Maintenance Tips for Longer Lifespan

Ensuring the longevity of your equipment requires consistent attention and care. By taking a proactive approach to upkeep, you can prevent potential issues and ensure reliable performance over time. Simple steps taken regularly can make a significant difference in maintaining the efficiency of your machine.

Begin with regular checks of the moving components. Cleaning and lubricating them helps minimize friction and wear, promoting smoother operation. Additionally, inspect belts and fasteners to ensure they are secure and free from damage, replacing them as needed to avoid unexpected breakdowns.

Maintaining clean air and fuel filters is also crucial. Replace them periodically to prevent clogging, which can lead to reduced efficiency. Keep the cutting blades sharp, as dull edges can strain the engine, making it work harder than necessary. Sharp blades ensure cleaner cuts and a healthier lawn.

Storing the equipment in a sheltered area protects it from harsh weather conditions that can lead to rust and corrosion. Before storing, clean all debris and mud from surfaces to avoid buildup. Draining fuel before long-term storage can prevent fuel system issues when it’s time

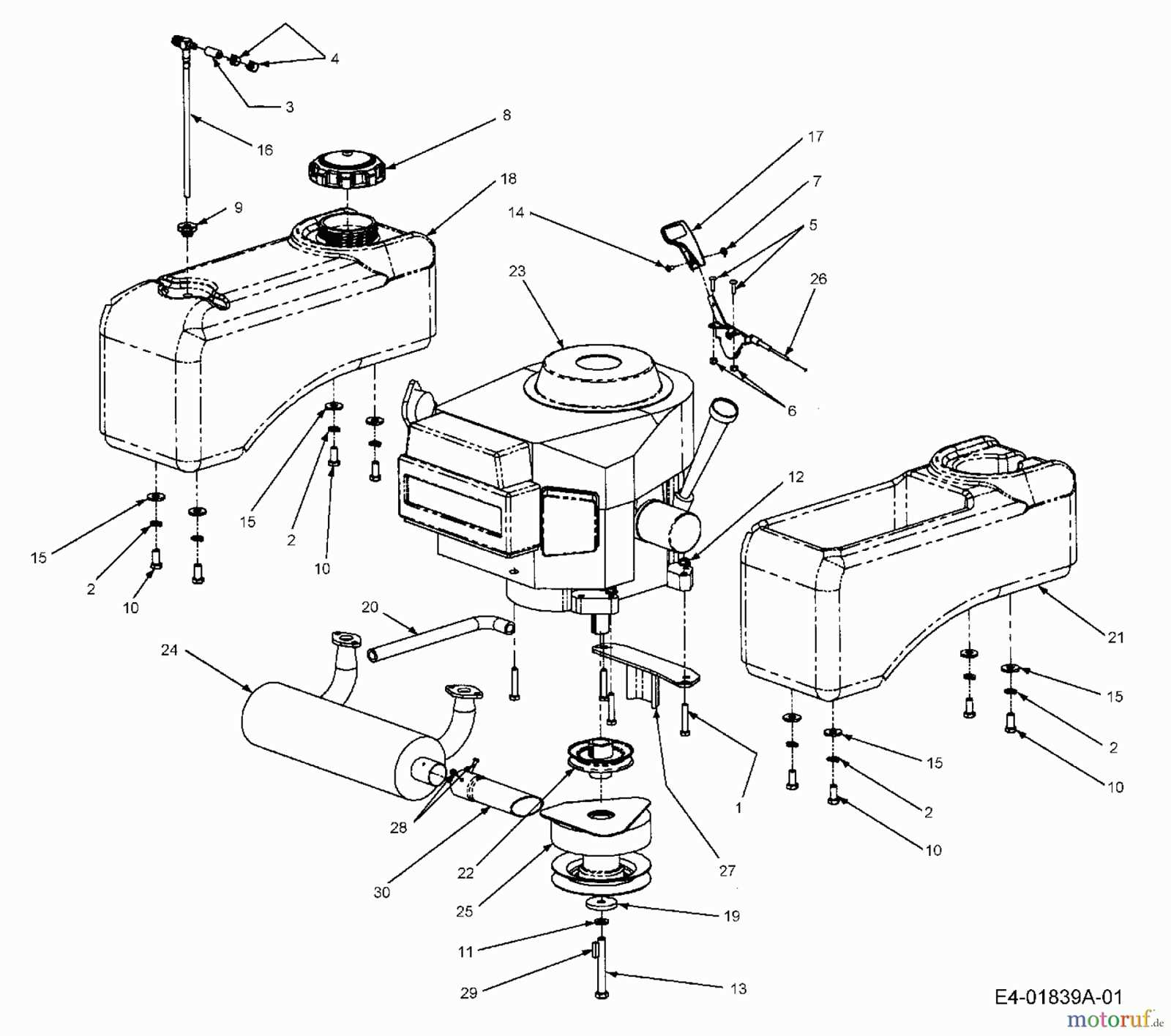

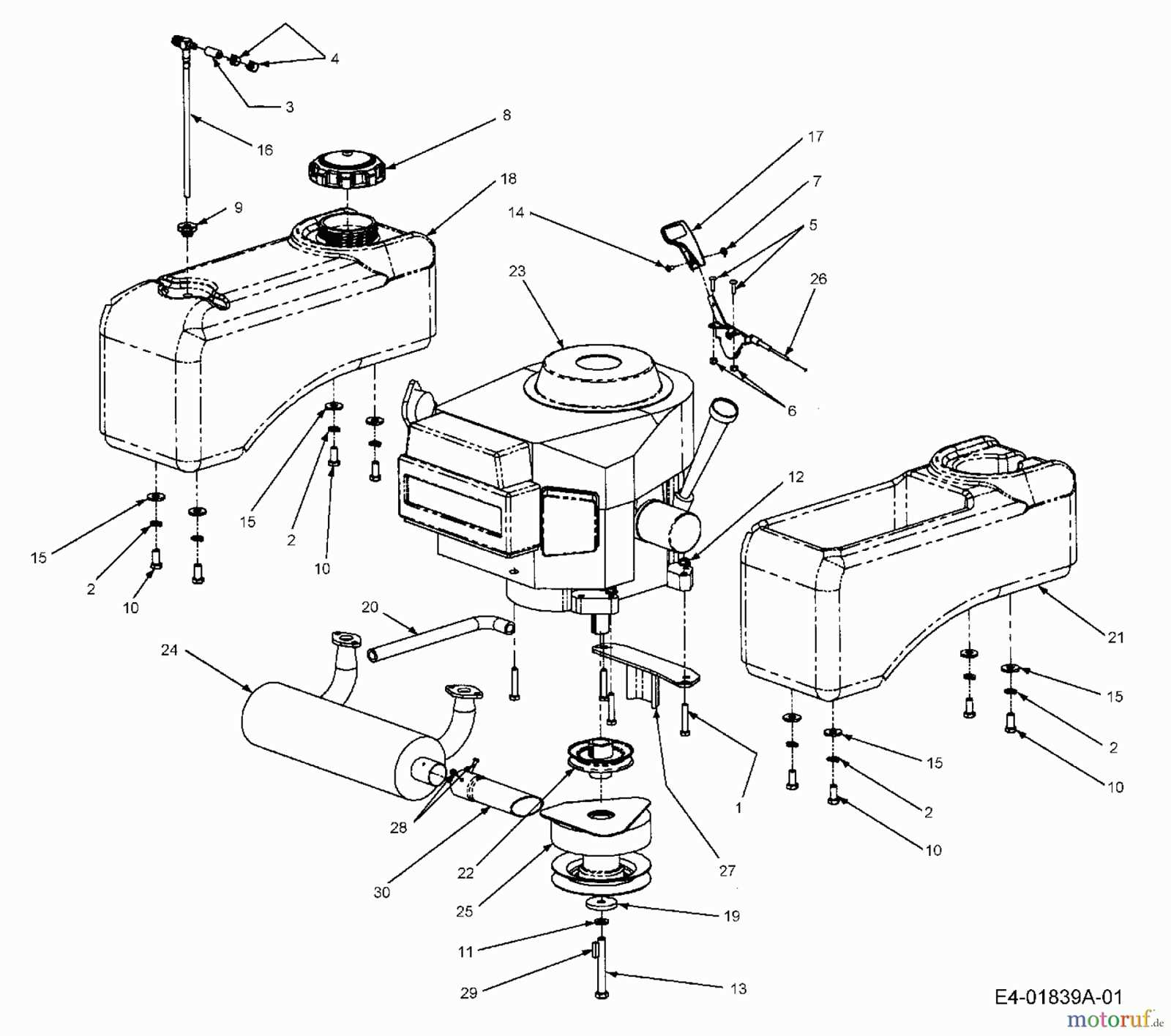

Essential Replacement Parts Guide

Maintaining your lawn care equipment requires a clear understanding of key components that may need periodic renewal. Regular upkeep not only ensures smooth functionality but also extends the lifespan of the machinery. Knowing which elements to inspect and update can simplify the maintenance process and prevent potential disruptions.

Common Wearable Components

Certain elements of the equipment endure more strain and therefore may require more frequent attention. These include items like blades, which gradually lose their sharpness, and filters that accumulate debris over time. Replacing these elements at the right intervals can help maintain optimal cutting performance and ensure the engine runs efficiently.

Critical Mechanical Elements

Beyond the obvious parts, there are other mechanical pieces that play a crucial role in the overall operation. Elements such as belts, which ensure smooth transmission, and bearings, which reduce friction, should be routinely checked for wear and replaced if needed. Regular monitoring of these aspects can prevent more complex mechanical issues, keeping your equipment in top condition.

Troubleshooting Common Issues

In this section, we’ll address common problems that users may encounter with their equipment. By identifying and resolving these issues, you can ensure optimal performance and longevity of your machine.

- Starting Problems: Difficulty in starting the equipment could be due to fuel issues or ignition problems.

- Engine Performance: If the engine runs rough or lacks power, check for air filter blockages or fuel line obstructions.

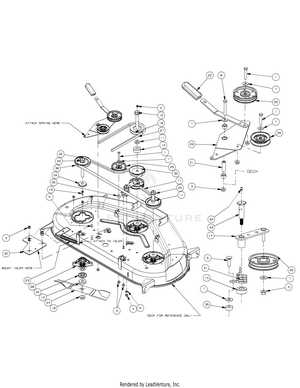

- Blade Issues: Blades not cutting effectively may indicate dull blades or improper deck adjustment.

- Electrical Malfunctions: Problems with electrical components such as lights or indicators may stem from loose connections or blown fuses.

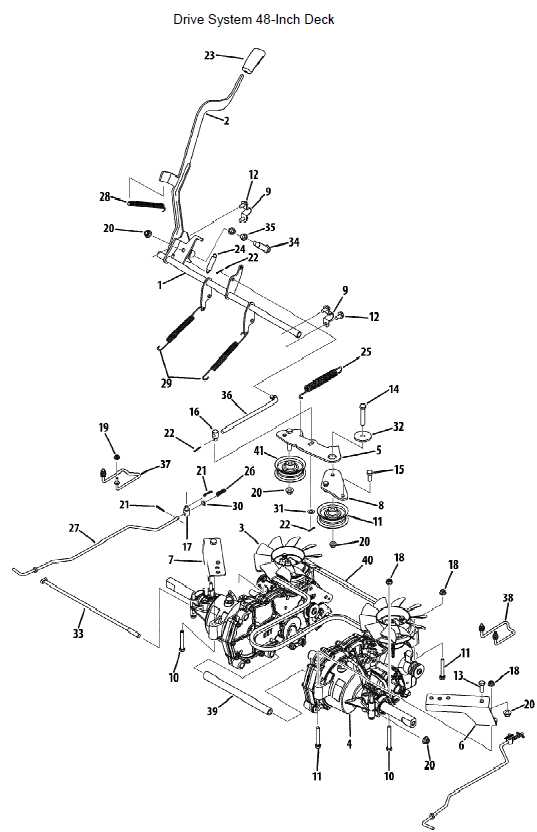

- Transmission Troubles: If the machine struggles with shifting or moving, inspect the transmission fluid levels and belts for wear.

By systematically checking and addressing these potential issues, you can keep your equipment running smoothly and efficiently throughout its lifespan.

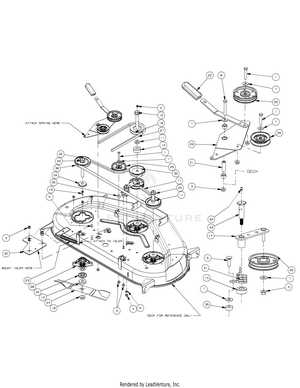

Blade Assembly and Adjustments

The assembly and alignment of the cutting blade are essential for optimal performance and smooth operation. Proper installation ensures that the cutting mechanism functions efficiently, providing a consistent and clean result on various surfaces. Following the correct steps and techniques helps in maintaining durability and safety during use.

Steps to Assemble the Blade:

- Position the blade holder securely, ensuring it is free of any obstructions.

- Align the cutting component with the mounting points and tighten the fasteners evenly to prevent any imbalance.

- Check the rotation direction, ensuring it matches the intended configuration.

Fine-Tuning for Balanced Operation

Adjusting the blade is crucial for achieving a smooth cut and preventing wear. To achieve this, ensure the blade is evenly balanced by checking the alignment with the deck structure. Minor adjustments to the mounting screws may be necessary to eliminate any vibrations.

Safety Considerations During Adjustment

Always disconnect the power source before making any changes to the cutting assembly. Use proper tools and protective gear

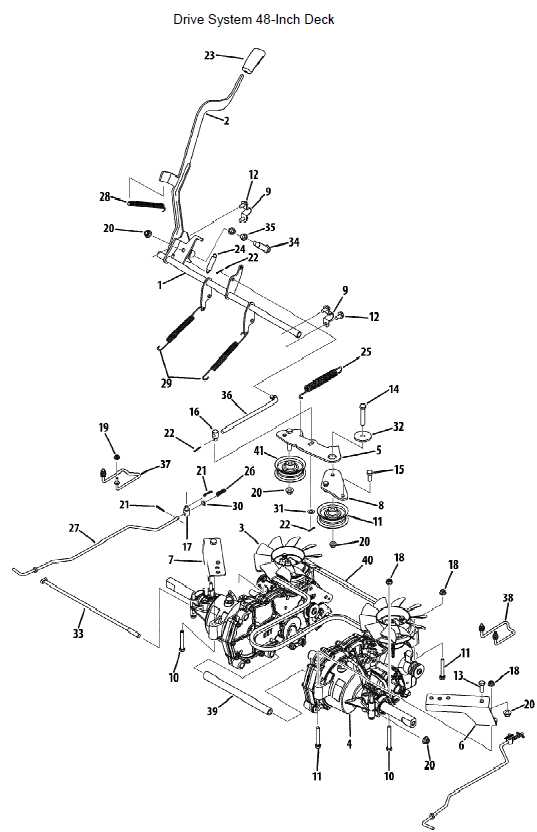

Proper Belt Installation Techniques

Correctly installing the drive belt is essential for the optimal performance of any machinery. A well-fitted belt ensures efficient power transmission and minimizes wear and tear on components. Following the right procedures can prevent future maintenance issues and extend the life of the equipment.

Begin by ensuring that the engine is off and all moving parts are stationary. This precaution is vital for safety. Next, examine the belt path as indicated in the manufacturer’s guidelines. Carefully route the belt over the designated pulleys, making sure it is seated properly in the grooves. Avoid twisting the belt, as this can lead to misalignment and premature failure.

Once the belt is positioned, check the tension. The belt should be tight enough to prevent slipping but not so tight that it strains the engine components. Adjust the tensioner, if available, to achieve the correct tightness. Finally, rotate the pulleys by hand to verify that the belt moves freely and does not bind or rub against any surfaces.

How to Clean and Store

To maintain your equipment in top condition, proper cleaning and storage practices are essential. Regular maintenance ensures longevity and optimal performance. Begin by removing any debris using a soft brush or cloth. Next, inspect the equipment for any visible dirt or residue.

| Cleaning: |

Use a mild detergent diluted in water to gently clean the surfaces. Avoid harsh chemicals that may damage the finish. Pay special attention to moving parts and joints, ensuring they are free of dirt and grease. |

| Drying: |

After cleaning, thoroughly dry all parts with a clean, dry cloth to prevent rust and corrosion. Allow the equipment to air dry if necessary, ensuring no moisture remains. |

| Storage: |

Store your equipment in a cool, dry place away from direct sunlight and moisture. Cover it with a breathable tarp or cloth to protect it from dust and debris. Ensure the storage area is secure to prevent unauthorized access. |

By following these simple steps regularly, you can extend the life of your equipment and ensure it is always ready for use when needed.

Choosing Quality Parts for Repairs

When it comes to maintaining your equipment’s performance over time, selecting the right components is crucial. Opting for durable, reliable parts ensures longevity and optimal functionality. It’s essential to consider the material quality and compatibility with your specific model, as this directly impacts performance and efficiency.

Key Considerations

Firstly, assess the material composition of the parts to ensure they meet industry standards for durability and resilience. Secondly, verify compatibility with your equipment model to avoid operational issues. Thirdly, prioritize suppliers known for their reliability and customer service to guarantee satisfaction with your purchase.