In the realm of automotive and machinery maintenance, having a clear visual representation of intricate components is essential. Such illustrations serve as a roadmap for mechanics and enthusiasts alike, guiding them through the various elements that contribute to the engine’s performance. By analyzing these visual guides, users can gain insights into assembly, troubleshooting, and repair processes, ultimately enhancing their understanding of the system.

Moreover, detailed schematics provide an opportunity to familiarize oneself with the specific parts involved in engine operation. Each section is meticulously organized, allowing for easy identification of components and their respective functions. This comprehensive approach not only aids in repairs but also fosters a deeper appreciation for the engineering behind the machinery.

Whether you’re a seasoned professional or a curious novice, navigating these illustrative resources can significantly elevate your technical skills. Engaging with these guides empowers individuals to make informed decisions during maintenance tasks and ensures that every aspect of the engine is operating optimally. As we delve into the nuances of these representations, the knowledge gained will prove invaluable in the long run.

Understanding the Dt466e Engine Layout

The intricate structure of an engine plays a crucial role in its overall performance and efficiency. A comprehensive grasp of the layout enables technicians and enthusiasts to troubleshoot issues, perform maintenance, and enhance functionality. This section will delve into the essential components and their arrangement within this specific power unit.

At the core of the engine’s design are several key elements:

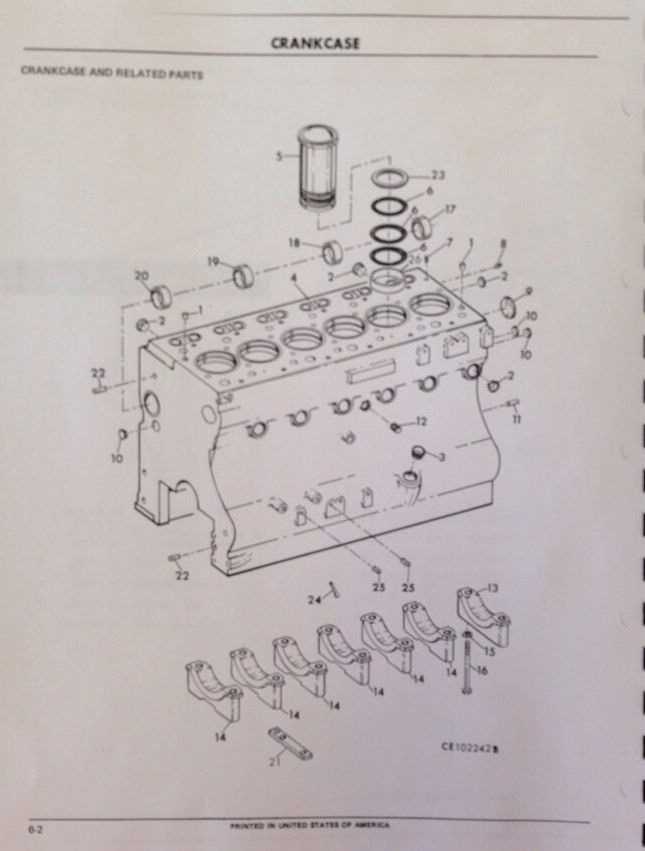

- Block: The foundation that houses the cylinders and various internal components.

- Cylinders: The chambers where combustion occurs, generating power.

- Pistons: Moving components within the cylinders that convert pressure into mechanical energy.

- Crankshaft: A vital part that translates the linear motion of the pistons into rotational motion.

- Valvetrain: Comprising valves and timing mechanisms, this system regulates airflow into and out of the cylinders.

Understanding the relationship between these parts is essential for effective operation. The following points outline the arrangement and function of each component:

- Positioning: Components are strategically placed to optimize airflow, cooling, and access for maintenance.

- Integration: Each part interacts seamlessly with others, contributing to the engine’s overall efficiency.

- Serviceability: An organized layout facilitates easier repairs and replacements, minimizing downtime.

In summary, a thorough knowledge of this engine’s configuration not only aids in understanding its mechanics but also enhances the ability to maintain and improve its performance effectively.

Key Components of the Dt466e

The performance and reliability of an engine depend significantly on its fundamental elements. Each part plays a vital role in the overall functionality, ensuring optimal operation and longevity. Understanding these essential components can help in maintaining and troubleshooting the system effectively.

1. Engine Block

The core of any engine, the block, serves as the main structure housing several critical components. It supports the cylinder sleeves, where combustion occurs, and provides a solid foundation for the rest of the assembly. A well-engineered block ensures efficient heat dissipation and durability under high-stress conditions.

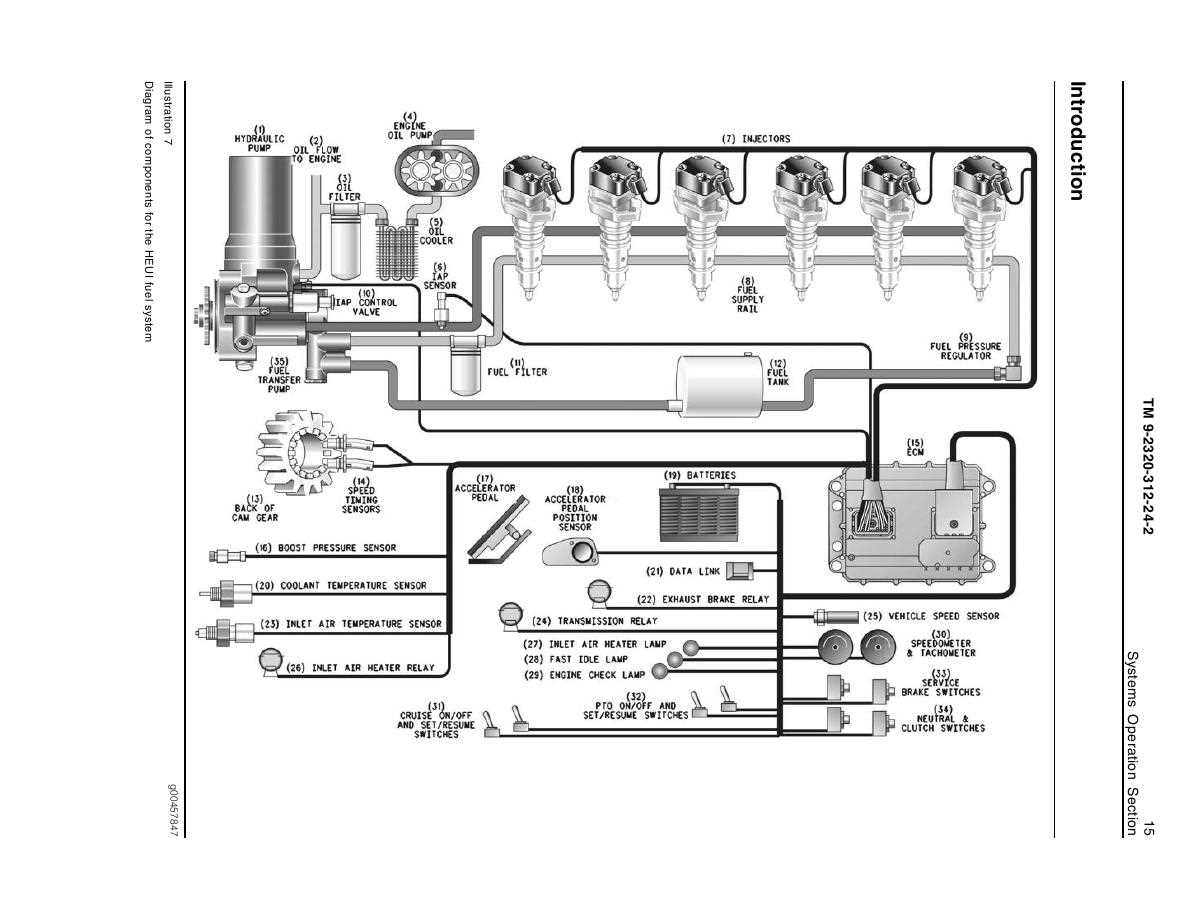

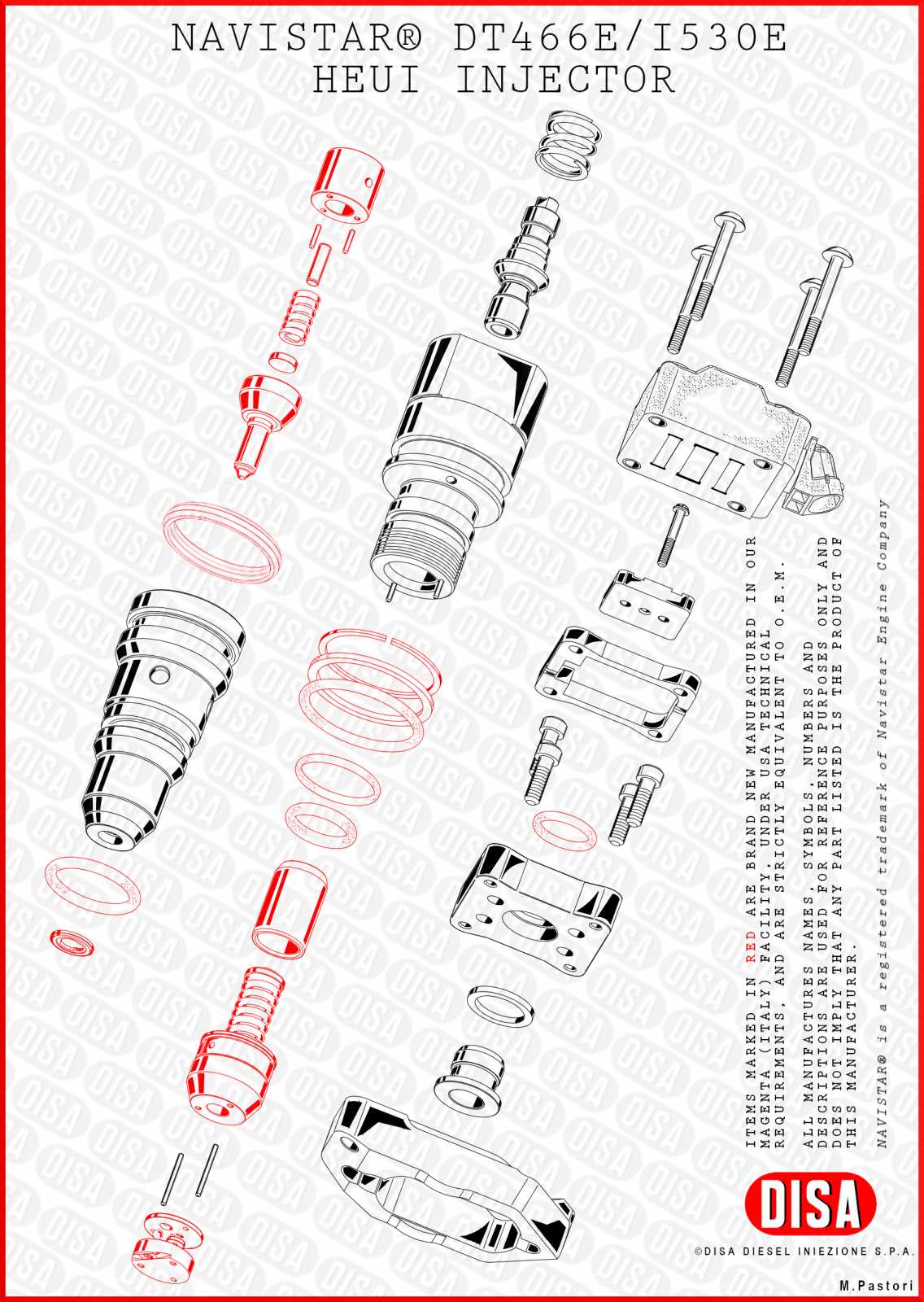

2. Fuel Injection System

This system is crucial for delivering the correct amount of fuel to the combustion chamber. It consists of injectors and a pump that work together to atomize the fuel, allowing for a more efficient combustion process. Proper functioning of the fuel injection system is essential for optimal power output and fuel efficiency.

In summary, a comprehensive understanding of these key components enables effective maintenance and troubleshooting, ultimately enhancing the engine’s performance and lifespan.

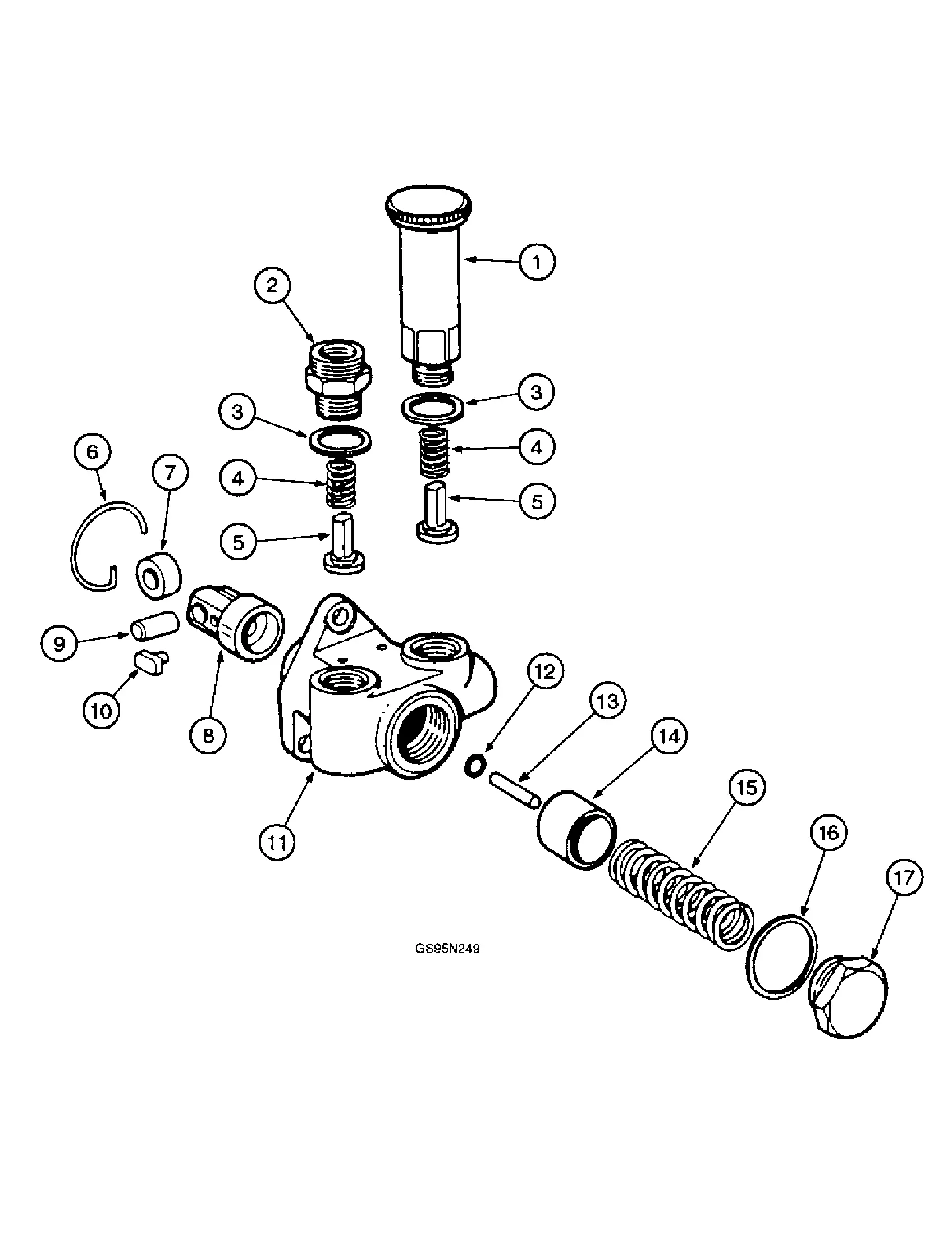

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations play a vital role in identifying individual elements and their relationships within a system. This clarity helps users to grasp complex assemblies and enhances troubleshooting capabilities.

Accurate representations provide a roadmap for technicians, enabling them to locate issues quickly and effectively. When issues arise, having a detailed overview allows for swift resolution, minimizing downtime and improving productivity.

Additionally, these visual aids serve as educational tools, empowering both novices and experienced professionals to delve into the intricacies of mechanical systems. They foster a deeper understanding of functionality, which is essential for optimal operation.

How to Read Engine Diagrams

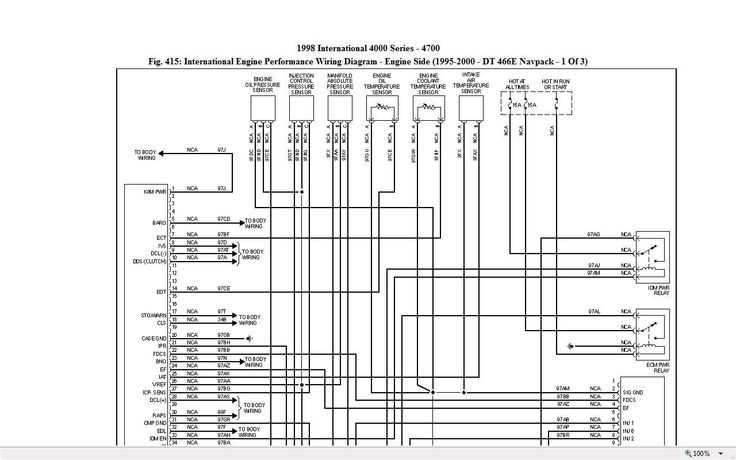

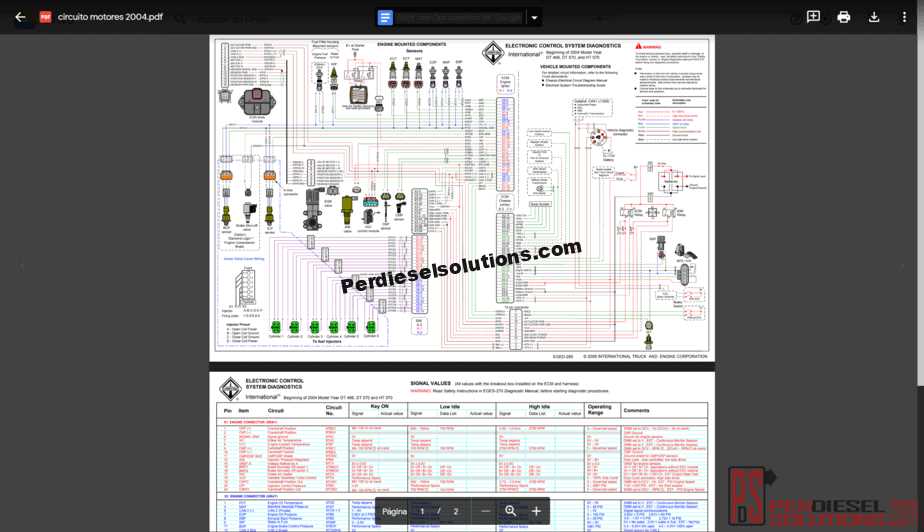

Understanding engine schematics is crucial for effective maintenance and repair. These visual representations provide insights into the relationships between various components, helping you grasp how everything functions together. Mastering the interpretation of these visuals can ultimately enhance your troubleshooting skills and efficiency.

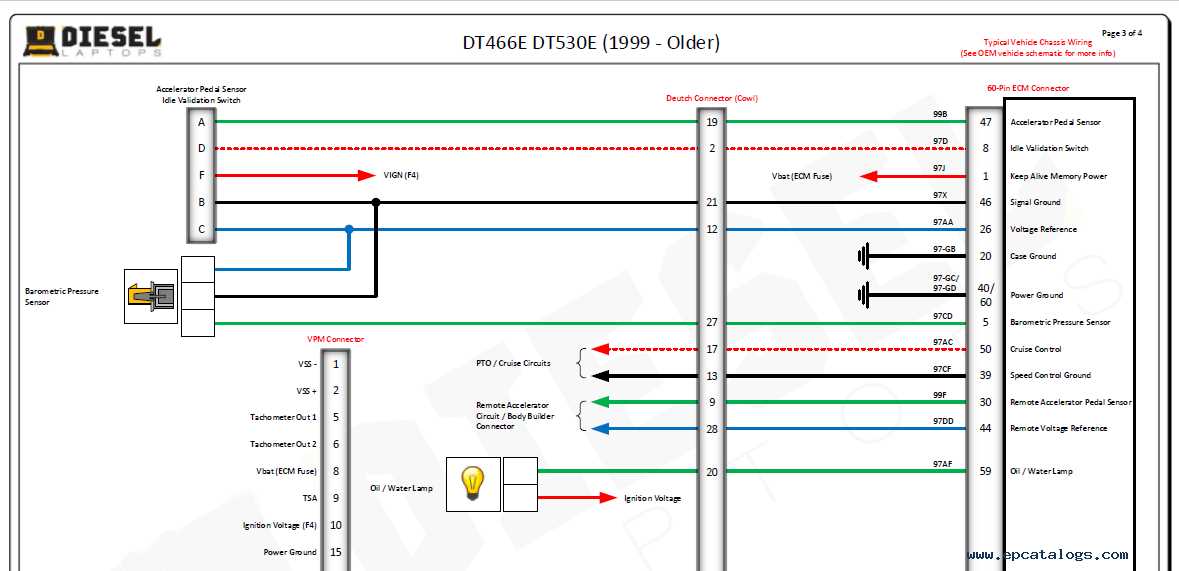

Familiarize Yourself with Symbols

Each engine schematic uses specific symbols to represent components like valves, pistons, and electrical systems. Familiarity with these symbols is essential. Take the time to consult a key or legend that outlines what each symbol signifies, ensuring you can navigate the illustration with confidence.

Follow the Flow

Look for the flow of energy or fluid through the system. Understanding how components interact will allow you to see the bigger picture. Pay attention to lines and arrows, as they indicate movement and connections, guiding you through the operational sequence.

Common Issues with Dt466e Parts

When it comes to the components of heavy-duty engines, there are several challenges that enthusiasts and mechanics frequently encounter. Understanding these issues can aid in effective maintenance and repair, ultimately prolonging the life of the engine. This section delves into some of the most prevalent concerns associated with these specific engine components.

Wear and Tear

One of the primary issues faced is the natural degradation of critical components over time. This wear can lead to decreased performance and efficiency. Commonly affected areas include gaskets, seals, and bearings, which may require regular inspection and timely replacement to prevent more significant damage.

Fuel System Problems

Another frequent problem involves the fuel delivery system. Clogs and leaks can disrupt the flow of fuel, resulting in poor engine performance. It’s essential to monitor fuel injectors and lines for any signs of wear or contamination, as neglecting these components can lead to serious operational issues.

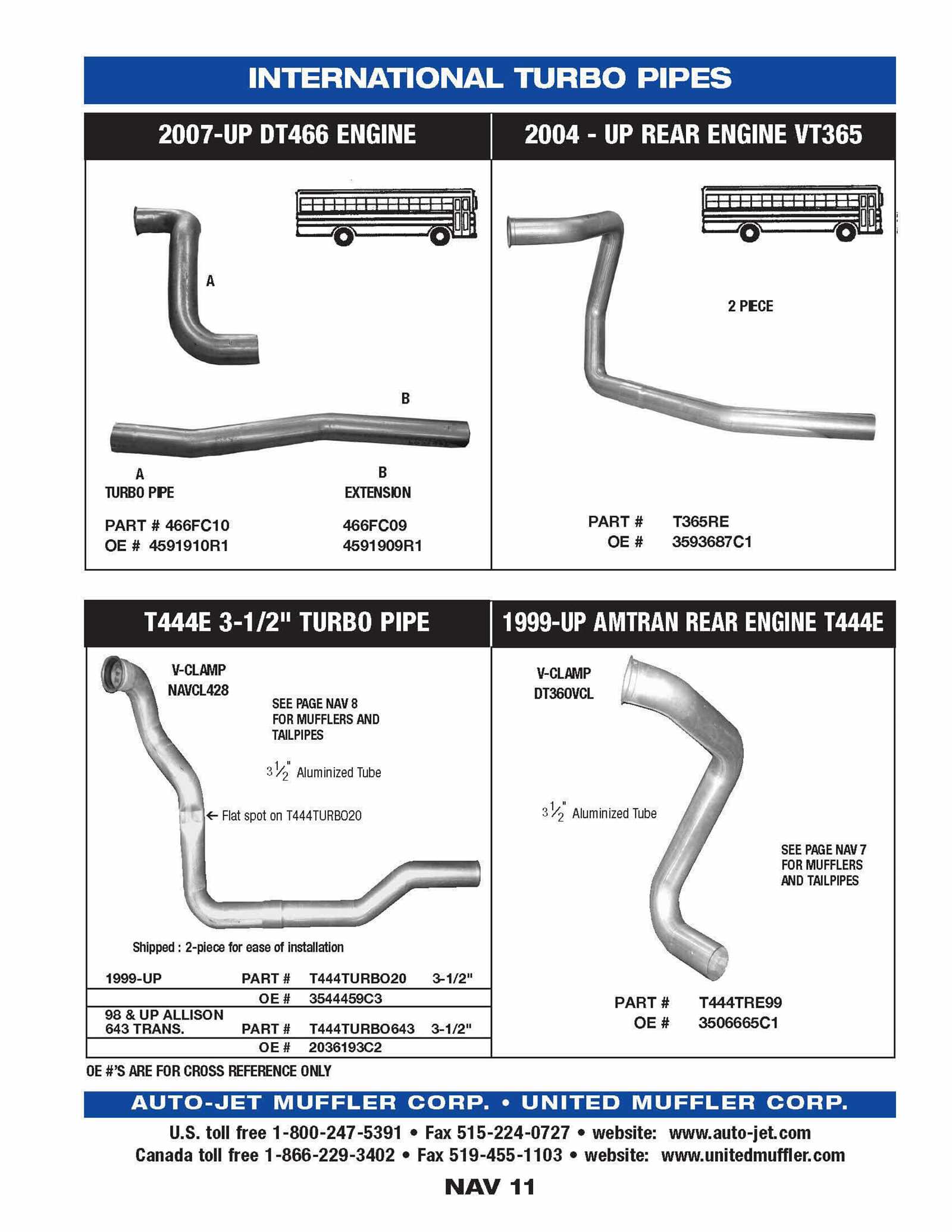

Where to Find Replacement Parts

Finding suitable components for your machinery is essential for maintaining optimal performance and longevity. Various resources are available that can help you locate the right items, whether you are conducting routine maintenance or addressing specific issues. By utilizing a combination of online platforms, local suppliers, and specialized distributors, you can ensure that you have access to quality replacements that meet your equipment’s requirements.

Online Marketplaces: One of the most convenient ways to source necessary components is through online marketplaces. Websites like eBay, Amazon, and specialized automotive parts retailers provide a vast selection of options. Be sure to read reviews and check seller ratings to ensure quality and reliability.

Local Retailers: Don’t overlook the value of visiting local retailers and auto supply stores. Many of these establishments carry a range of items and can often order specific components if they are not in stock. Establishing a relationship with local suppliers can also lead to helpful advice and recommendations.

Manufacturer Distributors: Contacting the original equipment manufacturer or authorized distributors can be a reliable way to obtain genuine components. They often have extensive catalogs and can provide expert guidance on compatibility and performance.

Online Forums and Communities: Engaging with online forums and communities dedicated to machinery enthusiasts can yield valuable insights. Members often share their experiences and recommend sources for obtaining quality replacements. These platforms can also help you connect with individuals who may have spare parts available for sale or trade.

In conclusion, whether you choose to shop online or visit local suppliers, there are numerous avenues to explore for finding the right components. Utilizing a mix of these resources will help you make informed decisions and keep your machinery running smoothly.

Benefits of Using Accurate Diagrams

Utilizing precise visual representations offers numerous advantages that enhance comprehension and efficiency. These illustrations serve as vital tools for understanding complex systems and streamline processes in various fields.

Improved Understanding

- Visual aids clarify intricate components and their relationships.

- Facilitate quicker learning and retention of information.

- Reduce the likelihood of errors in interpretation.

Enhanced Communication

- Provide a common reference point for team discussions.

- Bridge gaps between technical and non-technical stakeholders.

- Enable more effective training and onboarding processes.

Maintenance Tips for Dt466e Engines

Regular upkeep is essential for ensuring optimal performance and longevity of any engine. By implementing a systematic maintenance schedule, owners can enhance reliability and minimize the risk of unexpected breakdowns. Here are some practical suggestions to keep your engine in top shape.

1. Routine Oil Changes: Change the oil at regular intervals to maintain proper lubrication and reduce wear. Use high-quality oil that meets the manufacturer’s specifications.

2. Air Filter Inspection: Check and replace the air filter as needed to ensure adequate airflow. A clean filter prevents dirt and debris from entering the engine, promoting efficient operation.

3. Coolant Levels: Regularly monitor coolant levels and inspect for leaks. Proper cooling is crucial for preventing overheating and maintaining performance.

4. Fuel System Maintenance: Keep the fuel system clean by using quality fuel and considering periodic fuel filter replacements. This helps prevent clogs and ensures smooth operation.

5. Regular Inspections: Conduct routine inspections of belts, hoses, and electrical connections. Early detection of wear or damage can save costly repairs later.

6. Use OEM Components: Whenever possible, opt for original equipment manufacturer parts to ensure compatibility and reliability. This can significantly extend the lifespan of your engine.

7. Follow the Manual: Always refer to the owner’s manual for specific maintenance recommendations. Adhering to the manufacturer’s guidelines will provide the ultimate protection for your engine.