When it comes to maintaining the efficiency of agricultural equipment, having a clear understanding of its various elements is essential. This knowledge not only helps in performing repairs but also aids in optimizing performance and ensuring longevity. Familiarity with the intricate layout of machinery components can make a significant difference in troubleshooting and servicing tasks.

In this section, we will explore the essential building blocks of a specific type of agricultural implement. Each element plays a crucial role in the overall functionality, and recognizing how they interact can empower users to make informed decisions about maintenance and upgrades. By gaining insight into these components, operators can enhance their operational efficiency and minimize downtime.

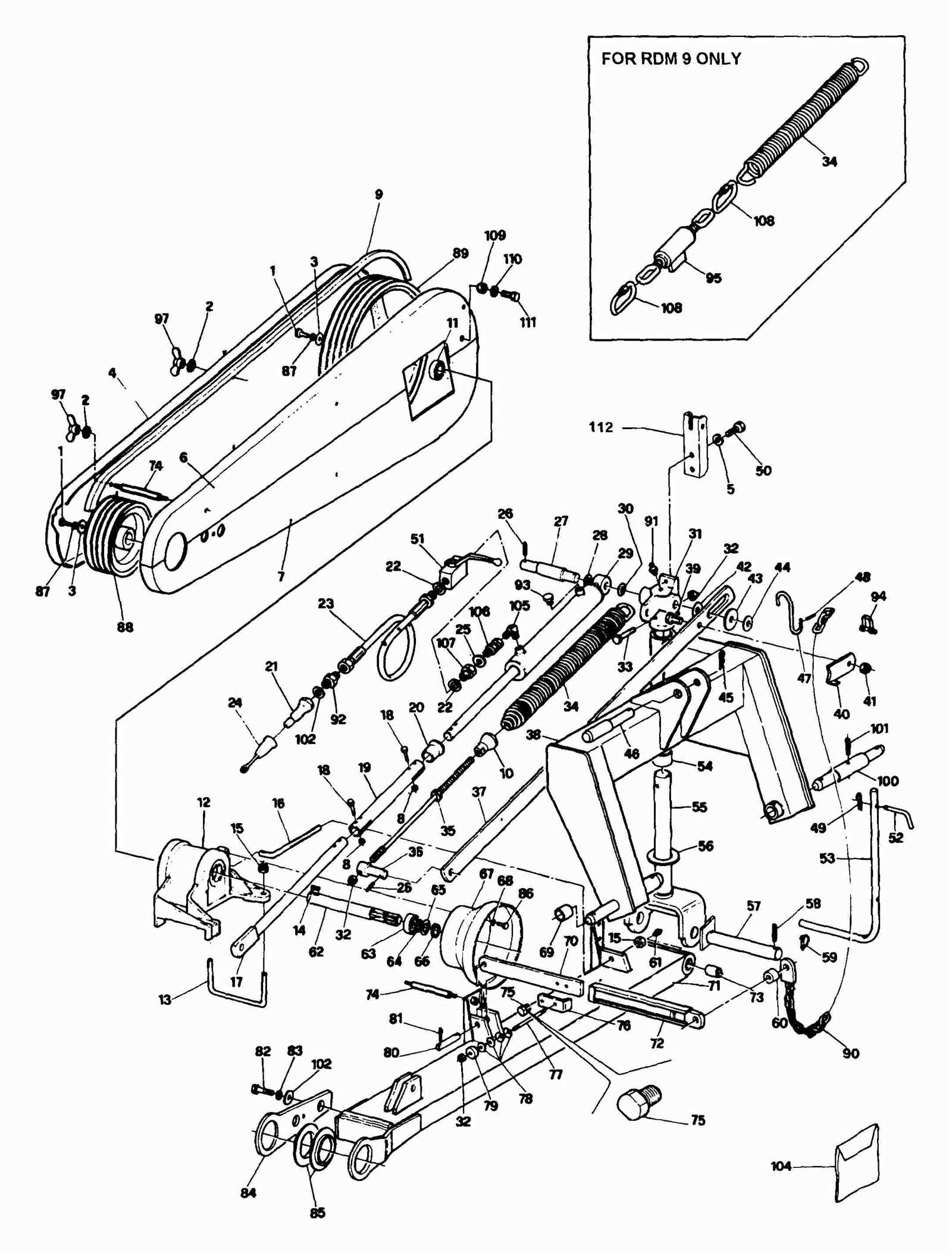

Through detailed visual representations and descriptions, this guide will demystify the structure of the equipment, allowing for better comprehension of its workings. Whether you are a seasoned professional or a novice, understanding these intricacies is key to mastering the art of machinery upkeep.

Rhino Mower Parts Diagram: Understanding the Basics

Gaining a clear understanding of the components involved in agricultural equipment is essential for effective maintenance and operation. Familiarity with the individual elements helps users to troubleshoot issues efficiently and ensure optimal performance of the machinery. This section aims to provide an overview of the essential components, their functions, and how they interact within the larger system.

Key Components and Their Functions

Every piece of machinery consists of various crucial elements, each playing a specific role in overall functionality. From the cutting mechanism to the drive system, understanding these components is vital. For instance, the cutting blades are designed to enhance precision and efficiency, while the frame provides stability and support during operation. Recognizing how these parts work together allows for better maintenance practices and improved longevity of the equipment.

Benefits of Understanding Your Equipment

By comprehending the various elements of your agricultural tools, you can troubleshoot common issues, perform regular maintenance, and make informed decisions regarding repairs or upgrades. This knowledge not only enhances operational efficiency but also reduces downtime, saving both time and resources. Investing time in learning about the components will ultimately lead to more productive and reliable equipment performance.

Exploring the Components of a Rhino Mower

This section delves into the essential elements that comprise a high-performance cutting machine. Understanding these components is crucial for maintenance and optimal operation.

| Component | Description |

|---|---|

| Blade Assembly | The cutting edge that ensures precise trimming of grass and vegetation. |

| Deck | The sturdy framework that houses the blade assembly and provides support. |

| Engine | The power source that drives the entire mechanism, ensuring efficiency and performance. |

| Transmission | A system that transfers power from the engine to the wheels, enabling mobility. |

| Wheels | Allow for movement across various terrains, facilitating ease of use. |

Key Elements in a Rhino Mower Parts Breakdown

Understanding the essential components of agricultural cutting machinery is vital for efficient maintenance and repair. A thorough examination of these elements allows users to enhance performance, extend longevity, and ensure safe operation. By focusing on specific parts, one can achieve the ultimate functionality of the equipment.

Critical Components

Key elements include the cutting blade assembly, which directly impacts the efficiency of grass and crop trimming. The drive system is also crucial, as it powers the entire mechanism and affects speed and reliability. Regular inspection of these areas helps identify wear and potential issues before they escalate.

Maintenance Tips

To maintain optimal performance, regularly clean and lubricate the moving parts. Additionally, keeping an eye on the condition of belts and bearings can prevent unexpected breakdowns. Routine checks and timely replacements contribute significantly to the overall health of the machinery.

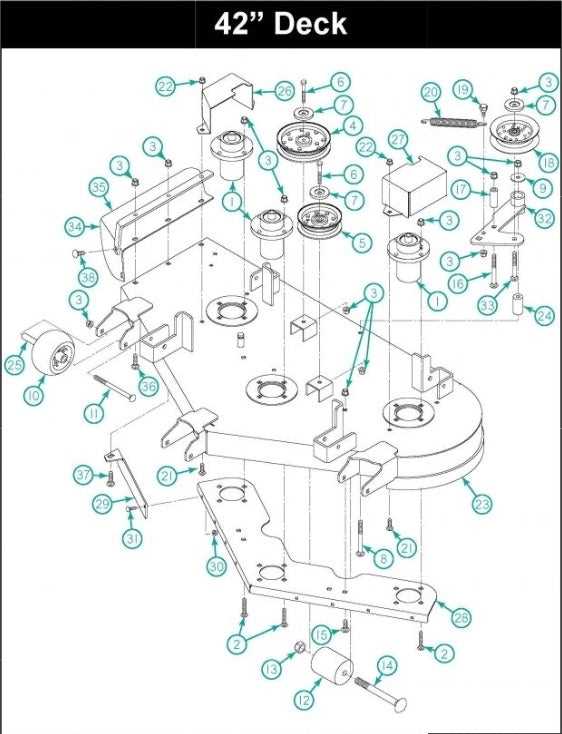

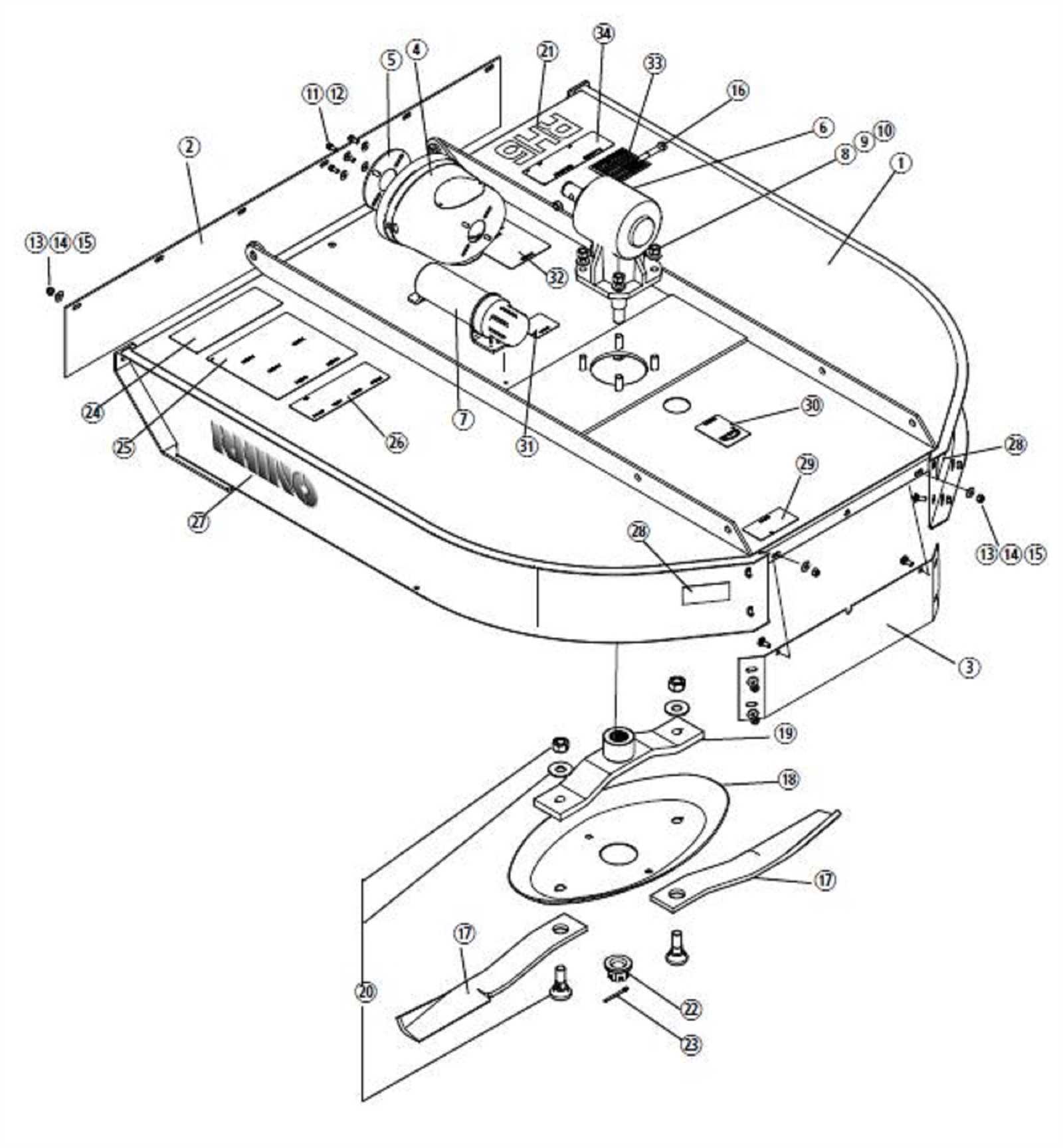

Visual Guide to Rhino Mower Parts

This section aims to provide a comprehensive overview of the essential components that contribute to the functionality of your lawn care equipment. Understanding these elements can enhance your maintenance skills and ensure optimal performance during use.

Essential Components Explained

Every piece of machinery consists of vital elements that work together seamlessly. From the cutting blades to the drive system, each part plays a significant role in achieving a pristine landscape. Familiarizing yourself with these components can help you identify potential issues and ensure longevity.

Maintenance and Troubleshooting Tips

Regular upkeep is crucial for any outdoor apparatus. Knowing how to inspect, replace, or repair specific elements can prevent breakdowns and improve efficiency. Keep an eye out for wear and tear, and don’t hesitate to consult your manual for detailed guidance on each segment’s care.

Functional Overview of Rhino Mower Components

This section provides a comprehensive examination of the various elements that contribute to the overall operation of cutting equipment. Each component plays a vital role in ensuring efficient performance, durability, and ease of use. Understanding these parts allows users to appreciate the mechanics behind their functionality and maintain optimal performance over time.

| Component | Description | Function |

|---|---|---|

| Blade Assembly | Sharp metal edges designed for cutting vegetation. | Facilitates the primary cutting action. |

| Deck | The main body housing the blade assembly. | Provides structural integrity and protects components. |

| Drive System | Mechanical elements that transmit power. | Enables movement and operation of the cutting mechanism. |

| Height Adjustment | System for altering the cutting height. | Allows customization for different terrain types. |

| Wheels | Support structures for mobility. | Facilitate movement across various surfaces. |

| Safety Features | Inbuilt mechanisms to ensure user protection. | Minimize risk during operation. |

By familiarizing oneself with these essential elements, operators can enhance their understanding of the machine’s capabilities and ensure effective maintenance practices, thereby prolonging the lifespan of their equipment.

Identifying Essential Parts in Your Rhino Mower

Understanding the key components of your equipment is crucial for optimal performance and maintenance. Recognizing each element not only enhances operational efficiency but also aids in troubleshooting and repairs. A clear knowledge of the various sections will empower you to make informed decisions regarding upkeep and replacements.

Key Components Overview

Every machine comprises several vital sections, each contributing to its overall functionality. Familiarizing yourself with these elements will allow for better management and care.

| Component | Function |

|---|---|

| Engine | Powers the equipment, providing the necessary energy for operation. |

| Blades | Execute the primary cutting action, determining the quality of the job. |

| Deck | Houses the blades and protects other components from debris. |

| Wheels | Enable movement and maneuverability across various terrains. |

Maintenance Tips

Regular inspection and care of these essential sections are paramount for longevity. Ensuring cleanliness and timely replacements will significantly enhance performance and prevent unexpected breakdowns.

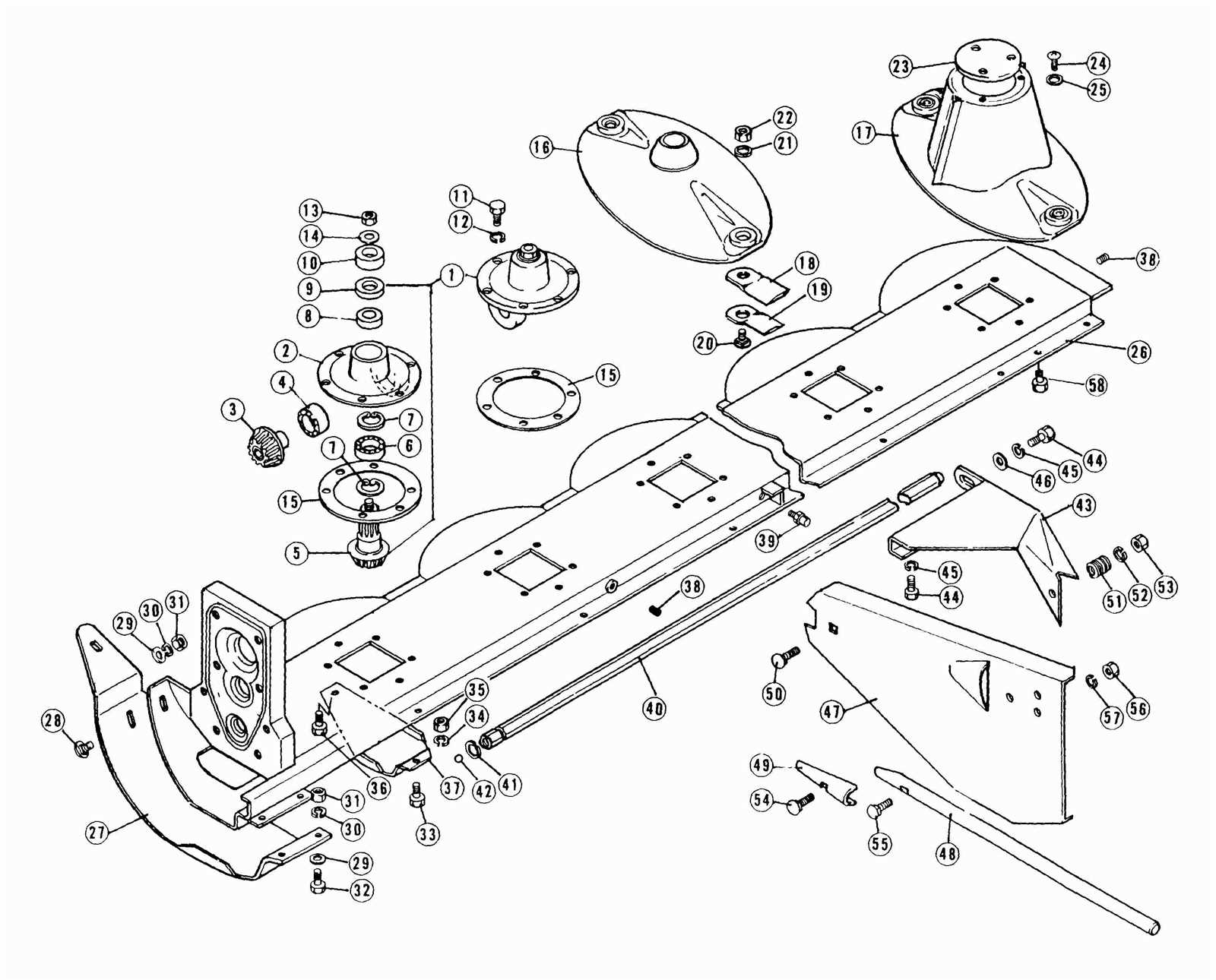

Comprehensive Diagram of Rhino Mower Parts

This section aims to provide an in-depth overview of the various components essential for the efficient operation of your equipment. Understanding the layout and function of each element can significantly enhance maintenance and repair efforts.

Identifying the crucial sections of the machine will aid users in troubleshooting and ensuring optimal performance. Below are the key categories and their respective elements:

- Cutting Mechanism:

- Blades

- Spindles

- Deck

- Power System:

- Engine

- Fuel Tank

- Transmission

- Control Features:

- Throttle Control

- Clutch

- Steering Mechanism

- Structural Components:

- Chassis

- Wheels

- Support Frame

By familiarizing yourself with these crucial components, you can improve your understanding of maintenance practices and enhance the longevity of your equipment.

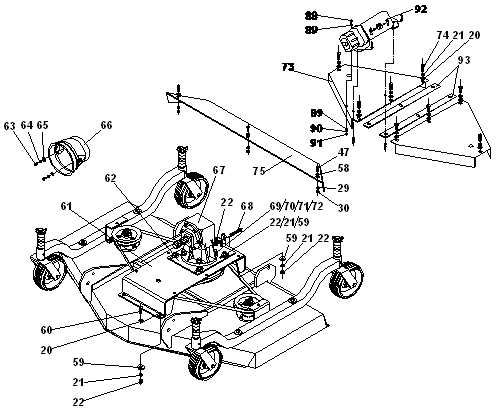

How to Use a Rhino Mower Parts Diagram Effectively

Understanding the intricacies of your machinery can significantly enhance its performance and longevity. By utilizing a visual representation of components, you can identify parts quickly and ensure correct replacements. This guide outlines key strategies for maximizing the utility of such illustrations.

Identifying Components

Begin by familiarizing yourself with each labeled section of the visual aid. Take note of the various elements, their functions, and how they interconnect within the system. This knowledge will empower you to troubleshoot issues efficiently.

Planning Maintenance

Use the illustration as a reference for routine upkeep. By knowing which parts require regular attention, you can schedule maintenance effectively, ensuring optimal functionality and preventing future breakdowns.

Common Maintenance Tips Based on Rhino Mower Diagrams

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Understanding the layout and functionality of various components can significantly enhance maintenance practices. Here are some fundamental tips to consider:

- Perform routine inspections to identify any signs of wear or damage.

- Keep all moving parts well-lubricated to minimize friction and prevent breakdowns.

- Regularly check and tighten bolts and screws to maintain structural integrity.

In addition to these general tips, specific attention should be paid to the following areas:

- Blades:

- Sharpen blades regularly for effective cutting.

- Inspect for chips or cracks to ensure safety during operation.

- Belts:

- Check for signs of wear and replace them as needed.

- Ensure proper tension to avoid slippage.

- Filters:

- Clean or replace air filters to ensure optimal airflow.

- Regularly change fuel filters to prevent clogging.

Following these maintenance practices will not only enhance the efficiency of your machinery but also extend its operational life, ensuring it performs reliably for years to come.