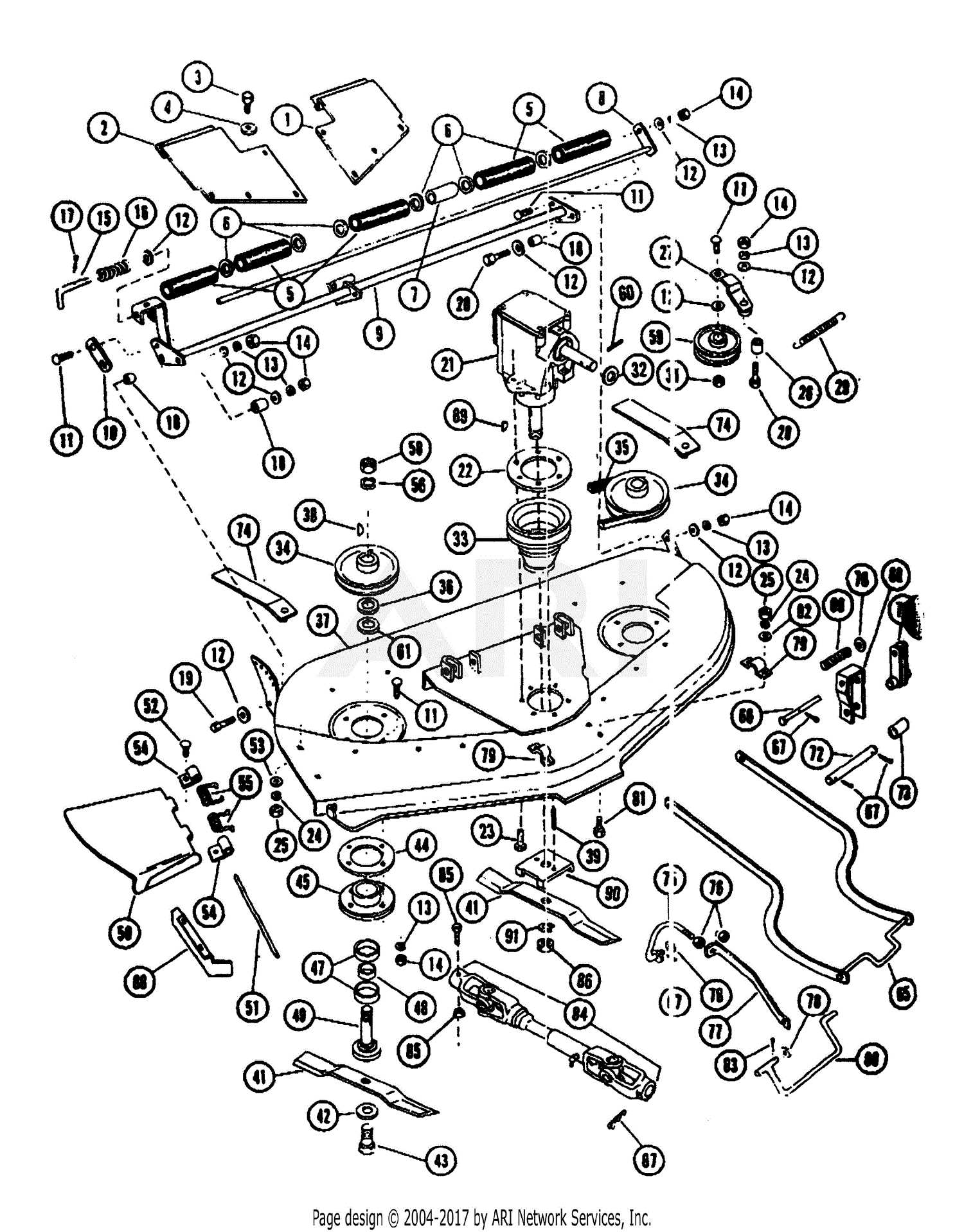

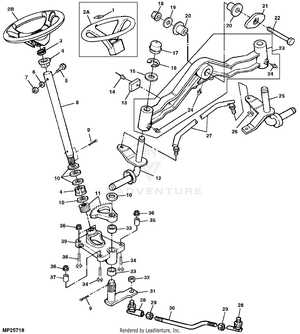

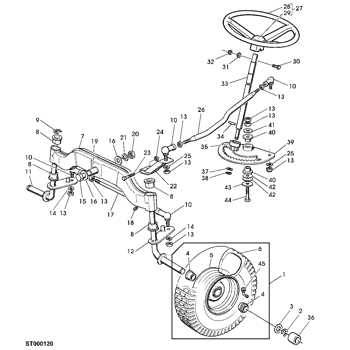

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visuals serve as crucial guides, providing a detailed overview of components and their arrangement within machinery. Learning to interpret these images can enhance your ability to identify and source the necessary elements for upkeep.

Key Elements to Consider

- Symbols: Familiarize yourself with common icons representing various components. Each symbol typically indicates a specific part, making it easier to navigate the illustration.

- Labels: Pay attention to labels that accompany the visuals. They often include part numbers and names, which are vital for locating replacements.

- Connections: Note how different elements are linked. Understanding these connections can help in troubleshooting issues and reassembling parts correctly.

Step-by-Step Approach

- Start by scanning the entire illustration to get an overview of the layout.

- Identify and focus on the main components first, then delve into the smaller, supporting parts.

- Cross-reference any numbers or labels with the accompanying documentation for precise identification.

- Make a list of any components that require replacement, using the information gathered from the visual guide.

By following these guidelines, you can effectively utilize technical illustrations, ensuring your maintenance tasks are carried out smoothly and efficiently.

Common Replacement Parts for Sabre Models

Maintaining the efficiency of your outdoor equipment is crucial for optimal performance. Various components may require replacement over time due to wear and tear. Understanding the common items that typically need attention can help you keep your machine running smoothly.

Frequently Needed Components

- Blades: Essential for cutting grass effectively, they can dull or become damaged with use.

- Batteries: A reliable power source is critical; batteries often need replacing after a few seasons.

- Belts: These drive components can wear out and affect the overall functionality.

- Filters: Air and fuel filters require regular changes to ensure clean operation.

- Spark Plugs: Essential for ignition, these may need replacement to maintain engine performance.

Other Important Items

- Tires: Flat or worn tires can hinder mobility; replacing them ensures safe operation.

- Deck Spindles: These can become corroded and may need to be changed for efficient cutting.

- Oil: Regular oil changes are necessary to keep the engine lubricated and functioning.

- Cables: Control cables can fray or break, requiring timely replacement for safety.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These elements are specifically designed to fit and function perfectly within the equipment, enhancing overall efficiency and reliability.

Quality Assurance: Authentic components undergo rigorous testing and adhere to strict manufacturing standards. This guarantees that each item meets the highest levels of quality, providing peace of mind for users.

Enhanced Performance: Using original components allows machinery to operate at its best. These parts are engineered to work seamlessly with the machine, ensuring that all systems function harmoniously.

Cost-Effectiveness: Although genuine components may have a higher initial price, they often lead to savings in the long run. Their durability reduces the frequency of replacements and repairs, minimizing downtime and associated costs.

Warranty Protection: Employing authentic parts helps maintain warranty coverage. Many manufacturers require the use of original components to ensure that warranties remain valid, protecting the investment in the equipment.

Safety Considerations: Genuine components are designed with safety in mind. Using non-authentic alternatives can compromise the safety features of the machinery, leading to potential hazards during operation.

Identifying Parts by Model Number

Understanding the components of your equipment is essential for effective maintenance and repairs. One efficient way to locate specific elements is by utilizing the model identifier, which provides a unique reference to the particular unit.

To effectively find the necessary components, follow these steps:

- Locate the model number on your machine, usually found on a label or stamped on the frame.

- Refer to the manufacturer’s manual or website for a breakdown of the model number’s significance.

- Use the model number to access online databases or catalogs that list compatible components.

- Cross-reference with reliable resources to ensure accuracy in your search.

By following this approach, you can streamline your search and ensure you acquire the correct elements for your equipment.

Maintenance Tips for Sabre Equipment

Proper upkeep of outdoor machinery is essential for ensuring optimal performance and longevity. By following a few key practices, you can keep your equipment running smoothly and efficiently, reducing the likelihood of costly repairs and downtime.

Regular Cleaning

Keeping your machinery clean is crucial for its performance. Dust and debris can accumulate, leading to potential issues.

- Inspect and clean the exterior surfaces frequently.

- Remove any grass clippings or dirt buildup from undercarriages and engines.

- Use a soft brush or compressed air for delicate areas.

Routine Inspections

Conducting regular inspections helps identify potential problems before they escalate.

- Check fluid levels regularly, including oil and fuel.

- Examine belts and hoses for signs of wear or damage.

- Inspect tires for proper inflation and tread wear.

By incorporating these practices into your maintenance routine, you can extend the life of your equipment and ensure it operates at peak efficiency.

Where to Find Sabre Parts Online

Locating components for your outdoor equipment can be a straightforward process if you know where to look. With the advancement of online shopping, a wide variety of resources are available to help you find what you need quickly and efficiently. This section will explore the best avenues for sourcing necessary items for your machinery.

Online Retailers

Numerous online marketplaces offer an extensive selection of components. Consider checking the following:

- Major e-commerce sites such as Amazon or eBay, which feature a vast range of options.

- Specialized retailers that focus on outdoor equipment and machinery supplies.

- Manufacturer websites that may sell direct to consumers or provide links to authorized dealers.

Community Forums and Marketplaces

Engaging with online communities can also be beneficial. Here are some platforms to consider:

- Forums dedicated to outdoor equipment enthusiasts, where members often share resources and recommendations.

- Social media groups that focus on machinery, which can provide leads on available items.

- Local classifieds or marketplace apps where users sell surplus items or parts directly.

DIY Repairs: A Step-by-Step Guide

Engaging in do-it-yourself maintenance can be a rewarding experience, allowing you to save money and gain a deeper understanding of your equipment. This guide will walk you through essential steps to effectively troubleshoot and resolve common issues, empowering you to tackle repairs with confidence.

Identifying the Problem

The first step in any repair process is to accurately identify the issue at hand. Start by observing the symptoms: unusual noises, reduced performance, or visible wear and tear. Taking notes on what you notice can help you diagnose the problem more efficiently. Utilize online resources or community forums to gather information and potential solutions relevant to your specific model.

Gathering Tools and Resources

Before diving into repairs, ensure you have the necessary tools and materials at your disposal. Common tools may include wrenches, screwdrivers, and pliers. It’s also helpful to acquire a repair manual or an online guide tailored to your equipment. Having the right resources on hand can significantly streamline the process and reduce the likelihood of errors.

Once you have pinpointed the issue and assembled your tools, follow a systematic approach to carry out the repairs. Document each step you take, and don’t hesitate to consult additional resources if you encounter any challenges. This methodical strategy not only aids in effective repair but also enhances your skills for future projects.