In the realm of heavy machinery, comprehending the intricate elements that contribute to operational efficiency is paramount. This section delves into the various constituents that form the backbone of a specific type of equipment, facilitating a deeper understanding of its functionality and maintenance. By exploring these individual elements, users can enhance their knowledge and improve their handling capabilities.

Each element plays a critical role in the overall performance and safety of the machinery. From the lifting mechanisms to the stabilization systems, a thorough grasp of these components allows operators to maximize efficiency and ensure optimal performance under various conditions. Furthermore, recognizing the significance of each part aids in timely maintenance and troubleshooting, ultimately extending the lifespan of the equipment.

As we dissect these integral components, it becomes evident how their interplay affects the machine’s operation. Understanding how each section contributes to the whole not only empowers operators but also fosters a greater appreciation for the engineering behind these sophisticated tools. This exploration promises to illuminate the complexity and innovation that define modern telehandlers.

Exploring the Anatomy of a Mechanical Assembly

In this section, we delve into the intricate details of a complex mechanical assembly, examining its various components and their interconnections. Our focus is on dissecting the inner workings without explicitly naming the whole structure, allowing us to appreciate the synergy of its parts.

The Core Elements: Understanding Key Functional Units

Here, we dissect the fundamental units that form the backbone of the assembly, each unit playing a crucial role in its overall functionality. We explore how these units interact dynamically, contributing to the seamless operation of the entire mechanism.

Throughout this exploration, we highlight the critical links between components, emphasizing their roles in sustaining operational efficiency and structural integrity. By examining these components in detail, we gain a comprehensive understanding of their individual contributions to the larger assembly.

Understanding the Basics

To grasp the fundamental concepts behind complex structures, it’s essential to break them down into their core components. This approach allows for a clearer understanding of how individual elements interact and contribute to the overall functionality. A comprehensive overview of these essential elements can facilitate better comprehension and effective application in various contexts.

Key Elements to Consider

- Functionality: What purpose does each component serve?

- Interaction: How do different elements influence one another?

- Design: What are the structural characteristics that define the system?

Importance of Structure

Recognizing the significance of arrangement is crucial. A well-organized framework not only enhances efficiency but also promotes stability and durability. Understanding the hierarchical relationships among the components can lead to more informed decisions and improved outcomes.

- Identify the main components.

- Analyze their roles and relationships.

- Evaluate the overall effectiveness of the structure.

Key Components of a Lull Machine

The functionality of any versatile lifting equipment relies heavily on its fundamental elements. Understanding these components is crucial for effective operation and maintenance, ensuring optimal performance in various applications.

- Chassis: The base structure that provides stability and support for the entire machine.

- Boom: A pivotal arm that extends and retracts, allowing for precise positioning of loads.

- Hydraulic System: A critical mechanism that powers the movement of the boom and other components through fluid pressure.

- Cabin: The enclosed space where the operator controls the machine, equipped with necessary instruments and controls.

- Drive Train: The assembly responsible for transferring power from the engine to the wheels, facilitating mobility.

Each of these elements plays a vital role in the overall functionality and efficiency of the equipment. Proper understanding and maintenance of these components contribute to the longevity and reliability of the machine.

- Safety Features: Systems designed to prevent accidents and ensure the well-being of operators and bystanders.

- Wheels and Tires: Essential for maneuverability, designed to handle various terrains.

- Load Management System: Technology that monitors and ensures safe lifting capacities are not exceeded.

In summary, familiarity with these key components enhances operational efficiency and safety, empowering operators to maximize the capabilities of their equipment.

Mechanical Components Demystified

Understanding the intricacies of mechanical systems is essential for grasping how various elements interact to produce motion and force. This section aims to unravel the complexities of these components, highlighting their functions, interrelationships, and significance in broader engineering contexts.

Key Elements of Mechanical Systems

Mechanical systems comprise numerous elements that work in harmony to achieve desired outcomes. Each element plays a unique role, contributing to the efficiency and functionality of the entire assembly. The following table outlines some fundamental components and their primary functions:

| Component | Function |

|---|---|

| Gear | Transmits torque and changes rotational speed. |

| Shaft | Transfers rotational motion between components. |

| Bearing | Reduces friction and supports rotational movement. |

| Spring | Stores and releases energy, allowing for flexibility in motion. |

Understanding Interactions

The interaction among these elements is crucial for the overall performance of mechanical systems. Analyzing how they work together can lead to better designs and innovations in engineering. By exploring these interactions, engineers can improve reliability, efficiency, and durability in various applications.

Electrical System Breakdown

The electrical framework of any machinery is crucial for its operational efficiency and reliability. This section provides an overview of the various components that contribute to the effective functioning of the electrical network, detailing how each element interacts to ensure optimal performance. Understanding the layout and relationship between these components is essential for maintenance and troubleshooting purposes.

Key Components

Within the electrical framework, several primary elements play a significant role. Each component is designed to fulfill specific functions, which collectively contribute to the overall system’s integrity. Below is a summary of these essential elements:

| Component | Description |

|---|---|

| Power Source | Provides the necessary energy for operation. |

| Circuitry | Facilitates the flow of electrical current between components. |

| Control Units | Regulates the system’s operation based on input signals. |

| Safety Mechanisms | Protects against electrical faults and ensures user safety. |

| Connectors | Enables secure connections between various components. |

Functionality and Maintenance

Regular examination and maintenance of the electrical elements are vital for preventing malfunctions and prolonging the lifespan of the system. A thorough understanding of how these components function together allows for more effective diagnostics and repairs. Addressing potential issues promptly can significantly enhance operational safety and efficiency.

Hydraulic Parts and Their Functions

In hydraulic systems, various components work together to enable the efficient transmission of power through fluid movement. These elements play crucial roles in controlling motion and force, contributing to the overall effectiveness of the mechanism. Understanding the functions of these components is essential for maintaining and troubleshooting such systems.

Hydraulic Cylinders are pivotal in converting hydraulic energy into mechanical force. When pressurized fluid enters the cylinder, it pushes a piston, creating linear motion. This action is fundamental in applications like lifting and pushing heavy loads.

Hydraulic Pumps are responsible for generating flow within the system. They draw fluid from a reservoir and pressurize it before delivering it to various components. The efficiency of the pump directly impacts the performance of the entire system.

Hydraulic Valves regulate fluid flow and direction, allowing operators to control the movement of actuators. By opening or closing pathways, these devices ensure that the right amount of fluid reaches specific components at the right time.

Hydraulic Accumulators store energy by holding pressurized fluid. They release this stored energy when needed, providing additional power during high-demand situations or compensating for fluctuations in pressure.

Hydraulic Hoses and Fittings serve as the conduits for fluid transfer between components. Their integrity is vital, as leaks or damage can lead to system failure. Choosing the right materials and sizes is essential for ensuring durability and performance.

In conclusion, a thorough understanding of these components and their roles is vital for anyone working with hydraulic systems. Proper maintenance and knowledge of each element’s function can significantly enhance the longevity and efficiency of these complex mechanisms.

Common Wear Parts and Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. Familiarizing yourself with frequently worn components can help you identify when replacements are necessary and maintain efficiency. By following proper maintenance procedures, you can avoid unnecessary downtime and extend the lifespan of your machinery.

Hydraulic Seals: These components are crucial for preventing leaks in hydraulic systems. Regularly inspect them for signs of wear, such as cracks or deformation. If you notice any issues, replace them promptly to avoid fluid loss and maintain system pressure.

Tires: Proper tire maintenance is vital for stability and traction. Check for uneven wear patterns, low tread depth, or damage. Rotate tires regularly and ensure they are inflated to the recommended pressure. Replace tires when they reach their wear limits to ensure safe operation.

Filters: Air and hydraulic filters are essential for keeping contaminants out of the system. Regularly check and replace them as needed to maintain optimal performance. Clogged filters can lead to decreased efficiency and potential damage to internal components.

Belts and Chains: These components experience significant wear over time. Inspect them for signs of fraying or stretching, and adjust their tension as necessary. Replacing worn belts and chains promptly can prevent further damage and ensure smooth operation.

By staying vigilant about maintenance and addressing worn components promptly, you can ensure that your equipment remains reliable and efficient throughout its service life.

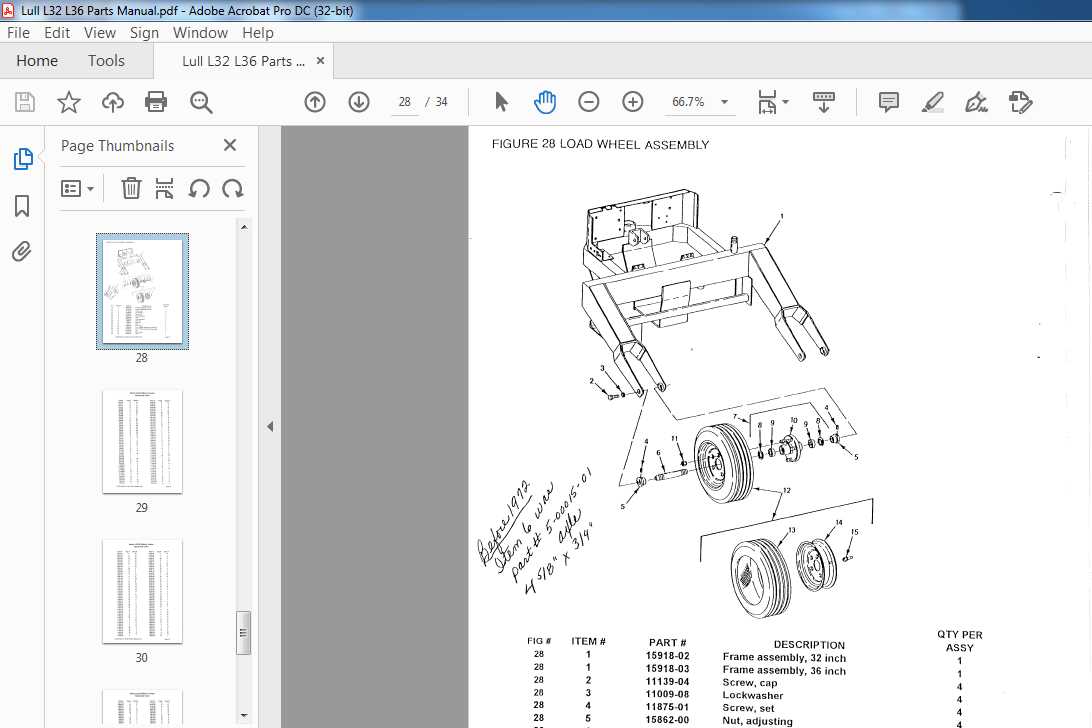

Interpreting a Lull Parts Manual

Understanding a technical reference document is crucial for effective maintenance and repair. This type of manual serves as a comprehensive guide, offering insights into the components and assembly of machinery. Familiarity with its structure and content allows users to troubleshoot issues efficiently and perform necessary replacements.

To navigate such a document effectively, consider the following key elements:

- Table of Contents: Begin by reviewing the table of contents. This section outlines the major categories and their respective pages, enabling quick access to specific topics.

- Component Listings: Each section typically includes detailed listings of components, often accompanied by unique identifiers. This helps in accurately identifying and sourcing replacements.

- Visual Representations: Look for illustrations that accompany the text. These visual aids are invaluable for understanding how parts fit together and function.

- Assembly Instructions: Pay attention to the assembly guidelines. Clear step-by-step instructions facilitate proper reassembly and reduce the risk of errors.

- Maintenance Tips: Many documents include a section dedicated to maintenance recommendations. These tips can extend the lifespan of the machinery and enhance performance.

By carefully studying the manual, users can gain a deeper understanding of the equipment, leading to more informed decisions regarding repairs and upkeep.

Resources for Finding Replacement Parts

When it comes to maintaining machinery, locating suitable components can be a crucial task. Various resources are available to assist individuals in sourcing the necessary items for repairs or upgrades. Utilizing the right platforms can simplify the process and ensure that you find high-quality replacements quickly and efficiently.

Online Marketplaces: Numerous e-commerce websites provide a wide array of options for acquiring necessary components. These platforms often feature user reviews, detailed descriptions, and competitive pricing, making it easier to compare and select the best options available.

Manufacturer Websites: Directly visiting the official websites of manufacturers can yield valuable information. They often have dedicated sections for support, where users can find manuals, specifications, and recommendations for compatible components. This ensures that you are sourcing the right items for your specific needs.

Forums and Online Communities: Engaging with online communities can be beneficial. Many forums are dedicated to discussions about machinery and repairs, allowing users to share their experiences and recommendations. These platforms can provide insights into where to find specific components and even offer suggestions on alternative solutions.

Local Retailers and Distributors: Visiting nearby retailers or contacting local distributors can also be a viable option. Establishing a relationship with local suppliers can lead to personalized assistance and access to inventory that may not be available online.

By exploring these various avenues, you can enhance your chances of successfully acquiring the components needed to keep your equipment running smoothly.