In the realm of agricultural machinery, efficient operation relies heavily on the seamless integration of various components. A comprehensive overview of these elements is essential for anyone looking to optimize their equipment’s functionality. This section aims to clarify the intricate relationships between different parts, ensuring that users can make informed decisions regarding maintenance and upgrades.

By delving into the specifics of each segment, operators can gain valuable insights into how their machinery functions as a cohesive unit. Recognizing how components interact not only enhances performance but also extends the lifespan of the equipment. Whether it’s for routine servicing or troubleshooting, understanding these intricacies proves invaluable.

Additionally, having a clear reference to the structure and arrangement of each element will aid users in identifying issues and implementing effective solutions. This guide serves as a vital resource for those aiming to maintain peak efficiency in their agricultural endeavors.

This section highlights the essential characteristics that contribute to the functionality and efficiency of the equipment designed for material handling and transport. These attributes ensure that users can rely on the machinery for various tasks, from lifting to moving heavy loads, thereby enhancing productivity in different environments.

Enhanced Performance

The machinery is engineered to deliver outstanding performance through a combination of robust design and advanced technology. Its powerful hydraulics and superior lifting capacity make it suitable for a range of applications, ensuring that users can handle heavy materials with ease.

Versatility and Adaptability

This equipment’s design allows for versatility in operations, accommodating a variety of attachments and accessories. Whether for construction, landscaping, or agricultural purposes, the machinery can be adapted to meet specific task requirements, making it a valuable asset across different industries.

| Feature | Description |

|---|---|

| Hydraulic System | Powerful hydraulic capabilities for efficient lifting and lowering of loads. |

| Lifting Capacity | High lifting capacity to handle heavy materials effortlessly. |

| Attachment Compatibility | Compatible with various tools and attachments for enhanced functionality. |

| Durable Construction | Robust design ensuring longevity and reliability in harsh working conditions. |

| Operator Comfort | Ergonomically designed controls and comfortable seating for ease of operation. |

Understanding Parts and Components

Comprehending the individual elements and their functionalities is crucial for effective maintenance and operation of machinery. Each component plays a vital role in the overall performance, contributing to the efficiency and reliability of the equipment. Familiarity with these elements not only enhances the user experience but also aids in troubleshooting and repairs.

Main Components

- Framework: The structural basis that supports all other elements, ensuring stability and durability.

- Hydraulic System: A critical assembly responsible for the movement and operation of various features.

- Attachment Mechanism: The interface that connects implements, enabling versatility in applications.

Functional Elements

- Control System: The interface through which the operator manages the functions, enhancing maneuverability.

- Power Source: The engine or motor that provides the necessary energy for operation.

- Safety Features: Components designed to protect the user and the machinery, ensuring secure operation.

Importance of Proper Maintenance

Maintaining equipment is crucial for ensuring its longevity and optimal performance. Regular upkeep not only enhances functionality but also prevents unexpected breakdowns that can disrupt operations. By adhering to a structured maintenance routine, operators can identify potential issues early, thereby saving time and resources in the long run.

Proper care involves a variety of tasks, including inspections, lubrication, and timely replacements of worn components. Each of these activities plays a significant role in the overall health of the machinery.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Weekly | Identifies visible wear or damage |

| Lubrication | Monthly | Reduces friction and wear |

| Component Replacement | As Needed | Ensures optimal performance |

| Filter Cleaning | Quarterly | Improves efficiency and airflow |

By prioritizing maintenance, operators can enhance the reliability and efficiency of their equipment, leading to improved productivity and lower operational costs.

Common Replacement Parts

In any machinery, certain components experience wear and tear over time and may need to be replaced to ensure optimal performance. Understanding the frequently replaced items can help in maintaining efficiency and extending the lifespan of the equipment. Below are some of the most commonly needed components that operators should be aware of.

- Hydraulic Cylinder Seals: These seals are essential for preventing fluid leaks and ensuring proper operation of hydraulic systems.

- Bucket Teeth: The teeth on the front attachment are subject to wear, making replacements necessary for effective digging and lifting.

- Filter Elements: Air, fuel, and hydraulic filters should be replaced regularly to maintain system cleanliness and performance.

- Hoses and Fittings: Over time, hoses can crack or become damaged, leading to leaks that require timely replacements.

- Belts: These components can wear down with use and may need to be changed to prevent system failures.

By keeping a stock of these essential components, operators can quickly address issues as they arise, minimizing downtime and ensuring that their machinery operates smoothly.

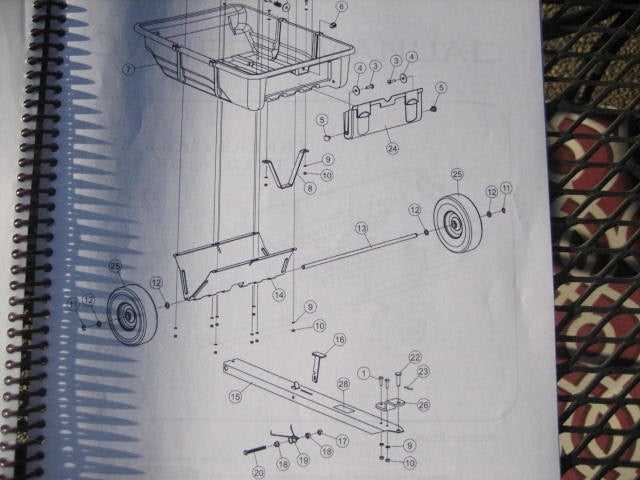

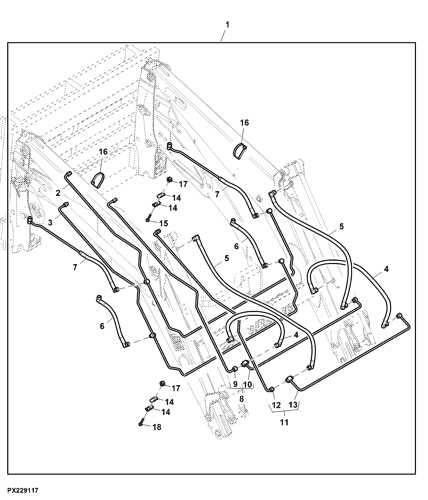

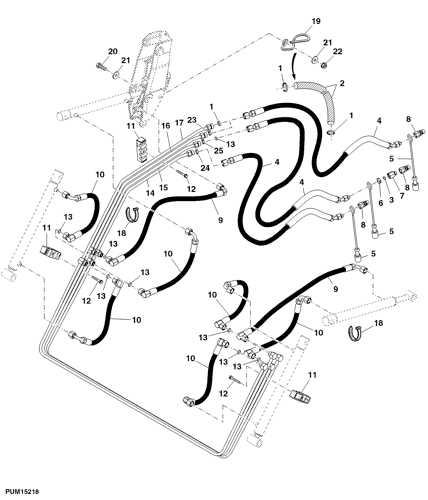

Illustrated Parts Breakdown

This section provides a comprehensive overview of the various components that comprise the specified equipment. By examining the visual representation of each element, users can gain a clearer understanding of how these pieces interact to ensure optimal functionality. A detailed breakdown assists in identifying the individual elements necessary for maintenance, repair, or enhancement of performance.

Component Overview

The equipment consists of multiple crucial elements, including structural frames, hydraulic systems, and attachment points. Each component plays a vital role in the overall operation, contributing to the machine’s efficiency and effectiveness. Understanding the relationship between these elements is essential for troubleshooting and enhancing the machine’s performance.

Visual Representation

Accompanying illustrations offer a visual guide to each section, enabling users to locate and recognize specific components easily. This clarity can streamline maintenance tasks and facilitate repairs by providing an intuitive reference for identifying parts that may require attention. Such visual aids are invaluable for both novice users and experienced operators alike.

Installation Tips for New Parts

Replacing components on your machinery can significantly enhance its performance and longevity. Proper installation is essential to ensure that the new components function correctly and integrate seamlessly with the existing system. Here are some valuable tips to facilitate the installation process.

Preparation Steps

- Review the user manual for specific instructions related to the component being installed.

- Gather all necessary tools and equipment before starting the installation.

- Inspect the new components for any signs of damage or defects before installation.

- Clear the workspace of debris and ensure it is well-lit to prevent accidents.

Installation Process

- Begin by removing the old component carefully, taking note of how it was installed.

- Align the new component with the corresponding fittings and ensure it is oriented correctly.

- Secure the component using appropriate fasteners, making sure not to overtighten, as this may cause damage.

- Once installed, double-check all connections and ensure everything is snug and secure.

- Test the functionality of the new component before putting the machinery back into regular use.

By following these steps, you can ensure a smooth and effective installation of new components, ultimately contributing to the overall efficiency and reliability of your equipment.

Where to Find Genuine Parts

When it comes to maintaining heavy machinery, sourcing authentic components is crucial for optimal performance and longevity. Relying on original equipment ensures that your machine operates efficiently and reduces the risk of breakdowns.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealerships. These establishments offer a wide range of genuine products and can provide expert assistance.

- Access to a comprehensive inventory.

- Professional guidance from knowledgeable staff.

- Availability of the latest updates and recalls.

Online Retailers

In today’s digital age, numerous online platforms specialize in genuine components for various machinery. These sites can be convenient for comparing prices and availability.

- Check user reviews to gauge reliability.

- Ensure the retailer has a return policy.

- Look for certification seals that guarantee authenticity.