In the realm of modern aviation, the intricate design and structure of each mechanical element plays a vital role in ensuring the efficiency and safety of every flight. These elements are meticulously engineered to work in harmony, contributing to the overall functionality and performance. Understanding the purpose and placement of each element within this system is key to comprehending how the entire structure operates as a cohesive unit.

The various mechanical elements are interconnected through a complex network of systems that support functions such as navigation, propulsion, and control. These systems must withstand extreme conditions and stresses, making their precision and durability essential. Gaining insight into the structure of these systems can enhance one’s appreciation for the engineering expertise involved.

Exploring the layout and relationships among these mechanical components provides a deeper understanding of how different systems work together to achieve optimal performance. This knowledge is fundamental for anyone involved in the maintenance, design, or study of aviation technology.

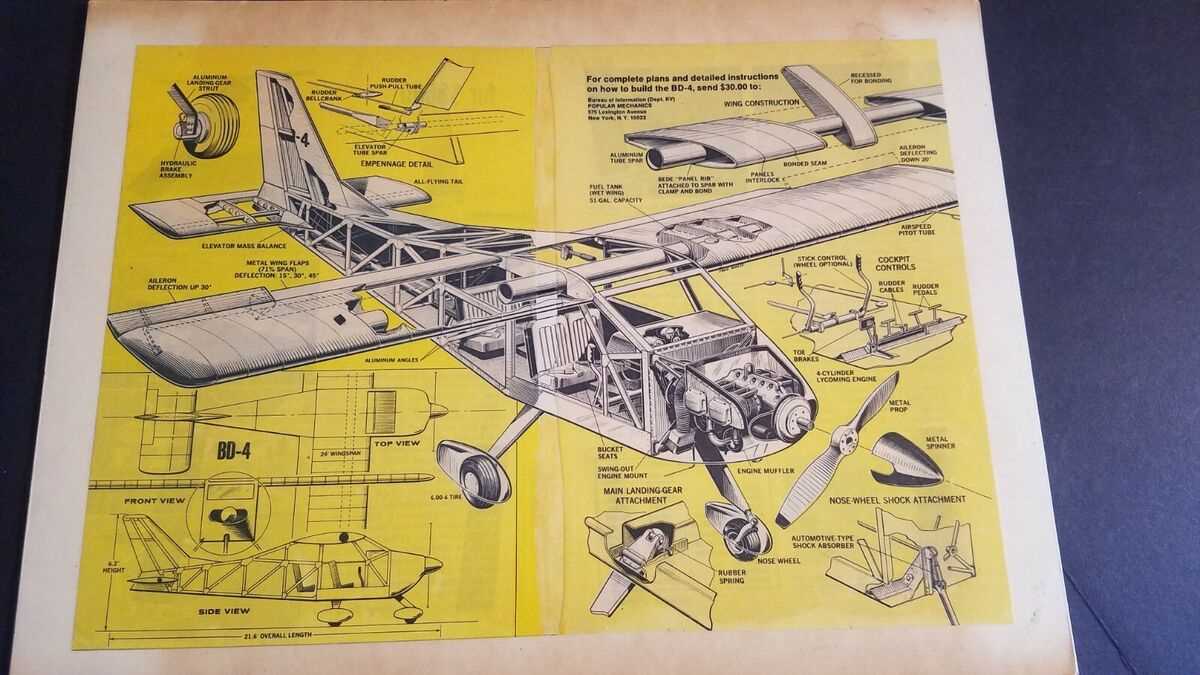

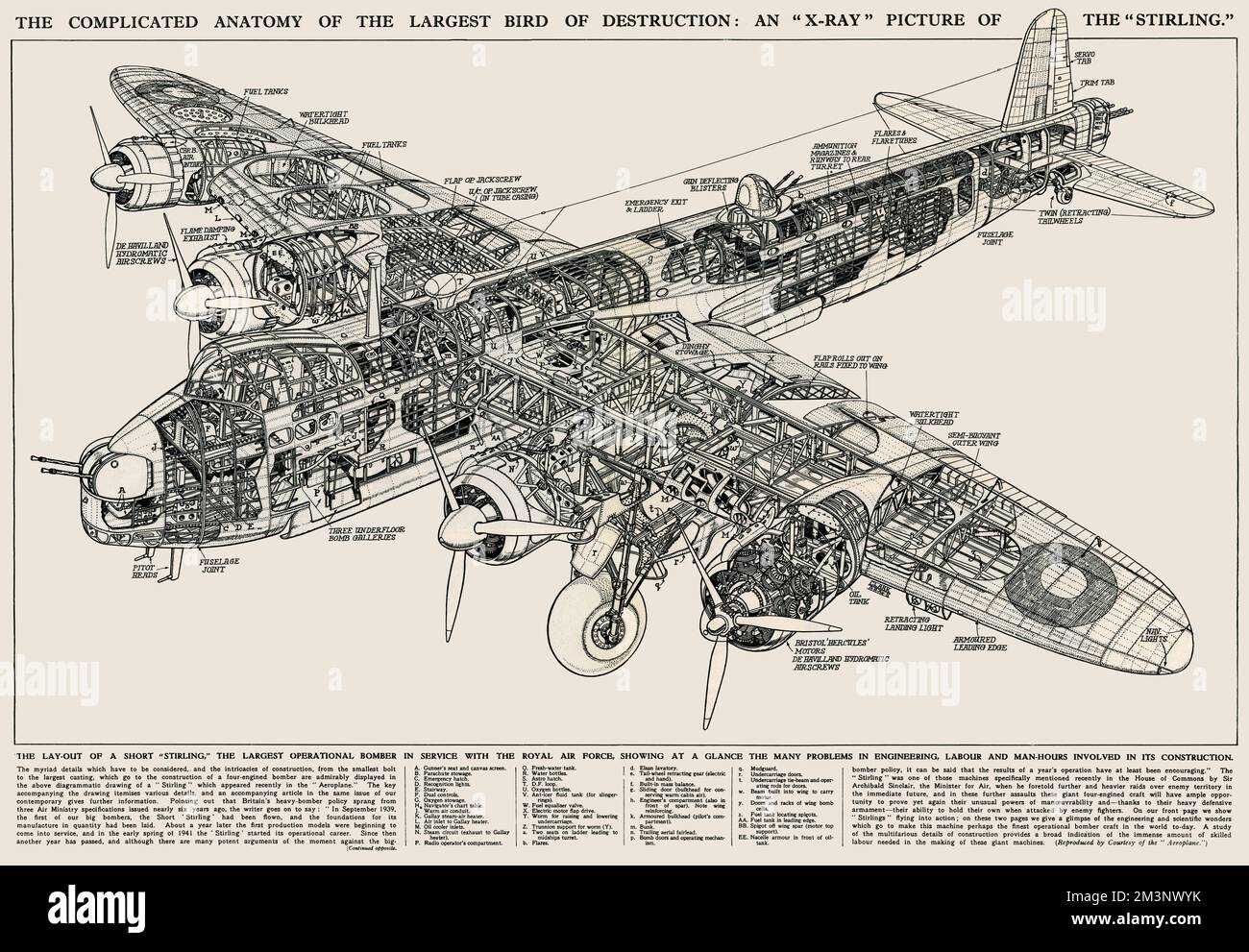

Understanding the Structure of an Aircraft

The intricate design of an aircraft is a marvel of engineering that combines various components to achieve flight. Each element plays a vital role in ensuring safety, performance, and efficiency. By examining the configuration and function of these elements, one can appreciate the complexity behind modern aviation.

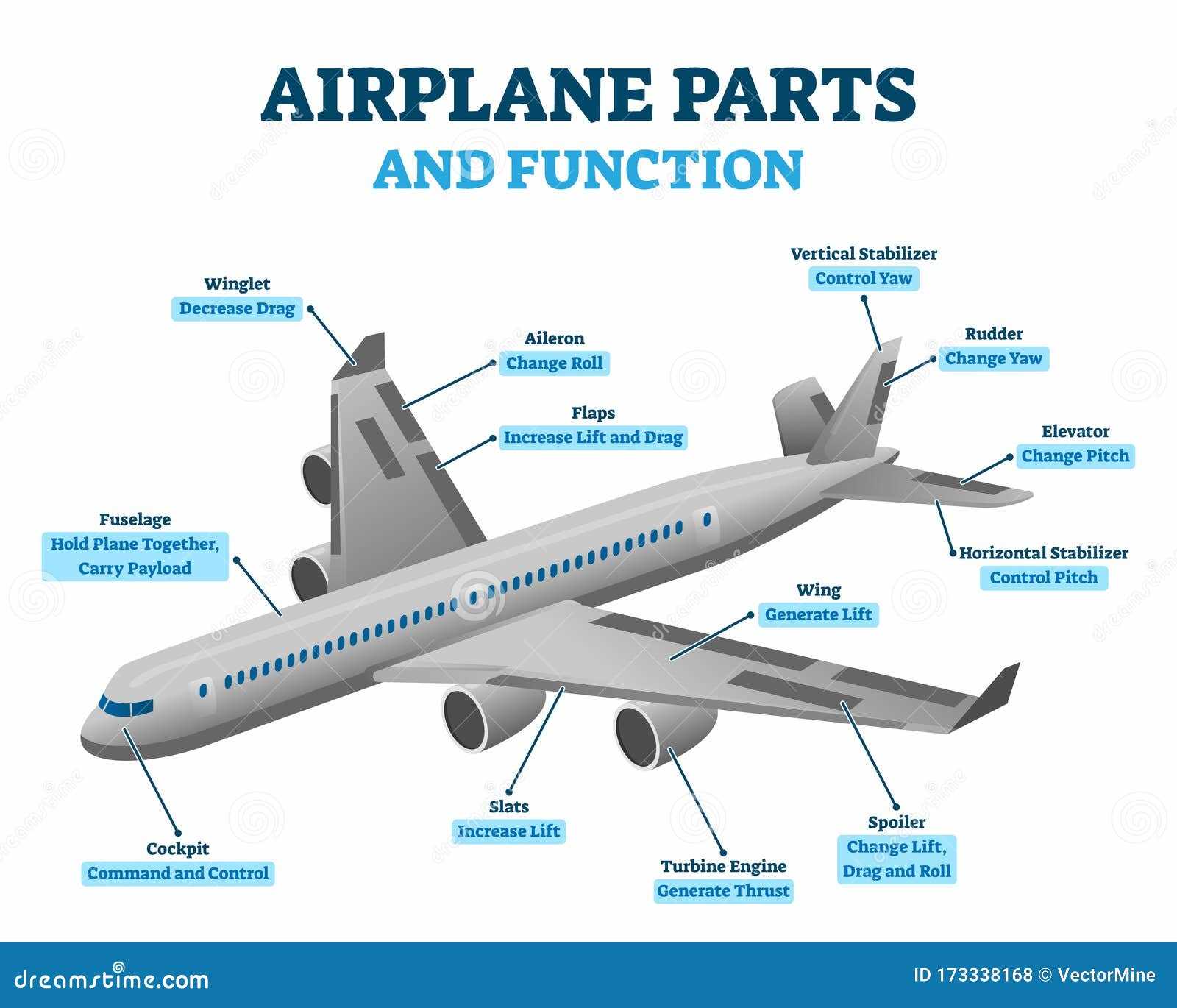

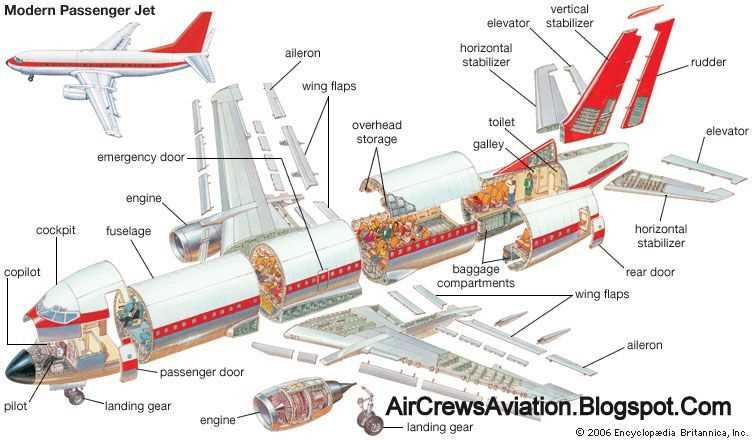

The primary framework serves as the skeleton, providing strength and stability while supporting all other components. This robust structure is essential for withstanding aerodynamic forces during flight. Additionally, the wings are crucial for generating lift, designed with specific shapes to optimize airflow and enhance performance.

Control surfaces, strategically positioned on the wings and tail, allow for maneuverability and stability. These elements work together to guide the vehicle through various flight conditions, ensuring a smooth journey. Meanwhile, the powerplant supplies the necessary thrust, illustrating the importance of efficient energy conversion in maintaining altitude and speed.

Understanding these components and their interactions highlights the sophistication of aircraft design, emphasizing the harmony between form and function in the realm of aviation.

Overview of Main Components

This section provides a concise exploration of the essential elements that contribute to the functionality and structure of a flying vehicle. Understanding these fundamental components is crucial for comprehending how they operate in unison to ensure safe and efficient travel through the skies.

| Component | Description |

|---|---|

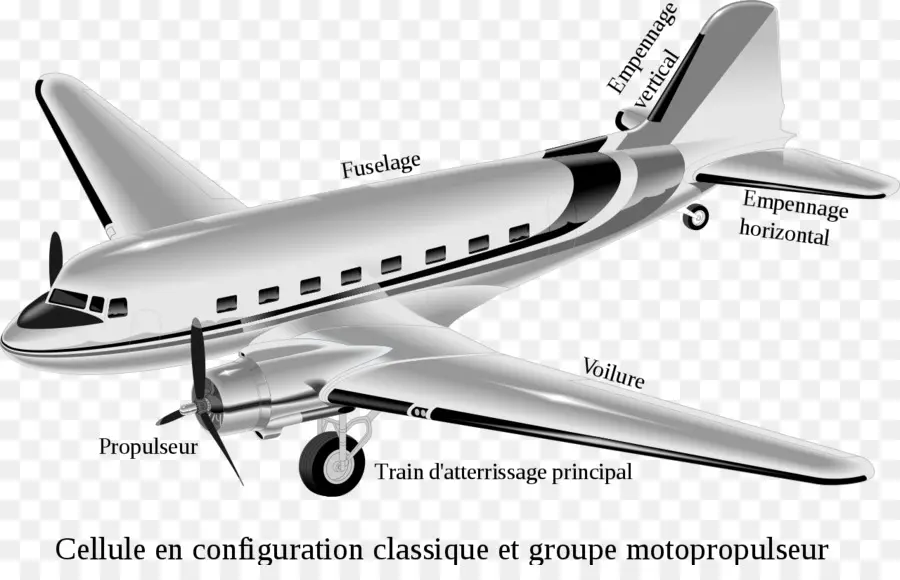

| Fuselage | The main body that houses passengers and cargo, providing structural integrity and aerodynamic efficiency. |

| Wings | Surface areas designed to generate lift, allowing the vehicle to rise and maintain altitude during flight. |

| Tail Assembly | Consists of the horizontal and vertical stabilizers, crucial for stability and control during flight. |

| Engines | Power units that propel the craft forward, enabling movement and flight through thrust generation. |

| Landing Gear | The undercarriage that supports the vehicle during ground operations, facilitating takeoffs and landings. |

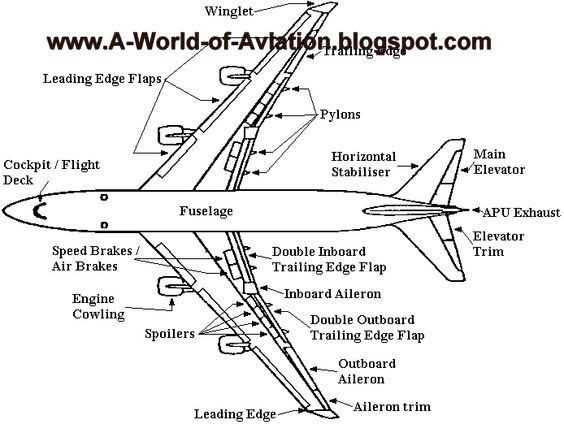

Wings: Function and Design Elements

The significance of wings in aircraft design cannot be overstated. These structures play a crucial role in generating lift, stability, and maneuverability, contributing to the overall performance of the vehicle. Their design is a harmonious blend of engineering principles and aerodynamic efficiency, ensuring that they meet the demands of various flight conditions.

Key functions of wings include:

- Lift Generation: Wings are primarily designed to create lift, allowing the aircraft to rise off the ground.

- Stability: The shape and positioning of wings enhance stability during flight, preventing unwanted movements.

- Maneuverability: Different wing designs enable improved handling and responsiveness in the air.

When considering the design elements of wings, several factors come into play:

- Wing Shape: The cross-sectional profile, or airfoil, affects the airflow and lift characteristics.

- Aspect Ratio: The ratio of the wingspan to the average wing width influences efficiency and performance.

- Wing Loading: This refers to the distribution of weight across the wing area, impacting flight capabilities.

- Control Surfaces: Elements such as ailerons and flaps allow for better control and adaptability during various phases of flight.

In summary, wings are essential components that combine functionality with intricate design features, enabling efficient and safe flight. Their development continues to evolve, reflecting advancements in technology and aerodynamics.

The Role of the Fuselage in Aerodynamics

The central body of an aircraft plays a crucial role in shaping its interaction with airflow. It serves not only as a structural element but also significantly influences performance, stability, and efficiency. The design of this component impacts how air moves around the vehicle, affecting lift and drag forces during flight.

One of the primary functions of the fuselage is to provide a streamlined profile that minimizes resistance as it traverses through the atmosphere. A well-designed structure reduces turbulence and enhances smooth airflow, which is essential for maintaining speed and fuel efficiency. Streamlining ensures that the aircraft can achieve optimal performance, especially during takeoff and landing.

Additionally, the fuselage contributes to the overall stability of the craft. Its shape and dimensions determine the center of gravity, which is vital for maintaining control and balance in various flight conditions. A balanced configuration enables smoother maneuvers and enhances safety, making it a fundamental consideration in the design process.

In summary, the design and configuration of the central body are integral to achieving superior aerodynamic performance. By focusing on factors such as shape, stability, and airflow management, engineers can create more efficient and effective flying machines.

Landing Gear: How It Supports the Aircraft

The landing gear is a crucial component that ensures stability and safety during both takeoff and landing. This system acts as the foundation of the aircraft when it is on the ground, providing necessary support and enabling smooth operations on various surfaces.

Constructed to withstand significant loads, the landing gear absorbs the impact during landing and helps distribute the weight of the aircraft evenly. Its design typically includes wheels, struts, and shock absorbers, all working together to enhance the overall performance and safety of the flight experience.

Additionally, the landing gear facilitates taxiing and maneuvering on the runway, playing an essential role in ground operations. The integration of advanced technology allows for better control and efficiency, making this system indispensable in modern aviation.

Propulsion Systems: Engines and Their Mechanisms

The driving force behind flight lies in the sophisticated systems that generate thrust, enabling vehicles to ascend and navigate through the skies. These mechanisms not only provide the necessary power but also integrate various technologies to enhance efficiency and performance. Understanding how these systems operate is essential for appreciating the intricacies of modern aviation.

Types of Propulsion Systems

Two primary types of propulsion systems dominate the industry: turbojet and turbofan engines. Turbojets are known for their simplicity and high-speed capabilities, making them ideal for military applications and supersonic travel. In contrast, turbofans offer greater fuel efficiency and reduced noise levels, which has made them the preferred choice for commercial transport.

Mechanisms at Work

Engines function through a series of intricate processes that convert fuel into kinetic energy. The combustion of fuel creates hot gases, which expand and are expelled at high speed, generating thrust. Key components include the compressor, which increases air pressure, and the turbine, which extracts energy to drive the compressor. Understanding these mechanisms not only illuminates how thrust is achieved but also highlights the ongoing advancements aimed at improving reliability and reducing environmental impact.

Avionics and Control Surfaces Explained

The interaction of electronic systems and movable elements is crucial for the operation of modern flying vehicles. These components ensure effective navigation, communication, and control, contributing to the overall safety and efficiency of flight. Understanding their roles is essential for grasping how these machines function seamlessly in the sky.

Avionics encompasses a range of sophisticated technologies designed to aid pilots and enhance flight operations. Key elements include:

- Navigation Systems: Instruments that provide positional information and help guide the craft along its intended route.

- Communication Equipment: Tools that facilitate contact between the pilot and ground control, ensuring clear exchange of information.

- Flight Control Systems: Automated systems that assist in managing flight operations and maintaining stability.

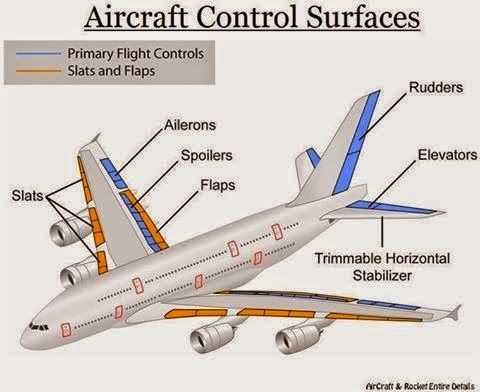

Control surfaces play a vital role in maneuverability and stability, allowing the operator to adjust the vehicle’s trajectory and attitude. These components include:

- Ailerons: Devices located on the wings that control roll by adjusting the lift on either side.

- Elevators: Found on the tail, these surfaces control pitch, helping to raise or lower the nose of the craft.

- Rudders: Positioned on the vertical stabilizer, they assist in controlling yaw, aiding in directional changes.

Together, avionics and control elements form an integrated system that enhances performance and ensures precise handling, making them indispensable in aviation technology.

Importance of the Tail Section for Stability

The rear section of an aircraft plays a crucial role in maintaining balance and control during flight. Its design and function are essential for ensuring that the vehicle behaves predictably in the air, especially during maneuvers or turbulent conditions.

One of the primary functions of this section is to provide directional stability. By generating a counteracting force against unwanted yawing motion, it helps the pilot maintain a straight flight path. Additionally, the design of the tail influences pitch control, enabling smooth ascents and descents.

| Function | Description |

|---|---|

| Directional Stability | Counteracts yawing motion for straight flight. |

| Pitch Control | Facilitates smooth ascents and descents. |

| Stability in Turbulence | Helps maintain control during changing air conditions. |

In summary, the rear structure is integral to the overall performance and safety of a flying machine. Its engineering directly impacts the ability to maneuver effectively and respond to environmental challenges.

Materials Used in Modern Aircraft Construction

The construction of contemporary flying vehicles relies on a diverse array of materials, each chosen for its unique properties and performance characteristics. These materials not only contribute to the structural integrity and weight efficiency but also play a vital role in enhancing fuel efficiency and safety.

Aluminum has long been a staple in the aerospace industry due to its favorable strength-to-weight ratio and resistance to corrosion. Its malleability allows for complex shapes, making it ideal for various components.

Recently, composite materials have gained popularity. Comprising a mixture of fibers and resins, these materials offer remarkable strength while significantly reducing weight. This innovation leads to improved fuel efficiency and greater aerodynamic performance.

Furthermore, titanium is utilized for specific high-stress areas due to its exceptional strength and ability to withstand extreme temperatures. Its lightweight nature enhances overall efficiency, particularly in engines and structural elements.

Lastly, steel remains essential for components requiring durability and resistance to wear. It is often used in critical areas where strength is paramount, ensuring safety and reliability.

In conclusion, the selection of materials in modern aviation is a carefully balanced process aimed at optimizing performance, safety, and efficiency, reflecting the ongoing advancements in technology and engineering.