The intricate workings of a lawn maintenance machine often go unnoticed, yet they are essential for optimal performance. Each element plays a vital role in ensuring efficiency and longevity, making familiarity with these parts beneficial for any user. A comprehensive overview of these components can aid in troubleshooting and maintenance, ensuring that the equipment runs smoothly.

By examining the layout and function of each section, one can gain valuable insights into how to properly care for and repair the machinery. Familiarity with the various elements, from cutting blades to drive systems, enhances the user’s ability to identify potential issues and perform necessary upgrades. Understanding these relationships is crucial for anyone looking to enhance their lawn care experience.

This exploration not only provides clarity on individual parts but also emphasizes the importance of regular maintenance. Knowledge of how different sections interact allows for informed decision-making, ultimately leading to improved performance and satisfaction. Proper care can significantly extend the life of the equipment, making it a wise investment for homeowners and landscapers alike.

Overview of the ZT1 42 Model

The ZT1 42 model exemplifies a cutting-edge approach to lawn care, combining efficiency with user-friendly features. This innovative machine is designed for those who seek a reliable solution for maintaining their outdoor spaces while maximizing comfort and control. With a blend of advanced technology and durable construction, it stands out as a valuable tool for homeowners and professionals alike.

Equipped with a robust engine and a precision cutting deck, this model offers superior performance and versatility. Users will appreciate its maneuverability, allowing for seamless navigation around obstacles and tight corners. The intuitive controls enhance the user experience, making operation straightforward, even for those new to riding equipment.

Safety features are prioritized, ensuring peace of mind during operation. The ergonomic seating and adjustable components cater to various user preferences, enhancing comfort during extended use. Overall, the ZT1 42 model is a powerful ally in lawn maintenance, designed to deliver exceptional results with minimal effort.

Understanding Parts and Components

Grasping the intricacies of machinery requires a thorough understanding of its various elements and how they function together. Each component plays a crucial role in the overall performance and reliability of the equipment. By familiarizing oneself with these individual pieces, one can ensure proper maintenance, troubleshooting, and enhancement of functionality.

Key Elements

- Engine: The heart of the machine, responsible for providing the necessary power.

- Chassis: The frame that supports all other components, ensuring structural integrity.

- Transmission: Transfers power from the engine to the wheels, allowing for movement.

- Wheels: Essential for mobility, providing traction and stability on various terrains.

- Control System: The interface that allows the operator to manage the machine’s functions.

Maintenance Considerations

Regular upkeep is essential for optimal performance. Focus on the following:

- Inspect and replace filters regularly to maintain engine efficiency.

- Check fluid levels and change them according to the manufacturer’s guidelines.

- Examine belts and cables for wear and tear, ensuring smooth operation.

- Keep the chassis clean and free of debris to prevent corrosion and damage.

Understanding each of these elements will empower users to maintain their equipment effectively, prolonging its lifespan and ensuring peak performance.

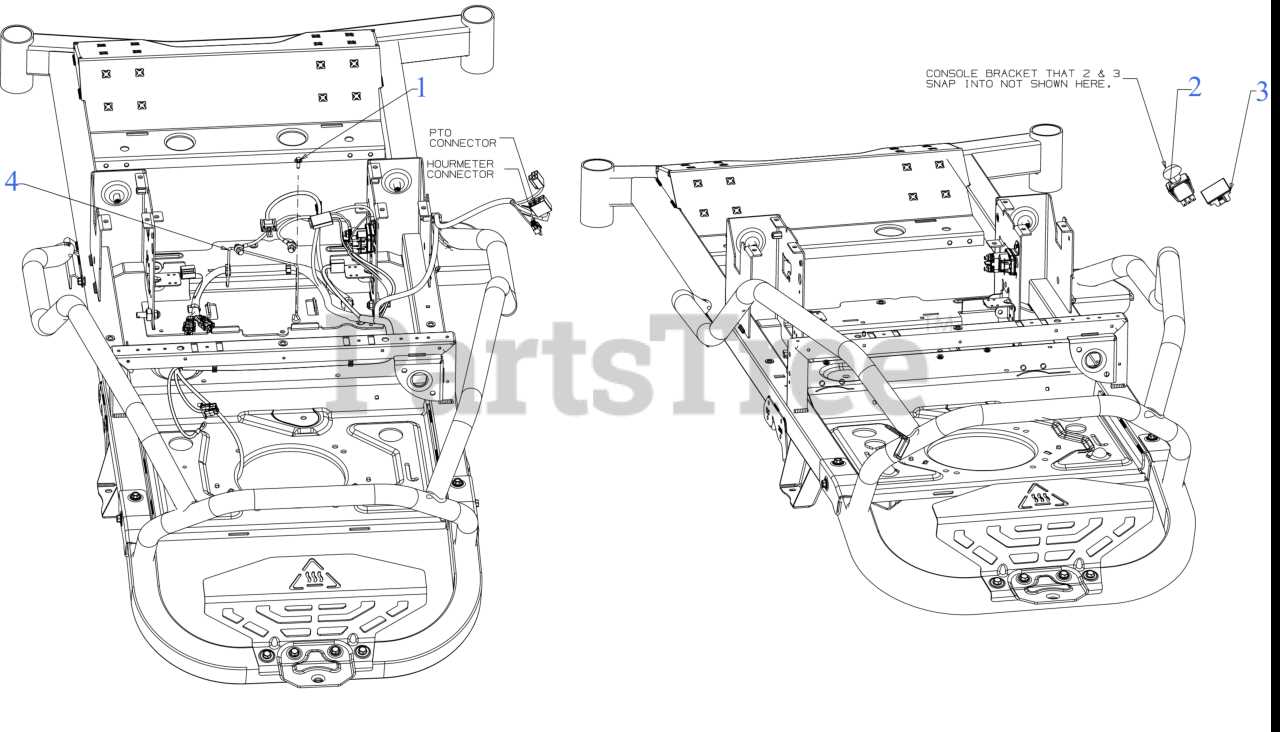

Importance of a Parts Diagram

A visual representation of components is essential for effective maintenance and repair of machinery. It provides users with a clear overview of how various elements fit together and function in unison. Understanding these relationships can enhance troubleshooting efficiency and minimize the risk of errors during repairs.

Enhanced Understanding

Having a schematic at hand facilitates better comprehension of the intricate workings of equipment. It allows technicians to identify individual pieces quickly, leading to more accurate assessments and quicker solutions. This clarity is particularly beneficial when dealing with complex systems where the interdependencies of components are not immediately apparent.

Streamlined Repairs

With a detailed visual guide, users can efficiently locate and order replacements for damaged or worn-out elements. This not only speeds up the repair process but also ensures that the right parts are obtained, reducing downtime. Moreover, familiarity with the layout encourages proactive maintenance, ultimately extending the lifespan of the machinery.

How to Access the Diagram

Finding the necessary visual representation for your machine components can streamline maintenance and repairs. This section will guide you through the steps to easily locate and view the essential schematic for your equipment.

Online Resources

The internet is a treasure trove of information. Start by visiting official manufacturer websites or dedicated forums where users share valuable insights. Utilize search engines with relevant keywords to discover useful links that may lead you to the desired blueprint.

User Manuals

Another effective approach is to consult the user manuals that accompany your equipment. These documents often contain detailed illustrations and are a reliable source for component identification. If you don’t have a physical copy, many manufacturers provide downloadable versions online.

Common Replacement Parts for ZT1 42

When maintaining and servicing a lawn mower, it is essential to be aware of the frequently replaced components that ensure optimal performance. Understanding these elements can help owners keep their equipment running smoothly and efficiently. Regular inspections and timely replacements can prevent more significant issues and extend the life of the machine.

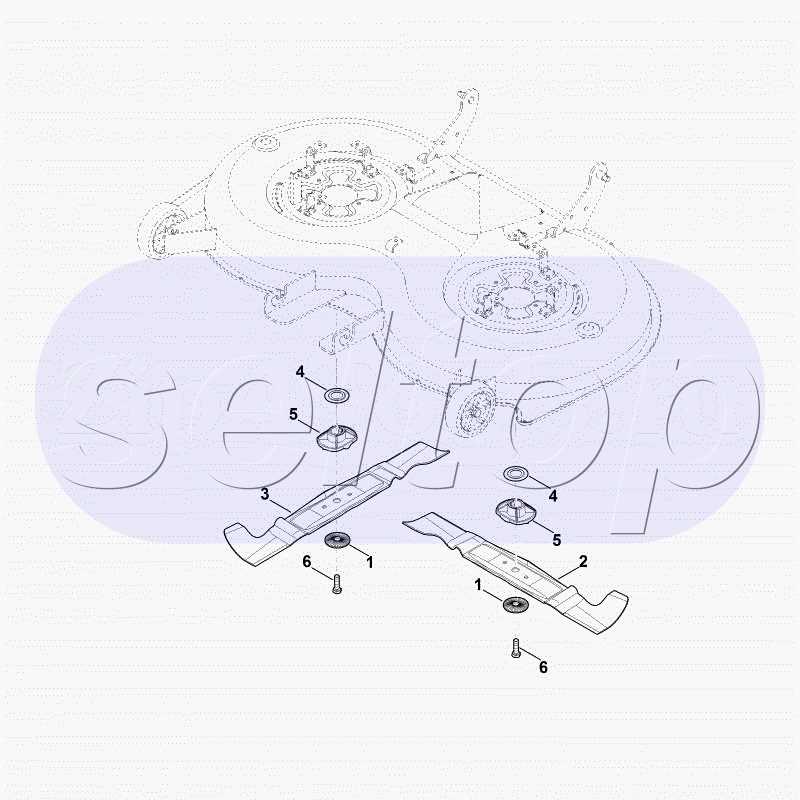

Key Components to Consider

Among the most crucial elements that often require replacement are the blades, which are essential for achieving a clean cut. Dull or damaged blades can lead to uneven mowing and stress on the engine. Additionally, the air filter plays a vital role in maintaining engine efficiency by ensuring proper airflow. A clogged filter can reduce performance and increase fuel consumption.

Other Important Elements

Furthermore, the drive belt is another critical component that may need to be replaced periodically. A worn or frayed belt can hinder the mower’s ability to propel itself effectively. Finally, the battery is vital for starting the machine and powering its electrical components. Regularly checking and replacing the battery when necessary will prevent inconvenient breakdowns and ensure reliable operation.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. By adhering to a consistent maintenance routine, you can significantly extend the lifespan of your machinery while optimizing its performance. Simple yet effective practices can prevent costly repairs and enhance the reliability of your investment.

1. Keep it Clean: Dirt and debris can accumulate on your equipment, leading to potential damage. Regularly clean the exterior and the undercarriage to prevent buildup that can hinder performance and cause premature wear.

2. Check Fluid Levels: Proper fluid levels are vital for the smooth operation of your machinery. Regularly inspect and top off engine oil, fuel, and hydraulic fluids to ensure everything runs smoothly.

3. Inspect Belts and Cables: Worn or damaged belts and cables can lead to operational failures. Regularly check for signs of wear and replace them as needed to maintain optimal functionality.

4. Sharpen Blades: Dull blades can result in uneven cuts and increased strain on the engine. Regularly sharpen or replace blades to ensure clean cuts and reduce unnecessary wear on the equipment.

5. Store Properly: When not in use, store your equipment in a dry, sheltered location. Protecting it from harsh weather conditions can prevent rust and other forms of damage, ensuring it remains in top condition for years to come.

6. Follow the Manufacturer’s Guidelines: Always refer to the manufacturer’s recommendations for maintenance schedules and procedures. Adhering to these guidelines will help you avoid voiding warranties and ensure your machinery operates efficiently.

By implementing these straightforward maintenance tips, you can enjoy the benefits of reliable performance and prolonged longevity, ensuring your equipment serves you well for many seasons ahead.

Finding Genuine Replacement Parts

Ensuring the longevity and efficiency of your equipment often hinges on the availability of authentic components. Utilizing original items is vital for maintaining performance standards, preventing premature wear, and guaranteeing compatibility. This section delves into the significance of sourcing genuine replacements and the advantages they offer over generic alternatives.

Benefits of Authentic Components

Quality Assurance: Original items are manufactured to the exact specifications of your machinery, ensuring optimal functionality. They undergo rigorous testing to meet high standards, significantly reducing the risk of malfunction.

Enhanced Durability: When opting for genuine components, you invest in longevity. These items are crafted from high-quality materials, which means they are designed to withstand the demands of regular use without compromising performance.

Where to Find Authentic Components

Authorized Dealers: The most reliable sources for original components are authorized distributors. They typically carry a comprehensive selection, ensuring you find exactly what you need. Additionally, these dealers often provide warranties, further safeguarding your investment.

Manufacturer’s Website: Many manufacturers maintain an online portal where you can browse available components. This is a convenient option to find specific items and verify their authenticity before making a purchase.

Repair Guides for ZT1 42 Model

Maintaining and fixing your lawn equipment is crucial for ensuring optimal performance and longevity. This section provides essential instructions and tips for addressing common issues encountered with this particular model. Whether you’re facing mechanical challenges or require guidance on routine upkeep, these resources aim to assist you in effectively managing repairs and enhancing the reliability of your machine.

Common Issues and Troubleshooting

Understanding the frequent problems that may arise is the first step towards effective maintenance. From engine performance issues to blade malfunctions, recognizing symptoms can aid in pinpointing the source of the trouble. For example, if you notice uneven cutting, it might indicate that the blades require sharpening or replacement. Similarly, if the engine is stalling, checking the fuel system and air filter could reveal underlying complications.

Maintenance Tips

Regular upkeep is vital for prolonging the lifespan of your equipment. Ensure to follow a consistent schedule for oil changes and filter replacements. Cleaning the deck after each use will prevent grass buildup, which can lead to corrosion and inefficient cutting. Furthermore, inspecting belts and cables periodically will help identify wear before it becomes a more significant problem, saving time and money in the long run.